All modern gas boilers are equipped with electronics. For normal operation of the equipment, a control board is required. If malfunctions occur, the automation gives a signal and an error code is indicated on the screen of the gas boiler. The operating instructions for the gas boiler describe the causes of errors. Let's look at the most popular error e01 in Baxi gas boilers in this article. In our store you can buy gas equipment.

Resetting error e01 in a Baxi gas boiler

Before you start troubleshooting the problem yourself, you should study the instructions for use and recommendations from the manufacturer. If you are not confident in your abilities, it is better to contact a qualified specialist.

This error is serious and does not allow the equipment to continue operating without its elimination. You need to reset the error by pressing and holding the R button for a few seconds. After this, the gas boiler should be started as usual.

Decoding

The Baksi manufacturer's instructions speak about error e04 in general terms: lack of ignition or frequent flame failure, but there is only one recommendation.

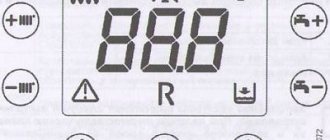

Error e04 on the Baxi boiler control panel

Its presence and the stability of the combustion process are monitored by an ionization sensor (current). Knowing that the boiler’s operation is blocked after 3 unsuccessful ignition attempts or six short-term flame failures, it becomes clear that it is impossible to unambiguously diagnose the reason for the appearance of this fault code. To reduce the time required to restore the functioning of the heating unit, this procedure is recommended.

Step 1

Restarting the Baxi boiler: by pressing (holding for at least 2 seconds) the R button on the control panel. If error e04 is caused by a random factor (power failure or other), it will disappear.

Reset error e04 on the Baxi boiler control panel using the reset button

Step 2

Checking the burner operation. When starting the Baksi boiler, characteristic clicks are heard as a spark jumps between the ignition electrodes. If the ionization sensor detects a current whose value is 6 times lower than the operating one, the control module generates an emergency stop error with code e04. The flame is easy to see through the viewing window. Its instability, small tongues, and uncharacteristic shade are regarded by the boiler automation as a violation of the combustion process and gives a command to activate the protection.

The baxi boiler works like a fireplace.

Step 3

Checking the ionization (flame) sensor. Baksi boilers are reliable heating installations, and the vast majority of problems that arise are not related to the equipment, but to external factors or incorrect user actions during operation.

Baxi boiler ionization sensor

Boiler Baxi mainfour 240 f error e01

This model of gas boiler includes a fourth-generation bithermal heat exchanger. The difference between this unit and the 24 brand boiler is the white display panel.

The Baxi mainfour 240 f gas boiler is single-circuit, which is equipped with a fan for forced removal of combustion products. The equipment of these elements is indicated by the letter F.

The operating principle and ignition scheme of this model are the same as those of other Baxi gas boilers. If error e01 occurs, you should follow all the recommendations that we will discuss in this article.

Preventive recommendations

Modern gas boilers are very practical and well-thought-out units; they have absorbed the best experience of past decades combined with the latest developments in the field of boiler materials, automatic control and protection. They are made in blocks, with the ability to replace worn parts and assemblies.

Units that are operated according to the manufacturer’s operating schedules are able to operate for decades without emergency stops or replacement of components.

The weakest components of the Proterm boilers and Buderus boilers:

- Heat exchanger - serves to transfer heat from flue gases through a developed pipe surface to the water of the heating circuit: heating and hot water. The duration of its operation largely depends on the quality of tap water and the presence of hardness salts and suspended impurities in it, as well as on the temperature conditions in the network. At temperatures above 70 C, hardness salts are intensively deposited on the walls of pipes on the water side, gradually clogging the flow area. Low circulation causes overheating of water and pipe walls, on the surface of which fistulas form due to excessive overheating. At the slightest suspicion of the presence of scale in the pipes, chemical cleaning of the internal surface of the heater is carried out using the technology and reagents specified by the boiler manufacturer. In order to prevent scale formation, water purification filters are installed at the entrance to the boiler.

- Circulation pumps. According to the new operating rules, the gas boiler operates using a closed heating system, which increases the efficiency of heating rooms and the ability to automatically control thermal conditions. Pump repairs are usually caused by damage to the mechanical and electrical parts of the structure.

- The temperature sensor of the heating circuit produces a parameter that is the main one in the automatic mode control system, in connection with which the boiler is turned on/off; its malfunction may be in the contact group or caused by a break in the communication line.

- A gas burner is the main device of a boiler, which burns fuel to produce thermal energy. Repairing this device involves cleaning the nozzles.

- The expansion tank is a unit that compensates for the excess pressure of the medium that occurs during the heating process. Repair is carried out by replacing elastic membranes.

Most of the parts and components for repairing a boiler unit are available in the retail chain, they are also easy to find on the Internet, but if the boiler is under warranty, it is recommended to purchase them through service centers, which will guarantee not only high-quality repairs, but also its durability.

Boiler Baxi Eco Four 24 f error e01

The Baxi Eco Four 24 f heating boiler is a double-circuit turbocharged boiler with a closed combustion chamber. One can highlight the difference from the previous model - a second plate heat exchanger for heating water.

The main cause of the boiler ignition error may be a malfunction of the electronic board. For an accurate diagnosis, you must contact a qualified specialist.

In this model, the ignition element is located on the board, and it is difficult to independently identify the cause of the error. The eco four and main four electronic boards can be replaced and customized for a specific model using parameter settings in configuration mode.

You can buy spare parts for Baxi gas boilers from us.

Briefly about the main thing

Baksi gas boilers do an excellent job of heating a home and last a long time if used correctly. Errors e01, e03, e10 that occur can often be corrected independently without the help of a service specialist. In some cases, it is necessary to increase the pressure in the heating circuit, in others, to check the serviceability of the power supply. Self-checking the sensors and electrodes will also help determine the cause of the error. Knowing the mechanics of the boiler’s functioning, you can easily eliminate the malfunction that has arisen.

Why does error e01 occur in a Baxi gas boiler?

Most often, this error indicates a failure to ignite the burner of the heating equipment. This signal comes from the flame control sensor. This element is an electrode that detects the presence of a flame and stops the operation of the gas unit if the combustion of the main burner is incomplete or gas supply interruptions occur.

Let's look at the main reasons for the error:

- No signal or poor signal contact with the flame control sensor.

- There is no gas supply to the system or insufficient pressure.

- The flame control sensor has failed. May occur due to breakdown or contamination.

- On phase-dependent models, the power supply may not be connected correctly.

- Insufficient air for normal combustion. For example, the intake pipe is clogged or there is no draft.

- Control board faulty.

If 3 unsuccessful starts occur, the boiler is blocked. In order to restore operation, you must hold the R button for several seconds.

You can find some possible causes of the error yourself. For example, the presence of contamination and air access, contact with the sensor. If after eliminating the error the error appears again, it is recommended to contact a specialist.

Automation

Automation for boiler equipment is very diverse. Some of it is preinstalled by the manufacturer. This category includes all sensors and electronic devices that ensure the safe operation of equipment.

The simplest example is a sensor that monitors the normal gas supply. When the gas is turned off, the sensor is triggered and the boiler automatically turns off. Restart will occur after the gas supply is restored.

Systems that ensure operational safety also include:

Boiler structure

- Frost protection (starts to work if the outside temperature is below 5 degrees).

- Protection against blocking of circulation pumping equipment.

- Protection against blocking of the three-way mixing valve in case of long-term equipment downtime.

- Protection against scale formation in the heat exchanger and boiler.

- Overheat protection.

- Voltage protection in the electrical network.

- Control of stray flames.

- Combustion and draft control.

- Coolant pressure control.

In addition to the pre-installed automatic systems, you can install additional electronics:

- Outdoor temperature sensor.

- Room temperature sensor.

- Thermostat.

- Electronic thermostat.

- Remote panels.

- Weather dependent sensors.

- Elements for remote control.

- Water quality sensors, etc.

Incorrect gas boiler power connection error e01

In any Baxi gas boiler, it is necessary to observe the polarity of the phase and zero connections. If the equipment was connected incorrectly, error e01 will appear. To check, you should turn the connection plug over or check the corresponding connectors on the board. The first option is the simplest.

Do not forget about grounding the gas boiler. In accordance with the PUE standards, all metal elements must be grounded. If the work is performed incorrectly, problems with electronics may occur.

A little more about electricity

In addition to the need for grounding, there are other nuances when connecting boilers:

Baxi luna 3 comfort 240 fi

Gas boiler equipment ensures stable operation in the range of 170-250 V. When the voltage drops, the boiler turns off, and when the voltage rises, the varistor burns out. The sinusoid in the power supply must be free of interference. Such devices do not tolerate power surges well. Experts recommend connecting additional voltage stabilizers

You should not use UPS for installation of gas heating appliances. The connection must have a separate machine. For phase-dependent models, it is important to ensure that zero and phase match.

Malfunction of the flame control sensor in the Baxi gas boiler

Some manufacturers recommend changing the igniter. But this is not necessary in all cases. The igniter may need to be replaced depending on gas quality, air pollution and conditions of use.

It is necessary to inspect and clean the electrode if necessary. This can be done with an alcohol solution, and then check the gap relative to the burner body and the correct position in accordance with the instructions. Each Baxi gas boiler model may have different requirements.

The flame control function is performed by the ignition electrode. The main function of the gas boiler safety system is flame control. It is necessary to automatically shut off the gas if the flame on the burner goes out. The operating instructions indicate the required gap that needs to be set.

The flame monitoring function consists of recording a small current that flows through the electrode during combustion. Since the flame structure contains an air gap, if the gap is small, the flame will not be registered, and, consequently, an accident will occur when the gas boiler operates at a certain power.

The electrode cannot be bent, as in most cases it breaks off.

Check what

Pressure

The manufacturer recommends maintaining the value within 0.7–1.5 bar (for a cold circuit).

Bringing the coolant level in the system to normal eliminates error 12 of the Baxi boiler. Advice. If there is a regular drop in pressure, it is necessary to check the equipment and circuit: the reason is a leak. If it is insignificant, puddles on the floor are not visible - the liquid does not have time to drain down due to evaporation from the hot surface. To identify the problem area, let the system cool, and then visually it is easy to find a microcrack (in connections, pipes, heating radiators and other places) by looking at spots and stains.

A pipe is leaking in the heating system

Air in the system

The accumulation of bubbles impedes the movement of the coolant, or even blocks the circulation channel. As a result, error 12 appears on the display of the Baksi boiler. You need to bleed wherever it is provided, including the pump and expansion tank. Automatic valves may not work due to poor fluid quality or deposits; you should not rely on them - only bleed air manually.

Air lock in the heating system

Filter

In Baksi boilers, a removable element is installed at the inlet (pos. 19). Prevents sediment from the return line from clogging the heat exchanger and internal pipes. Cleaning the filter removes error 12 Baxi.

Boiler filter baxi

Boiler pump

Baxi are equipped with pumping devices with a “wet” type rotor. The coolant constantly flows around the inside of the pump, performing the functions of lubrication and cooling. Scale that forms on structural parts leads to a drop in shaft rotation speed. As a result, the Baksi boiler pump does not reach its designed capacity, circulation decreases, and error 12 is displayed.

Boiler pump Baxi Mainfour 24f

The simplest test of the pump is performed by turning its shaft by hand. The voltage is removed from the Baksi boiler, the plug is removed from the end of the pumping device, and the tip of a flat screwdriver is inserted into the rotor slot. The condition of the mechanical part is assessed by how easily the shaft rotates.

The cause of error 12 may be a problem with the electrical circuit: the voltage value at the pump terminals is lower than required. Power and signal lines are checked, their integrity, and the reliability of contacts. To determine whether the pump is working, you need to apply power directly. Although error e25 indicates a complete blockage of the circulation channel, when searching for the cause of fault code 12, everything is assessed - the hydraulic sensor is characterized by a sensitivity threshold.

Advice. If there is difficulty in rotating the shaft, you need to dismantle the pump and inspect the impeller. A decrease in the fluid flow rate and error 12 of the Baxi boiler are caused by a mechanical defect (replacement) or scale deposits (rinsing). Repairing complex breakdowns is impractical - a waste of time. It is easier to purchase and install a working pump.

Flow sensor

The electronic board of the Baksi boiler receives a signal of readiness to ignite the burner through the contacts of the microswitch of the hydraulic pressure switch. It is triggered by a movable membrane that responds to pressure in the heating circuit.

Boiler flow sensor Baxi MAIN

Control board fault error e01 Baxi

If all checks have been made and the cause has not been identified, then it is necessary to diagnose and then repair the gas boiler board. In Baxi equipment, the board contains modules and an ignition unit, which are responsible for modulating the flame. If these elements fail, error e01 will appear. For diagnostics, it is recommended to consult a specialist.

If the cause of error e01 is a malfunction of the electronic board, then you need to contact a service center, where experienced specialists will perform all the work in accordance with safety standards and regulations.

In our online store you can buy a Baksi gas boiler.

Check what

Signal line status

An open circuit, melted conductor insulation, unreliable contact (or lack thereof) are the causes of error e27. The defect is detected visually after tilting the bottom panel of the Baxi boiler.

Baxi boiler control board at the bottom of the boiler

NTC mount

Unreliable contact with the pipe causes error e27. Typical for Baxi boilers with overhead measuring instruments when the clamps are loosened.

Ariston gas boiler temperature sensor

Temperature sensor performance

One option is to swap the NTC of the DHW and DHW circuits. In Baksi boilers, these devices (thermistors) are identical. The disappearance of the E27 fault code indicates the cause of the error.

Assessing the suitability of an immersion type NTC sensor begins with its removal and inspection. The coolant is first drained from the Baksi boiler. If the owner does not pay attention to the quality of water treatment, scale forms on the sensitive element of the device, the characteristics “float”, which causes error e27 to appear.

Baxi boiler temperature sensor

Testing is carried out with a multimeter (in resistance measurement mode, Ohm). R=0 – breakdown of the p/n junction of the semiconductor device, =∞ – internal break. The instructions for some Baksi boilers contain a graph of R versus t. If absent, you can compare with the values: at room temperature (25 C) the multimeter shows 10 Ohms, at 40 - 5. A significant deviation is the reason for rejecting the sensor. It’s easy to find and inexpensive (600±100 rubles depending on the region). After installing a working NTC, error e27 will be removed.

If the Baxi boiler has a surface-mounted temperature sensor, check the layer of special paste under the device holder. A decrease in heat transfer affects the temperature measurement, error e27 is displayed. Eliminated by applying fresh thermal paste.

Serviceability of the electronic board

An extreme case is if error E27 is not removed by the measures taken. Self-testing (without diagrams, guidelines from the Baksi manufacturer, special equipment, experience) is a futile task: for diagnostics you need a stand. If, after replacing the DHW sensor, code 27 continues to be displayed, contact the service center. His representative will replace the board and send the faulty one to the laboratory to check and eliminate the defect. Advantage of the solution: the Baksi boiler will not be idle, and the home will not be left without heating.

I01

This error can appear either independently or in combination with errors E5 and E6. Indicates contamination of the coolant, which is causing the heater to suffer. The problem is solved by dismantling and cleaning it using special means.

Some models have the ability to pour a cleaner into the system and drain it after a certain time. All manipulations are performed only by a specialist. Dismantling without skill and experience is strictly prohibited.

E6

Malfunction of the hot water control sensor, which happens after 10-12 years of operation of the boiler. The cause is usually oxide compounds, which you can either try to clean or completely replace the sensor with a new one.

The board itself can also give an E6 error. This happens when there is a power outage in the network. You can try to reboot the boiler using the “Reset” button. If this does not help, call the experts.

E9

The error code signals a critically low temperature of the coolant in the system, which is fraught with freezing. This happens when the boiler has not been used for a long time, and the temperature in the room drops to 0 degrees. In an apartment this error is less common than in private houses.

Expert opinion

Grebnev Vadim Savelievich

Heating system installer

If you need to leave, and you decide to turn off the heating, and it’s severely cold outside, it makes sense to drain the water from the system. It’s easier to ask someone you know to look after the house than to then warm it up from scratch.

Electronics

The heart of the boiler is complex electronics. It is this that ensures the normal operation of the device and will turn it off in the event of a malfunction. The automation will report problems to the owner by displaying an error code. These alphanumeric codes are essentially a description of the problem. They talk about what is broken in the operation of the unit and how the situation can be corrected.

Before talking about the most common error codes, it is worth recalling that independent intervention and repair attempts are not the best solution. Correcting problems without the intervention of a specialist is permissible only within the limits limited by the manufacturer’s instructions.