Solid fuel has been used by humanity to produce thermal energy since time immemorial. Its most famous types, which can be called “classic”, are coal, firewood and peat. They remain popular and in demand even despite the proliferation of more convenient energy sources, such as usable gas and electricity. This state of affairs is facilitated by the low cost of solid fuel and its almost universal availability.

An additional role in the spread of classical heat sources in our time has been played by advanced technologies, which have also not bypassed this part of the energy sector. Thanks to them, such modern types of solid fuel as briquettes and pellets, which have a large number of advantages, appeared. But are they really better than their classic and long-known counterparts? This review will help answer this question, which will present a comparison of pellets and coal. However, before we begin to consider these two types of solid fuels, it is necessary to provide a brief description of each of them.

Consumption

It is necessary to take into account that granulated pellets are a packaging product that is sold in bags of a specific volume.

That is why calculate what the consumption of granules will be for 1 kW and 1 sq. m. will not be difficult. There is no need to convert weight into volume, because manufacturers of such a product always register their products in kilograms, and the unit that measures heat is kW. The correct calculation of granule consumption is carried out in several steps. The result will be the monthly fuel consumption of the boiler during the entire heating season, as well as its average cost. Below we describe in detail how to make all the necessary calculations using the example of an area of 100 square meters. m.

First, it is important to understand how much heat actually penetrates the heating system when burning 1 kg of pellets. This stage must be taken into account, since boilers operating from solid fuel are not ideal for directing absolutely all the heat energy received to warm up a private or country house - part of it is still redirected to the chimney pipe

For this purpose, the heat of combustion of particles is multiplied by the efficiency of the heat generator, divided by 100:

5 kW/kg x 80% / 100 = 4 kW/kg.

To make calculations easier, you should use the reverse action to find out how many pellets you need to burn to generate 1 kW of heat under the current circumstances:

1 kW / 4 kW/kg = 0.25 kg.

Since during the heating season the weather outside usually remains unchanged, and the temperature varies from +10 to -30 degrees, the specific heat consumption per season in a house with an area of 100 square meters. m will not be 10 kW, but half as much, that is, 5 kW. If we take into account that all power units refer to a time of 1 hour, then the heat consumption per day will be:

5 kW/h x 24 hours = 120 kW.

The same, but for a month:

120 W x 30 days = 3600 kW.

Then you can calculate the approximate costs of pellets per month when heating a house of 100 square meters. m. throughout the heating season:

3600 kW x 0.25 kg/kW = 900 kg.

If you need to know the approximate consumption of pellets from wood waste per day, then you should make the following calculation:

120 kW x 0.25 kg/kW = 30 kg.

The principle of operation of boilers for heating a house using pellets

Pellets are used as the main source of energy for heating devices of this design. This is pressed waste from the wood processing industry (chips, shavings, sawdust, etc.). They look like granules up to 7 cm long and up to 10 mm in diameter. As a result of burning 1 kg of pellets, 5.2 kW of thermal energy is released. The combustion reaction in boilers occurs using a burner.

Types of burners for pellet heating boilers

Today, two main types of burners for pellet heating devices enjoy consumer recognition:

- retort burners. They are a bowl (cast iron or steel, heat-resistant), on the surface of which the combustion reaction occurs. Fuel is supplied from the loading hopper using a screw device to the middle of the retort burner. This is where primary air is supplied. It supports the combustion reaction by blowing fuel from below, and prevents the burner itself from heating up to a critical temperature. Secondary air is supplied to the combustion chamber through special openings in the boiler structure. It regulates the intensity of pellet combustion. Retort burners can be movable (designed for burning high-ash and high-dust energy carriers) and stationary (designed for using prepared raw materials - fine coal, pellets);

- grate burners. In boilers with this type of burner, pellets are fed through a chute from the loading hopper under the influence of their own weight onto cast iron or steel grates. Primary air is supplied from the bottom of the grate, which supports the combustion reaction of the pellets and prevents the grate from overheating. Combustion products - ash - are removed through holes in the grate and collected in the bottom drawer of the boiler. Grate burners can be movable or fixed.

Ease of use

From a convenience point of view, coal-fired boilers do not have an automatic supply, so the fuel level in the boiler must be continuously monitored by adding it to the combustion chamber. If we are talking about heating a large house in winter, then this becomes a problem.

In the case of a pellet boiler, the opposite is true. The need to manually add fuel is completely eliminated. The fuel supply in this case falls on the shoulders of the automatic boiler system.

Types of sawdust boilers

Heating systems operating on sawdust are divided into two types:

- conventional - heat is generated only as a result of fuel combustion, such boilers are less profitable than those that have a gas generator chamber;

- with a gas generator element - more efficient units, may have different designs.

Some manufacturers offer condensing-type models, as well as long-burning boilers.

You can assemble a homemade sawdust boiler if you wish, but it will be the simplest design. As for automated heating systems, even domestic manufacturers cannot offer high-quality and economical equipment.

The German Hargassner models are considered the best - they are highly effective, but at the same time expensive. Some other foreign companies also produce high-quality boilers.

WHO sounds the alarm

More than 5 years ago, the World Health Organization released research on the negative impact of suspended particulate matter (PM2.5), which comes from the combustion of coal and wood, on human health. The author of “20 Ideas for the Development of Russia,” Dmitry Davydov, reports this on the project website (20idei.ru). According to information for 2010, 61,000 people die prematurely in European countries every year. The reason is air pollution with the above substances. In addition, burning coal at home releases large amounts of sulfur and nitrogen oxides, as well as fluorine, arsenic, selenium, mercury and lead. As a result, people have problems with respiratory and heart diseases much more often, and the risk of cancer increases.

Pros and cons of alternative energy

Traditional heat sources, used for heating for many years, can be abandoned. Surprising as it may seem, it is quite real. Many ardent opponents argue that it is impossible to replace natural resources with environmentally friendly analogues.

The alternative is the energy of the sun, the power of the wind, the heat hidden in the bowels of the earth, waste from production and human activity. Such options are relevant in the modern world, given the general pollution of the environment.

Alternative sources can provide a country house with electricity and thermal energy

Another significant advantage is tangible savings when using environmental sources of spontaneously renewable energy. At first glance, it seems that this is unreasonably expensive and is unlikely to pay off.

Having understood in more detail the features of each method, you can see that the eco-project pays off in 4-7 years, and then only the current costs of maintaining the used mechanisms in working order remain.

The possibility of fully replacing conventional fuel with an alternative one has been proven by more than one real example. Homeowners around the world are turning to green heating options. In our country, only a few decide to radically change their usual fuel, which is becoming more expensive every year.

The main problem with using eco-fuel is significant investment at the initial stage. After all, you first need to calculate in detail the amount of energy required for a particular house or cottage. Then find out what type of eco-resources are most beneficial in a particular area.

Next, you need to draw up a plan for the location of energy-generating equipment, buy everything you need and install it.

If all these issues are dealt with by relevant specialists, then the final cost of eco-heating will be very high. To save money, you can try to do it yourself.

To do this, you will have to immerse yourself in the topic of alternative energy sources in order to refuse to attract outside help. In this case, the cost of the project will be several times cheaper.

It is the second option that many owners of private houses choose. Their practice proves that becoming energy independent is quite possible. You can completely or partially replace traditional fuel - it all depends on the size of the household, financial capabilities at the initial stage, and the chosen heating option.

The scope of “green energy” will be demonstrated by a photo selection:

Briquettes

Briquettes are solid fuels that are in many ways similar to pellets. For their manufacture, identical materials are used: wood chips, shavings, peat, husks and straw. During the production process, raw materials are crushed and formed into briquettes by compression. This material is also an environmentally friendly fuel. It is convenient to store even outdoors. Smooth, uniform and slow combustion of this fuel can be observed both in fireplaces and stoves, and in heating boilers.

The types of environmentally friendly solid fuel discussed above are a good alternative for generating heat. Compared to fossil sources of thermal energy, which have a negative impact on the environment when burned and are, moreover, non-renewable, alternative fuels have clear advantages and a relatively low cost, which is important for certain categories of consumers.

At the same time, the fire hazard of such fuels is much higher. Therefore, it is necessary to take some safety measures regarding their storage and the use of fire-resistant materials for walls.

How to choose the right pellet boiler

Prices for pellet boilers for heating a private home start at 70-75 thousand rubles. A little expensive, but for the money you will get equipment with a spacious bunker and automatic supply of pellet fuel. For less money you will get a universal solid fuel boiler with manual loading. A pellet boiler for a private home can be more expensive - it all depends on its filling.

Heat exchanger type

When choosing a pellet burner, pay attention to the heat exchanger; it is advisable that it be made of cast iron. We recommend purchasing pellet boilers with cast iron heat exchangers, and multi-pass ones

Cast iron is an ideal material for creating heat exchangers - it is quite durable, heats up quickly and cools down slowly, and can withstand temperature overloads well. If there are several moves in it, then this is a plus - the exchanger will be able to absorb the maximum amount of heat. The main disadvantages of cast iron are fragility and lack of resistance to water hammer

We recommend purchasing pellet boilers with cast iron heat exchangers, and multi-pass ones. Cast iron is an ideal material for creating heat exchangers - it is quite durable, heats up quickly and cools down slowly, and can withstand temperature overloads well. If there are several moves in it, then this is a plus - the exchanger will be able to absorb the maximum amount of heat. The main disadvantages of cast iron are fragility and lack of resistance to water hammer.

Steel heat exchangers differ from their cast iron counterparts in their resistance to water hammer. True, they are more susceptible to corrosion and do not tolerate temperature overloads well. Therefore, they are used only in the cheapest pellet boilers used for heating private households.

Recommended types of heat exchangers are fire tube or flat plate, made of cast iron. If the exchanger is vertical, then this is only a plus - they are well cleaned of ash, which simply falls down.

Automation of work

We have already said that pellet boilers used for heating private houses can work without regular approaches from the users - you just need to periodically add new portions of pellets and remove the ash. The most advanced pellet boilers are equipped with the following functions:

- Automatic temperature control in the heating system of a private house;

- Automatic ignition - no need to ignite the fuel yourself;

- Control of operating parameters - here the pressure in the heating system, the temperature of the coolant, the quality of fuel combustion and many other parameters are monitored.

In addition, some pellet boilers provide fuel availability control.

Fuel supply

Using a flexible auger will allow you to place the fuel hopper far from the boiler itself.

Pellet boilers for heating a private home are equipped with two types of augers - flexible and rigid. Rigid augers are implemented in all boilers with automatic pellet feeding. In their design, they resemble a meat grinder, smoothly moving granules from the hopper into the combustion chamber. The main feature of a rigid auger is its fixed length. That is, we cannot move the bunker to another location.

Flexible augers allow you to place bins with pellet granules at any point, for example, in the next corner of the house. The fuel enters the pellet boilers through a kind of flexible pipe in which a flexible auger rotates. Its length can reach 10 meters and above. To synchronize the standard rigid and external flexible augers, automation with electric motors is used.

Burner type

We have come to a very important criterion for choosing a pellet boiler for organizing heating in a private home - this is the type of burner. There is not much variety here; in pellet boilers there are either retort burners or torch burners

The retort burner operates in a vertical plane, the flame shoots upward, and fuel enters it from below or from the side (in bulk). Air enters through the gaps on the sides. The disadvantage of such a burner is that it can periodically go out, becoming clogged with ash.

If you want to get rid of this drawback, use low-ash pellet fuel - it burns almost completely and does not form a large amount of ash.

We advise you to choose pellet burners with a torch burner; it works much more stable than a retort burner.

Horizontal flare burners do not have the disadvantages of retort burners. The flame here is literally blown out by a powerful fan, emerging in a horizontal plane. Pellet combustion occurs on a special platform, the ash is discharged downwards. Thanks to powerful blowing, such a burner is characterized by high efficiency, allowing for good heating performance in private households.

What are pellets?

In essence, pellets are waste obtained from wood processing compressed into small granules. That is, these are ordinary shavings, sawdust, which previously were simply disposed of in large quantities as unnecessary. Today, with the help of special equipment, this waste becomes extremely useful fuel for humans. Moreover, it should be noted that pellet heating is the most environmentally friendly today.

Moreover, this type of fuel has fairly high calorific characteristics. Another advantage of pellets is that they burn almost completely - the ash residue is only 0.5% of the original mass. In addition, pellets are very easy to transport, without requiring special conditions. This also applies to storage.

Pellets are made from different types of wood. In many respects, only the size of the granule depends on this. Most often they are 6-8 mm in diameter and 5-70 mm in length. The granules have a fairly high density - 1.5. That is, they drown in water.

As mentioned earlier, pellets have excellent calorific properties. 1 kilogram of fuel emits 5 kW/hour. For comparison: the calorific value of ordinary firewood is approximately 3.5-3.7 kW. Of course, pellet heating is somewhat inferior to liquid fuel in terms of calorific value. However, it is undoubtedly safer and more environmentally friendly.

Specific heat of combustion of various types of fuel

It should be noted that some unscrupulous manufacturers add sand to the shavings when producing pellets - this will increase the mass of the resulting granules. However, there is a simple way to check the quality of the fuel - just burn a small amount of it. In the remaining ash, sand will be immediately noticeable.

That is, when they are burned, there is no release of sulfur dioxide into the atmosphere. When pellet heating is produced, carbon dioxide is released during combustion, but its amount is equal to that released during normal decomposition of wood under natural conditions.

Types of fuel for solid fuel boilers and a comparative table of their calorific value

Main types of fuel for solid fuel boilers:

— Firewood

— Pellets (fuel granules)

— Fuel briquettes

- Coal

Firewood

Firewood is sawn or chopped pieces of wood intended for burning in stoves, fireplaces, etc. to produce heat, heat and light.

The moisture content should be as low as possible.

Fireplace wood is about 25 - 33 cm long.

The priority characteristics of firewood for fireplaces and stoves are their calorific value, burning time and comfort during use (flame pattern, smell).

For heating purposes, it is important that heat release occurs more slowly, but over a longer period of time.

For heating purposes, all hardwood firewood is best suited, including oak, ash, birch, hazel, yew, and hawthorn.

Features of burning firewood of different types of wood:

- firewood from beech, birch, ash, hazel is difficult to melt, but they can burn damp because they have little moisture, and firewood from all these tree species, except beech, splits easily;

— alder and aspen burn without the formation of soot and even burn it out of the chimney;

— birch firewood is good for heat, but if there is not enough air in the firebox, it burns smoky and forms tar (birch resin), which settles on the walls of the pipe;

— pine firewood burns hotter than spruce firewood due to its higher resin content, with sparking when the temperature rises sharply;

— oak and hornbeam have better heat transfer during combustion, but do not split easily;

— firewood from pear and apple trees splits easily and burns well;

- firewood made from medium-hard rocks, easy to split;

- cedar produces long-smoldering coals;

— cherry and elm wood smokes when burned;

— sycamore firewood melts easily, but is difficult to split;

— coniferous wood has a low calorific value, smokes and sparks, contributing to the formation of resinous deposits in the pipe, but easily splits and melts;

— poplar and linden burn well, spark strongly and burn out very quickly.

The calorific value of firewood of different types of wood varies greatly, which entails fluctuations in the density of wood and fluctuations in the conversion factors cubic meter => storage meter.

Table with average calorific values per 1 meter of firewood.

| Firewood (natural drying) | Calorific value, kWh/kg | Calorific value, mega Joule/kg | Calorific value, MWh/storage meter | Bulk density, kg/dm³ | Density, kg/storage meter |

| Hornbeam firewood | 4,2 | 15 | 2,1 | 0,72 | 495 |

| Beech firewood | 4,2 | 15 | 2,0 | 0,69 | 480 |

| Ash firewood | 4,2 | 15 | 2,0 | 0,69 | 480 |

| Oak firewood | 4,2 | 15 | 2,0 | 0,67 | 470 |

| Birch firewood | 4,2 | 15 | 1,9 | 0.65 | 450 |

| Larch firewood | 4,3 | 15,5 | 1,8 | 0,59 | 420 |

| Pine firewood | 4,3 | 15,5 | 1,6 | 0,52 | 360 |

| Spruce firewood | 4,3 | 15,5 | 1,4 | 0,47 | 330 |

1 storage meter of dry wood from deciduous trees replaces 200 - 210 liters of liquid fuel or 200 - 210 m³ of natural gas.

Pellets

Pellets (fuel granules) are natural raw materials of plant origin pressed under high pressure in the form of cylindrical granules of standard size.

The raw materials for their production are bark, sawdust, wood chips and other logging waste, and agricultural waste (sunflower husks, straw, substandard flax, etc.), as well as organic packaging materials, cardboard containers, etc.

The pellet production process consists of the stages: crushing, drying and granulation.

The raw materials are ground to the state of flour, then thoroughly dried and compressed into standard size granules using special equipment - a granulator.

During granulation, accompanied by an increase in the temperature of the material, the lignin polymer contained in it, contained in the cells of plant materials, tightly glues the crushed particles together. Chemical binders are not used.

The output is light, inexpensive, easy to store and absolutely safe fuel, an alternative to traditional fuels (coal, peat, firewood, natural gas).

The press granulator gives the pellets their shape.

Pellets are a modern universal type of biofuel, equivalent in efficiency to coal.

Types of pellets:

— obtained by processing round timber of hard and soft trees;

— obtained by processing straw;

— obtained processing of sunflower husks;

— obtained by processing cobs and stalks of corn;

- peat.

Advantage of pellets:

- environmentally friendly fuel corresponding to green technology, produced from materials that are harmless to humans and the environment and subject to recycling: 10-50 times lower carbon dioxide (CO2) emissions into the environment, 15-20 times lower ash formation than during combustion coal;

— unlimited production, including from low-quality wood,

- lower cost compared to the price of coal, liquid fuel or firewood,

— ease of transportation, both in packaged bags and in bulk, and unloading through sleeves with the possibility of automating the process;

- do not require large storage areas and can be stored outdoors without swelling or rotting,

- do not spontaneously ignite during storage,

— do not require additional processing before use, no worse than gas or coal.

- greater calorific value than sawdust and wood chips, 1.5 times more than firewood,

— when burning 1.9 tons of pellets, approximately the same amount of heat is released as when burning 1 ton of fuel oil, while the cost of pellets on the domestic market is 3 times cheaper, that is, heating with pellets is 40% cheaper than fuel oil;

— almost complete combustion with a minimum amount of slag, which reduces the frequency of boiler cleaning and can be done much less frequently,

— automation of loading pellets into the firebox in industrial conditions is possible,

- adjustment of household heating devices operating on pellets is adjusted automatically,

— low price volatility, since the price is internal,

- pellet boilers last longer, require less maintenance and are more economical,

Application of pellets:

- for heating residential buildings by combustion in stoves, fireplaces and boilers,

— to provide heat and electricity to industrial facilities and small settlements (using large granules with a high content of tree bark.

The demand for this alternative fuel and for equipment for its production and combustion is constantly increasing.

Comparative characteristics of fuel types

| Type of fuel | Heat of combustion MJ/kg | % sulfur | % ash | Carbon dioxide kg/GJ |

| Coal | 15 — 25 | 1-3 | 10 — 35 | 60 |

| Motor fuel | 42,5 | 0,2 | 1 | 78 |

| Fuel oil | 42 | 1,2 | 1,5 | 78 |

| Wood chips | 10 | 0 | 2 | 0 |

| Wood pellets | 17,5 | 0,1 | 1 | 0 |

| Peat granules | 10 | 0 | 20 | 70 |

| Straw pellets | 14,5 | 0,2 | 4 | 0 |

| Natural gas | 35 – 38 MJ/m3 | 0 | 0 | 57 |

Note:

“0” means that when a product is burned, the amount of CO2 released does not exceed the volume that is formed during natural decomposition, and the amount of other harmful emissions is negligible.

- Measurement of calorific value in Kcal/kg. 1 calorie is the amount of heat required to heat 1 g of water by 1°C. 4,500 Cal/kg ( 4,500 Cal/kg ) - heat of combustion of 1 kg of fuel in Cal.

- Measurement of calorific value in MJ/kg. System international thermal unit. 1 Calorie = 4.19 Joules, 4.500 Kcal/kg * 4.19 J = 18.855 MJ/kg - heat of combustion of 1 kg of fuel in Joules.

- Measurement of calorific value in kW*hour. 5.238 kW* hour/kg is the heat of combustion of 1 kg of fuel, measured in “electrical units”. The amount of energy released per second (that is, thermal power) = 18,855,000 J (see point 2) / 3600 sec = 5238 J/sec = 5,238 kWh.

Table 1. Heat transfer of pellets and alternative energy sources

| Type of fuel | Thermal capacity kcal/kg |

| Pellets | 4500 |

| Firewood | 2500 |

| Charcoal | 7500 |

| Coal | 7400 |

| Fuel oil | 9800 |

| Diesel fuel | 10200 |

| Natural gas | 8300 |

Pellet production standards:

— in the USA: Standard Regulations & Standards for Pellets in the US: The PFI (pellet), which is allowed to produce Premium and Standard pellets. Premium, which makes up about 95% of pellets produced in the United States, is no more than 1% ash, and Standard is no more than 3%. Premium can be used for heating any buildings. The Standard variety contains a larger volume of bark or agricultural waste. The standards also determine the density, size of pellets, humidity, dust content and other substances.

- in Germany: DIN 51731, in Austria: ONORM M-7135, in the UK: The British BioGen Code of Practice for biofuel (pellets), in Switzerland: SN 166000, in Sweden: SS 187120.

Basic European quality standards for fuel pellets

| Parameter | DIN 51 731 | O-Norm M-7135 | DINplus | SS187120 |

| Germany | Austria | Germany | Sweden | |

| Diameter (mm) | 4-10 | 4-10 | ||

| Length (mm) | < 50 | < 5*d | < 5*d | < 5*d |

| Density (kg/dm3) | > 1,0-1,4 | > 1,12 | > 1,12 | No |

| Humidity (%) | < 12 | < 10 | < 10 | < 10 |

| Bulk mass (kg/m3) | 650 | 650 | 650 | 650 |

| Briquette dust (%) | No | < 2,3 | < 2,3 | No |

| Ash content (%) | < 1,5 | < 0,5 | < 0,5 | < 1,5 |

| Heat of combustion (MJ/kg) | 17,5-19,5 | > 18 | > 18 | > 18 |

| Sulfur content (%) | < 0,08 | < 0,04 | < 0,04 | < 0,08 |

| Nitrogen content (%) | < 0,3 | < 0,3 | < 0,3 | No |

| Chlorine content (%) | < 0,03 | < 0,02 | < 0,02 | < 0,03 |

| Arsenic (mg/kg) | < 0,8 | No | < 0,8 | No |

| Lead (mg/kg) | < 10 | No | < 10 | No |

| Cadmium (mg/kg) | < 0,5 | No | < 0,5 | No |

| Chromium (mg/kg) | < 8 | No | < 8 | No |

| Copper(mg/kg) | < 5 | No | < 5 | No |

| Mercury(mg/kg) | < 1,5 | No | < 1,5 | No |

| Zinc(mg/kg) | < 100 | No | < 100 | No |

| Fixer, binding materials (%) | No | < 2 | < 2 |

* “no” does not mean a value, it may be, there is no information, it is not defined, there is no exact value, etc.

Fuel briquettes

Fuel briquettes are compressed wood waste (shavings, wood chips), agricultural waste (straw, sunflower seed husks, buckwheat), as well as peat.

The binder is a natural polymer lignin. Chemical binders are not used.

Fuel briquettes are actively used for heating private homes in various types of fireboxes (stoves), wood-burning boilers, fireplaces, and when cooking on the grill.

Advantages of fuel briquettes:

- an environmentally friendly product, the material of which is entirely natural raw materials, and

- not affected by fungi,

— burns 2-4 times longer than wood,

— convenient to store and use.

- high calorific value comparable to coal, on average 2 times higher in comparison with conventional firewood,

— constant temperature at each stage of combustion due to an even flame,

— ash content after combustion — 1-3%. For comparison: the ash content after burning coal is 30-40%, firewood is 8-16%, wood chips is 11-18%,

- modern solid fuel boilers using briquettes can be cleaned no more than once a year,

- ash can be used as an environmentally friendly fertilizer,

— carbon monoxide is not released and other harmful substances are not formed,

— heating costs are lower than when using coal or firewood.

Types of fuel briquettes:

— RUF briquettes — in the form of a large rectangular brick,

— NESTRO briquettes — a cylindrical briquette, sometimes with a radial hole inside,

— Pini&Kay briquettes are a briquette having 4, 6 or 8 sides with a longitudinal radial hole inside.

Coal

Coal is a combustible sedimentary rock of plant origin, consisting mainly of carbon and a number of other chemical elements.

The composition of coal depends on the age and conditions of coalification:

— brown coal is the youngest,

- coal,

— anthracite is the oldest.

With aging, carbon concentration occurred and the content of volatile components, in particular moisture, decreased.

Brown coal has a moisture content of 30-40%, more than 50% of volatile components; for anthracite, these 2 indicators are 5-7%.

The moisture content of coal is 12-16%, the amount of volatile components is about 40%.

Coal also contains various non-combustible ash-forming additives, "rock".

The ash pollutes the environment and is sintered into slag on the grate, which makes it difficult to burn coal.

The presence of rock reduces the specific heat of combustion of coal.

Depending on the type and mining conditions, the amount of minerals varies greatly; the ash content of hard coal is about 15% (10-20%).

A harmful component of coal is also sulfur, during the combustion of which oxides are formed, which in the air turn into sulfuric acid.

Specific heat of combustion (coal concentrate)

| Type of coal | Specific heat of combustion of coal | |

| kJ/kg | kcal/kg | |

| Brown | 14 700 | 3 500 |

| Stone | 29 300 | 7 000 |

| Anthracite | 31 000 | 7 400 |

Actual figures may vary significantly.

Kuzbass hard coal - 5000-5500 kcal/kg. .

The density of coal is 1 - 1.7 (hard coal - 1.3-1.4) g/cm3, depending on the type and content of mineral substances.

The “bulk density” indicator is used, which is about 800-1,000 kg/m3.

Types and grades of coal

Coal is classified according to many parameters (geography of production, chemical composition), but from a “everyday” point of view, it is enough to know the labeling and possibilities of use.

The following coal designation system is used: Grade = (grade) + (size class).

| Brown | B | |

| Stone | Long flame | D |

| Gas | G | |

| Fat | AND | |

| Coke | TO | |

| Lean-sintering | OS | |

| Low-caking | SS | |

| Skinny | T | |

| Anthracites | A | |

In addition to the main grades, there are intermediate grades of coal: DG (long-flame gas), GZh (gas fat), KZh (coke fat), PA (semi-anthracite), brown coals are also divided into groups.

Coking grades of coal (G, coke, Zh, K, OS) are practically not used in thermal power engineering, since they are a scarce raw material for the coke-chemical industry.

According to the size class (size of pieces, fractions), graded coal is divided into:

| P | Slab | more than 100 mm |

| TO | Large | 50-100 mm |

| ABOUT | Nut | 26-50 mm |

| M | Small | 13-25 mm |

| WITH | seed | 6-13 mm |

| Sh | Shtyb | less than 6 mm |

| R | Private | not limited by size |

In addition to graded coal, there are combined fractions and screenings available for sale (PK, KO, OM, MS, SSh, MSSh, OMSSh).

The size of coal is determined based on the smaller value of the finest fraction and the larger value of the largest fraction indicated in the name of the coal grade.

For example, the OM fraction (M - 13-25, O - 25-50) is 13-50 mm.

In addition to the above-mentioned types of coal, you can find coal briquettes on sale, which are pressed from low-enriched coal slurry.

Coal combustion process

Coal consists of 2 flammable components: volatile substances and solid (coke) residue

At the 1st stage of combustion, volatile substances are released; When there is an excess of oxygen, they burn quickly, producing a long flame but little heat.

At the 2nd stage, the coke residue burns out; the intensity of its combustion and ignition temperature depend on the degree of coalification, that is, on the type of coal (brown, hard, anthracite).

The higher the degree of carbonization (the highest is for anthracite), the higher the ignition temperature and heat of combustion, but the lower the combustion intensity.

Coal grades B, D, G

Due to the high content of volatile substances, such coal flares up quickly and burns out quickly.

Coal of these grades is available and suitable for almost all types of boilers, however, for complete combustion, this coal must be supplied in small portions so that the released volatile substances have time to completely combine with oxygen in the air.

Complete combustion of coal is characterized by a yellow flame and clear flue gases; incomplete combustion of volatile substances produces a purple flame and black smoke

To effectively burn such coal, the process must be constantly monitored.

Coal grades SS, T, A

It is more difficult to light, but it burns for a long time and produces much more heat.

Coal can be loaded in large batches, since they burn mainly coke residue and there is no mass release of volatile substances.

The blowing mode is very important, since if there is a lack of air, combustion occurs slowly, it may stop, or, on the contrary, an excessive increase in temperature, leading to heat loss and burnout of the boiler.

Comparative table of calorific value of some types of fuel

The calorific value of fuel characterizes the amount of heat released during complete combustion of fuel weighing 1 kg or volume 1 m³ (1 l).

Most often, calorific value is measured in J/kg (J/m³; J/l).

The higher the specific heat of combustion of the fuel, the lower its consumption.

The specific heat of combustion of each type of fuel depends on:

— from its flammable components (carbon, hydrogen, volatile combustible sulfur, etc.);

- from its humidity and ash content.

| Type of fuel | Unit change | Specific heat of combustion | Equivalent | ||||

| kcal | kW | MJ | Natural gas, m3 | Dis. fuel, l | Fuel oil, l | ||

| Electricity | 1 kW/h | 864 | 1,0 | 3,62 | 0,108 | 0,084 | 0,089 |

| Diesel fuel (diesel fuel) | 1 l | 10300 | 11,9 | 43,12 | 1,288 | — | 1,062 |

| Fuel oil | 1 l | 9700 | 11,2 | 40,61 | 1,213 | 0,942 | — |

| Kerosene | 1 l | 10400 | 12,0 | 43,50 | 1,300 | 1,010 | 1,072 |

| Oil | 1 l | 10500 | 12,2 | 44,00 | 1,313 | 1,019 | 1,082 |

| Petrol | 1 l | 10500 | 12,2 | 44,00 | 1,313 | 1,019 | 1,082 |

| Natural gas | 1 m3 | 8000 | 9,3 | 33,50 | — | 0,777 | 0,825 |

| Liquefied gas | 1 kg | 10800 | 12,5 | 45,20 | 1,350 | 1,049 | 1,113 |

| Methane | 1 m3 | 11950 | 13,8 | 50,03 | 1,494 | 1,160 | 1,232 |

| Propane | 1 m3 | 10885 | 12,6 | 45,57 | 1,361 | 1,057 | 1,122 |

| Ethylene | 1 m3 | 11470 | 13,3 | 48,02 | 1,434 | 1,114 | 1,182 |

| Hydrogen | 1 m3 | 28700 | 33,2 | 120,00 | 3,588 | 2,786 | 2,959 |

| Coal (W=10%) | 1 kg | 6450 | 7,5 | 27,00 | 0,806 | 0,626 | 0,665 |

| Brown coal (W=30…40%) | 1 kg | 3100 | 3,6 | 12,98 | 0,388 | 0,301 | 0,320 |

| Coal-anthracite | 1 kg | 6700 | 7,8 | 28,05 | 0,838 | 0,650 | 0,691 |

| Charcoal | 1 kg | 6510 | 7,5 | 27,26 | 0,814 | 0,632 | 0,671 |

| Peat (W=40%) | 1 kg | 2900 | 3,6 | 12,10 | 0,363 | 0,282 | 0,299 |

| Peat briquettes (W=15%) | 1 kg | 4200 | 4,9 | 17,58 | 0,525 | 0,408 | 0,433 |

| Peat crumbs | 1 kg | 2590 | 3,0 | 10,84 | 0,324 | 0,251 | 0,267 |

| Wood pellets | 1 kg | 4100 | 4,7 | 17,17 | 0,513 | 0,398 | 0,423 |

| Straw pellets | 1 kg | 3465 | 4,0 | 14,51 | 0,433 | 0,336 | 0,357 |

| Sunflower husk pellets | 1 kg | 4320 | 5,0 | 18,09 | 0,540 | 0,419 | 0,445 |

| Freshly cut wood (W=50…60%) | 1 kg | 1940 | 2,2 | 8,12 | 0,243 | 0,188 | 0,200 |

| Dried wood (W=20%) | 1 kg | 3400 | 3,9 | 14,24 | 0,425 | 0,330 | 0,351 |

| wood chips | 1 kg | 2610 | 3,0 | 10,93 | 0,326 | 0,253 | 0,269 |

| Sawdust | 1 kg | 2000 | 2,3 | 8,37 | 0,250 | 0,194 | 0,206 |

| Paper | 1 kg | 3970 | 4,6 | 16,62 | 0,496 | 0,385 | 0,409 |

| Sunflower husk, soybean | 1 kg | 4060 | 4,7 | 17,00 | 0,508 | 0,394 | 0,419 |

| Rice husk | 1 kg | 3180 | 3,7 | 13,31 | 0,398 | 0,309 | 0,328 |

| Linen bonfire | 1 kg | 3805 | 4,4 | 15,93 | 0,477 | 0,369 | 0,392 |

| Corn on the cob (W>10%) | 1 kg | 3500 | 4,0 | 14,65 | 0,438 | 0,340 | 0,361 |

| Straw | 1 kg | 3750 | 4,3 | 15,70 | 0,469 | 0,364 | 0,387 |

| Cotton stalks | 1 kg | 3470 | 4,0 | 14,53 | 0,434 | 0,337 | 0,358 |

| Grapevine (W=20%) | 1 kg | 3345 | 3,9 | 14,00 | 0,418 | 0,325 | 0,345 |

How to determine quality fuel pellets?

Let's talk about the cost of fuel right away. It depends on the quality and class of pellets, but on average, wood pellets (for example, from pine) cost about 6 thousand rubles per ton, and from peat - about 5.5. Prices may vary in one direction or another, but the general figures are clear.

The efficiency of heating with pellets depends mainly on their quality. And this quality, in turn, is completely determined visually. Read the instructions below to learn how to determine product quality.

- Dust. If there is a lot of dust in the package of pellets, it means that the product is of low quality and you have every reason to return it to the seller.

- The surface of the granules must be smooth and free of any defects (bumps or cracks). If such defects exist, it means that there were violations in the production process.

- Color. If pellets for heating have a grayish tint, this indicates that they are stale. And the quality of such fuel will certainly be low.

- Length. Often this is 2.5 centimeters, but, frankly, this figure only indicates European production standards.

- Smell. Good granules should smell slightly sweet - this indicates that all requirements were met during production.

Storage space

When choosing between these two types of fuel, do not forget that either of them requires storage space. Most often, owners purchase fuel in large quantities so that it lasts for a certain period of time.

Of course, everyone knows that coal and dirt are inseparable. That is why heating with coal requires a special room for storing fuel. However, in any case, dust from the use of coal can penetrate into the living space, contaminating furniture and other interior items.

As for the use of pellets, the issue of cleanliness in this case is not so acute. Most often, pellets are packaged in bags, the weight of which varies from 40 to 600 kilograms. When using pellets, only a small amount of wood dust is released. At the same time, pellets can be stored directly in the residential part of the house.

Pellet boilers - device

Pellet boilers are stationary equipment with a universal installation method. The power of the devices varies from 15 kW to several megawatts

Pellet boilers are a steel structure, the components of which are the body, burner, firebox, heat exchanger, fuel hopper and chimney. After burning the fuel, hot gas is formed; when it leaves the furnace, it flows around the heat exchanger and transfers almost all of its heat to it. The “smart” design of pellet boilers is the key to amazingly high efficiency (at least 85%)

The heat exchanger is made of various materials, such as cast iron or steel. What type of equipment should I choose? Cast iron is heavy, but not susceptible to corrosion. Steel has less weight (which means the boiler is easier to install), however, it can rust over time; steel boilers have a shorter service life. Manufacturers solve this problem by adding anti-corrosion components to the steel for heat exchangers.

Pellet boilers are designed for heating and organizing hot water supply (hot water supply). private house, residential and non-residential premises. They are produced both abroad and in Russia. It should be noted that domestic models are usually cheaper than imported ones, and foreign ones have more service functions

How do pellet boilers work?

Servicing the boiler is easy. It is enough to load fuel into the bunker. Pellets are fed into the firebox from a special hopper by an automatic conveyor. The capacity of the standard bunker provides the boiler with fuel for about 7 days, then the storage is refilled. If desired, this process can be fully automated. There are systems in which pellets from the warehouse are supplied by a separate conveyor

The fuel is ignited automatically. This process involves an electric heating element and a fan that pumps air into the firebox. When the fuel burns steadily, the ignition system is turned off.

Pellet boilers - varieties

- Equipment intended only for the use of pellets Conditionally combined boilers - usually run on bio-pellets, but can accept briquettes or firewood as a “spare” fuel for a short time. The firebox in such systems is designed in a special way; it is transformable (the standard grate is removable) Universal boilers - can operate on any solid fuel. As a rule, they have several combustion chambers - one for each type of energy carrier. It is enough to dismantle the pellet burner, and the device is ready to be loaded with traditional solid fuel

Comparison of pellets and coal

Having briefly familiarized yourself with the description and characteristics of the two types of solid fuel, you can move on to studying information that will allow you to answer the question - pellets or coal, which is better? One of the most important characteristics for any combustible energy source is its calorific value, which is where the comparison begins. For pellets and coal, this figure is almost the same and amounts to 4.8 kWh/kg. However, it is worth noting that we are talking about high-quality pellets made from hardwood and high-quality coal. In turn, the calorific value of pellets made from agricultural waste will be slightly worse.

Another important characteristic for any type of solid fuel is its cost - due to the high consumption during the heating season, any buyer pays close attention to it. In this review, we will not give prices for coal and pellets, as they often change and depend on the number of offers on the market. Regarding this issue, it is only worth noting that if previously fuel pellets were somewhat more expensive than coal, at the moment the situation has changed dramatically

Now a ton of high-quality wood pellets is equal in price and has even become cheaper than a ton of the same high-quality anthracite

Regarding this issue, it is only worth noting that if previously fuel pellets were somewhat more expensive than coal, at the moment the situation has changed dramatically. Now a ton of high-quality wood pellets has become equal in price and has even become cheaper than a ton of the same high-quality anthracite.

Next, we move on to comparing the performance characteristics of coal and pellets. The ease of use of both types of fuel differs significantly. Owners of coal boilers need to constantly add rock to their firebox, and also constantly clean the heat generators from accumulating ash. And its level in some types of black fuel can reach 50%. Also, coal dust tends to eat into the ceilings and walls of the room, so a boiler room of this type will always be very dirty. In addition, we should not forget about the harmful chemical compounds that will be constantly released into the atmosphere during the combustion of such fuel.

As for wood pellets, they are much more practical and easy to use. An extremely important fact is that pellet boilers are fully automated. Such heat generators are equipped with a special tank containing a supply of mini-briquettes, which are independently fed into the firebox. Since very little ash remains after the combustion of the pellets, this type of boiler will have to be cleaned very rarely - only a few times per season. And the resulting ash can be used as organic fertilizer. In addition, the operating efficiency of pellet heaters is higher than that of their coal counterparts. An additional advantage of the granules is their organic origin, due to which during the combustion process they do not emit substances hazardous to the environment.

Taking into account the above information, it becomes quite obvious the answer to the question - coal or pellets, which fuel is better? Good quality wood pellets are truly superior to charcoal in most respects as well as ease of use. The high efficiency and practicality of pellets is also confirmed by the fact that in some European countries about half of all households are heated with such fuel.

Use of pellets in Asia

Vietnam ranks third in the world in the production of wood pellets. In 2022, about 3.2 million tons of pellets were produced here. The figures are second only to the USA and Canada. Most of the fuel was destined for Japan and South Korea, the largest buyers of biofuel outside Europe.

Photo source: 1000dosok.ru

As part of campaigns to phase out fossil fuels, coal-fired power plants are being forced to switch to pellets and other fuels. Proponents say the pellets produce fewer carbon emissions in the long run. Unlike coal, they are produced from renewable sources. However, experts from the British non-governmental analytical center Chatham House note that the use of pellets can inspire false optimism.

Heating a private house without fuel

In regions where there are enough sunny days all year round, they are starting to use heating of a private house without fuel. It would seem nonsense, but it is true. Traditional local fuel systems are being replaced by systems that convert solar energy into thermal energy. To do this, it is enough to purchase special radiation-absorbing screens from specialized trading enterprises, usually installed on the roofs of houses (less often on the ground) and connect them to electric coolant heaters. The generated electrical energy is enough not only to heat the house in winter, but there will also be hot water left for domestic needs. Electric wind turbines are also installed, which consistently generate electricity for heating a private residential home. In short, there are many options, but yours is one.

Modern wooden houses allow you to achieve a high level of comfort. All city communications in a building made of environmentally friendly materials, away from the city limits: isn’t this the dream of any metropolis resident? First of all, a high-quality heating system helps to achieve such conditions in a wooden house.

Heating a wooden house today means modern heating systems, using boilers of any level of automation, operating on any type of fuel. The specifics of environmentally friendly and high-quality construction of a house from rounded logs places strict technological requirements on engineering systems.

Therefore, when designing heating systems, it is necessary to take into account the permanent or temporary use of the room. If it is impossible to connect to the central heating network, an autonomous heating system for a wooden house is planned.

Price

If we consider coal and pellets from an economic point of view, heating a house with coal is much cheaper. In this case, it is worth considering not only the high cost of the pellets themselves, but also of pellet boilers, which are more expensive than coal boilers. This high cost is explained quite simply: pellet boilers are equipped with an automatic fuel supply device, which immediately affects their cost.

Therefore, we can conclude that the choice of one fuel or another is strictly individual. If we are talking about savings, then it is, of course, coal, and if we are talking about convenience, then it is pellets.

Pros and cons of a pellet boiler

A solid fuel pellet boiler is much more convenient than its counterparts that burn conventional wood. And many people who have tried this equipment have already been convinced of this. Let's see what are the advantages of pellet boilers:

Pellet machines can be equipped with individual hoppers of impressive size.

- Convenient loading of fuel - each fuel pellet weighs a few grams at most; this type of fuel is free-flowing. Pellets are poured into the bunkers directly from the bags, but you can use any spatula (like those used in supermarkets for picking up bulk products). As for boilers, they take pellet fuel on their own;

- Automated operation - pellet heating boilers with small bunkers require one or two approaches per day, and models with large bunkers do not need to be approached for 7-10 days. Some advanced modifications can work according to predetermined programs;

- Low ash formation - pellets burn almost completely, so cleaning is required less often than when using firewood. Also on sale are low-ash granules that burn almost 100%;

- High efficiency - if a classic solid fuel heating boiler using wood cannot boast an efficiency higher than 80-85%, then pellet boilers show an efficiency of up to 93% (almost like gas equipment);

- Ease of maintenance - if possible, you can do without maintenance by third-party companies and specialists;

- Inexpensive heat - depending on operating conditions, pellet boilers can be very profitable. Compared to wood, electric and liquid versions they are very economical;

- Safety – pellet boilers do not use gas, electricity or flammable liquid fuel;

- Environmental friendliness - pellet boilers do not pollute the environment.

Not without certain disadvantages:

When pellets are burned, they leave behind ash, which can be used as fertilizer for the garden.

- Pellet-fired boilers require regular ash removal. However, this disadvantage can be turned into a plus, because ash is an excellent fertilizer for your garden plot, vegetable garden or indoor flowers;

- The equipment is quite expensive - here we mean models equipped with automatic fuel supply;

- Pellets can become damp - they should be stored in sealed factory bags or stored in a dry place.

There are disadvantages, but they are not the most serious. In fact, consumers are only confused by the price - for most models it is high.

If you search well in Yandex.Market, you can also find relatively inexpensive models with a small bunker and a device for automatically supplying fuel to the combustion chamber. Prices for good domestic pellet boilers start at 70 thousand rubles with an equipment power of 15 kW.

The solution is obvious

If heating “the old fashioned way” is so harmful, then it should be replaced by more efficient and safe technologies. One of the worthy options to get out of the situation is to replace old stoves with those that run on pellets - granulated fuel from wood processing residues.

As you already understand, environmental pollution as a result of using this technology is much lower. And the fuel is relatively economical: a kilogram of pellets can give off as much heat as half a liter of diesel. Since everything is automated in modern models, they are easy to operate and less fire hazardous.

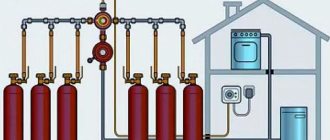

Installation of a heating system includes several stages:

1. Preparatory - visit of a specialist to agree with the client on the heating system. selection of components for the project, drawing up the estimated cost of installation and consultation on related work.

2. Design - at this stage, taking into account the structural features of the object, climatic conditions, and the financial wishes of the customer, the heating of a country house is calculated according to the parameters of the thermal regime, calculation of external fences (from the shade). determination of thermal loads (heat loss of premises); boiler equipment operating on the selected type of fuel is selected, the placement of equipment, risers, and mains is determined, and equipment connection diagrams are agreed upon.

3. Installation - heating a country house at the installation stage includes the installation of a boiler room and heating radiators. water or electric heated floors, as well as commissioning work; The heating system is carried out according to the terms agreed with the customer.

From the moment the installation of the system is completed, the heating of a country house

enters the stage of warranty service, which is carried out by qualified personnel in accordance with the warranty obligations specified in the coupon. Service maintenance includes carrying out repair work after the manufacturer’s warranty period has expired for the equipment.