Hello everyone who is reading this post! In it, I decided to express my thoughts about all sorts of non-standard options for the design of water heated floors.

Here I will state my opinion, it is not necessarily correct, but it definitely is.

I myself am engaged in the sale of equipment for HTP (abbreviated water heated floor), and not in its installation.

Therefore, I am more familiar with the theoretical side of this matter, rather than the practical one.

My opponents will be numerous folk craftsmen who “have done this a hundred times and everything works.”

It, of course, may work, but the whole question is whether it works correctly or not.

And then all sorts of questions begin for the craftsmen, which they cannot answer clearly and start shouting.

Okay, let's not talk about sad things. Let's get to the point.

System design features

A water heated floor is a complex structure consisting of the following layers:

- base;

- hydro and heat layers;

- reinforcing elements;

- pipes;

- concrete screed.

The finishing floor covering is laid on the top concrete screed.

The coolant is supplied to the pipes from a gas boiler. It is also possible to connect pipes to a solid fuel boiler, but economically this option will be less profitable. Purified water or antifreeze is used as a coolant. In addition to pipes in the floor, radiators are installed in the room. But in most cases, with high-quality thermal insulation of the house, they are rarely used.

General diagram of a water heated floor

A distribution unit is connected to the boiler, which consists of a circulation pump, a mixing unit and a manifold group. It “routes” various heating circuits and allows you to regulate their heating.

Conclusion

The installation scheme for a heated floor is selected based on the area of a specific room, based on the heating option. Laying pipes with a snail is a universal and economical way to heat a room in any weather conditions.

The longer the plastic pipes are, the more powerful the pump should be. After all, you will need good pressure and the need to overcome large hydraulic resistance.

It is better to purchase and install adjustable pumps that have three speeds.

dom-s-ymom.org

Advantages and disadvantages of the system

Water heated floors in private households are rapidly gaining popularity. This is explained by the advantages of this system:

- high energy efficiency;

- reliability;

- long, at least 50 years, service life.

The VHP may be the only source of heating in the room. This allows you to eliminate radiators and use room space more efficiently. This point is especially important in small rooms.

Along with the advantages, the system has a number of disadvantages. The most significant is the impossibility of using it in apartment buildings with central heating.

Theoretically, you can submit an application to the organization servicing the apartment building, go through an endless cycle of checks and approvals, and get the go-ahead to install the system. In practice, a positive solution to this issue is rather an exception to general practice.

Illegal tapping into the heating system is an administrative offense for which a fine will be issued and an order will be received to return everything to its original position.

The refusal of the management company to install a heated floor in an apartment building is quite justified. The pressure and temperature in the centralized heating system are high, so even the slightest error during installation can result in the most unpleasant consequences for the apartment owners and neighbors below. In the event of an accident, the neighbors above will be left without heating for a long time. In this regard, in apartment buildings it is worth choosing to install electric heated floors.

When choosing a solid floor, it is important that the house has good thermal insulation

The disadvantages also include the high cost of the equipment and the duration of the installation process. It takes at least 30 days to lay all the layers of the pie.

Expert opinion

Grebnev Vadim Savelievich

Heating system installer

One of the main conditions for the high-quality functioning of a heated floor system is high-quality thermal insulation of the building. Heat losses over 100 W/m2 will make the operation of this type of OS ineffective.

Joint connection of two boilers

To increase the heating comfort of a private home, many owners install two or more heat sources that run on different energy sources. At the moment, the most relevant combinations of boilers are:

- natural gas and wood;

- solid fuel and electricity.

Accordingly, the gas and solid fuel boiler must be connected in such a way that the second automatically replaces the first after burning the next portion of firewood. The same requirements are put forward for connecting an electric boiler to a wood boiler. This is quite simple to do when a buffer tank is involved in the piping scheme, since it simultaneously plays the role of a hydraulic arrow, as shown in the figure.

As you can see, thanks to the presence of an intermediate storage tank, 2 different boilers can serve several heating distribution circuits at once - radiators and heated floors, and in addition load an indirect heating boiler. But not everyone installs a heat accumulator with a TT boiler, since this is not a cheap pleasure. In this case, there is a simple diagram, and you can install it yourself:

Note. The scheme is valid for both electric and gas heat generators operating together with solid fuel.

Here the main source of heat is a wood heater. After a stack of firewood burns out, the air temperature in the house begins to drop, which is registered by the room thermostat sensor and immediately turns on heating by the electric boiler. Without a new load of firewood, the temperature in the supply pipe decreases and the overhead mechanical thermostat turns off the pump of the solid fuel unit. If you ignite it after some time, everything will happen in the reverse order. This video is described in detail about this joint connection method:

Tying using the method of primary and secondary rings

There is another way to combine a solid fuel boiler with an electric one to supply a large number of consumers. This is a method of primary and secondary circulation rings, which provides for hydraulic separation of flows, but without the use of a hydraulic needle. Also, for reliable operation of the system, a minimum of electronics is required, and a controller is not needed at all, despite the apparent complexity of the circuit:

The trick is that all consumers and boilers are connected to one primary circulation ring by both the supply and return pipelines. Due to the small distance between connections (up to 300 mm), the pressure drop is minimal compared to the pressure of the main circuit pump. Due to this, the movement of water in the primary ring does not depend on the operation of the secondary ring pumps. Only the temperature of the coolant changes.

Theoretically, any number of heat sources and secondary rings can be included in the main circuit. The main thing is to choose the right pipe diameters and the performance of the pumping units. The actual performance of the main ring pump must exceed the flow rate in the most “gluttonous” secondary circuit.

To achieve this, it is necessary to perform a hydraulic calculation and only then will it be possible to select the right pumps, so an ordinary homeowner cannot do without the help of specialists. In addition, it is necessary to link the operation of solid fuel and electric boilers by installing shut-off thermostats, as described in the following video:

Project development

The HTP design stage begins with deciding whether the system will be the only source of heat or whether radiators will be additionally installed in the premises. If installation of batteries is not intended, all circuits are connected directly to the boiler, without installing a distribution unit. With this scheme, the temperature on the boiler is set to 45 degrees, and the coolant flows directly into the pipes.

When combining floor pipes and radiators, installation of a mixing unit is mandatory. For the batteries to work, the coolant must be heated to 70 degrees, and for a heated floor this is too high a temperature. In the mixing unit, the coolant will cool before being supplied to the pipes.

Before installation begins, a detailed design for the placement of collector units and mixers is drawn up. Craftsmen recommend placing them in the center of the entire system so that the length of the pipes in all rooms is the same. This will help you make precise adjustments.

The next design stage is sketching a pipe laying diagram. There are 2 options:

- For small rooms (less than 10 sq/m) - parallel laying in a “snake” pattern in increments of 20 – 30 cm.

- In large areas (from 15 sq/m) - in a spiral. This method is more labor-intensive, but ensures uniform heating of the pipes over the entire area. Snake installation in large rooms can lead to broken pipes due to excessive bending and uneven heating in different corners of the room.

Spiral laying option

For rooms from 10 to 15 square meters, both installation schemes are suitable. The pitch between the pipes can be increased to 35 cm if additional radiators are to be installed.

If the room is large, divide it into several circuits. They must be the same size, the difference is allowed within 15 meters. If there is good thermal insulation, the standard step is 15 cm.

Standard formula for determining contour size:

- The heated area in squares is divided by the laying step in meters.

- The size of the curls and the distance to the collector are added to the result.

Expert opinion

Grebnev Vadim Savelievich

Heating system installer

When preparing the calculation and pipe laying diagram, hydraulic resistance is taken into account. It depends on the number of turns: the more there are, the higher the resistance. Please note that each circuit connected to the collector must have the same resistance.

How to choose a manifold and pipes

More often, users choose inexpensive collector models. But if there is no need to save money, then it is better to buy a model with servos and mixing units. Such devices allow you to automatically regulate the degree of heating of the water entering the pipes

A mandatory attribute of the manifold is an air vent valve and a drain valve for emergency situations. For the device to work normally, you can configure all valves once according to the required parameters.

To install the collector you will also need a cabinet. The best option is to use ready-made cabinets that are assembled and tested in the factory.

In this case, you only need to select the required number of collector groups, the power of the circulation pump and the mixing unit, if necessary. The cabinet is mounted in the wall and the heating circuit from the common riser and the circulation circuits of the heated floor are connected to it.

The standard option is to install the cabinet in the wall

The only drawback of using a ready-made manifold cabinet is its relatively high price, but when it comes to increased reliability and safety, it makes no sense to save.

For a rough estimate of the required number of pipes, you can proceed from the calculation of 5 linear meters of pipe per 1 square meter of floor. Polymer pipes made of cross-linked polyethylene are optimal in terms of price and quality ratio. They are lightweight, easy to install and have a service life of at least 50 years. Metal ones last longer, but they are more expensive and more difficult to install.

Preparing the base

The area for laying pipes must be perfectly level, with a height difference at the location of one circuit of no more than 6 mm. A concrete screed is used as the base. A layer of insulation is laid on it.

Extruded polystyrene foam is often used for the base.

Experts advise using extruded polystyrene foam - the degree of thermal conductivity is low and mechanical strength is high. This material is not exposed to moisture and does not absorb it. This type of gasket is produced in slabs measuring 50 by 1000 mm or 600 by 1250 mm, and with a thickness of 20, 30, 50, 80 and 100 mm. The product is equipped with snap grooves, this will allow for a strong connection.

Expert opinion

Grebnev Vadim Savelievich

Heating system installer

Expanded polystyrene sheets with a foil layer should not be used. There is no significant benefit from it, since the reflective property does not work in an opaque environment. In addition, the cement mixture is alkaline, it will very quickly corrode the foil.

Profile polystyrene mats are highly plastic, equipped with special bosses, and pipes are laid between them. Also, the bosses serve as a retainer for the heating elements. In them, the contour is attached in increments of 50 mm. The use of mats greatly simplifies the installation process, but they are more expensive than polystyrene foam insulation. The thickness of the slabs is from 1 to 3 mm, and the sizes are 500 by 1000 or 600 by 1200 mm.

If there is a heated room under the floor, a layer 3-5 mm thick is sufficient. If the room below is cold, the layer is increased to at least 20 mm. If this is the first floor and there is soil below the floor, the insulation layer should be 70-80 mm.

Along the perimeter of the room, the walls are taped with damper tape. It serves to compensate for the thermal expansion of the screed. If expansion is not taken into account, the screed may crack or swell. The height of the tape usually does not exceed 10 cm. It must be glued to the wall. After filling the screed, the excess is cut off.

After laying the thermal insulation, draw the contours of the pipes on the surface. This will facilitate the installation process and help identify design errors in advance.

Pipe installation

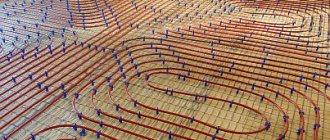

The most suitable base for laying pipes is a special mounting mesh made of metal or plastic with 100 mm cells. It is spread on thermal insulation, pipes are pulled from above, along pre-designated contours, and secured with wire or plastic clamps.

The advantage of using mesh is additional reinforcement of the base for laying pipes. The disadvantages include the complication of the installation process. But the end result eliminates this drawback.

Pipes can also be laid on polystyrene mats. They are specially designed for water heated floors. The mats are a kind of mats with protrusions on the front side in which pipes are fixed. Economically, this is a more expensive method, but installation on mats is much easier and faster. In addition, polystyrene serves as additional insulation.

During installation, try not to step on the pipes or drop heavy objects on them. Even microscopic damage can cause leakage when pressure is applied. Cut the pipe only after it is completely on the floor and back to the manifold. Don't skimp on stretching the material. Savings will lead to leaks in the future.

Expert opinion

Grebnev Vadim Savelievich

Heating system installer

If you choose snake installation, place the beginning of the pipe at the coldest wall or at a window. This will help avoid uneven heating. When laying in a spiral, this condition does not need to be observed. In any case, heating will be uniform.

Connection

The most common way to connect a water heated floor is a distribution unit. Its goal is to increase pressure, implement temperature regulation and uniformly supply coolant to several circuits. There are different devices - with manual or automatic adjustment.

Connecting the system involves connecting both ends of the pipe to the manifold distribution with clamp fittings. Using a collector, the heated floor is connected to the main heating system or to a specially equipped boiler.

When choosing a heating boiler, it is important to take into account its power; it should equal the power of all areas of the floor with a small margin. The boilers have an inlet and outlet for water, which are equipped with shut-off valves.

Also, to circulate the coolant, it is necessary to install a pump. Most often it is included with the boiler. But if you plan to heat a large area, you will need to install an additional pump.

After connecting the pipes, you can fill the system with coolant. The manifold responsible for supplying the coolant is equipped with a ball valve; water is connected to it. And a pressure testing pump is connected to one of the outputs connected to the heated floor circuit.

The system filling process is as follows:

- Close all channels except one. Open all air vents at the same time.

- Supply water. Using the drain hose, monitor the degree of cleanliness and air exit from the system.

- When all the air is out and the water comes out completely clean, close the drain valve.

- After this, shut off the filled system. If there are several circuits, perform the actions for each one.

- After flushing and filling all circuits, close the tap.

Expert opinion

Grebnev Vadim Savelievich

Heating system installer

Upon completion of the procedure, there should be no air in the pipes, and the water should flow perfectly clean.

Hydraulic tests

Concrete can be poured only after a test run of the system. Fill the pipes with coolant at high pressure and maximum temperature. Make sure all pipes are filled and heated evenly.

The next stage is crimping. To carry this out you will need a special pump.

Procedure:

- Bring the pressure to 5 bar and wait until it drops to 3 bar.

- Then bring it up to 5 bar again. Repeat the cycle 4 – 5 times. At the same time, inspect the circuits for leaks.

- At a pressure of 2 bar, leave the system running for 12 hours. If the pressure does not drop, proceed with the finishing tests:

- Set the maximum temperature and turn on the circulation pumps to achieve maximum pressure. If the system has radiators, set the mixing unit regulators to the operating marks.

- Wait for the entire system to warm up completely, including batteries (if any).

- Make sure that all circuits and radiators are heated evenly.

- Leave the heating running for a day. If the condition does not change, you can turn off the boiler and begin concreting the pipes.

When pressure rises in the pipes, they try to straighten out. If their fixation is not secure, then unpleasant surprises will arise during testing. After filling the pipes with concrete, there is no need to worry about this.

Bay screed

Pipes that have cooled to 25 degrees can be concreted. Use a special mixture to prepare the solution. It has the best thermal conductivity coefficient and will ensure uniform heating. The thickness of the concrete layer for living rooms is 20 mm, in utility rooms - 40 mm.

There are special requirements for screed mortar. The surface will be subject to mechanical and temperature stress, which can lead to deformation. Therefore, plasticizers and fiber are added to the cement-sand mixture.

Plasticizers will give the solution elasticity and increase mobility. This is important for free penetration of concrete between the pipes. Fiber will increase the strength of the base and, in addition, will prevent the formation of cracks in the screed. Polypropylene and basalt fibers are intended for warm water floors. The standard fiber rate per square meter is 500 grams.

The solution is mixed mechanically. Before pouring pipes, the surface is cleaned of dust. The concrete screed must be poured in one step, without interruptions in work. 4 hours after concreting, cover the floor with film to ensure that the solution strengthens evenly and prevents premature evaporation of moisture.

Expert opinion

Grebnev Vadim Savelievich

Heating system installer

Do not turn on the heating and do not lay the finishing coating until the concrete has completely hardened. This will take at least 28 days.

Finish coating

It is recommended to use porcelain stoneware or tiles as a finishing material for a water heated floor. Laminate, linoleum or carpet are acceptable only if there is a corresponding marking on the packaging.

Pipe laying methods

Along the perimeter of the house, highways in such a system, both on the first and second floors, are usually carried out under the floor. Such a “hidden” system does not spoil the appearance of the premises. However, it should be taken into account that with such an installation, most likely, you will have to use the bottom method of connecting radiators. And with this insertion method, unfortunately, the batteries do not work at full capacity. The solution may be to use a bypass of a special design.

In this case, a metal-plastic piece of length equal to the height of the battery is cut into the “supply” pipe in front of the radiator. Connection to the main line is made through it, at the top of the section. A short vertical section is welded to the “return” pipe. The radiator is connected to it at the lower point of the opposite section.

Installation errors and their consequences

Strict adherence to the recommendations of specialists when installing heated floors yourself is an important condition for the successful functioning of the system.

Most often, beginners make the following mistakes:

The height difference between the beginning and end of the pipe. If it exceeds half the diameter of the pipes, air pockets will form inside. As a result, the circulation of the coolant will be difficult and the quality of heating will decrease. To prevent this from happening, it is important to place the pipes strictly parallel to the floor.- Connection of pipes within one circuit. There is no point in installing a circuit of 2 pipe sections and filling it with concrete. This may cause leakage. Each circuit must consist of a whole piece of pipe. Connections should only be made to the collector group.

- Neglect of hydraulic testing. A test run of the system at maximum pressure must be carried out before pouring concrete into the pipes. Otherwise, it will be almost impossible to find a leak, if one occurs.

- Pouring screed onto empty pipes. The concrete pushes through the pipe material and the circulation of the coolant will subsequently be difficult.

- Premature heating start. Heating the pipes until the concrete gains strength will lead to cracking of the screed.

Outdoor temperature sensors

These devices are recommended for systems as automated adjustment of the coolant according to weather conditions. For example, if it is cold outside, a signal is sent to increase the temperature of the coolant. When warming is observed, the sensor tells the system that the temperature can be lowered.

The device is designed to rotate 90 degrees. A special controller divides them into 20 sections and monitors the conditions on the street. If the water temperature does not correspond to them, the valve turns the required number of divisions. Of course, you can do all this yourself, but it’s much more convenient with a weather temperature sensor.

Questions about the installation and operation of heated floors

Is it possible to install a pumping and mixing unit for a heated floor separately from the manifold block?

If we are talking about VT.COMBI (COMBIMIX), then this arrangement of the mixing unit is acceptable.

A neighbor advised adding fine gravel to the cement mortar under the heated floor screed to save material. Is this acceptable?

No. The solution is mixed only from sand, cement and plasticizer.

The craftsmen from the team I hired claim that the pipes must be 100% in a protective corrugation. Won't this reduce heat transfer?

Your doubts are fair. The corrugated casing should only be in the places where the pipes are connected to the manifold and at the intersections of the damper joint in the screed.

The temperature at the heated floor supply does not rise above 38 degrees, although on the boiler it is 60, before entering the COMBIMIX it is about 58, and on the thermal head it is set to 40 - 50. Why does the temperature of the pipes not rise?

In the VT.COMBI (COMBIMIX) pumping and mixing unit, two flows are mixed - supply from the boiler and return from the heated floor. Use a balancing valve to set the correct ratio. Most likely, too much cooled coolant is supplied.

If all installation recommendations are followed and the correct choice of materials, the water heated floor will function perfectly for a long time and will make the room cozy and comfortable.

Installing a heated floor without using a mixing unit

The need to install a pump is completely eliminated if you purchase and install a boiler with a built-in pump. The main advantage of such a boiler is its well-chosen equipment. This means that you should not choose a boiler based on any characteristics; it is enough to determine the required power.

The installation methods described do exist, but it is better to purchase all the elements once, connect the heated water floor system correctly and not worry that the money spent on installing such a floor will be wasted.

Average score of ratings is more than 0

Share link

Comments There are no comments yet, but you could be the first...