In the Baxi gas boiler, error e03 appears after the draft sensor signal. Depending on the equipment configuration, this may be a thermostat in units with an open combustion chamber or a pneumatic relay in models with a closed combustion chamber. Boilers with LEDs will show a "house" or "fan" icon.

For high-quality and safe operation of gas equipment, normal draft for exhaust gases must be ensured. Under no circumstances should combustion products enter the premises. These factors are controlled by the automatic gas boiler. If the required conditions are not present, the sensor is triggered and the equipment generates error e03.

What could be the reasons for the error?

Here are the most likely reasons for the lack of draft in a gas boiler:

- insufficient diameter of the exhaust channel (chimney) - design error, contamination with dirt, icing of the inner wall. The diameter of the chimney has decreased - the draft is insufficient.

- exceeding the permissible length of smoke exhaust pipes. It is necessary to familiarize yourself with the manufacturer’s recommendations for installing the boiler and check that the necessary requirements are met. A horizontal section of the chimney pipe that is too long will result in a lack of necessary draft.

- The pneumatic relay is faulty - the traction sensor. It is checked by the presence of a characteristic click when a vacuum is created in the supply tube (you can simulate it yourself).

- missing or poor contact of the sensor with the board

- Venturi device is faulty (melted or clogged)

- the presence of condensate in the tube connecting the pneumatic relay with the Venturi device (true for boiler models without a special condensate collector)

- incorrect connection of tubes to the pneumatic relay

- fan is not working properly. May be due to clogging of the fan impeller, lack of sufficient lubrication on the fan shaft (does not develop the required speed)

- lack of normal contact between the control board and the fan

- malfunction of the boiler board (more common on LUNA (SLIM) series boilers)

For turbocharged boiler models:

For boilers of the Main 5, ECO-5 Compact series with a closed combustion chamber, the error may also be caused by incorrect setting of parameter F43 when configuring the control boards.

Some sources indicate that the cause of error E03 may be a faulty control board.

We have been repairing control boards of gas boilers for several years, so we can responsibly say that the probability of a board malfunction with such an error tends to zero. Instructions for many models of Baxi boilers are also available for download on our website.

Next, we will examine in more detail possible options for eliminating the error.

How to proceed

Check electrical parameters

Imported boilers are sensitive to U, f.

Manufacturers do not take into account the nuances that we constantly encounter: voltage surges, increased/lowered values, phase imbalances and other “surprises”. With an autonomous power supply, error E98 of the Baksi boiler is caused by incorrect operation, failure of the source (diesel, gas generator). Check, make adjustments - for this, the owner of the object does not need the help of a service technician. Uninterruptible power supply SKAT

Check grounding

This is the main reason for the appearance of error E98 in Baksi boilers installed in apartments. In houses built according to old designs, grounding is not provided. It is easy to verify by removing the cover from the socket: two wires enter the nozzle box - phase and zero.

In the private sector, circuit testing is carried out with a device - a megohmmeter. When measuring resistance, R should show no more than 4 ohms.

Grounding the baxi boiler

Check the potential on the metal part of the boiler

Error e98 may be associated with interference (stray currents). They appear for various reasons (a power line is located nearby, a powerful radiation source, the insulation of a power cable is damaged, or something else), but the result is the same: where there should not be potential, it is present.

Advice. The gas pipe is metal, laid in the ground, so the energy going into the ground is “collected” on it. To eliminate the influence of interference on the electronic board, you need to install a dielectric coupling on the main line (between the shut-off valve and the Baxi boiler). Helps get rid of error E98 and a number of others.

Connecting a dialectical coupling

one dielectric coupling

Check boiler settings

One of the reasons for error E98 after replacing the Baksi electronic board. The code appears if the parameters (F03, 12) are entered incorrectly. To correct the configuration, you do not need to call a service technician - the instructions describe in detail the setting method.

Error e03. Checking chimneys.

First of all, it is necessary to carry out a visual inspection of the chimneys. It happens that the head of a coaxial chimney at the outlet can be equipped with a fine mesh to prevent the entry of large objects. In winter, when conditions are created for the formation of frost and this mesh is covered with frost so that air intake completely stops.

The rules clearly stipulate how chimney pipes should be installed for different building options. Incorrect installation of chimneys (for example, lack of slope or too long pipe sections) can lead to boiler shutdown under certain weather conditions.

The formation of ice or icicles is not a rare occurrence; ideally, when designing the boiler installation site, even the wind rose of a particular region should be taken into account.

If we are talking about the summer period, then the reason for the “narrowing” of chimneys may be spiders making webs or birds making nests. Here, I think everything is clear.

Carefully inspect the intake pipe and the air outlet pipe, if there are no obstacles there, you can proceed to consider the following possible causes of error e03 baxi.

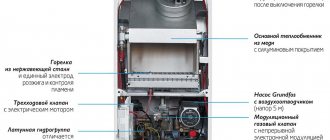

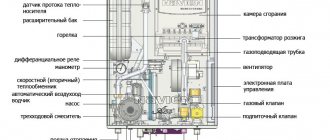

Checking fan operation (for turbocharged models)

To evaluate the operation of the fan, you need to remove the front cover. First of all, when the boiler is operating, you need to check whether it rotates at all. This can also be assessed visually - there are rotating blades on the front part. If rotation does not occur, you need to turn off the boiler and try to rotate the blades yourself to eliminate the possibility of jamming and evaluate how freely the blades rotate. There should not be any difficulties, rotation should occur evenly without extraneous noise.

In practice, several problems are often encountered: the lubrication in the fan axle bearings runs out, the internal blades become overgrown with dirt, and the axle bushing wears out (less often).

In the BAXI ecofour boiler, the fan can be easily removed along with the top cover of the combustion chamber. And inspect the turbine blades and, if necessary, clean them of dirt. The bearing is lubricated with a special high-temperature grease; if the axle bushing is broken (this happens during long-term operation with dirt on the blades), it will have to be replaced.

If the fan does not start when the boiler is operating, it is necessary to check the reliability of its connection to the board and preferably the presence of voltage at the terminals (220V). A common reason is the failure of the relay on the board responsible for turning on the turbine, but in this case, the diagnostic system will record an internal error on the board. If all checks have shown that everything is in order here, we move on to the next stage of troubleshooting.

For service technicians, Baxi boilers have a special outlet (black, located at the fan outlet). If you have a device, you can measure the vacuum created (it should be approximately 45 mbar).

Features of operation and diagnostics

Baksi boilers have some features that distinguish them from other similar devices and which are an undoubted advantage during operation.

- Adjustable flame, gradual ignition. First, the burner heats up the combustion chamber at minimum power for one minute, then it switches to the level set by the electronics.

- The temperature control sensor maintains the flame power required for the set mode. Thanks to this, the number of on-off cycles is reduced, and wear on the injectors, combustion chamber, and coils is reduced. As a result of all this together, the service life of the unit increases.

- Reduced gas and electricity consumption thanks to the post-circulation system. The coolant continues to circulate even after the burners are turned off until a signal is received from the electronics to reduce the temperature.

- Double temperature control. This means that you will be able to control the boiler not only from the room where it is installed, but also outside, using additional sensors installed there.

- Small dimensions and weight. Possibility of connecting both wall and floor models according to standard circuits, depending on the conditions. This minimizes the occurrence of faults and ensures ease of troubleshooting.

- The operating instructions for Baksi gas boilers indicate that they can be used in conjunction with boilers of a similar brand to obtain better results.

- Flexible control system thanks to direct connection of control electronics.

- Stable operation of the boiler under pressure changes of water and gas.

Diagnostics and adjustment of boiler operating parameters is carried out only by specialists after installing the boiler in the room using an electronic display and control buttons. All boiler malfunctions have their own codes, thanks to which you can determine the type of malfunction and, accordingly, choose a method to eliminate it. Floor-standing units are sensitive to improper installation, which will also cause increased noise during operation, popping noises at the moment of ignition, etc.

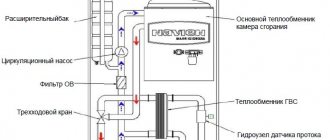

BAXI e03 error due to a faulty traction sensor (pressostat)

To put it simply, the draft sensor is a gray box connected by tubes to a fan. The operating principle is extremely simple: the contacts are normally open and close when a vacuum occurs in the outlet pipe. That is, if the vacuum is insufficient or absent, the boiler simply does not start or stops if the boiler was working.

You can eliminate the malfunction of the pneumatic relay as follows: when the boiler starts, the fan starts working, then the signal for the control unit to ignite should be the closing of the contacts of the pressure switch relay, therefore, you can close them manually to simulate operation. If ignition occurs, the cause must be sought either in the sensor itself or in the connection with the outlet pipe.

You can check the operation of the relay inside the sensor by creating a vacuum through the supply tube (suck air from it) according to the characteristic sound of operation - a click. The pneumatic relay itself may have two outputs, one of them is simply open, and a tube from the fan is connected to the second. I read once on a forum that one of the users had a tube connected to the wrong outlet, but how the boiler worked before is a mystery.

Error E 02 - the emergency overheating thermostat has tripped

The thermostat is a sensor that is located on the outlet pipe from the main heat exchanger of the boiler and is designed to block the boiler if the coolant boils. This is a mechanical sensor whose contacts close when the maximum temperature is reached.

Overheating (boiling) of the boiler is most often caused by poor circulation of the coolant (filters are clogged, the heat exchanger is overgrown with scale, air in the heating system) or problems with the circulation pump. At the same time, boiler boiling is most often accompanied by a characteristic crackling sound in the area of the primary heat exchanger. If there is in fact no overheating, then you should look for the problem in the sensor itself: poor contact with the control board or a breakdown. You can check the sensor very simply with a tester: remove the sensor connector; at temperatures below 90 degrees, the contacts should be closed.

In case of real problems with circulation and overheating, the NTC temperature sensor of the heating system is usually triggered first (records a too rapid rise in temperature).

BAXI error E 03. Condensation in tubes

Another option for the occurrence of error E03 on the boiler is

is condensate, which under certain conditions can accumulate in the tube. It can either get on the relay itself, or simply affect the amount of vacuum and prevent the relay from operating.

Boilers of a later production date are equipped with either special extensions to collect condensate or insulated tubes to prevent its formation. If you see drops of liquid, you can remove the tube and blow it out.

Other malfunctions and solutions

In addition to those described above, other codes may appear on the display during operation:

- E111 - appears when the supply fluid is heated above 95 degrees. Press and hold the Reset button for a couple of seconds. If the value does not disappear, you need to call service.

- E129 - fan speed is below the minimum permissible. You need to contact a service center for repairs.

- E153 - accidental pressing of the “Reset” button. What you need to do to set the previous mode is just press and hold this button until the settings are restored.

- E154 - lack of flow circulation. To resolve the problem, contact customer service.

We invite you to watch a video about eliminating error E03 on a Baksi boiler:

Damage to the Venturi device

This malfunction most likely occurs on boilers from other manufacturers and boilers, but I think it is necessary to describe it too. Since the plastic tubes themselves are located near the gas burner, there is a possibility of exposure to high temperatures.

This mainly happens due to the presence of other malfunctions, for example, a primary heat exchanger clogged with scale or prolonged operation of the boiler at maximum power. The tubes of the device simply melt, and any, even the slightest, deformation leads to the entire system not working correctly and the unit stopping.

If the information from this article was useful and helped you, you can share it with your friends using the social buttons below.

Almost everything described above can also be viewed in the video, which describes error e 03 in detail:

Error E03 if the control board is faulty

Indication of a chimney error in baxi boilers due to a faulty board is not so common - but is nevertheless possible for some models. Most often, baxi luna3 (luna3 comfort) boards are sent for repair with this error. The main symptom (and how to identify the cause) is that the fan does not turn on (or does not turn on periodically). Unlike the boiler boards of the Ecofor or Mainfor series, the self-diagnosis system of which detects a malfunction of the fan relay with error E00 - on the moon boards this may be a lack of power to the fan and an error in the pneumatic relay due to the lack of a sensor signal during the control time.

In practice, the cause of the malfunction looks like this in the photo (you can see the burnt and oxidized contacts of the relay that turns on the fan):

If you are interested, we have posted an article on our website with a complete list of error codes for Baxi boilers.

Error E35 on a Baxi boiler, how to fix it

Reboot the boiler. On the Baksi panel, the Reset (R) button: after pressing and holding for 2 seconds, the false error E35 will disappear. If the code appears again, the following procedure is recommended.

Restart the boiler Baxi boiler

Check what

Presence of condensate

Dampness is the cause of error E35 in a gas boiler. If Baksi is in an unheated room, after a long period of inactivity, the appearance of code 35 is expected: you need to evaluate the condition of the ionization sensor. In conditions of high humidity, it gives a false signal of the presence of a flame, even when the valve on the pipe is closed. Located in the chamber, it serves to record the current between the metal of the boiler burner and the sensor electrode; in some models Baksi is combined with an ignition device. When the unit is not working, in damp conditions, it produces a parasitic signal on the board, which generates error e35.

Baxi boiler ionization sensor

Solution to the problem:

- dry the combustion chamber with a stream of warm air (hair dryer, heater or the like);

- if the Baxi boiler is installed in the kitchen, organize an effective exhaust hood. The cause of error E35 is increased humidity.

Electrical parameters

Deviation from the value specified in the instructions for Baxi (~230V) initiates malfunctions in the electronics and causes the boiler to stop with an error.

Tips. If there is a power line near the object, another source of powerful EM radiation, an error in the Baxi E35 boiler is not uncommon. Under such conditions, the operating algorithm of the electronic board is disrupted and a false fault code is generated. Incorrect functioning of the external stabilizer also causes code 35.

Recommendation. One way to get rid of error E35 is to install a cut-off fitting (dielectric coupling) on the gas pipe between the boiler and the tap. It will prevent the influence of stray currents and interference on Baksi electronics. Sources of interference include power lines, tram lines, electrified railway tracks, and the like during accidental breakdowns. Electricity “dumped” into the ground, passing to the metal of the gas main, affects the “brain” of the boiler, causing error E35.

one dielectric coupling Connection of a dialectical coupling

Connection diagram to the dielectric coupling

Grounding

This is faced by users who are piping the Baksi boiler on their own, and by owners of apartments in high-rise buildings. The connection must be checked when the unit is put into operation for the first time. It is not without reason that violation of the grounding procedure, its non-compliance with the requirements of the PUE, is the basis for removing the heating installation from the factory warranty.

Grounding the baxi boiler

This is specifically stated in the manufacturer’s instructions, which, unfortunately, not everyone carefully studies. Poor connection of the Baksi boiler to the circuit causes malfunctions in the control board, an emergency stop and the display of error E35. At home, the reliability and effectiveness of grounding can be easily determined using an indicator screwdriver by the absence of glow when the probe touches metal parts, components, or the body of the Baksi boiler.

Gas valve

Its leakage is the cause of error E35. If the solenoid valves do not completely block the gas path after removing the opening command, the Baksi boiler ionization sensor detects the burner flame. Its repair is a separate topic, but it is more rational to replace it: the defect is associated with the depletion of the resource.

Electronic board

If error E35 is present, after taking measures, you need to check this unit. Baksi boilers (depending on the year of manufacture, series) are equipped with different boards. While functioning identically, they differ in their response to external factors (power supply, interference, grounding). Honeywell boards are the most “sensitive” to moisture.

How to proceed

Rinse the surface. To remove dust, which when moistened becomes a conductive layer, isopropyl alcohol and a brush (with medium-hard bristles) are used; in laboratory conditions, an ultrasonic bath is used. After removing contamination from the electronic board and drying it, error E35 will disappear.

Install a new unit into the boiler. You should consult a professional on this issue - not all boards are interchangeable. The product specification (numbers, letters) is indicated on the panel

When ordering (selecting) an electronic unit, you need to take this code into account - there will be no errors. Owners of Baksi mainfour should know that these boilers are equipped with boards of 3 options: one has a different circuit and is not interchangeable.