A correctly selected and correctly installed expansion tank of the heating system will prevent its failure and will maintain the pressure at the required level. It is needed as a reserve for water expanding when heated. Depending on the type of system, the built-in expander can be open or closed.

We will tell you how to select a reserve capacity depending on the heating scheme being created. The article we presented describes the design features and specifics of installing expanders. Recommendations are given that, if followed, will ensure ideal operation of any type of heating circuit.

Open type expansion tanks

A design feature of open type expanders is the contact of the coolant with the atmosphere. The circulation in systems with an expander of this type is convection. When heated, the volume of liquid increases, its excess is absorbed by the reservoir of the container.

When the temperature drops, the liquid returns by gravity, under the influence of gravity.

Due to zero pressure in the tank, the device does not require a strong metal structure, therefore:

- any metal is used in the manufacture of the case;

- a ready-made container made of heat-resistant plastic can be used;

- The shape of the tank is not important.

In country houses, such equipment can be assembled from available materials. As a container, you can use a plastic canister or barrel equipped with an inlet pipe and an outlet for overflow.

Open type expanders can be made in the form of a rectangular tank with a leak-proof lid on the top plane

Externally, it is an ordinary metal tank, the upper plane of which is equipped with a hole for servicing and adding liquid. The leak-proof lid provides protection against clogging. Fastening units are provided at the bottom or on the side plane.

Image gallery

Photo from

Expansion tank in the heating circuit

An open vessel for collecting excess coolant

The simplest version of the expander

Container with free evaporation

Open heating systems are used in low-rise buildings, where the volume of coolant and the length of heating communications are relatively small.

Installation requirements are simple:

- the expander is placed at maximum height, on the supply line;

- the supply is connected to the tank through a pipe;

- To drain excess liquid, an overflow is inserted above the calculated level.

To ensure circulation by gravity, it is recommended to use pipes of increased cross-section for installation.

The open structure is placed at the top point, from where the liquid drains by gravity

Usually they try to install the tank in a heated room, equipped with an insulated attic, and if this is not possible, then the tank will need to be insulated. The presence of insulation will prevent freezing of the liquid and loss of system functionality.

Service

Knowing how to choose the right expansion tank for heating your home is only half the battle. It is also important to provide the required level of maintenance so that this element, together with the entire heating system, lasts a long time. It includes:

- Mandatory inspections are carried out every six months. External damage is looked for first. If there is corrosion, smudges and dents, the cause of their appearance must be eliminated.

- Once every six months you should check the initial pressure and calculated values. Before this, you should disconnect the tank from the heating system, drain the water and connect the pressure gauge through the nipple. At lower values, the pressure increases through it.

- Checking the condition of the membrane. Provided that the water drains along with the air flow, and the pressure recorded in the gas space decreases, we can talk about the presence of damage. The membrane, if possible, must be replaced.

- If the tank is not intended to be used for a long time, the water is drained and the tank itself is kept in dry conditions.

Rules for calculating tank capacity

Any type of dilator will be effective only if the volume is chosen correctly. To do this, take into account the ability of the liquid to expand during the heating period. Water in heating rings expands by at least 3% of the total volume of the water system, antifreeze - by almost 5%.

Liquids belong to the category of incompressible media, so the tank must provide them with a sufficient reserve for thermal expansion with some margin. Provided that the circuit is completely filled with coolant, even thermal expansion in the calculated volumes can lead to liquid discharge through the safety valve and spillage of coolant onto the floor.

Therefore, so that exceeding the volume of expanding coolant does not lead to accidents, closed tanks for small circuits in private houses are purchased so that their volume is equal to 10% of the total volume of coolant circulating through the system. This rule is valid for systems with a capacity of up to 150 l.

If more than 150 liters of coolant moves along the heating ring, then the capacity of a closed tank is calculated by multiplying the total volume of liquid by its expansion coefficient at specific operating temperatures in the system.

To the obtained value you need to add the size of the water seal, i.e. the volume of coolant formed in the tank as a result of standard static fluid pressure. For large heating rings, this figure is usually equal to 0.5% of the total coolant volume; for small ones, with a capacity of up to 150 liters, it is taken to be 20%.

The resulting amount is multiplied by a correction factor determined from the values of preliminary and final pressure in the heating system. The preliminary estimate is that there is 1 bar per 10 m of contour height. The final pressure is formed as a result of the operation of the system.

Calculation of the volume of a closed tank for large complex heating structures looks like this:

The calculations used: Vn – nominal volume of a closed tank; Ve is the volume of the coolant during thermal expansion (calculated using the formula Vsystem×n%, where n is the coefficient of thermal expansion of the coolant); Vv – water seal; po – preliminary pressure; pe – final pressure indicator, equal to the maximum pressure value of the safety valve minus 0.5 bar

The capacity of the open type is not strictly regulated by regulations, but there is a rule: the volume of the open tank to the overflow pipe should be 3.5 - 4% of the total volume of coolant in the heating circuit.

This estimate is sufficient for a small country house, but a building for permanent residence will require a more accurate calculation. First of all, you will need to find out the total volume of the heating system.

Options for calculating the total heating capacity

This indicator can be determined with varying degrees of accuracy in three main ways. Firstly, based on the boiler’s passport data. Thus, about 15 liters of liquid are needed per unit of boiler equipment power. To obtain the necessary data, you will need to multiply 15 by the boiler power indicated in the data sheet.

Secondly, you can find out the volume using a water meter when filling the system. As you fill, the amount of liquid used is taken into account. This is a more accurate and troublesome option.

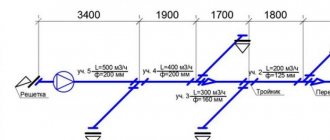

The third method involves calculating the total volume of all elements of the heating system. This is the most accurate option. The capacity of the heat exchanger of the boiler, radiators, convectors, and measuring instruments can be determined from the passport characteristics. To calculate the pipe capacity, data from the table is used.

The table shows the pipe sizes in inches and their volume in liters per 1 meter, which is used to summarize the total volume

The table shows the volume of pipes per meter of length, made from the most popular and modern materials. The internal diameter is indicated in inches from 0.5 to 1.5 units.

Another method that claims to be highly accurate is calculation using the formula:

Vtotal = π x D2 x L/4,

Where:

- π is equal to 3.14;

- D - indicates the parameters of the internal diameter of the pipes;

- L - indicates the length of the system pipeline.

After receiving the necessary data, they are summed up and the total volume of the system is obtained, which is used in further calculations.

Steps and formulas for the full cycle of calculations for designing and organizing the heating of a private home are given here. We recommend that you read the useful information.

Selecting an expansion tank according to the table

If you have the necessary data, the optimal expander option can be selected using the table of volumes and design pressure.

The total volume of the system is calculated according to the specified method; the pressure parameters are relevant only for closed modifications and are indicated in the equipment data sheet.

The data from the table allows you to select the expander volume from 4 to 300 liters

This option does not require special calculations other than calculating the total volume of the system. Using the table greatly simplifies and speeds up the selection of an expander with the required tank capacity.

Using calculation formulas

If the table data is not enough, it is possible to calculate the required capacity indicator yourself.

To do this, use the following formula:

Vb = Vc xk/D,

Where:

- Vb - indicates the desired expander capacity;

- Vc – total system capacity;

- k is the expansion coefficient of the liquid when heated;

- D – expander efficiency coefficient.

Of the data necessary for the calculation, the coefficients k and D remain unknown. The first is a tabular value, and the second is calculated using a separate formula.

A temperature expansion table also exists and is used. It allows you to determine the coefficient for systems with water or antifreeze. The value is not linear; it changes when heated, depending on the presence and concentration of glycol in the liquid.

Using these data, it is possible to determine the parameters of the coefficient of expansion of the liquid when heated (k), necessary for calculating the volume of the expansion cylinder

For water, the concentration of ethylene glycol is taken as “0”; for antifreeze, the concentration is determined according to the data declared by the manufacturer. The heating temperature is considered operational for a specific system.

To independently calculate the efficiency coefficient of the expansion tank, use the formula:

(Qm – Qb) : (Qm + 1),

Where:

- Qm is the maximum pressure of the system according to the safety valve’s nominal response threshold;

- Qb is the preliminary pressure in the air chamber of the expander according to the data sheet.

If the latter parameter is unknown, it is measured during inflation or by bleeding through the nipple of the cylinder.

Other calculation methods

In addition to independent calculations using formulas and tables, there are alternative methods. An accessible calculation option is the help of an online calculator.

There is no shortage of network resources offering online calculation of the required value. They are easy to find by keyword

Another option to obtain the necessary data is to contact professional designers. This is the most reliable way, but the accuracy of the information obtained will be quite expensive.

The following article dedicated to these issues will introduce you to the rules for installing and connecting closed and open type expanders.

Safety requirements for operation

The expansion tank cannot be subject to additional static load; pipes and assemblies must not be exposed to it.

Design changes or any changes in the shape of the container are also not allowed. Testing and repair work must be carried out by specialists with appropriate professional training. Only original spare parts should be used when replacing parts of the equipment. Only tanks that do not have obvious external damage can be installed and operated. During commissioning, appropriate measures must be taken to ensure that the minimum and maximum pressure and temperature parameters are observed. It is unacceptable to exceed the operating pressure in the gas and water compartments of the tank, both during setup and during operation. The air chamber pre-pressure must always be below the maximum permissible overpressure. It is better to fill the gas space with an inert gas, for example, nitrogen.

Dismantling of parts that are under pressure can be carried out with the tank disconnected from the heating system, having previously drained the water from it and releasing the pressure to atmospheric pressure. Typically, the inner surface of the tanks is not coated, so the energy carriers must be non-aggressive. Modern technologies make it possible to make heating systems so airtight that the entry of substances that cause corrosion is reduced to a minimum.

To install an expansion tank, you must choose a place whose load-bearing capacity is to support the tank at 100% fullness. It is also necessary to provide for the possibility of draining water from the tank and replenishing the system with water. Compliance with these rules will ensure safe operation of the tank, the health and lives of people will be safe.

The service life of the expansion tank is noticeably reduced at maximum loads.

How to choose the right expansion tank?

It is recommended to decide on the type of heating system at the planning stage. The choice of tank is usually postponed until after the box has been erected, when the system is installed and its volume is known.

When selecting the optimal expansion tank option, it is recommended:

- focus on the volume of the closed expansion tank, which exceeds the value of the thermal expansion of the coolant;

- when purchasing, you should pay attention to the connection, the shape of the container and the location of the connectors for fasteners - this will avoid surprises during the installation process;

- It is important to pay attention to the instructions on the case, which contain useful installation information and technical parameters.

When purchasing, it is better to focus on a trusted manufacturer, even if its cylinders will cost more. This will be the key to the longevity of the heating system, provided that it is used correctly and regularly maintained.

Before connection, the preliminary pressure in the gas compartment of the membrane tank is adjusted to a value equal to the static pressure of the coolant column in the heating circuit. The adjustment is made using a regular car pump and is controlled by a pressure gauge.

The main thing is not to buy a boiler tank for the heating system - they are completely different in their technical characteristics

Do not confuse expanders for heating systems and hydraulic accumulators for cold water supply lines. They differ in appearance and design features. The former are painted red and are usually not dismountable, the latter are blue and equipped with a removable flange for repairing the membrane.

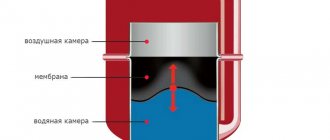

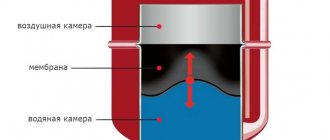

Membrane tanks for hot water systems

The main difference between membrane tanks for water supply is that the water in them should not come into contact with the walls of the housing, as is allowed in heating systems. Therefore, they always use a chamber-type membrane (in the form of a bag). In addition, the membrane material of water supply tanks is subject to increased requirements regarding the permissibility of contact with food liquids.

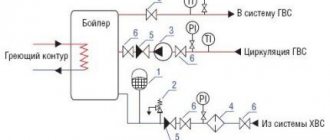

The calculation of a membrane expansion tank for domestic hot water is carried out according to formula 1. The volume of water in the system is calculated taking into account the water contained in the pipelines and the water heater or heat exchanger.

| The design of some water heaters provides for the presence of a damping air cushion in the closed volume of the water heater itself. The volume of this pillow is determined by the height of the DHW outlet pipe and should also be taken into account when selecting a DHW expansion tank. |

An example of installing a membrane tank for domestic hot water is shown in Fig.

7. Fig. 7. Installation of an expansion tank in the hot water supply system: 1 – expansion tank; 2 – safety valve; 3 – pump; 4 – filter; 5 – check valve; 6 – shut-off valve

Design and functionality

When the temperature changes, the coolant tends to expand or contract. This leads to a change in pressure inside the constituent elements of the structure. Because of this, there is a risk of a line rupture. To eliminate this phenomenon, an additional device is installed - an expansion tank.

In addition to compensating the pressure in the line, the device is necessary to combat the appearance of air in equipment and pipes. During cooling, the volume of the heat carrier decreases, a void is formed, which is filled with air. This process can also cause boiler failure, rupture of pipes or radiators. Or zones appear in the batteries that are not heated.

Installation

Installation diagram of a tank in a private house system

If you are confident in the calculations and your own abilities, the tank and all materials have been purchased, then you can install the container yourself.

Tools you will need:

- Step and adjustable wrenches;

- Soldering device for plastic pipes;

- Wrench for installing plastic pipes;

- In some cases, a welding machine and an angle grinder .

Before installation, you need to turn off the power to the boiler, turn off the valves and drain the coolant if it is already in the pipes.

The installation is carried out taking into account certain rules.

- The tank must be mounted and installed so that it can be easily approached for adjustment and maintenance .

- The room temperature should not be below 0.

- on the supply pipe , which will allow the expander to be removed for maintenance and repair .

Find out more about installing metal-plastic pipes and welding propylene pipes.

After installing the tank, you need to start the entire heating system. If boiling is detected in it, then the reason lies in the incorrectly selected pipe diameter. It's not about the tank. The installation of the expansion tank is described in the following video:

Recommendations from experts

A closed expansion tank does not have to be installed at the highest point of the system.

The main advantage of membrane expansion joints lies precisely in the possibility of placing it in the place most convenient for installation and operation.

Small tanks with a volume of 20-25 liters are usually installed in systems with a circulation pump whose power is 1.2 kW. Increasing the capacity to 20-60 liters will lead to an increase in pump power to 2.0 kW.

There are compensating devices with a volume of 100-200 liters on sale. In addition to their direct purpose, they can play the role of a storage tank for warm water. True, they can be used in this way only if the main source of hot water is turned off for a short period of time.

The standard sizes of expansion tanks cover a fairly wide range. Among them there are models with dimensions so large that standard doorways do not allow them to be brought inside the room. In such a situation, it is better to replace one huge container with several small ones. The main thing is that their total volume is equal to the calculated one.

Online calculator

The third way to perform calculations is an online calculator. On the Internet you can find several different programs that simplify the question of how to choose the volume of the expansion tank. Information about coefficients and the dependence of the desired value on temperatures or pressure in communications is already included here.

Our website provides a program for determining the capacity of a closed tank. Here, the adjusted gas pressure refers to the minimum limit that is typical for a heating boiler. For example, if it is 1.5 Atm, then there should be the same amount in the tank. The safety valve is often set to the maximum pressure in the line or equipment. The third thing you need to know is the volume of the coolant.

There are two advantages to working with online calculators, and they are significant:

- immediate results;

- accounting for tabular data that the user does not need to search for.

However, there are also disadvantages. Here it is impossible to track what exactly was taken into account by the developers to produce a particular result. The result can also be considered as close to the exact one.