In the garage it is necessary to provide sufficiently comfortable conditions not only for the car, but also for the person who works in it. At the same time, you need to understand how to insulate garage doors from the inside with your own hands. What types of gates exist, what are the features of the various insulation materials used and what needs to be done to make the gates of high quality - all this needs to be known in order to get the job done.

Insulated gate leaf Source ad-cd.net

Is it necessary to do this

The garage is used for more than just car maintenance. Some owners may use it for storage or make a workshop in this room. One of the possible options is the ability to communicate with friends. No matter what the garage is used for, it is not comfortable to be in it in the cold season without heating.

Temperatures below zero cause damage to the vehicle. If it is overcooled, it will be difficult to start it, and frozen condensation will begin to accumulate, which can damage metal parts. If you know how to insulate a garage door, this can be prevented.

FakeHeader

Comments 51

I chose a day where there was not much thaw and foamed the gap between the threshold and the gate, it became better) By the time I had time, the frosts now reached -30.

The bottom can be made with felt

Frozen to the gate.

Then from the heart's sleeve

Hang a curtain made of dornite, we have one of these hanging in every garage and you will be happy

You can put felt padding on the gates, but I also saw that in the neighborhood in garages people wrap a tarp around a board and just lay it down with their hands every time.

Thank you! I am also inclined towards this design, make brackets for the threshold and insert a board with felt there.

I was also intrigued by the question until I saw that people were just using the boards, not just one person, but quite a lot.

such a good corner for a sealant... my toad says that a profile for drywall would be enough, it is noticeably cheaper!

The threshold is coated with the compound and the foam is applied directly into the crack on the closed door. After hardening, the foam will remain on the door itself, creating a seal and will not stick to the threshold.

I support! I did exactly the same thing around the entire perimeter, everything worked out perfectly and it turned out hermetically sealed. Only I didn’t smear it with polish, but with a thin layer of lithol. Three years have already passed, no complaints.

The threshold is coated with the compound and the foam is applied directly into the crack on the closed door. After hardening, the foam will remain on the door itself, creating a seal and will not stick to the threshold.

You can cover it with tape; the foam won’t stick to it either.

I screwed a doubled fire hose around the perimeter. Bend outward. First, you put a galvanized metal strip with holes into the sleeve. Self-tapping screws every 200 mm.

And I have insulation around the perimeter with frost. Just so neatly.

Nope)) I don’t like this kind of insulation, I used it for a while too)

I sewed up the gate first with a wooden sheathing around the perimeter, then with polystyrene foam and then the whole OSB-3 thing on top. So I tried to adjust the OSB so that it would fit right next to the frame. But there’s still such a neat frost around the perimeter. It doesn’t grow and melts when you heat it too much. Or rather , it doesn’t melt, but falls off in pieces. I’ll have to hang a curtain.

I should have taken a photo of the gap at the bottom too, the options depend on its size

I cut rubber inner tubes from Kamaz into strips. I secured these rubber strips in two layers - on one side and the other side of the rail (it turned out to be a double shutter). I did this around the entire perimeter of the gate. Then I trimmed these strips in place (in width so as not to interfere with the closing of the gate).

Polyurethane foam. I did this to myself, everything tightly in a circle. There are a lot of videos on YouTube.

Now on sale there are a lot of rubber profiles for sealing the joints of window doors and gates. Why reinvent the wheel?

I didn't see the rapids.

You can use the same ones for thresholds. Or too small?

Create an anti-threshold! )))))www.antiporog.ru/ustanovka-antiporoga.html

Cool stuff! I'm afraid it will freeze and the mechanism will become clogged with frost.

to seal the cracks at the gate, the first thing you need to look at is that at the exit from the garage - it’s just the ground that rises in winter or thoughtfully poured concrete... and so that it’s straight according to Feng Shui, or make second light doors so that there is a vestibule so that it plays the role of an “air cushion” or a more budget-friendly option for curtains made of felt and there will be a song

The only problem is with the threshold. I got confused with the rubber bands because I didn’t want a curtain.

A huge canvas curtain covers the entire wall, it will have a very cool effect.

I have a 50th corner welded to the prog without insulation and there are no problems.

a dozen mops with the bristles down. But in general, leave it, ventilation has never harmed anyone.

ventilation and draft are very different things... and where there are cracks, in winter there will be frost and quite a bit of it, which then melts and moisture - one wonders where are the advantages of such “ventilation”...

moisture is where the humid air of the garage comes into contact with cold objects; if there is a blow through the gap under the gate, then there will be no frost there, but if there is frost, what is the problem at the frost threshold? This is not a ceiling. Besides, the more ventilation, the less chance of catching the dew point. And I probably won’t list the advantages of ventilation.

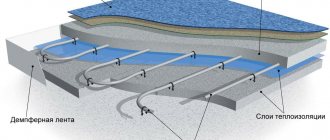

General principles for maintaining room temperature

Sometimes garages are used, provided not only with electricity, but also with other communications. However, in most cases this room can easily lose heat.

Cutting insulation Source ad-cd.net

This happens in the following ways:

- Heat is lost because the walls, floor and ceiling transfer heat to the atmosphere.

- The movement of air can significantly lower the temperature in this room.

- Every heated body is capable of radiating heat. By releasing it into the surrounding atmosphere and into the ground, the garage loses it irrevocably.

To save heat, you need to use an additional layer of insulation and stop the air convection that cools the garage. To do this, you need to know how to make a garage door with your own hands.

In winter, it is not recommended to allow negative temperatures in the garage. Building codes recommend maintaining the temperature at least 5 degrees Celsius. It is believed that in this case no difficulties can arise. If you need to start the car.

Insulated gates Source ad-cd.net

Providing heat is a goal that must be strived for, including when planning and building a garage. Some owners don't think about it. So that the garage has not only a gate, but also a gate. However, its use will significantly save heat during the cold season.

At first glance, they sometimes try to close the ventilation holes for insulation. However, this is not recommended. Lack of ventilation can have a detrimental effect on the health of those inside. However, it is advisable to close other holes, if any.

Even when a layer of insulation is laid, it will be important to leave ventilation holes. It must be remembered that it must be both supply and exhaust. When planning how to make a garage door, you need to take this into account.

Garage doors with wicket Source refite.ru

Sealing the sashes is the finishing touch in the insulation process

Sealing the leaves when insulating garage doors

Often, measures taken to lay insulation are not enough to preserve heat - heated air is blown out through the cracks in the sashes. This problem can be easily solved by using a garage door seal. A hollow rubber strip with a circular cross-section, resembling a hose, will do. It is attached to a special tail, which is fixed using a strip of metal and self-tapping screws.

Advice. The bottom of the sashes cannot be insulated with a sealant, but heat loss can be reduced by using a brush profile. It is also mounted with self-tapping screws.

Types of gates used in garages

When insulating, it makes sense to pay the main attention to garage doors - the maximum amount of heat usually escapes through them. In practice, various types are used:

- The most common are swing gates. They are a structure of two doors, which are suspended on hinges. They have the following features:

- This design will cost the owner less than other options.

- It is easy to insulate such gates.

- They can be used even in cases where space is limited.

- The owner can choose how to install them: open them outward or inward.

- It is possible to provide opening using an electric motor.

However, they have certain disadvantages. The main one is that it requires additional space to open. This may play a role in the situation. When there is a lot of snow. The vulnerable part of the design is the door hinges.

When insulating, you need to pay attention to gate hinges and wickets Source svarkavdom.ru

If they are frozen over, they can only be opened after warming up.

Another type of gate is folding. They consist of rectangular parts that are connected to each other using hinges. The outer section is attached at the top to the horizontal bar using door hinges. The remaining sections are lifted up and secured.

Such gates are more expensive than swing gates. The opening mechanism used here is less reliable compared to door hinges.

Sliding gates have this name because they are installed on guides and when opened they move to the sides. Manual or automatic options are available.

The roller system requires maintenance, but is reliable and durable. It is important to exclude snow. Rain and foreign objects.

Such gates are convenient because they do not require much space when opening.

Up and over gates Source i.ytimg.com

Lifting-type structures are considered one of the most convenient and practical options. They are made metal. When a car enters, they rise, becoming horizontal, and secured. It is necessary to take into account that when planning how to make garage doors with your own hands, lifting drawings provide for the use of a complex mechanism. Therefore, it is more profitable to invite professional specialists to perform such work.

They do not require much space and are known to resist intrusion attempts.

The disadvantages of this option include the high cost and the fact that the structure occupies part of the opening. If you think about how to make a garage door with your own hands, you need to take into account that this work requires the knowledge and skills of professionals.

If you install the gate yourself, then in such a situation the best choice is the swing option.

Sectional doors Source static.tildacdn.com

See also: Catalog of projects of one-story houses with an attic and a garage.

Important little things

Insulated metal gates in a garage are a whole complex of measures and it does not end only with the arrangement of the inner surface of the doors

It is equally important to correctly install the seal around the perimeter of the sashes, plus take into account the accompanying factors that reduce heat loss.

- Let's start with the fact that when you order or choose a door for your garage, do not skimp and take a model that has a simple door . If you constantly open a whole sash, then as soon as your neighbor comes to you several times in the winter for advice, all your warmth will disappear. After all, no matter how hard you try, you won’t be able to squeeze through quickly, the open door is too big;

Doors with and without entrance doors.

- Now about compaction . It is clear that with such large dimensions it is unlikely that the shutters will fit tightly along the entire perimeter of contact with the frame of the opening. You should immediately forget about such things as self-adhesive seals for windows and ordinary doors; they will last a maximum of a week. Rubber hoses with fastening tape are produced for garage doors and other similar structures. They can be hollow or filled with some soft porous material such as foam rubber. Such a seal is fixed to the base with self-tapping screws using mounting strips or comes with the strip;

Types of rubber seals for garage doors.

- It would also be a good idea to install a curtain on the inside next to the gate.. There are several options here:

- A thermal curtain that works on the principle of a fan heater and cuts off cold air at the inlet is certainly a good thing. But, firstly, such a unit itself is quite expensive. And secondly, the power of such a garage curtain starts from 2 - 3 kW, respectively, such pleasure will cost a tidy sum;

Thermal curtain.

- The next option is more loyal. A piece of tarpaulin with water-repellent impregnation is used as a curtain. In fact, this is a classic curtain. You need to stretch a metal string or baguette on top and hang your sliding canvas curtains on it;

Canvas curtains over the gates.

- Almost every motorist has been to a car wash; remember how their driveway is equipped. The curtain there is made of vertically cut soft transparent tapes, such as polyethylene. But this is not entirely polyethylene, and if you buy such a thing in a factory version, it will be expensive. It is unlikely that your garage will have the same amount of traffic as a car wash. Therefore, you can simply cut strips of thick technical polyethylene about 10 - 20 cm wide and, with a slight overlap (10 - 15 mm), staple them to a wooden strip. Next, for reliability, screw another similar rail on top, so that the polyethylene is between them, and fasten it above the entrance to the garage. Please note that any curtain should not drag on the floor; a small gap is always left;

Polyethylene curtain.

- I would also like to say a few words about lining the gate from the inside . Izolon and lining, as you understand, are far from the only materials that can be used for such purposes. One of the most popular in garage design is OSB-3 or OSB-4, about 10 mm thick; it has decent moisture resistance and can be bought for reasonable money. If you take plywood, then in this case you need to buy the FSF brand. For those who like a warmer design, we can advise covering the inside of the doors with PVC panels. They are glued directly onto the foam plastic with liquid nails or something similar, and a edging is put on around the perimeter;

Standard OSB board.

- There is one more interesting detail. I've seen advice online about insulating gates with polyurethane foam. People say that you can buy 5 - 7 cans of foam, make a frame and fill it with this foam . They promise that such insulation can supposedly last for almost 50 years. But in the open air and with minor vibration, I have seen polyurethane foam deteriorate within 3 to 5 years. Perhaps the person used some special type of foam, but in any case, I do not recommend this method to you.

Polyurethane foam and blowing gun.

Features of various insulation materials

Before starting construction, you need to select the most suitable insulation material. In this case, it is necessary to take into account its existing features.

Use of mineral wool

This is a well-known type of insulation. However, it must be taken into account that three different materials are used under this name. All of them are known for their high ability to absorb moisture. For this reason, they try to avoid using them for the purpose in question. Once wet, mineral wool loses its heat-protective properties. Of the variety of such options, only basalt wool covered with a vapor barrier film is considered suitable for this purpose. This is a prerequisite for how to insulate garage doors using this material.

Using mineral wool Source strport.ru

Glass wool

In the production of glass wool, the finest glass strands are used. Their diameter is 5-15 microns. The length of one thread is in the range of 15-50 mm. It has low thermal conductivity. It is equal to 0.03-0.05 W/m*deg. Use can be carried out at temperatures from -60 to +450 degrees. Glass wool has not only high strength, but also elasticity. When planning how to make a garage door, you must remember that working with glass wool without using protective equipment poses a health hazard. Fibers can break and can injure the skin and penetrate the respiratory tract.

Required Tools

Markings for fastening profiles, slats, insulation boards are carried out using a tape measure, the length of which should be more than 5 m. Right angles are checked with a construction square.

Prepare tools for work:

- electric drill, screwdriver with a set of metal drills;

- hammer, pliers, metal brush;

- screwdrivers and cardboard knife;

- a hacksaw for wooden slats or a grinder for an iron profile;

- brush or roller for priming.

You can cut the elements for the sheathing with an electric jigsaw with metal or wood files.

Video description

In this video you can see how door insulation work is carried out

Slag

It is prepared from by-products of metallurgical production. The raw material for slag wool is slag. This is a fibrous material made from threads with a diameter of 4-12 microns. This material has a higher thermal conductivity compared to glass wool - it is in the range of 0.04-0.05 W/m*deg. This value is within acceptable limits.

The ability to absorb moisture makes the material in question unprofitable. Its acidity has a negative effect on metal parts.

Stone wool

For its production, a melt of stones of volcanic origin is used. It has a structure that resembles slag wool. Compared to it, it has higher heat resistance. Stone wool has no acidity. Thermal conductivity is in the range of 0.03-0.04 W/m*deg.

Video description

This video shows the use of mineral wool to insulate a garage.

The binding element is a formaldehyde resin that can release phenol as a result of heating. This substance has a damaging effect on health. This can absorb a lot of moisture. When planning how to make a garage door using it, you need to ensure the use of a waterproofing film.

See also: Catalog of companies that specialize in the installation of heating systems and electrical systems.

Application of foam plastic

Here we mean a whole class of materials made from polymers that have a foam base with air bubbles. The classification is made in accordance with the type of polymer used.

Thermal insulation with curtains

A curtain in front of the gate is a controversial method of insulation and here's why:

- To sew curtains, you need a tarpaulin or thick rubberized fabric, comparable in cost to polystyrene foam.

- The curtain prevents entry through the gate, and making a special cutout means worsening the thermal insulation.

- The curtain promotes abundant condensation on internal metal surfaces during frosts. As a result, the locks become covered with ice inside and out, making it very difficult to warm them up.

The curtain is useful when the garage owner needs to constantly go outside by opening one gate leaf. Such insulation is realized by hanging a tarpaulin on a cable threaded through sewn steel rings. There is one way to prevent frosting of locks - do not leave the curtains closed at night.

Video description

This video shows how to insulate using polystyrene foam

Polystyrene foam

This material is considered the most famous and widespread type of foam. In appearance, such insulation looks like sintered balls filled with gas. This material is preferred for use as insulation. It has its own designation: PSB. Of its varieties, the highest quality is extruded polystyrene (EPS). It has high resistance to sunburn, low hygroscopicity and relatively high strength. This material may be sold under the name Penoplex, Stirex, or in some other way. When thinking about how to insulate a garage door from the inside with your own hands, you need to remember that this material allows for better insulation.

Polyvinyl chloride

It is used not only for thermal insulation, but also for sound insulation. Panels made from it can be of two types: elastic and rigid. This material is highly fire resistant and is comparable in quality to EPS.

Final cladding

After installation of the insulation is completed, the sheathing is installed. Sheet materials are used - chipboard, plywood, OSB, etc.

The final stage is the final cladding of the gate

As an option, lining or wall panels are suitable.

Lining is a reliable and popular option

Some owners finish the gates with vinyl leatherette with quilting, which looks solid, although somewhat unnecessary.

Vinyl leather will give the gate a richer look

The sheathing is attached to the sheathing strips. It is recommended to first apply a strip of polyurethane foam around the perimeter to ensure the tightness of the entire system. After installation, the material is painted and covered with various coatings. There are many finishing options, but most owners do not see the point in decorating a garage door too pompously. Functionality is considered the main task; additional procedures are not important for everyone.

Video description

This video shows in detail the procedure for insulating a garage.

KFP

When drying, urea-formaldehyde foam (UF) has the property that there is no increase in volume during the drying process. This makes it possible to fill the cavities in liquid form, and then wait until it dries completely. This is another option for how to insulate a garage door with your own hands. This material can be sold under the names: Penoizol, Omiflex and others. Its use as garage insulation is effective.

Polyurethane foam

It exists in various forms. The elastic option is foam rubber. Insulation with a rigid structure - polyurethane foam. The latter option is more preferable for use as insulation for garage doors. Its important feature is high adhesion to various surfaces. This type of foam has excellent thermal insulation and waterproofing properties.

Insulation with polyurethane foam Source uteplenieplus.ru

The material is usually applied by spraying and waiting until it hardens completely. It is applied in several layers, each done after the previous one has dried. Many consider this material to be the best choice for the purpose in question. Its disadvantage is the need to use special equipment during operation. This feature makes the use of this material more expensive.

Choosing material

The following are particularly suitable as insulation for garage doors:

- Mineral wool (basalt, glass wool, etc.). The first option is considered optimal. Basalt wool slabs have low thermal conductivity and block noise well. The material can also be purchased in rolls. It is important to remember that if you decide to work with glass wool, you need to wear protective equipment for your hands, eyes and respiratory system. And also protect the cotton wool itself from moisture. Otherwise, it will sag and lose its thermal insulation properties.

- Styrofoam. Due to the fact that it is foamed during manufacturing, the material has a low level of thermal conductivity. In addition, it is resistant to mechanical stress and water. As a type of foam plastic, extruded polystyrene foam is distinguished. More often they take the brands Penoplex , TechnoNIKOL, URSA XPS, etc. Like any type of air insulation, polystyrene foam is lightweight.

- Polyurethane foam. Or simply polyurethane foam. Expands several times after application. Resists cold and water well. Excellent contact with metal sheets. This guarantees the absence of condensation under the insulation. In addition, the foam is not afraid of fire.

How to insulate gates

Garage doors have different designs, but in most cases a swing model is used. The most pressing issue is the insulation of this type of gate.

They are usually made of metal, but you can also use wooden parts to make them. Installation of insulation begins with the installation of a frame made of beams on the inside of the sashes. It must have sufficient depth to install a suitable layer of insulation.

Insulated garage Source i1.wp.com

Carrying out preparatory work

Preparatory work begins with surface development. To do this you need:

- Work on the garage ventilation. If it is installed on the gate, we may accidentally cover it with insulating material. Find both the supply and exhaust openings.

- Now you need to process the inner surface. The gate may be dirty, corroded, or the paint may have started to peel off. We remove everything unnecessary. Rust can be removed using a sanding machine. If corrosion has begun, anti-corrosion protection should be used to coat the gate. Anticorrosive is a primer that protects the gate. It will be better if you can apply it with a spray.

Some tips for installing gates

Installing gates with insulation is a complex and time-consuming process. It is important to complete the work in such a way that there is no need to redo it next year. It is recommended to pay attention to the following:

- When planning a gate, it is important to take care of how to make a gate in a garage door with your own hands in one of the leaves. In cold weather, this will help conserve heat in the room. If the gate is massive, then using a gate for entry will be more convenient.

Using a gate will help keep the garage warm Source refite.ru

- It is convenient to provide the ability to open automatically when installing. This option is convenient and affordable for most garage owners.

- Although the gate can be made of wood, it is nevertheless better to use metal. A wooden product may only be convenient as a temporary budget option.

- It is important to ensure good ventilation in the garage. An inlet hole for it is made in the gate. When carrying out thermal insulation, it is necessary to monitor. So that such a hole is not closed. The use of slits as an inlet is not permitted.

- Using high-quality protective paint will increase the product's resistance to wear.

- Although aluminum gates will be lightweight and durable, it is not recommended to use this material due to the fact that it wears out quickly.

- It is recommended to use sheet steel five millimeters thick as the manufacturing material. It will provide reliable protection to the vehicle.

Steel gates will provide reliable protection for the garage Source ad-cd.net

When designing gates, you must take into account that they need enough space to open. You need to choose how best to open them: inward or outward. In this case, you need to free up the necessary space inside or take into account the location of surrounding objects from the outside.

Surface preparation and lathing creation

The first step is to prepare the surfaces for installation of materials. To do this you need:

- Free the sashes from all foreign objects - brackets, hangers, and other elements that are often installed on the sashes. Only the upper and lower latches of the fixed sash and the lock are not removed, which in any case are attached directly to the metal and cannot be moved;

- The surface of the gate is cleaned of old paint, peeling or crumbling areas. It is most convenient to use a drill with attachments - a wire brush or an emery wheel;

- Detected cracks or deep corrosive potholes are repaired by welding. In difficult cases, patches are welded in, after which the seams are carefully cleaned flush with the main surface;

- The prepared surface is covered with a protective layer of bitumen mastic using a brush. The coating is applied in 2 layers in the transverse direction.

After the protective layer has dried, they proceed to installing the sheathing. It is a system of wooden bars installed around the perimeter of each door with several lintels inside.

Installing the sheathing is an important step in the process of insulating garage doors.

The sheathing serves as a support system for installing the sheathing, which protects the heat insulator and gives the sashes a neat appearance. After finishing, the inside of the gate can look much more impressive than the outside.

To install the sheathing, a reinforcing corner is used, welded along the perimeter of the sashes, in which holes are drilled for self-tapping screws. In some cases, you have to make holes directly in the sashes, which is acceptable, but undesirable.

- The bars under the sheathing must have a thickness no less than the selected heat insulator. This is important because after installing the material, the sheathing will need to be attached to the bars. The internal cavity formed by the sheathing and sheathing must be sealed and not allow air to pass through, so the sheathing must be equal to or even slightly thicker than the insulator.

- When installing the sheathing, it is necessary to leave the upper and lower latches with a lock and bolt free. These elements are subsequently provided with their own protective covers that cut off contact with warm air.

- The sides of the bars adjacent to the sashes must be covered with a strip of polyurethane foam before direct fastening. This will ensure the tightness of the sheathing and prevent the formation of cold bridges. All joints between the bars are also insulated with polyurethane foam.

- The finished sheathing should completely cover the perimeter of each sash. Inside, the lintels are installed based on the area of the sash and the degree of rigidity of the cladding. Sometimes one jumper is enough, but usually several bars are used. It must be taken into account that installing strips too frequently reduces the effectiveness of insulation and makes work more difficult.

After installing the sheathing, installation of the heat insulator begins.