When heating a private home, a fairly important issue is stabilizing the pressure in the boiler. If the pressure is low, the boiler will not be able to function. If the pressure is high, the heating equipment will wear out quickly. In order to stabilize the pressure, an expansion tank .

Expansion tank

Purpose of the expansion tank

An expansion tank is needed to compensate for the coolant pressure in the heating system. The pressure difference occurs due to changes in its temperature during the heating process, since its volume changes depending on the temperature.

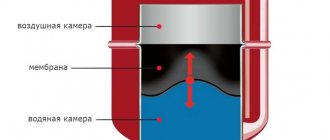

Closed heating systems use an expansion tank of a closed, hermetically sealed structure. Inside the tank there is an elastic membrane that divides it into two parts. One of the parts of the tank contains air under pressure, the coolant penetrates into the second part.

The circulation of coolant in a closed heating system is ensured using a circulation pump. In an open heating system, a pump is not needed, and therefore any container can act as a tank, into which the coolant will be drained directly from the heating pipes.

Expansion tank in a closed heating system

Installation of membrane device

A hydraulic accumulator of this type is installed where there is a minimum probability of coolant turbulence, since a pump is used for normal circulation of water flow along the circuit.

Correct container position

When connecting the expansion tank to a closed heating system, be sure to take into account the location of the air chamber of the device.

The rubber membrane periodically stretches and then contracts. Due to this impact, microcracks appear on it over time, which gradually increase. After this, the membrane has to be replaced with a new one.

It is better to install an expansion tank with a membrane so that the air-filled compartment is on top, this will extend the life of the device

If the air chamber of such a tank remains at the bottom during installation, the pressure on the membrane will increase due to gravitational influence. Cracks will appear faster and repairs will be needed sooner.

It makes more sense to install the expansion tank in such a way that the compartment filled with air remains on top. This will extend the life of the device.

Features of choosing an installation location

There are a number of requirements that must be taken into account when installing a membrane expansion tank:

- It cannot be placed close to the wall.

- The device should be freely accessible for regular maintenance and necessary repairs.

- The wall-hung tank should not be positioned too high.

- A shut-off valve should be placed between the tank and the heating pipes, which will allow you to remove the device without completely draining the coolant from the system.

- When installing on a wall, the pipes connected to the expansion tank must also be attached to the wall in order to remove possible additional load from the tank pipe.

For a membrane device, the most suitable connection point is the return section of the line between the circulation pump and the boiler. Theoretically, it is possible to install an expansion tank on the supply pipe, but high water temperatures will negatively affect the integrity of the membrane and its service life.

When installing an expansion tank, it is necessary to provide shut-off valves that will allow you to disconnect the device from the system and drain the water from it

When using solid fuel equipment, such placement is also dangerous because steam can enter the container due to overheating. This will seriously disrupt the operation of the membrane and may even damage it.

In addition to the shut-off valve and the “American” connection, it is recommended to install an additional tee and tap when connecting, which will allow you to empty the expansion tank before disconnecting.

Setting up the device before use

Before installation or immediately after it, it is necessary to correctly configure the expansion tank, otherwise called an expansion tank. This is not difficult to do, but first you need to find out what pressure should be in the heating system. Let's say an acceptable value is 1.5 bar.

Now you need to measure the pressure inside the air part of the membrane tank. It should be less by about 0.2-0.3 bar. Measurements are carried out with a pressure gauge with a suitable gradation through the nipple connection, which is located on the tank body. If necessary, air is pumped into the compartment or excess air is vented.

Before installing the membrane tank in the heating system, check the air pressure in the air compartment and adjust it according to the requirements

The technical documentation usually indicates the operating pressure, which is set by the manufacturer at the factory. But practice shows that this is not always true. During storage and transportation, some air may escape from the compartment. You must take your own measurements.

If the pressure in the tank is not set correctly, this can lead to air leakage through the air removal device. This phenomenon causes a gradual cooling of the coolant in the tank. There is no need to pre-fill the membrane tank with coolant; simply fill the system.

Tank as additional capacity

Modern models of heating boilers are often already equipped with a built-in expansion tank. However, its characteristics do not always correspond to the requirements of a specific heating system. If the built-in tank is too small, you need to install an additional tank.

It will ensure normal coolant pressure in the system. This addition will also be relevant if the heating circuit configuration changes. For example, when a gravity system is converted into a circulation pump and the old pipes are left behind.

This is true for any systems with a significant volume of coolant, for example, in a two- or three-story cottage or where, in addition to radiators, there is a heated floor. If a boiler with a small built-in membrane tank is used, installing another tank is almost inevitable.

An expansion tank will also be appropriate when using an indirect heating boiler. A relief valve, similar to that installed on electric boilers, will not be effective here; an expansomat is an adequate way out of the situation.

Advantages of a closed heating system

- The first advantage of a closed heating system is that the tank can be installed wherever it is convenient for you, but in an open one, only in the attic or at some other high point in the system. And due to the tightness, the coolant practically does not evaporate.

- The coolant is always saturated with air in an open heating system, which leads to corrosion in heating pipes and radiators. In a closed environment, as you understand, this cannot happen.

- In a closed system, there are fewer losses in the tank than in an open system, which heats up very quickly and has increased sensitivity. Plus, the temperature difference in a closed system is smaller, which allows you to use heating equipment longer.

- The closed system is suitable for a wide variety of radiators, convectors and air curtains; you can connect a “warm floor” system. Plus, you can add an indirect heating boiler for domestic hot water to a closed system.

Pros and cons of thermal accumulators

pros

- If the power goes out, you will be able to heat your home for another 5-10 hours;

- The heat accumulator perfectly protects the boiler from overheating and boiling;

- Several heat generators can be connected to one heating circuit at once;

- A large increase in efficiency, since in a short period of time it is possible to store a significant amount of heat in the storage tank;

- Reduced fuel costs;

- You can install a hot water supply system.

Minuses

- The storage tank takes up a lot of space in the boiler room;

- The overall cost of the heating system increases significantly, so additional equipment needs to be purchased and installed.

Expansion tank design

Tanks can be either with the ability to replace the membrane with a new one, or completely non-removable. To secure the tank to the wall, brackets and clamps may be included; to install the tank on the floor, special legs may be included. The tank membrane, in turn, can also be of different designs.

Non-separable models are equipped with a membrane in the form of a diaphragm; less commonly, a membrane in the form of a cylinder is found. It stretches under pressure, so it can be considered an independent water chamber. To replace this type of membrane, a special flange is used.

Expansion tank design

Installation of an open type hydraulic tank

An open-type device is used less and less often, as it requires constant user intervention in its operation. An open expansion tank is an unsealed container that serves to generate pressure in the water supply system, accumulate water, and also serves as an expansion chamber.

The tank is connected to: a drain tap, pipes for the recirculation and supply pipes, a control and overflow pipe

The tank is installed above the highest plumbing point, for example, in the attic, water enters the system by gravity. Every meter the device rises increases the pressure in the water supply by 0.1 atmospheres.

To automate the process of providing water, the tank is equipped with a float switch and an automatic relay is installed that will turn the pump on and off.

The container is mounted in a frost-free room, covered with a lid to prevent dust and debris, and the walls are wrapped in mineral wool or other insulation.

This method of organizing water supply requires regular monitoring by the user, otherwise the water may freeze at subzero temperatures (if the room is not heated). The liquid will evaporate, so you will have to constantly add it.

In addition, such a container is bulky and not aesthetically pleasing; it requires an attic space in the house. But the main drawback of the device is that the tank is not designed to work under conditions of high water pressure in the system.

Calculation of tank volume

To determine the volume of the tank, you can follow the simplest path. That is, take 10% of the volume of coolant used, which is calculated at the design stage of the heating system. Or you can drain the old coolant and fill in a new one, measuring the volume with a meter.

You can also find out the volume of radiators and pipes, this way you will get the volume of the heating system, from which you will need to take 10%.

There is also a way to calculate the tank using the formula:

V=(E*C*(Pmax+1))/(Pmax+Pmin), where

E – coefficient of expansion of the coolant indicated on the packaging,

Pmax and Pmin are the maximum and minimum operating pressure of the system, respectively.

It should be said that for an open heating system no calculations need to be made, but for a closed one it is still worthwhile. Moreover, if the boiler already has a built-in tank, if its volume is insufficient, a new one is installed.

If there is insufficient tank volume, the volume of coolant decreases and the pressure in the heating system drops as it begins to drain into the sewer. If there is a critical shortage of coolant, the operation of the boiler may simply stall.

If you are at home at this moment, you will just need to add coolant. If you are not at home, the heating system will begin to defrost. And there is nothing good about operating a boiler in critical condition either.

Therefore, it is always better to carry out similar calculations and purchase a slightly larger tank than required.

Expansion tank pressure

Some boilers have the function of manually setting pressure using an expander. Otherwise, it should be approximately 0.3 atmospheres lower than the operating pressure of the heating system in a country private house. And it is usually equal to from 1.5 to 1.8 atmospheres, resulting in approximately 1.6 atmospheres maximum or 1.2 minimum.

To measure the pressure in the tank, connect the pressure gauge to the nipple at the top of the tank, under the plastic cap. Under the cover there is a spool through which excess pressure can be released. You just need to bend the plate and release the air to normal pressure.

To increase the pressure, the car pump along with a pressure gauge should be connected to the nipple, then pump to the required level. Do not forget that all these operations must be performed when the tank is disconnected from the heating system! The coolant must be completely drained.

Installed expansion tank

What is a heat accumulator?

A heat accumulator is a buffer tank designed to accumulate excess heat from a heating system boiler. The accumulated resource is subsequently used for various needs: long-term heating of the house, hot heating, and so on.

If you correctly connect a heat accumulator to the CO, you can reduce fuel costs by almost 2 times, be it gas, firewood or even electricity.

In addition to accumulating excess heat, this container protects the boiler from cracking, which occurs during a sharp temperature change.

If such a system is equipped with various sensors and valves for multi-level savings, then heat transfer will increase and the cost of purchasing fuel will be significantly reduced.

Position of the expansion tank in the heating system

In a closed heating system, the tank should be installed after the boiler, but before the pump, to create a flow in the opposite direction. To connect the pump to the pipe, you need to install a tee; the tank is screwed onto a perpendicular outlet, which should have a vertical upward direction.

We recommend that you install the next tee after the tank so that a shut-off valve is installed on it. This way you can check the tank without draining the coolant. Turn off the tank and check the pressure, which should be at zero.

Summarizing all of the above, we can conclude that a closed heating system with an expansion tank is an almost universal solution for most types of boilers, radiators and other heating equipment.

Calculations for installing the tank are also highly recommended. An open heating system is mainly an option for a village house with an attic and a solid fuel boiler; in other situations such a scheme is of little use.