In an underfloor heating system, one of the key roles is played by the underfloor heating collector. Let's figure out how to choose and connect a collector or heating comb correctly, and how to avoid typical mistakes when installing a distribution unit yourself. We asked the specialists of the Miralex store, which offers a wide range of components for water heated floors, to tell us which models of collectors are popular today and meet all safety requirements.

Collection group Source roomester.ru

Purpose

A warm floor is usually a system that includes several heating circuits - at least one for each room. With a large floor area or to control heating separately in different zones of the same room, two or more circuits are used.

Heating comb, distribution manifold - names of the device that ensures the flow of coolant into the circuits of the floor heating system. The distribution unit consists of two combs - one of them is responsible for distributing the coolant heated by the boiler over the connected heating circuits, the second collects the cooled coolant and supplies it to the return pipe for return to the boiler.

Mounted distribution unit Source ad-cd.net

In addition to the main function of distributing and collecting coolant, the collector unit can solve a number of other problems. Depending on the configuration, it can:

- be responsible for deaerating the system;

- ensure regulation of the coolant supply in the required volumes;

- regulate the flow of circulating fluid using manual or automatic flow meters.

This allows you to maintain optimal temperature conditions in each room, depending on the requirements for the microclimate, and eliminate airing of the heating system, which results in a decrease in the efficiency of its operation. Shut-off valves are also installed on the supply and return manifolds - through them the circuits are filled with coolant, the system is pressure tested, and the liquid is drained.

Manifold group with automatic air vents Source tvo.by

Scheme

The collector is the main unit of the circuit, which collects all the floor heating circuits into a single whole. Its main tasks:

- Preparing water for entering pipes. The floor must be warm, not scalding. Consequently, the system cannot be immediately supplied with water coming from the heating boiler, because its temperature is about +70°C. The hot liquid in the manifold mixes with the cold liquid, acquiring the temperature necessary for comfortable use (from +40°C to +45°C).

- Temperature control in the system as a whole and in each circuit separately.

Thus, the normal functioning of the entire system depends on the correct operation of the collector. To make such a device with your own hands, you first need to figure out how a factory-made manifold works. Let's take a closer look at the diagram of this device:

The following parts can be distinguished:

- Distribution comb. The liquid from it is distributed through the underfloor heating pipes. Most often it is equipped with flow meters - transparent flasks that allow you to monitor how the coolant is consumed in each circuit.

- The element to which the return pipe is connected. There are no flow meters, but rather thermostatic valves. They can be controlled via servos or RTL thermal heads, adjusting the temperature in each circuit.

- Air vents - one for each collector.

- Taps with plugs. Through these taps it is possible to empty or fill the circuits with water.

- Ball valves that cut off the entire assembly from the boiler.

- Thermometers that allow you to control the temperature of the coolant entering the system and discharged back to the boiler.

The kit usually also includes brackets for mounting the device on the wall.

For different models, depending on the cost, the contents may vary slightly. For example, there are devices with different numbers of circuits. Some models do not use rotamers. There are also options with one or two thermometers.

Additional devices

In order for the underfloor heating system to function correctly, the hydraulic resistance in its circuits must be the same, for which it is recommended to install loops of approximately the same length. However, in practice this is not always possible to do. If circuits of different lengths are directly connected to the collector, the main part of the coolant flow will go through the shortest one. This is explained by the fact that it has the lowest hydraulic resistance.

Flow meters installed on the supply comb on each of the pipes to which the underfloor heating loops are connected help to avoid the problem. Flow meters allow you to regulate flows by narrowing and expanding the lumen through which liquid enters a specific circuit. The use of flow meters makes it possible to install loops of different lengths without compromising the functioning of the underfloor heating.

Block with flow meters on the feed comb Source leroymerlin.ru

Design features

The comb has a hollow body with outlets for connecting circuits. Shut-off and control valves are installed at the ends and connecting pipes. The manifold for underfloor heating consists of a supply and return comb. The supply distributor is usually installed above the return distributor, but can also be mounted below - this depends on the characteristics of the installation location of the manifold and the type of mixing unit being connected.

One end of the heated floor loop is connected to each outlet of the distribution comb - the second end of the pipeline is connected to the outlet of the return comb. It collects the cooled coolant and directs the flow to the heating boiler.

Cabinet with connected collector block Source yandex.net

The base part of the manifold is a piece of pipe with two or more threaded elbows. At the same time, a variety of device models are available for sale, differing in final configuration, assembly complexity, functional parameters and cost.

With fittings

Budget models include combs with threaded pipes, equipped with fittings for connecting underfloor heating circuits. The underfloor heating pipeline can be made of cross-linked polyethylene or metal-plastic.

Comb with pipes Source okstock.ru

With built-in taps

The heating comb of a simplified design can be equipped with integrated two-way ball valves. Such a collector is not designed to adjust the operating parameters of individual circuits - using a tap you can only completely shut off the coolant flow in order to turn off a certain loop.

Budget models of combs (with fittings or built-in taps) can only be used for secondary underfloor heating systems, which include one or two short circuits. Also, without modifications, they can be installed in systems where several loops of the same length are involved - with the same hydraulic resistance and temperature requirements.

The design of such collectors does not provide for the installation of additional equipment on each outlet to adjust the operating parameters of individual underfloor heating circuits.

Comb with ball valves Source www.tklimat.com

With control valves

Improving functionality entails increasing cost. A higher price category includes a comb for heated floors, equipped with control valves on each outlet. This device makes it possible to manually regulate the intensity of the supply of heated coolant to each of the heating circuits.

When choosing a model, pay attention to the possibility of replacing a manual control valve with an automatic one. Many manufacturers provide for the installation of actuators designed to operate in conjunction with temperature sensors or as part of a home climate control system. Automatic control valves are driven by servo drives based on a signal from an electronic device - central or autonomous.

Comb with manual control valves Source mvi-rus.ru

With flow meters

Combs with flow meters on the outlets allow you to connect pipeline loops of various lengths and ensure uniform coolant circulation in all circuits. The markings applied to the flow meters simplifies system balancing and makes it possible to achieve fine temperature control.

Flow meter with graduations Source plastic-s.ru

See also: Catalog of companies that specialize in heating systems.

Twin assembly

The twin assembly includes supply and return distributors. Depending on the configuration, the underfloor heating manifold can be equipped with:

- automatic or manual air vent;

- security group;

- “American” - quick-release threaded connecting elements for connection to a mixing unit or primary heating circuits.

Twin assembly Source zoon.ru

Assembly with mixing unit and pump

The temperature of the coolant in the heated floor system does not exceed 35-40°C. Since almost all heating boilers, excluding condensing gas boilers, cannot operate in this mode and heat the coolant to higher temperatures, a mixing unit is installed. The temperature of the coolant is lowered to the required values by mixing cooled coolant in the required proportions with the heated coolant.

If the house only has underfloor heating, it is enough to install a mixing unit as part of the boiler piping. In the case where the heated floor operates in conjunction with radiator heating, a heated floor collector with a mixing unit is installed.

Pumping and mixing unit Source prom.st

The mixing group is made on the basis of a two-way or three-way control valve. The distribution unit includes a circulation pump specifically for the forced supply of coolant to the underfloor heating circuits - the common pump for the radiator system and heated floor, which is part of the boiler piping, is not able to cope alone.

On a note ! It is worth paying attention to the fact that the reliability of installation depends on the quality of shut-off and control valves. One of the most reliable manufacturers of components is the Cimberio brand.

The best option is to purchase a ready-made pair of combs with fasteners, with technical holes for installing additional control and adjustment equipment or an already completed manifold. This will reduce the risk of installation errors of the underfloor heating distribution unit and simplify its installation.

Collector block with mixing unit Source festima.ru

Seven most popular models

| Illustrations | Recommendations |

| Model No. 1: LUXOR. The Italian brand LUXOR produces reliable brass equipment.

| |

| Model No. 2: GIACOMINI. Another bright representative of Italian quality.

| |

| Model No. 3: ARS. These Turkish-Italian manifolds are of excellent quality at a reasonable price; such equipment can be called the golden mean.

| |

| Model No. 4: FADO. The company itself is Italian, but now they have begun cooperation with APC and the products can be declared as joint production.

| |

| Model No. 5: BIANCHI. The technical characteristics of the Italian collector BIANCHI are similar to its Italian counterpart from GIACOMINI. The only difference is the number of circuits and price. Here the combs come from 2 to 10 pins, and the price ranges from 9–22 thousand rubles. | |

| Model No. 6: Valtec. The Italian brand Valtec is one of the most popular on our market.

| |

| Model No. 7: Caleffi . The Italian manufacturer Caleffi operates in the luxury goods sector. The combs are made of brass, steel and polymer; the characteristics here are among the highest, but the price also reaches 43 thousand rubles. |

Manufacturing materials

The reliability and durability of the collector directly depends on the material from which it is made. A comb for heated floors can be metal or polymer. Each option has its own advantages and disadvantages.

Polypropylene

A manifold made of polypropylene pipe is an extremely economical option. In addition to the affordable price, one can note the light weight of the device. Models with fittings and combs with shut-off ball valves are available for sale. To connect metal products, combined fittings are used.

The disadvantages of polypropylene collectors include:

- thick walls, due to which the passage cross-section is smaller than that of metal combs of the same size;

- less strength and durability compared to metal models;

- oxygen permeability - even if polypropylene is reinforced with fiberglass reinforcement, there is diffusion of oxygen, which provokes corrosion of steel elements of the heating system and boiler.

Collector block made of polypropylene Source chudopol.ru

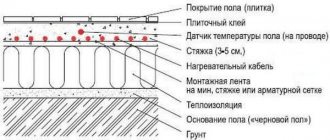

The principle of operation of the device in the assembly

There are several working schemes for assembling a distribution unit, but the operating principle of the device remains virtually unchanged. Let's consider one of the standard assembly options, in which the manifold for a heated floor is equipped with:

- Shut-off valves for the distribution manifold and return.

- Taps for draining the working medium from the supply and return lines.

- Three way valve.

- Circulation pump.

- Pressure gauge.

- Flow meters for each circuit.

- Manual control valves for each circuit.

Video description

The capabilities of the collector, its configuration and operation are shown in the video:

Adjusting the supply of working medium

Flow meters (rotameters) make it possible to ensure uniform heating of loops regardless of their length, even if circuits that differ markedly in length and hydraulic resistance are connected to the comb.

For short pipelines, the fluid supply is regulated by reducing the passage opening; for long branches, on the contrary, the flow intensity is increased. This parameter is determined on the scale of the balancing rotameter for each circuit, after which the throughput of the flow valve is adjusted.

Adjustable flow meters are installed on the feed manifold only if it is equipped with manual valves for adjustment. They are not necessary if:

- branches of the same length are connected to the collector, and regulation of distributed flows is not provided;

- the collector block is equipped with automatic control valves with servo drives - in this case, the automation is controlled by an electronic thermostat and manual equalization of the heating of the branches is not required.

Criterias of choice

When choosing a heating distribution manifold for an underfloor heating system, you need to know in advance how many circuits you plan to connect. It is recommended to select devices with a reserve of one or two outputs in order to be able to adjust the system design and split an extended circuit into two branches or connect additional equipment (pressure gauge, thermometer). No more than nine loops can be connected to one collector; if there are more loops, two or more distribution blocks are installed.

Maximum comb size Source sgon24.ru

Next, you should pay attention to the material used to make the comb. Reliable and durable cases are made of stainless steel, chrome-plated or nickel-plated brass, and bronze. It is recommended to give preference to products manufactured in accordance with Russian GOSTs, or products from well-known manufacturers that have a certificate of compliance with European standards. Each comb should be carefully inspected to identify possible flaws - cracks, corrosion, surface defects.

The list of reliable brands includes: Kermi, Valtec, Rehau, Valliant, Rossini, FIV. When purchasing branded products, it is advisable to buy ready-made manifold blocks so as not to overpay for individual parts and to avoid problems associated with the incompatibility of elements from different manufacturers.

Components

In total, the collector contains two pipes:

- one performs the functions of a mixer and supply of coolant to the circuits;

- the other serves to collect return flow from all circuits and return the water cooled in the circuits to the boiler, and, partially, through a two- or three-way valve, to the output mixer.

Hot water from the boiler is added to the mixer by turning on a thermostatic valve, which is placed in the path of water supply to the mixer. When the temperature in the mixer drops below the permissible level (we remember - this is 40°C), the valve supplies a portion of hot water.

Please note: a thermostat is installed at each outlet of the mixer comb to limit the volume of hot water for each heated floor circuit. This group of bimetallic valves changes the flow area, as well as the volume of water passed through

This allows you to set the temperature as desired. Flow sensors are installed at the return inlets, and the return comb is also equipped with an air vent. The coolant is pumped through the system using a water pump, which creates the necessary pressure in the line

This group of bimetallic valves changes the flow area, as well as the volume of water passed through. This allows you to set the temperature as desired. Flow sensors are installed at the return inlets, and the return comb is also equipped with an air vent. The coolant is pumped through the system using a water pump, which creates the necessary pressure in the line.

A complete set of manifold parts also contains various plumbing fittings. In a set of devices for warm water floors, the collector is perhaps the most important of them, as it provides:

- safety and proper use of floors;

- the ability to configure comfortable conditions for using heating appliances.

Assembly and installation

It is recommended to install a cabinet with a manifold block in such a way that the heated floor loops are approximately the same length. If the distribution device is located above the level of the heating circuit, air from the system will be automatically removed through the air vent. In the case where the cabinet is planned to be hidden in the basement or placed on the floor below, you will have to install an air vent on each circuit, complete with a ball shut-off valve, as well as on the return line.

When assembling the collector block, pay attention to the tightness of the connections. If the equipment does not come with rubber sealing rings, the threads are sealed by winding.

Next, the underfloor heating manifold is installed in a special cabinet. The guides, equipped with bolts and nuts for fastening the combs, are moved in accordance with their length. If the collector block is mounted without a cabinet, use clamps with dowels or brackets. At the same stage, if necessary, a mixing unit is installed and a circulation pump for the heated floor is installed. Finally, the circuits are connected and the system is tested.

Collector cabinet

The mixing and distribution point for coolants will not look aesthetically pleasing if it is not hidden in a closet. Its price is low and it’s easier to buy it than to make it yourself if you don’t have the necessary tools. Cabinet designs are most often used built-in, but they can also be external.

Built-in cabinet with manifold

They have holes for fastening. Fixation methods are always described in detail in the instructions

You should pay attention to this when purchasing

It is also important where the piping openings are located in the cabinet and how they fit into the manifold design. All its parts must be freely placed and have access for maintenance and repair.

The cabinet must be securely closed with access to the equipment only to those involved in servicing the system.

All its parts must be freely placed and have access for maintenance and repair. The cabinet must be securely closed so that only those servicing the system can access the equipment.