I welcome my dear reader and bring to your attention an article on how to correctly calculate the chimney in your home.

The main component of comfort in the home is warmth. The owner of the house has to solve heating problems in a private house. For heating, small units are used that can be installed independently (except for gas ones), including chimneys.

To ensure complete removal of flue gases from the room, good draft and prevent draft overturning, it is necessary to comply with the requirements of regulatory documentation.

Why do you need to know the diameter?

Beginners do not understand the importance of the chimney cross-section for a stove and why it is so important to correctly calculate not only the internal size, but also the height of the pipe. When developing an individual project for an autonomous heating system for a residential or industrial premises, the level of traction and performance of the unit depends on the accuracy of the data.

Inexperienced builders can make a pipe with a large or insufficient cross-section. In any such option, the operation of the heating device is disrupted, and you are simply throwing money away. For optimal operation of the home heating system, it is important to carry out an accurate calculation and familiarize yourself with the recommendations of regulatory documents.

Important! Fire safety at home, work productivity, comfortable temperature - the solution to all these issues depends on the correct determination of the size and length of the chimney.

A couple of tips

When the house has alternative heating, it also requires a chimney. But it is unprofitable to produce different smoke exhaust systems. It is easier to combine them into one, which will connect all the channels made taking into account such parameters as equipment power, amount of smoke and type of fuel. Such structures have a number of advantageous qualities:

- they save living space;

- all systems work stably;

- time, money and labor are saved.

But only specialists can calculate such structures.

What should be the diameter of the chimney for a stove?

The size of the chimney can be calculated in several ways. The simplest one is to determine the cross-section of the chimney depending on the size of the combustion compartment. Solid fuel consumption is determined by this characteristic, and based on these data, the volume of exhaust gases can be determined.

If you have an open firebox and the chimney is made of a round steel pipe, these values should be in a ratio of 10 to 1. For example, the dimensions of the combustion chamber are 50/40. Such a stove must be equipped with a chimney with a cross-section of 180 mm.

If we make a pipe from brick, its internal size should exceed the size of the ash pan or ash door by one and a half times. The minimum size of a square cavity for gas removal is 140/140 mm.

How to calculate the cross-sectional area of a chimney?

There are several methods for calculating the optimal cross-section. For example, on the size of the combustion chamber of the hearth or on the area of the furnace blower window. But in this publication, attention will be focused on the methodology, which is based on assessing the volume of flue gases generated during the combustion process.

The combustion of wood and other solid fuels is always accompanied by very significant smoke formation. And the chimney pipe must be able to discharge these volumes outside in a timely manner.

Based on calculations and experiments, experts have long compiled tables from which information can be obtained on specific smoke production for different types of solid fuel. That is, what volume of combustion products is formed when burning, say, one kilogram of firewood, coal, peat, etc.

We will also present such a table (in an abbreviated version). In addition to the specific smoke formation, it shows the calorie content of the fuel (the amount of heat released when burning one kilogram) and the approximate temperature of the combustion products at the exit from the chimney. The first of these characteristics does not particularly interest us at a given moment - it simply gives a general idea of fuel efficiency. But the temperature, yes, will be needed for calculations.

Fuel typeSpecific caloric content of fuel, kcal/kg, averageSpecific volume of combustion products released from combustion of 1 kg, m³Recommended temperature at the chimney outlet, °C

| Firewood with an average humidity level - 25% | 3300 | 10 | 150 |

| Lump peat (in bulk), air-dried, with an average moisture level of no higher than 30% | 3000 | 10 | 130 |

| Peat - briquettes | 4000 | 11 | 130 |

| Brown coal | 4700 | 12 | 120 |

| Coal | 5200 | 17 | 110 |

| Anthracite | 7000 | 17 | 110 |

| Pellets or wood briquettes | 4800 | 9 | 150 |

As you can see, the volumes are impressive. Even types of fuel that produce minimal smoke are already about 10 cubic meters for every kilogram burned. This means, simply for reasons of physics and geometry, the cross-section of the chimney duct must be able to constantly drain these considerable volumes out.

This is why we “dance” when calculating.

Calculation methods

Exact method + formula

Calculating a chimney for a stove is not a task for beginners. It is better to entrust such work to professionals. But if you decide to calculate this parameter yourself, you will need knowledge of basic data and several formulas:

- To determine the volume of exhaust gases, it is important to know the power of the heating unit. For calculations we use the formula:, where:

- B is the combustion rate coefficient of solid fuel. This value is determined based on the data in table No. 10 of GOST 2127;

- V – level of volume of fuel burned. This value is indicated on the tag of the industrial device;

- T – heating level of exhaust gases at the exit point from the chimney. For wood stoves – 1500.

- The total area of the chimney. It is calculated based on the ratio of gas volumes, this value is designated “Vr”, and the speed of their movement in the pipeline. For a household wood-burning stove, this number is 2 m/sec.

- The diameter of a round pipe is calculated using the formula – d² = (4 * Vr) / (π * W), where W is the speed of gas movement. It is better to perform all calculations on a calculator and carefully enter all values.

Calculating the optimal amount of thrust

This operation is performed to control the calculations of the optimal height and cross-section of the chimney. This calculation can be carried out using 2 formulas. We will present the basic, but complex formula in this chapter, and we will present the basic, simple formula when performing a trial data calculation:

, Where:

- C is a constant coefficient equal to 0.034 for wood-burning stoves;

- The letter “a” is the value of atmospheric pressure. The value of natural pressure in the chimney is 4 Pa;

- The height of the chimney is indicated by the letter “h”.

- Т0 – average level of atmospheric temperatures;

- Ti is the amount of heating of the exhaust gases as they exit the pipe.

Example of calculating the cross-section of a chimney

We take as a basis:

- the potbelly stove runs on solid fuel;

- within 60 minutes, up to 10 kg of hardwood firewood burns in the stove;

- fuel moisture level – up to 25%.

Let's look at the basic formula again:

The calculation is carried out in several stages:

- We perform the action in brackets – 1+150/273. After calculations we get the number 1.55.

- We determine the cubic capacity of the exhaust gases - Vr = (10*10*1.55)/3600. After calculations, we obtain a volume equal to 0.043 m3/sec.

- The area of the chimney pipe is (4*0.043)/3.14*2. The calculation gives a value of 0.027 m2.

- We take the square root of the chimney area and calculate its diameter. It is equal to 165 mm.

Now we determine the amount of thrust using a simple formula:

- Using the formula for calculating power, we calculate this value - 10 * 3300 * 1.16. this value is equal to 32.28 kW.

- We calculate the level of heat loss for each meter of pipe. 0.34*0.196=1.730.

- The level of gas heating at the exit from the pipe. 150-(1.73*3)=144.80.

- Atmospheric gas pressure in the chimney. 3*(1.2932-0.8452)=1.34 m/sec.

Important! Using the data from your furnace, you can perform the calculation yourself, but to be on the safe side, it is better to consult with specialists. The safety of your home and the economical operation of heating devices depend on the correctness of the calculation.

Swedish calculation method

The size of a chimney for a stove can be done using this method, but the main purpose of the Swedish method is to calculate the chimneys of fireplaces with an open firebox.

In this calculation method, the size of the combustion compartment and the volume of air in it are not used. To determine the correctness of the calculation, use the following graph:

What is important here is the correspondence between the area of the combustion chamber (“F”) and the opening of the chimney (“f”). For example:

- firebox dimensions 770/350 mm. We calculate the area of the compartment - 7.7 * 3.5 = 26.95 cm2;

- chimney size 260/130 mm, pipe area – 2.6*1.3=3.38 m2;

- We calculate the ratio. (338/2695)*100=12.5%.

- We look at the value 12.5 at the bottom of the table and see that the calculation of length and diameter was made correctly. For our stove it is necessary to build a chimney 5 m high.

Let's look at another example of calculation:

- firebox 800/500 mm, its area is 40 cm2;

- chimney cross-section 200/200 mm, area 4 cm2;

- We calculate the ratio (400/4000)*100=10%.

- Using the table, we determine the length of the chimney. In our case, for a round sandwich pipe it should be 7 m.

Chimney design depending on heating configuration

Go ahead. What chimneys are installed most often today? These are brick, ceramic and insulated and non-insulated steel.

And first of all, when designing a chimney, its minimum throughput indicators are calculated. If mistakes are made here, flue gases will begin to accumulate inside the pipe and cause a lot of problems.

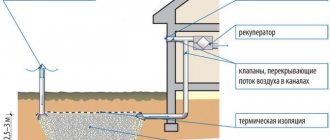

The general layout of the chimney looks like this:

If the temperature of the exhaust gases is low, as in modern low-temperature boilers, then so-called electric smoke exhausters are installed in the upper part of the chimney.

They are a small fan with blades. Such a device forcibly removes combustion products from the pipe, thereby increasing the traction force. And then the traction force no longer directly affects the height of the chimney, because it is achieved in a different way, and not by “catching the wind.”

If there is no additional device, then you will still have to catch the wind. And in this case, you need to build on the available power of the boiler, stove or fireplace, which can be found in the technical documentation. It is expressed in the amount of fuel that is burned in one hour of work.

If the amount of fuel volume is known, then the volume of gases is calculated using the following formula:

Vg = B∙V∙(1+t/273)/3600

The result will be in m3/s. This is the speed of gas movement in the pipe. We calculate the cross-section of the pipe using the following formula:

F = π∙d²/4

And the resulting value is determined in m2. This is the cross-sectional area of the chimney, and the diameter is calculated using the formula:

dt = √4∙B∙V∙(1+t/273)/π∙ω∙3600

The remaining characteristics are almost the same for most heating devices. Thus, the exit speed of gases in the chimney is usually no less than 2 meters per second, and the temperature of the gases at the entrance to the pipes is from 150 to 200 degrees.

Also, the standard gas pressure per 1 meter is no less than 0.4 mm H2O, or 4 Pa:

Therefore, according to SNiP, the height of the chimney from the grate must be at least 5 meters.

What to do if the chimney cross-section is square?

Cylindrical chimneys, especially after the advent of sandwich pipes, are the most common types of devices. But when building a brick kiln, you have to lay out a square or rectangular shape.

In such chimneys, turbulence is formed, which prevents the normal passage of exhaust gases and reduces draft. But for wood stoves or fireplaces, rectangular pipes remain the most popular shape. Such devices do not require an increased level of exhaust gas extraction.

The calculation of a chimney for a wood-burning stove with a square or rectangular cross-section is made taking into account the ratio of the dimensions of the pipe to the size of the blower hole on the stove. This proportion is 1/1.5, where 1 is the internal cross-section of the pipeline, and 1.5 is the dimensions of the blower or ash pan.

Requirements for the installation of a chimney for a gas boiler

- there must be good traction;

- reliability and durability;

- corrosion resistance;

- resistance of the chimney for a gas boiler to aggressive chemical environments;

- ability to withstand high temperatures.

The height of the pipe depends on the cross-section and power of the equipment

In modern construction, only round or oval fireplaces are used as outlets for combustion products in heating systems. Soot practically does not settle on their walls. It is also important that the surface of the internal diameter of the chimney for a gas boiler is smooth. Square-section structures are more problematic to operate. The soot gets stuck in the corners, so you have to get it out somehow, it’s a hassle. Ideally, with constant use of the heating system, inspection of the chimney for the heating boiler should be carried out twice a year. Performed by an experienced person, a master. If the cross-section is round, you can get by by calling a specialist only once a year.

Be sure to carry out preventive maintenance every year if we are talking about a house in which you live permanently. Before the start of the heating season, call a specialist. Otherwise, the soot, accumulating, will reduce the diameter of the chimney for the gas boiler.

What should be the height of the chimney pipe for a stove?

Calculation of this parameter allows you to avoid the occurrence of backdraft and other possible troubles. This issue is regulated by the rules of SNiP and other documents.

Why is this parameter needed?

In order to understand the importance of this factor, let's take a closer look at several physical laws and the consequences of incorrectly made chimneys. As heated gases pass through, the temperature drops, but warm air or gases always rise.

At the outlet of the pipe, the temperature drops even more. Exhaust gases located in a pipeline with a reliable layer of thermal insulation have a high temperature and a column of heated smoke, rising upward, increases the draft in the firebox.

Let's analyze the situation - we reduce the internal cross-section of the pipe and increase the height of the pipe above the roof ridge. If you think that the volume of heated gas increases, the cooling time of the smoke increases and the draft increases, this statement is only half true. The traction will be excellent, even with a large surplus. Firewood will burn quickly and the cost of purchasing fuel will increase.

An excessive increase in the height of the chimney can cause an increase in aerodynamic turbulence and a decrease in the draft level. This is fraught with the occurrence of reverse draft and smoke escaping into living spaces.

SNiP requirements

The length of exhaust gas exhaust pipelines is regulated by the requirements of SNiP 2.04.05. the rules require compliance with several basic installation rules:

- The minimum distance from the grate in the firebox to the protective canopy on the roof is 5000 mm. Height above the level of the flat roof covering 500 mm;

- the height of the pipe above the roof slope or ridge must correspond to the recommended one. We will talk about this in a separate chapter;

- if there are buildings on a flat roof, the pipe should be higher. In this case, with a large pipe height, it is secured with braces made of wire or cable;

- if the building is equipped with a ventilation system, their height should not exceed the exhaust gas outlet hood.

Self-calculation method

How to independently calculate the height of the smoke channel, for this you will need to perform a calculation using the formula:

, Where:

- “A” – climatic and weather conditions in a given region. For the north, this coefficient is 160. You can find the value in other areas on the Internet;

- “Mi” is the mass of gases passing through the chimney in a certain time. This value can be found in the documentation of your heating device;

- “F” is the time for ash and other waste to settle on the walls of the chimney. For wood stoves the coefficient is 25, for electric units - 1;

- “Spdki”, “Sfi” – level of concentration of substances in the exhaust gas;

- “V” – exhaust gas volume level;

- “T” is the temperature difference between the air coming from the atmosphere and the exhaust gases.

Important! Independent calculation will require finding a large number of quantities and performing complex calculations. Therefore, we recommend turning to professionals.

There is no point in giving a trial calculation - the coefficients and other values will not be suitable for your unit, and extracting square roots will require downloading an engineering calculator.

Table “Height of the chimney above the ridge”

The table of the height of the chimney above the roof structure will help you determine the size of the pipes without making complex calculations. First, we will analyze the selection of pipe length for flat roofs.

| Selection of pipe length for flat roofs. | Min. pipe height in mm |

| There are no parapets or other structures or devices on the roof. | 1200. |

| A protective curb or other structures are built on the roof and the distance to them is up to 300 mm. | 1300. |

| Excess over other ventilation ducts | 500. The minimum distance to the ventilation shaft is 5000. |

| For pitched types of roof structures. | Min. pipe height in mm |

| The chimney exits to the roof at a distance of 1500 mm from the ridge. | 500. |

| The pipe is located at a distance of 1500-3000 mm from the ridge. | The pipe is brought out to the level of the roof ridge. |

| The distance from the ridge to the passage of the exhaust pipeline is over 3000 mm. | We set aside 100 from the ridge cavity. The top of the pipe should be at the level of this line. |

Checking the planned pipe for the amount of natural draft

In fact, we have already determined the main parameters of the chimney - the sufficient cross-section of its channel and height. But for devices with natural draft, it is never a bad idea to check the strength of this very draft. So that it does not happen that the constructed chimney suddenly refuses to perform its main functions.

Draft is essentially the difference in pressure between hot gases in the pipe and the outside air. It is this difference that stimulates the movement of gas flow through the chimney channel.

It is believed that for normal operation of a chimney with natural draft, this difference must be at least 4 pascals for each meter of pipe height (0.408 mm of water column or 0.03 mm of mercury). That is, for a five-meter pipe (our minimum), the thrust should be at least 20 Pa. This ensures both normal gas removal and the necessary air flow for continuous combustion of the fuel.

How to calculate this thrust. Naturally, it largely depends on the densities of gases, which, in turn, are closely related to temperature. You can verify this by looking at the formula with which we will work:

ΔP = Htr × g × Patm × (1 / TV – 1 / Tds) / 287.1

ΔP is the natural draft in the pipe, Pa.

Htr—chimney height, m.

g—gravitational acceleration (9.8 m/s²);

Patm - atmospheric pressure. A value of 750 mmHg is considered normal. However, the area for which the calculation is carried out may have its own specifics. We must understand correctly that sea level is considered the norm. And with increasing altitude, this rate begins to decrease. And quite significantly. So when making calculations you will need to be guided by the norm for your region of residence.

Atmospheric pressure is usually measured in millimeters of mercury. However, to calculate in the SI system it is necessary to convert it to pascals. This is not difficult if you know that 1 mm Hg. Art. = 133.3 Pa.

TV - outside air temperature. Moreover, reduced to the Kelvin scale, that is, C° + 273.

Tds is the average temperature of gases in the chimney. Defined as the arithmetic average of the input and output indicators, followed by conversion to the Kelvin scale.

287.1 is the gas constant of air. It would be more correct to select this value for the specific chemical composition of the exhaust gases. But in our case, the error will not be significant, greatly affecting the final result.

A few important notes on inlet and outlet temperatures

You should always strive for its optimal values. Statistics show that most fires occur with sauna stoves, into which there is practically no heat removal; the heat in the steam room builds up in a short time, and the chimney usually heats up to dangerous temperatures. Therefore, you need to be able to control the temperatures in the pipe using available means - gate valves, valves, additional heat recovery devices (for example, water heating tanks).

In household and heating stoves this is easier, but control is still necessary. In boilers, where the very essence of the work is the constant transfer of heat to the circulating coolant, these issues are not so pressing.

The 900 ÷ 600 ℃ (input and output) mode, found on some sauna stoves, is extremely dangerous in all respects, and should not even be considered! Reasonable limits (and even then their upper limit) are 600 ÷ 400 degrees for household brick and metal stoves. Usually they try to maintain it in the range of 400 ÷ 200 ℃. For gas equipment, the lower limit can fall below 100 degrees.

If all the initial values for substitution into the formula are known, you can proceed to the calculation. To do this, we again suggest using the capabilities of a special online calculator.

Organization of a node through the walls of a house or bathhouse

Today, installing a sandwich chimney is practiced mainly in two ways: inside the house or outside. After all, you can increasingly see that chimneys are installed directly through the wall to the street and from the first floor - and from there they are already directed vertically upward. And this makes sense: this way the chimney cools much faster and does not pass through fireproof ceilings and roofs. On the other hand, a chimney that rises through the attic usually serves as an additional heating element. But the risk of fire here, of course, will be higher.

Surprisingly, the outer shell of the stainless steel sandwich is not far from the temperature of a single-circuit fireplace. Indeed, such a chimney was originally designed to improve draft, and therefore the gases leaving the stove usually have a temperature of 800 degrees Celsius, and the outer casing can heat up to 300 degrees! And this is far from a fireproof surface.

A modern sandwich chimney is exhausted both through the roof and directly through the walls of a residential building:

The node can be seen in more detail in this illustration:

So, the following step-by-step instructions will help you position your sandwich fireplace at the right angle so that it fits through the walls:

- Step 1. Before starting work, be sure to calculate the length of the horizontal multilayer pipe that will need to be passed through the wall. And also think about the shirt you install. Calculate the slope of the roof so that the chimney does not come too close to the eaves.

- Step 2. Fill the box that you insert into the wall with non-flammable basalt material.

- Step 3: Cover the inlet assembly with the lid so that the basalt cardboard spacer remains visible.

- Step 4. Cover the edges of such a knotted cover with a film made from the components of the exterior of the house, for example, siding.

- Step 5: Seal the edges of the box with clear roofing sealant.

- Step 6. Install a major repair to the chimney outlet from the wall.

- Step 7. Secure the chimney with special wall brackets, one for every 1.5-2 meters.

- Step 8: Then, after installing the pipe, check that it is vertical using a spirit level.

- Step 9: Make sure the seam is facing the house.

After all, the most important rule is the following: the passage of the fireplace through the wall of the house or bathroom should be protected as much as possible from fire. Here is a good example of such a node:

In order for the horizontal element of the sandwich chimney to be securely installed, it must be correctly supported with a metal corner:

Special drawings will also help you secure such a fireplace to the wall in a strictly vertical position:

Believe me, at this stage the work is not finished yet, especially if your fireplace has a complex design (which we strongly do not recommend):

Connecting a collective smoke duct

With a collective chimney, heating devices must be of the same type

The need to have one smoker for several households arises if there is a need to save money, space, or if it is not possible to organize the exhaust gas removal system differently. From a technical point of view, this is a completely acceptable option and such structures are effectively operated. In this case, it is necessary to consider two options:

- Connecting heating devices of the same type to the device.

- Connecting fundamentally different heating units to the line, for example, a gas boiler and a brick fireplace.

In the first case, there is no difficulty in including equipment in a common channel, since for such devices it is possible to calculate a smoke channel for one draft value at which all units will operate correctly.

In the second option, it will not be possible to coordinate the devices, since the chimney for the fireplace should occupy 1/10 of the firebox area, and this is too much for the boiler. The result is either excessive or insufficient thrust for one of the devices, which is fraught with negative consequences.

The most correct solution would be to use a two-channel system. Its essence is that the internal space of the pipe is divided into two channels, each of which is designed for its own heating equipment.

Alternative to stainless steel: asbestos cement

Asbestos pipes are an alternative to steel structures. But they cannot be used for all types of gas ducts. Products made from the materials in question can be used in operating conditions up to three hundred degrees.

The key advantage of asbestos-cement pipelines is their low price. The cost of these products is significantly cheaper than stainless steel pipes. However, in terms of its performance qualities it is inferior to the products discussed in this article. If you want to create a truly reliable pipeline, use stainless steel pipes.

Watch the video:

Structural elements

Structurally, stove chimneys consist of several sections, each of which has its own purpose and technical features. The chimney design is represented by the following elements:

- Gate valve.

- Pipe insulation.

- Beam with overlap.

- With fluff.

- Pipe riser.

- Rafters.

- Roofing.

- Otter.

- Lathing.

- Cement mortar.

- Pipe neck.

- Headline.

- Iron cap.

The main purpose of the chimney is to quickly and safely remove combustion products of fuel material from the combustion chamber to the outside. To do this, a connection is provided between the chimney pipe and the internal channels with which the furnace equipment is equipped.

The fluff is the wide part of the chimney pipe, which is located in the area where it is discharged through the ceiling of the attic. It is designed to protect floor beams from the negative effects of high temperatures. The wall thickness ranges from 32 to 40 cm, which ensures high-quality insulation up to 25 cm thick.

Otter is a technically complex section of the chimney system, which serves to protect the roofing material and pipes from the negative effects of precipitation and the formation of condensation. In addition, it provides the necessary space for laying waterproofing material.

The neck of the chimney pipe is a structural element that is equipped with a smoke damper to adjust the draft.

The riser is a straight section of pipe, made of even masonry, which is located in the attic between the fluff and the otter.

The cap is part of the chimney, which forms a special canopy made of brickwork, providing the necessary protection of the pipe from external negative factors.

An iron cap is a structural element in the form of an umbrella or cap, located above the head of the pipe. It is designed to protect the internal smoke exhaust duct from clogging.

Building regulations

The installation of chimneys is determined by the provisions of SNiP 41-01-2003.

The chimney design must meet the following regulatory requirements:

- the minimum height must be at least 5 meters from the combustion point or grate;

- the pipe must rise above the flat roof to a height of at least 1 meter;

- when located on the roof slope at a distance of less than 1.5 m to the ridge, the pipe should be 0.5 m higher than the ridge;

- when located on the roof slope at a distance of 1.5-3 m to the ridge, the pipe may not be lower than the ridge;

- when located on the roof slope at a distance of more than 3 m to the ridge, the angle between the horizontal and the line passing through the ridge and the top of the pipe should be no more than 10°;

the maximum length of each horizontal and inclined section should not be more than 1 m, the total length of their projections onto the horizontal should not exceed 2 m. If there are oblique and horizontal sections, it is necessary to extend the pipe by the length of the horizontal projections. For ceramics, horizontal sections are not allowed.

Fire safety requirements for chimneys

The distance from the surface of ceramic, insulated steel and asbestos-cement chimneys to combustible house structures must be at least 0.25 m; for brick chimneys and sandwich pipe structures - at least 130 mm.

If the roof is covered with flammable materials (roofing felt, bitumen tiles, ondulin), or leaves or fluff can accumulate on it, a spark arrestor made of mesh should be installed on the head of the pipe.

Traction force

Factors influencing traction force:

- height of the structure;

- condition of the internal channel - smoothness of the walls, regularity of soot removal;

the presence of inclined or horizontal sections. For pipes of long-burning units, the presence of horizontal and inclined sections is not allowed, since the exhaust gases have a low temperature and lengthening the chimney is undesirable - the gases will cool, the draft will decrease until they tip over;

- installing a deflector;

- quality and thickness of insulation;

- air supply to the firebox.

Your safety depends on the presence and strength of traction, so you need to check the presence of traction and take measures to clear the channel of soot and icing of the pipe head.

Tools

You just need cutting tools - an angle grinder, a jigsaw, a knife. All work is done manually and does not require special equipment.

Installation diagram

There are several types of fireplaces; the most suitable type of design is selected individually.

Installation methods

It is important to take into account the collection of condensate in the system, therefore it is necessary to have a plug, a condensate drain and a container for collecting condensate.

If a pot-bellied stove is installed through a wall made of a pipe located on the street, it would be advisable to lead the chimney through a window so that you do not have to prepare a hole for the pipe in the ceiling.

The outer part of the chimney is insulated with thermal insulation coated with a protective material. A mushroom is installed at the end of the pipe, which will protect the chimney from debris, rain, various small animals and foreign objects.

Floor preparation

The chimney for a stove is often installed in such a way that it passes through the ceiling, therefore, before installing and fixing the pipe structure, it is necessary to drill a hole in the ceiling: with a jigsaw or other suitable cutting tool, the diameter is up to the passage of the glass for the elbows of the internal chimney.

Example of a hole for a chimney

Through the glass

Before installing the chimney for the stove, through glass is installed in the hole. The diameter of the glass should be chosen based on the diameter of the inner pipe, although sometimes the joint is made before the chimney passes through the ceiling. It should be understood that it is important to securely fasten the glass - it serves as a latch. But in addition to this, the pipeline must be fixed to the wall surface.

If installed incorrectly, the following consequences may occur:

If there are flammable materials, insulation or wood in the ceiling, they must be removed so they do not come into contact with passing glass.

Once the pipe is inserted, the whole thing must be sealed with a fire-resistant material, such as heat-resistant sealant or special fire-resistant wool.

The photo shows the following stages of work:

Seal

Bring the pipe to the roof We work on the roof

At the last stage, you need to put a deflector on the pipe

Tips for working

- The pipes used in the design are located exclusively in a vertical position; To secure them, it is advisable to use special brackets with dimensions corresponding to the system elbows. To save money, you can make the brackets yourself using a metal corner.

- All connections should be treated with sealant so that there are no holes through which smoke could escape into the room air. There is a wide selection of suitable sealants on the market for sealing pipe joints from the chimney:

- Sealants for high temperatures;

- Heat-resistant sealants;

- Heat-resistant sealants;

- Heat-resistant sealants;

High temperature and heat resistant sealants are used to seal areas that reach temperatures of up to 350 degrees Celsius. Because the furnace flue reaches higher temperatures, these types of sealants are only suitable for parts outside the piping system.

Heat-resistant and heat-resistant polymers can withstand enormous temperatures, up to 1500 degrees Celsius - they are better suited for a fireplace than a stove.

Types of bricks

The operation of a chimney made of refractory bricks is carried out in special conditions with temperature changes, so for its construction it is necessary to use building material of the best quality. The safety and reliability of the structure, the resistance of the structure to cracking and deformation, and reducing the risk of creating a fire hazard depend on the correct choice.

First class

Solid refractory bricks are made from high-quality clay by prolonged firing at high temperatures. The following signs are characteristic of it:

- Density of the consumable material, absence of porosity and foreign inclusions.

- Smooth and even surface without deformations, potholes, cracks and other visual defects.

- When tapped, a clear and pleasant sound appears.

- It has high frost resistance and strength.

- It has an attractive red color with a slight yellowish tint.

Second-rate

Brick is produced by insufficient firing of clay, so it is characterized by:

- Dull and short sound when tapped.

- Porosity and low density of the structure.

- The presence of various deformations and defects on the surface.

- A desaturated orange or ocher hue.

In addition, this material has low heat capacity, frost resistance and durability.

Third-rate

Third grade bricks are of low quality and have a burnt structure. They have the following features:

- Too high and ringing sound when tapping.

- Porous structure with low density.

- The presence of significant visual defects and flaws.

- Rich red and brown tint.

Burnt blocks are not able to withstand significant mechanical loads, and therefore are prone to cracking and deformation. In addition, they do not tolerate excessive heating and cooling.

For the construction of the chimney, first-grade building material grades M 150 and 200 are used.

Fire safety technology

It is allowed to install a chimney in accordance with the requirements:

SNiP 2.04.05–91U.

DBN B 2.5-20–200.

NAPB A.01.001–2004.

Installation should only be carried out by professionals. The cross-section of the chimney must correspond to the value specified by the manufacturer in the instructions supplied with the boiler.

The required chimney height is usually recommended by the manufacturer, or it must exceed 5 meters.

If there is a horizontal section, its length should not exceed one meter.

The design must provide for the possibility of draining condensate, as well as cleaning the smoke exhaust channel.

How to connect a chimney

All connections of parts to the nozzle of a solid fuel boiler are made with a heat-resistant sealant that can withstand temperatures in the range of 1250-1500 degrees.

When the diameter of the chimney does not match the size of the chimney outlet, an adapter is installed to create a tight joint.

How the parts are assembled

Any single-walled, as well as sandwich, with insulation, are assembled in only one option: “pipe is inserted into pipe.” The connection points of the chimney parts do not require the installation of additional clamps.

If the structure is made of special stainless steel, assembly is carried out only using condensate. In this case, condensate, as well as the resulting tar deposits, will never get out; they will flow along the walls of the pipe directly into the condensate drain.

If a revision is used in the chimney and tees are installed, all parts are assembled “according to the smoke.” The assembly of vertical parts extending from the tee is carried out “using condensate”.

If it is necessary to line the channel, the gap formed between the pipe and the channel must be more than 4 cm. It is necessary when the metal expands when heated.

To ensure that the chimney sandwich parts have a more rigid fastening, rivets are installed or screws are screwed in.

Fixing the chimney

The pipe is attached to the wall only with special materials.

The single-wall structure must be fastened with a fastening step of 1.5 meters on all vertical sections of the pipe.

If the sandwich chimney does not have a supporting structure, it is necessary to secure each element.

If the system uses a 45–87 degree tee or a 45–90 degree elbow, installation is carried out in such a way that the load on the rotating parts of these parts is completely eliminated.

If installation requires additional support, use a floor stand installed under the inspection.

When the chimney pipe is raised above the roof by more than 1.5 meters, a bracket must be installed under the brace.

Passage through floors

To make a passage through the wall of a house or its ceiling, it is necessary to use the building codes that are in force in Ukraine today.

If a sandwich chimney with insulation passes through wooden walls, a liner must be installed and another layer of thermal insulation is applied.

When a chimney pipe is installed through the roof, builders must install a special additional pipe part, the so-called “roof”. Another additional layer is created, consisting of fireproof insulating materials.

The final stage of construction

When a brick chimney is lined, its upper part is covered with an additional part - the end.

Usually the top of the pipe is covered with a baffle or a beautiful fungus.

If the building's roof covering is made of a fire-hazardous material, such as bitumen shingles, a special spark arrestor is mounted on the top of the chimney.

If a gas boiler is installed in the house, installing a deflector is strictly prohibited. According to current regulations, the upper part of the gas device pipe is always kept open.

Starting the chimney

Check again that there are no flammable or flammable objects near the chimney to prevent a fire.

The protective film is removed from the parts.

The gate that regulates the traction force opens.