Here you will learn:

- Features of the stove heating device

- Choosing a furnace with a water circuit

- Brick oven

- Correct oven placement

- What size house can be heated using a brick stove with a water circuit?

- Stove heating using an air system

- Choosing the best option

- Fire safety requirements for stove heating at home

- Safety rules for operating furnaces with a water circuit

In order to understand the need to install a stove for heating a private home, you need to know a number of its advantages:

- absolute autonomy of operation and independence from external factors, such as turning off water, gas or electricity;

- brickwork can warm a room for a long time, even if the fire in the firebox has already gone out;

- simultaneously with heating the rooms, the stove can be used for cooking;

- cost-effectiveness in terms of purchasing fuel and the need to pay bills for the general supply of gas, electricity and water, availability of firewood, compared to peat or coal;

- absence of overheated and dry air;

- just a pleasant atmosphere in the house;

- Ease of operation: no high-tech electronic equipment required.

The advantage of a brick oven is that it can be designed according to your wishes and preferences.

Disadvantages of stove heating

Along with the advantages, stoves also have negative qualities:

- Quite a long heating time. This happens because bricks take a long time to heat up.

- A certain amount of usable space is lost, since the larger the house, the larger the stove will have to be installed.

- Heavy weight. If the stove is very large, you will have to build a separate foundation for it.

- Uneven heating of all rooms, that is, the further the room is from the stove, the more time it will take to heat it; warm air will reach it last.

Features of the stove heating device

When choosing stove heating, one of the most common mistakes is the idea that you first need to build a house, and only then start laying the heating device. The house and the stove should be perceived as two objects closely interconnected with each other, requiring an integrated approach and careful calculation.

“Dance from the stove!” – this is exactly what the stove-makers’ motto sounds like. This means that before starting construction, you must:

- Understand what kind of oven you need;

- Calculate its dimensions and mass;

- Determine the location of its installation in the house.

- Calculate the load from it on the foundation or floors.

- Consider a chimney system.

Figuratively speaking, it is not the stove that is built inside the house, but the house that is built around the stove!

Alexey Telegin:

– It happens like this: the developer first builds a house, puts on the roof, does the finishing, and then suddenly remembers about heating and wants to install a stove. Here it turns out that she simply does not “fit” into the room. We have to solve this problem, redo or strengthen the foundation, break and rebuild the floors and rafter system.

“Implanting” a heating device into an already built house leads to unjustified costs.

– Only if you have a project or sketch of the stove, you can link it to the house plan.

Therefore, the construction of the stove should be divided into a number of successive stages. Namely:

1. Design. At this stage:

- choose the type and design of the furnace;

- we first determine the place for it;

- we calculate safe distances at the intersections and junctions of its surface with the floor, ceiling, ceilings, roofing, walls, partitions;

- We think over its appearance, finishing materials, surface texture.

2. Control. At this stage, you need to make sure that all work is carried out in accordance with the project.

This approach guarantees a high-quality result.

It is also necessary to select in advance the correct material for the manufacture of the stove and chimney. It is better to use solid plastic-molded bricks, since dry-pressed bricks cannot withstand high temperatures.

Choosing a furnace with a water circuit

The choice of a furnace with a water circuit has its own characteristics. Here we will omit the issue of calculating and constructing a brick kiln with a heat exchanger - it is quite problematic to carry out the entire complex yourself; the best solution would be to invite specialists in this field. Moreover, it is recommended to initially build a brick oven with a heat exchanger - from scratch, because it is not easy to install a heat exchanger later - it is problematic to install and can make changes to the technical and thermal characteristics of the oven itself.

As for metal furnaces, it is better to turn to industrially produced products. They have a more attractive appearance, are made of high-quality materials, and in any case have greater efficiency compared to homemade ones.

It should be noted that domestic models of stoves with water heating circuits compare favorably in price with their foreign counterparts and are not inferior to them in quality. Moreover, the cost may vary significantly.

The thermal power of factory products is indicated in the equipment passports. Here you need to pay attention to the power division. The total power is divided into 2 parts - the performance of the heat exchanger and the convection-radiation power of the furnace body. For example, for a 20 kW furnace it could be 12 kW for the casing and 8 kW for the heat exchanger.

The future configuration of the heating system - placement of the stove, power and number of radiators - depends on the division of power. In this case, the stove acts as a powerful heating device and is usually located in the largest room. The power of the heat exchanger is distributed among individual heating devices.

You should also pay attention to the functionality of the stove - sellers often refer to stoves with a DHW circuit as stoves with a water circuit. At the same time, the heat exchanger does not have serious power and is not intended for heating needs.

Furnaces with a water circuit are a rational solution to improve the characteristics of a classic furnace. Modernization allows for better heating of premises and reduction of fuel consumption. The selection and installation of this equipment depends on the desire of the owner of a private home, the availability and cost of fuel, the required functionality and operating mode of the equipment.

Conclusions and useful video on the topic

A working heating system based on a stove and a water circuit in a private house with an area of 80 square meters:

Heat is supplied to the heating system from stoves and fireplaces in portions, which complicates the task of calculating the parameters of the heating circuit elements. Carrying out work on altering the circuit is quite problematic, so if you lack experience in this area, it is better to turn to specialists who have the skills to solve such problems.

Do you have experience in organizing stove heating? Or do you heat your home this way and would like to share your impressions of using the stove? Please leave comments and ask questions. The feedback form is located below.

Brick oven

A stove is not only a home heating device, but also a decorative element.

In a small house, you can install one stove, which will require firewood or coal to fire it. Modern stove heating of a private house provides many types of heating structure designs. You should choose one that is intended not only for heating the room, but also for cooking. Before installing the stove, you need to choose a suitable place so that its use is as efficient as possible:

- The firebox should be directed towards the corridor or kitchen, and the heated surfaces should be directed towards the rooms. When designing a stove, you should know that 1 m² of its area heats up to 30 m² of room.

- You cannot place furniture near the stove or install partitions, and do not build the stove in the corner of the room. Its large wall should go into the living spaces, then they will always be warm.

- The design of the stove should be chosen according to its purpose. They are used only for heating the room or also for cooking. In this case, you should take into account the hob and oven

It should be taken into account that a large oven takes much longer to cool down. If you heat it well in the evening, the heat will remain until the morning.

Heating stove:

Construction of a furnace structure

The stove structure is erected during the construction of the house, but the foundation is built separately from the general foundation. You can install a stove in an already built house, but then you will need to raise part of the floor and make holes in the ceiling and roof to install the chimney.

Detailed furnace laying:

The size and depth of the foundation depends on the type of furnace structure. It is erected immediately after the construction of the general foundation of the house. For a brick oven, it should be monolithic reinforced concrete, 10-15 cm larger than its parameters on each side. It is required to observe the depth size - from 0.5 m to 1 m. If the soil is loose, or groundwater is close, you do not need to deepen the foundation, but increase its area.

To build a stove, you should use well-burnt red brick. When tapped, it gives off a metallic sound. If it falls, it breaks into large pieces. It is easy to work with, as it can be broken correctly. The areas of the stove in contact with the fire are lined with refractory bricks (the firebox and part of the chimney).

The mortar for laying the stove is mixed from clay and sand. You will need approximately 2 buckets of clay per 1.5 buckets of sand. Brick consumption - 100 pieces. For masonry strength, Portland cement is added to the solution (0.5 liters per bucket).

Detailed furnace laying:

Room heating process

A well-thought-out design of a stove in a private home determines effective heating of the room. Solid fuel (usually wood or coal) is burned in a combustion chamber with air supply. Natural draft promotes the movement of flue gases through the channels to the vertical exhaust passages, from where they exit outside. During this time, the brick walls of the oven warm up, and the heat from the hot stone spreads throughout all the rooms.

For good heating, 1-2 fireboxes per day are enough. At the same time, do not forget to set the valves in a certain position in time and remove the ash from the ash pit. The stove’s sufficient heat capacity and good insulation of the house allow it to be heated once a day - this is a fairly common option.

A well-thought-out stove design in a private home determines the quality of heating of the room

Advantages

When the layout is well thought out taking into account a specific heating system, the installation of the stove practically does not depend on the building material from which the home is built. It is suitable for both wooden and brick houses. Its advantage is that there is always a wide choice of fuel for heating premises: coal, peat, firewood, even cardboard and dry tree branches. The user himself decides what to heat with, what is more accessible and costs less.

The next advantage is that heating the house does not depend on the heating season of the heating plant, on emergency repairs and long-term interruptions in fuel supplies. The stove is autonomous, its operating mode is determined by the user himself, who does not need a plan for seasonal system shutdowns.

Layout of a house with a stove 6×9 meters

The ability of a stove to create a cozy and comfortable atmosphere is well known. Thanks to this quality, no other heating system can compare with it. It’s nice to sit with a book by the stove, inhale the smell of resinous wood and listen to its quiet crackling. This is reminiscent of distant times, shrouded in romance. In addition to these advantages, the stove can be equipped so that it becomes an original addition to the interior.

The Russian stove gives the room a special charm. In terms of heat capacity, nothing can compare with it. It is able to accumulate heat and then gradually release it, maintaining constant coziness and comfort in the hut. In the past, it performed a cooking and heating function. Today it is quite rare.

Only those who like the rustic design style of the house will decide to decorate their apartments with it. True, there are no more stove makers who don’t need a drawing to build one.

The century of technological progress has made its own adjustments. Today, it is common to have a house with a stove that runs not only on solid fuel, but also on electricity, gas, and fuel oil. But the most affordable heating material is still firewood.

Correct oven placement

As in the old days, building a house begins with planning the placement of the stove. There are some rules to follow:

- The area of the room must be more than 16 square meters.

- You should not install it close to a stone wall, then most of the heat will be transferred to the outside of the house. But in wooden houses this is not at all recommended for fire safety reasons.

- A heavy stove will eventually break any joists and rafters, so a brick stove needs a separate foundation.

Large stove with storage for firewood and a stove bench separating the kitchen and living room

If the goal is to heat as many rooms as possible, then it should be installed so that the stove is part of all these rooms. It is installed in the partitions of rooms in such a way that its walls or corners fall into these rooms.

This is how, for example, stoves were installed in the old days in many village huts. The stove is located in the center, and the rooms are located around its perimeter. This is a classic option for placing a stove. The whole house is heated at the same time.

Classic oven layout

If the layout consists of two rooms: a common room and a kitchen, then it makes more sense to move the main part into the room, and the hob and firebox into the kitchen.

What size house can be heated using a brick stove with a water circuit?

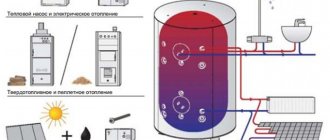

A brick stove can also be adapted for heating large areas if, when building it, a heat exchange element is placed near the firebox through which the coolant will pass, heating up and then circulating in the heating system distributed throughout the house. In this case, you may need to connect a water pump, which will accelerate the movement of coolant in the system.

Homemade efficient heat exchanger

Heat exchange elements can be of different shapes; the photo shows one of them. It is embedded in the structure of the stove near the combustion chamber so that, passing through it, the water quickly heats up and enters the pipes and radiators.

The inlet and outlet pipes from the heat exchanger are led outside the furnace structure, and the heating circuit is connected to them. Next, the system is filled with water, which will act as a coolant.

Wiring can be done using metal-plastic or polypropylene pipes

In this case, metal-plastic pipes are used for wiring and connection to the circuit.

Diagram of a wood stove with a water heating circuit

In this diagram, the heat exchanger is located above the firebox and is shown as a red grate. The blue line marks the cooled coolant, which passes through the circulation pump and enters the heat exchanger - this part of the circuit is called return. The red line marks the heated water entering the radiators.

A membrane tank is also installed in the heating circuit, which can be located in any accessible location in the circuit, but it is advisable to install it on the return pipe.

Diaphragm tank

It is also called a closed expansion tank. There is a nipple on its upper part, through which air is pumped into the upper chamber. When water in the system heats up, it expands and excess water rises into the tank, stretching the membrane. When cooling and the corresponding pressure drop, water is pressed back into the system. In this way, possible pressure surges in the pipes are smoothed out, and the risk of destruction of the integrity of the system from overheating is minimized.

Heating registers

Before installing stove heating, it is worth deciding on the type of heating water circuit, also called a register, heat exchanger, coil or water jacket. Most often it is a rectangular flat container or several tubes connected together.

But before connecting the heating to the stove, two pipes must be welded to the register. The first serves to draw hot coolant from the furnace, and the second supplies cooled water back to the heat exchanger.

The size of the heat exchanger can be determined by the level of heat loss in a particular house. So, if 10 kW of thermal energy is required, the heat exchanger area should be 1 m2. It is worth considering that the oven does not work all day, but for about 1.5-3 hours, depending on the outside temperature. This time should be enough to warm up the water in the heat accumulator. Consequently, to calculate the register area, the daily consumption of thermal energy in the house is determined.

So, with heat loss at home of 12 kW/hour, daily consumption will be 288 kW of energy. Let's assume that the oven operates 3 hours a day. It turns out that every hour 288÷3=96 kW of energy should be released. Then the area of the heating register will be 96÷10=9.6 m2. The shape of the heat exchanger in this case is not important, the main thing is that the surface area is no less than the obtained data.

When using antifreeze as a coolant, you can further increase the volume of the heat accumulator, since water and antifreeze have different heat capacities.

If the buffer tank is additionally insulated, the heat will be retained in it further, and the efficiency of stove heating will increase.

Stove heating using an air system

The reason for the strong preference that owners of private houses give to the stove heating option is the cost-effectiveness of operation - the availability of firewood, fuel briquettes or coal.

The disadvantage is the limited space to be processed, which can be eliminated by installing a water and air system based on a brick unit.

The operating principle of air heating based on a stove or fireplace is to transfer a warm flow heated to operating temperature in a heat exchanger or boiler. The air enters either directly into the room or through air ducts.

Thanks to the relatively short path, it does not have time to lose temperature. The result is an even distribution of heat throughout the house.

A chamber for heating air is placed above the firebox so that the hot upper surface of the firebox and the chimney transfer the maximum amount of heat to it. Air circulation occurs naturally or with the help of fans.

Natural circulation occurs as a result of the difference in density of cold and hot air. Cold air entering the heating chamber displaces hot air into the air ducts.

This method does not require electricity, but if the air does not move quickly enough through the heating chamber, it becomes very hot, which can cause problems.

Air heating with natural movement of heated air involves the installation of air ducts for directed movement. In forced versions, air movement is stimulated by a fan (+)

Forced circulation occurs using fans or pumps. However, the heating of the premises occurs more quickly and evenly. With forced ventilation, by adjusting its mode, you can easily control the volume of air supplied to various rooms, thereby determining the microclimate of individual rooms of the house.

Based on the type of cold air supply, systems are divided into two types:

- With full recycling. Heated air masses alternate with cooled ones within the same room. The disadvantage of the scheme is that the air quality decreases with each heating/cooling cycle.

- With partial reclamation. Part of the fresh air is taken from the street, which is mixed with part of the air from the room. After heating, the mixture of two air portions is delivered to the consumer. The advantage is stable air quality, the disadvantage is energy dependence.

It is clear that the first group includes duct systems with natural movement of air coolant. The second includes options with forced air movement, for the movement of which it is not necessary to install a network of air ducts.

The influx of air from the street gives the natural circulation system an additional boost, which eliminates the need for fans

The main advantages of air heating compared to water heating:

- high efficiency;

- accident-free;

- lack of radiators in the rooms.

The design of the circuit with forced movement allows you to do without the construction of an air duct system. In addition, this type can be combined with air conditioning, humidification and air ionization.

Increasing the efficiency will spontaneously increase the speed of the air flow: the faster the air heats up, the more intense the change of cooled and heated air mass occurs.

The main disadvantages of air heating compared to water heating:

- when using a furnace, the temperature of the supplied air has a significant range, unlike the use of other heating means;

- air ducts have a large diameter, so installation must be carried out at the construction stage;

- It is advisable to locate the stove in the basement, otherwise it is necessary to use fans that make noise.

Air movement in the room has a negative side - it raises dust, but the use of filters at the outlet of the air duct allows you to effectively catch this dust, thus reducing the total amount of dust in the house.

Another feature of air heating that has both positive and negative sides is the rate of heat transfer. On the one hand, the rooms heat up faster than when heating using a water circuit, on the other hand, there is no thermal inertia - as soon as the stove or fireplace goes out, the room immediately begins to cool down.

To ensure uniform pressure in the side branches of the air duct, it is necessary to exclude their insertion into the last half meter of the main air duct

Unlike water heating, installing an air heating system is not difficult. All elements (pipes, bends, ventilation grilles) can be connected quite simply without welding. There are flexible air ducts that can take any shape, depending on the geometry of the premises.

Despite this, air heating systems based on stoves or fireplaces have not yet become widespread. Much more often in individual low-rise construction, a water circuit is used to heat rooms.

Based on a stove or fireplace with a brick or steel firebox, you can arrange both air and water heating

How wood stoves work

One of the features of heating devices is a secondary combustion chamber, which is characterized by slow combustion of fuel. Simply put, the logs in the firebox do not burn, but smolder. This effect is achieved by adjusting the amount of air entering the fuel chamber.

The combustion chamber is divided into two compartments. When wood is smoldering, unburnt combustible gas enters the second compartment of the chamber, where additional air is supplied from the injection pipes, after which the gas burns out completely, and the wood remains to smolder further.

Unburned gas from the main combustion chamber enters the additional combustion chamber, where, after mixing with an additional portion of air, it ignites, releasing additional thermal energy

Among the advantages of the system, it is worth noting: an increase in the operating life of the devices, greater efficiency - the stove operates for 8-9 hours on one stack of firewood.

There are a few more disadvantages: the system only works on dry wood, the combustion mode will have to be constantly adjusted, which is somewhat inconvenient. It is also necessary to constantly monitor the cleanliness of the chimney and periodically clean it.

Choosing the best option

It will be difficult to install a massive brick stove in an already built house. In this case, water heating is best organized on the basis of a metal potbelly stove, which can be placed on a reinforced wooden floor without pouring the foundation.

However, if it is possible to make the foundation as it should be, then preference should be given to a more reliable brick stove structure.

The water circuit around the house for a wood-burning stove is best made from thick steel pipes and with natural circulation of coolant

Installing a circulation pump and/or accumulator in the heating circuit in question is a waste of money and zero additional benefit. They will only complicate the installation of the system. And if the lights go out, these devices will create problems. Whereas the heating option without them will continue to calmly heat the house if there are problems in the electrical network.

Fire safety requirements for stove heating at home

Before installing a stove, you should think about fire safety in advance, since during combustion the stove will heat up to a high temperature. To avoid fire when installing the stove, the following safety precautions must be observed:

- The stove must be installed at some distance from the wall. Firstly, there will be no direct contact with the wall, especially if the surfaces are wooden. Stone walls will further cool the stove, which will affect fuel consumption. Secondly, the air in this gap will heat up, and not the wall itself;

- The walls where the stove is installed should be additionally sheathed with non-combustible material. Sheet slate is ideal for these purposes. It conducts heat poorly and does not ignite. All walls should be sheathed in places where the future stove will even indirectly come into contact with the wall.

Self-installation

To make your own stove heating, you need to think through everything down to the smallest detail in advance so that you don’t have to solve unforeseen problems later. It is necessary to calculate the thermal power of the future furnace and the amount of material required.

Where to place

If you plan to install a brick stove in a house under construction, you need to determine its location on the plan so that it can heat as large an area as possible. The ideal location would be approximately in the center of the house at the junction of several partitions. In this case, the chimney will be able to heat the premises of the second floor or attic.

For more efficient heating of the rooms on the upper floor, holes are provided in the ceiling for the circulation of heated air. There must be at least two such holes in the ceiling within one room - one near the stove, the other on the opposite side.

Safety rules for operating furnaces with a water circuit

To ensure proper operation of the stove and boiler, it is recommended to follow important safety rules, as well as recommendations for caring for the equipment:

- Water heating devices must be operated under human supervision. This applies to adding fuel and regularly cleaning the chamber from soot and ash.

- Safe operation of the stove requires control of the smoke exhaust ducts. Before starting the fire, it is necessary to check the technical condition of the channels and the position of the valves. When starting a fire, the valves must be completely open.

- Such a system is recommended for use in winter, when it is necessary to provide rapid heating of rooms and hot water supply. Using a stove with a water circuit in the summer only for cooking and heating water is irrational. In this case, it is recommended to choose more economical heat sources.

- An open fire leads to excessive heating of the stove structure, which can be the main cause of heat exchanger failure.

- When using a homemade heating system, you can install a pumping unit to inject liquid and devices to control pressure levels.

Flaws

Along with many positive aspects, of course, there are also negative aspects of using stove heating.

The initial launch requires a significant amount of time. It will take some more time to warm up the furnace array until it begins to give off heat inside the building.

Note! Fireplaces, whose open firebox generates infrared radiation that quickly warms up the volume of the room, do not have this last drawback.

Stove heating requires human intervention to operate. It is almost impossible to automate the process. The stove heating system has low efficiency. Its increase is facilitated by an increase in the length of the smoke channels - revolutions, an increase in the outer surface, as well as the correct position of the chimney valve during the combustion process. Firewood must be prepared in advance to ensure drying.

A good stove should be massive and have a fairly large volume. Moreover, this entire volume should be located inside the building, reducing the usable area of the rooms. The decision to install stove heating should be made at the building design stage, since stoves very often require a foundation.