Most of Russia's territory is located in latitudes with a cold climate. The heating season there can last six months or more. The population of most regions of our country has to spend a lot of time in heated rooms, so very high demands are placed on heating systems in terms of their efficiency and the presentable appearance of the batteries. Increasingly, more modern appliances are being preferred to the cast-iron monsters of Soviet times. There is a growing demand for bimetallic radiators - heating elements that combine the excellent heat transfer of aluminum and fairly good corrosion resistance of steel.

Why we prefer bimetallic devices

Combining the useful characteristics and properties of different materials in one product often gives very good results. A clear example of this is bimetallic devices, which have both the reliability of steel and the high thermal conductivity of aluminum. The combination of these two metals made it possible to design batteries with high heat transfer, an impressive modern design and the ability to withstand hydraulic shocks. Initially, radiators of this type were created for use in centralized heating systems, characterized by high operating pressures and low-quality coolant. Now the scope of application of bimetallic radiators has been significantly expanded; they have begun to be successfully used in the arrangement of individual autonomous heating.

We have been using steel and aluminum radiators made in our country or abroad for a long time. Steel batteries are characterized by strength and immunity to the effects of alkalis, acids and other impurities added to the coolant composition. But the efficiency of steel radiators is not too high, since this metal, although it heats up very quickly, also cools down just as quickly. Aluminum undoubtedly has high heat dissipation, but cannot effectively resist corrosion. Bimetallic batteries use the best properties of these metals, so the heating system in which they are used is characterized by increased efficiency. This is especially important given the high price of energy.

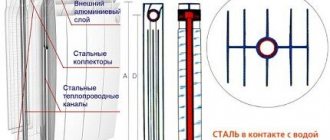

On what principle do bimetallic batteries work? The coolant, which can be not only water, but also more aggressive liquid substances, transfers heat to the internal radiator core made of steel. It is important that contact of easily oxidized aluminum with an aggressive coolant is completely excluded. The heated steel then transfers thermal energy to the aluminum body, which directs it to heat the room.

Sectional and non-separable radiators

It was noted above that bimetallic heating radiators can consist of several sections or be of a non-separable type.

In the first case, each horizontal section inside has a pipe, threaded on both sides. With its help, connecting nipples with rubber gaskets are screwed in for sealing. It is the connection points that are the weakest point in sectional batteries and are most prone to damage. In addition, high temperature and high pressure in the system also cause leaks in these places. As a result, the time between preventative maintenance is reduced. However, sectional radiators still have a positive aspect. If one of the sections is damaged, only the failed element is replaced or removed. This should be taken into account when determining which bimetal radiators are better.

Monolithic production of bimetallic radiators allows you to avoid many troubles. The technological process involves manufacturing a solid manifold from stainless steel or copper, placing it in a special mold, which is subsequently filled with aluminum under pressure. The output is monolithic bimetallic batteries.

The disadvantage of monolithic radiators is the lack of maintainability. A leak in such a battery requires its complete replacement.

Comparing the characteristics of two types of radiators and determining which bimetal heating radiators are better, the following can be noted:

- The service life of sectional radiators is 30 years; monolithic products can be used for half a century.

- The operating pressure of sectional batteries does not exceed 25 bar, monolithic - can reach 100 bar.

- As for cost, monolithic radiators cost almost 20% more than sectional batteries.

- Sectional domestic heating radiators allow you to regulate the amount of heat in the room by installing or removing a certain number of sections. In the case of monolithic batteries, this possibility is not available, so before purchasing them, it is necessary to accurately determine the required power.

In addition, when choosing sectional or monolithic batteries, the features of the heating system are taken into account. For example, systems of multi-storey buildings are characterized by high pressure and the presence of water hammer, as a result of which the connecting nodes of sectional radiators can be damaged. To decide which bimetal radiator to choose that does not allow leakage, you should purchase monolithic devices.

Aluminum or bimetal - learning to distinguish between radiators

Manufacturers offer various models of hybrid batteries. They come in different designs, differ in power, and in the technology of connecting to the system. Radiators are available with top and bottom connections. After installing these heating elements, it is almost impossible to visually determine the difference between bimetallic devices and aluminum batteries, especially for a non-professional. This must be done before connecting them. The main sign that you have a bimetallic radiator is the presence of an internal steel core encased in an aluminum body. This structure ensures excellent performance properties of the device. The weight can also give away a bimetallic battery: a radiator weighted with a steel core cannot be as light as an aluminum one.

Sectional bimetallic radiator Royal Thermo BiLiner 500 black 6 sections

Manufacturers

Currently, on the heating equipment market you can find a large number of different models of bimetallic radiators produced by both Russian and foreign manufacturers. Let's look at the main characteristics of the most popular models.

| Model | Distance between axles, mm | Section size: width*height*depth (mm) | Maximum working pressure, Bar | Thermal power of the section, W |

| Rifar (Russia) | ||||

| Rifar Forza 350 | 350 | 415*90*80 | 20 | 136 |

| Rifar Forza 500 | 500 | 570*100*80 | 20 | 202 |

| Rifar MONOLIT 350 | 350 | 415*100*80 | 100 | 136 |

| Rifar MONOLIT 500 | 500 | 577*100*80 | 100 | 194 |

| Global Radiatori (Italy) | ||||

| Style 350 | 350 | 425*80*80 | 35 | 125 |

| Style 500 | 500 | 575*80*80 | 35 | 168 |

| Style Plus 350 | 350 | 425*80*95 | 35 | 140 |

| Style Plus 500 | 500 | 575*80*95 | 35 | 185 |

| Royal Thermo (Italy) | ||||

| BiLiner Inox 500 | 500 | 574*80*87 | 20 | 171 |

| BiLiner 500 | 500 | 574*80*87 | 20 | 171 |

| Tenrad (Germany) | ||||

| Tenrad 350 | 350 | 400*80*77 | 24 | 120 |

| Tenrad 500 | 500 | 550*80*77 | 24 | 161 |

| Gordi (China) | ||||

| Gordi 350 | 350 | 412*80*80 | 30 | 460 |

| Gordi 500 | 500 | 572*80*80 | 30 | 181 |

| Sira Industrie (Italy) | ||||

| Gladiator 200 | 200 | 275*80*80 | 30 | 90 |

| Gladiator 350 | 350 | 275*80*80 | 30 | 140 |

| Gladiator 500 | 500 | 423*80*80 | 30 | 185 |

| LLC Litiz (Ukraine) | ||||

| Altermo LRB | 500 | 575*82*80 | 18 | 169 |

| Altermo RIO 500 | 500 | 570*82*80 | 18 | 166 |

| Grandini (Italy) | ||||

| Grandini 350 | 350 | 430*80*82 | 16 | 130 |

| Grandini 500 | 500 | 580*80*80 | 16 | 167 |

Thus, high-quality bimetallic heating radiators are able to operate effectively for a long period of time.

Advantages and disadvantages of hybrids

After the appearance on the market of bimetallic radiators, more efficient and progressive, it seemed that their complete leadership was just around the corner, but everything is not so clear. Along with the important advantages of batteries of this type, they also have significant disadvantages, and the choice of radiators for a heating system takes into account many factors, and together they sometimes turn out to be too early to write off both steel and even cast iron models. Let's take a closer look at the pros and cons of hybrid radiators.

Advantages of bimetallic models

Of course, these include:

- excellent heat transfer, it is higher for bimetallic devices than for heating elements made of other materials (in some models - 190 kW);

- reduced coolant consumption - the presence of a steel core in the radiator design inside an aluminum casing reduces the volume of the radiator, less coolant is required, which is very important when the system uses not water, but some expensive liquid substance;

- long service life, strength and corrosion resistance, which is ensured by the inherent operational properties of steel and the insulation of aluminum from interaction with the coolant. Bimetallic radiators last, depending on operating conditions, from two to three decades;

- wide scope of application, including use in centralized heating systems, the operating pressure in which can reach 40 atm. In this case, only cast iron radiators can compete with bimetal;

- compactness and light weight;

- modern attractive design and rich color palette. Colored hybrid heating radiators do not spoil the interior of the room at all; on the contrary, they become an important and effective element of it;

- ease of installation and ease of use.

Disadvantages of bimetallic batteries

No matter how good bimetallic radiators are, everything has a downside, so they are not without some disadvantages:

- In terms of heat transfer, hybrid devices are still inferior to pure aluminum radiators;

- their price is high compared to the batteries used before them. But here it is impossible not to mention that high costs are more than compensated for by a long service life - two or even three decades;

- It is rare, but it happens that corrosion occurs - this happens when the steel core comes into immediate contact with both water and air. This happens if you drain the water from it during a period when the heating system is not in use. The use of antifreeze as a coolant in the autonomous heating system of a private home can also lead to corrosion of radiators. If you decide to use antifreeze in a system of this type, then sectional bimetallic batteries will not work here; opt for monolithic or aluminum ones.

Sectional bimetallic radiator Royal Thermo BiLiner 500 gray 8 sections

Bimetallic battery design

Bimetallic heating radiators consist of two parts, each of which is made of a different metal. The internal part of the radiator is made of metals that are resistant to the aggressive environment of heated coolant, in most cases it is stainless steel or copper. Tubes made of these materials are installed in vertical and horizontal positions, with coolant moving through them.

The outer part of the radiator is an aluminum casing with fins. The use of aluminum for the manufacture of this part allows for rapid heating of the radiators and heat transfer to the room. The choice of this material for the external part of the structure is explained by its excellent thermal conductivity.

The connection of the internal and external parts of each section is carried out by spot welding or injection molding. The sections are assembled into a battery using steel nipples using heat-resistant rubber gaskets that can withstand temperatures up to 2000C. In addition, radiators can be monolithic; similar materials are used for their manufacture.

Each manufacturer indicates in the passport its own value for the crimping pressure of a bimetallic radiator, since this indicator is determined by the size of the battery and the material used to make its internal part.

The high thermal conductivity of the devices makes them more efficient compared to cast iron batteries (more: “Cast iron or bimetallic radiators - advantages and disadvantages, which is better to choose”).

In appearance, Russian bimetallic heating radiators are similar to aluminum models, but there are serious differences in weight. The steel tubular internal part makes bimetallic batteries heavier than aluminum models by almost 50%. A certificate of conformity and accompanying technical documentation, which must be supplied by the manufacturer with each batch of equipment, helps to avoid mistakes when choosing radiators. In a specialized store, such documentation is kept by the seller.

Choosing a bimetallic radiator

Choosing batteries for a heating system requires a balanced, thoughtful approach. The best option would be to seek the help of an experienced professional and make a choice following his recommendations. If there is no specialist in mind whom you can trust, then such a serious decision will have to be made independently.

Parameters that you should pay special attention to when purchasing bimetallic radiators:

- size of radiators - usually the batteries are mounted under the window, thus creating an additional barrier to heat loss. On the construction market today you can purchase different modifications of batteries with different heights. Most of them have a center distance of 200 or 350 mm. Also found on sale, but much less frequently, are taller bimetallic radiators with an interaxial distance of 500 mm, which means that the height of the sections of such batteries is 581 mm;

- operating pressure of the heating network - in a central heating system, as a rule, it does not exceed 15 atmospheres, so it is enough for a bimetallic radiator to easily withstand loads of this level;

- battery power - it must correspond to the volume of the heated room;

- thickness of steel inlays - if they are too thin, this significantly impairs the performance properties of the radiator; this indicator can be estimated by the weight of the radiator: the thinner the inlays, the smaller it is;

- brand - when buying a radiator from a well-known brand, you can count on high quality. The leading positions on the market are occupied by hybrid heating devices made in Europe - Italian and Czech. But domestically produced radiators are also in demand due to the combination of good quality and affordable price.

Cost/quality ratio is another important aspect of choosing a hybrid radiator. Of course, no one likes to overpay. But the bargain price for such equipment, which a priori cannot be too cheap due to the specifics of production, should alert buyers. Ask yourself, what did the manufacturer save on when he managed to significantly reduce the cost of his products? This is hardly possible without compromising the quality of the radiators, so do not chase cheapness, remain vigilant and objective in your judgment.

Even in the store you may come across unscrupulous sales assistants who will offer you bimetallic batteries that are not actually bimetallic. In genuine "bimetals" the steel core is always a solid structure, filled from the outside with aluminum supplied under high pressure. In stores, you often find radiators in which the steel is not present in full, but only in the vertical channels. Such batteries are characterized by increased durability when compared with aluminum analogues, but cannot be called bimetallic.

Sectional bimetallic radiator Atlant 500 8 sections

Recommendations for selection

It is clear that you need to select the appropriate characteristics of bimetallic radiators. But this is not the only point. Calculations are one of the main tasks when purchasing a radiator. It is recommended to calculate the number of sections using the following formula:

Room area *100/power of 1 section

. For example, we have a 15 m2 room and a bimetallic heating radiator with a heat output of 185 W. We count: 15*100/185=8.1. We round up and get 9 sections.

But that's not all. There are many correction factors that affect the final calculations. This is the average temperature outside in winter, wind rose, floor, ceiling height, etc. Sometimes errors in calculations reach up to 50%, so correction factors need to be taken into account.

A couple more tips for choosing bimetallic heating batteries:

- Choose products from a manufacturer that has proven itself well. And not necessarily imported. Domestic brands are no worse, and the cost of radiators is more affordable.

- For an autonomous heating system there is no point in using bimetal. There are no large pressure surges here, the coolant composition is of a higher quality. Bimetallic devices are better suited for the harsh conditions of central systems, although no one forbids installing them in individual highways.

- Don't go for a very low price. A low price indicates the poor quality of the materials from which the radiator is made. It is unlikely that such a device will satisfy you with its performance and service life.

If possible, it is better to enlist the help of a specialist in choosing batteries. He will help with calculations and determination of characteristics.

How to calculate the number of sections in a battery

Even a heating system installed in accordance with all the rules will not be able to provide heat to the object on which it is installed if an error was made during preliminary calculations. This primarily relates to calculating the number of sections.

The main characteristic of a radiator is its power, this indicator must be indicated by the manufacturer. Having information about the power of one radiator section, it is easy to calculate how many sections are needed to heat a particular room. To do this, you need to measure the area of the room in which the battery will be installed and perform simple arithmetic. To determine the required number of sections, you need to multiply the area of the object by 100, and divide the resulting value by the capacity of one section declared by the manufacturer. For example, to heat a room with an area of 10 m2, you need a radiator of six sections with a power of 180 W each - the number 5.5555 obtained in the calculation must be rounded according to the rules - up.

Installation features

The installation of bimetallic batteries is similar to the installation of steel and aluminum radiators, but it still has characteristic features. For example, before connecting hybrid devices, it is imperative to flush the communications, but it is prohibited to use alkaline solutions for this. When processing mating elements, you cannot use products containing abrasives - this can lead to depressurization of the system and the release of coolant.

Installation of bimetallic radiators is carried out as follows:

- mark the installation points of the brackets and fasten them to the wall;

- we hang the radiators on the fixed brackets so that the horizontal sections fit exactly on them;

- We connect the batteries to the heating system using taps and air valves that allow air to bleed.

Bimetallic radiator ROYAL THERMO BiLiner 500, 12 sections

A number of recommendations for the selection and operation of hybrid devices

In pursuit of the beauty of your interiors, do not cover the radiators with massive decorative screens; this will reduce the efficiency of these important elements of the heating system.

You can paint bimetallic radiators yourself, but not more than once a decade. Painting appliances dark increases their heat transfer.

When choosing heating devices and leaning towards buying bimetallic radiators, the technical characteristics and advantages of which have made them in demand and popular, weigh all the arguments for and against. Remember that when heating private houses and apartments with autonomous systems in which the pressure does not rise to critical levels, you can use less expensive batteries. But if the system uses poor quality coolant, bimetallic radiators will be the best option.

When installing hybrid appliances, strictly observe all standards and relevant SNIPs, and you will get rid of problems associated with heating systems for many years.

Description and principle of operation

The peculiarities of the domestic climate dictate their conditions, because people are forced to spend a considerable part of their lives in heated rooms. The problem of lack of heat during the harsh seasons in modern multi-storey buildings can be solved by powerful and reliable heating radiators, which can return home comfort to apartments in cold weather.

Such devices, which, if necessary, regulate the temperature in the room, are designed to maintain optimal comfort. The main thing is to be able to find a winning option, to acquire ideal batteries, whose characteristics will best provide heating for an apartment, residential building, or office.

These can be bimetal heating radiators . But what are their convenience and advantages over other heat exchangers? Let's try to evaluate everything in order.

When choosing a radiator, of course, its cost and possible service life are taken into account. But the most important feature of a heating device is the level of heat transfer.

It all depends on the physical properties of the material that forms the basis of the battery case. For example, to operate a cast-iron structure that was common in the recent past, an excessive amount of coolant is required. Its role is played by hot water. It is supplied from one side and, heating the sections, comes out from the other, this is the principle of operation of almost any battery.

Aluminum radiators, which have replaced cast iron designs on the market, although they have poor resistance to corrosion, are attractive due to their high heat transfer, at the same time they have a nice design and are easy to install.

The listed advantages also apply to steel structures, which, together with the previous type of heat exchangers, came into use in our everyday life relatively recently. But having reliability, durability, and structural stability when in contact with chemicals: acid, alkali, which serve as additives to the coolant, at low temperatures, they can create big problems.

The reason is the high thermal conductivity of this material, so the steel heating system too quickly releases both heat and cold into the surrounding space. This greatly reduces the efficiency of such radiators.

Bimetallic heating devices, created from aluminum and durable steel, as a result, have the useful characteristics of both of these materials at once. Therefore, their thermal conductivity is high, as is their durability.

A bimetal radiator will be an excellent option for solving many problems; it is suitable for homes and offices, being corrosion-resistant, constructive and compact.

Such a heat exchanger consists of vertical steel tubes, the outer coating of which is aluminum, which helps to gently regulate the process of heat transfer.

In this case, the role of coolant is, as before, water and other liquid substances; they transfer the required amount of energy to the steel base.

Harmful additives do not corrode the structure, which is protected by the properties of a substance such as steel, and do not affect the external coating, which is prone to corrosion. Next, the heat is supplied to the aluminum shell, which heats the room according to its valuable physical properties.

Having replaced cast iron batteries, which do not have a very impressive appearance, as well as other monometallic devices, bimetallic heating devices have a very attractive design and are also resistant to hydraulic and air shocks.

Initially intended for working systems with enormous pressure and low-quality coolant, they are increasingly used as individual heating devices. As can be understood from the above, using the valuable properties of a combination of metals, they significantly increase the efficiency and quality of heating the room.

Having decided to buy a bimetal radiator , when choosing it, you should take into account that it is visually difficult for a non-professional to distinguish it from purely aluminum devices. More precisely, this can be done if the device is not yet connected to the heating system.

The main visual difference between bimetallic structures is the presence of a steel core inside the body. Another indicator will be the weight characteristics of the radiator, because pure aluminum structures are much lighter.