Almost all modern household gas boilers are controlled electronically. The boiler control board is designed primarily to ensure its correct operation. If problems or malfunctions occur, the automation also informs the user of the cause of the failure in the form of an error on the screen. Error codes and probable causes of their occurrence are usually described in the gas boiler operating manual, and in this article we will look at the most common reasons for the appearance of error e01 on a baxi boiler

.

Attention! Before taking independent steps to troubleshoot your gas boiler, carefully study the operating instructions and manufacturer’s recommendations, or better yet, contact a specialist.

Error e01 is classified as critical, in which the boiler cannot continue to operate until the cause of the problem is eliminated, so it must be reset! Resetting the error in baxi boilers is done by pressing and holding the R button for 2-3 seconds. After resetting the error, the boiler should attempt to start in normal mode.

Boiler baxi mainfour 240f error e01 does not see flame

The baxi mainfour 240f baxi boiler is a single-circuit boiler with one fourth-generation bithermal heat exchanger from a well-known brand; it is usually distinguished from the similar baxi 24 by a white display panel. The letter F in the name means that the model is equipped with a fan for forced removal of combustion products. The principle and functional diagram of ignition of this boiler is no different from other boilers, and if the Baxi Main For 24 boiler produces error e01, you must follow the general recommendations that we describe in this article below or by watching the first two minutes of a video from one of the service organizations (exactly about the reasons errors e01 baxi mine for 24).

Reasons for the attenuation of double-circuit gas boilers with hot water supply function

Double-circuit models of gas boilers spontaneously extinguish (among other things) when the water overheating protection system is triggered. Main reasons:

- mixing hot and cold running water;

- thinning of the gearbox membrane (water unit).

The instructions for most boilers with a water heating circuit (DHW) indicate that two taps cannot be opened at the same time: when cold water is turned on, the hot water flow is reduced, and heat continues to be produced, overheating the heat exchanger. Therefore, at low pressure the gas shuts off and the flame goes out.

To avoid overheating, it is recommended to select a comfortable hot water temperature by changing the position of the regulator on the boiler control panel. If the dual-circuit unit turns off during proper operation, then it is necessary to change the gasket of the water unit, since it is probably already worn out.

BAXI eco four 24 f error e01

Ecofor 24 is a series of double-circuit turbocharged boilers with a closed combustion chamber. They differ fundamentally from the Baxi Main For by the presence of a second plate heat exchanger for preparing hot water. One of the reasons for boiler ignition errors may be the electronic board, but for diagnostics it is advisable to contact specialists in order to exclude all other options for the occurrence of error e01 baxi eco four 24 f. This is due to the fact that the ignition module of these boilers is located directly on the board and the average user is unlikely to be able to figure it out on their own. It is also worth noting that the boards of the Main For and Eco For boilers themselves are interchangeable and are customized for a specific model by setting specific parameters in the configuration mode.

Ways to solve the problem

The problem can be solved in ways that require significant investment, for example:

- using an indirect heating boiler together with a boiler,

- purchasing a new boiler with a built-in boiler.

However, there is a less expensive, but very productive method - inserting an electric storage heater into the hot water supply circuit. Moreover, for this purpose, any standard heater with a volume of 30 liters is quite suitable, regardless of the manufacturer.

Why does the Baxi boiler give error E01?

In most cases, this error indicates that the boiler burner has not ignited (the signal is supplied from the flame control sensor or also called the flame ionization sensor). The sensor is an electrode for determining the presence of a flame and blocks the operation of the gas boiler in the event of incomplete combustion of the main burner or gas supply interruptions.

- Insufficient pressure or lack of gas supply to the system (for example, gas valve malfunction)

- Incorrect connection of the boiler power supply for phase-dependent models

- Poor contact or no signal from the flame ionization sensor

- Malfunction of the flame control sensor (contamination, breakdown)

- Failure of the control board

- Lack of air for proper combustion (lack of draft, clogged inlet pipe)

The boiler is blocked after three unsuccessful attempts to start; to restore operation, you must hold the “R” button for at least 2 seconds (using the example of a BAXI boiler of the eco four or main four series).

Check some reasons for the baccy error e01

you can do it yourself, for example, the presence of contact with the sensor, the state of its contamination and air access, but if the error occurs again, it is better to contact a service organization or service center. Let's look at this issue in more detail.

How does a boiler work?

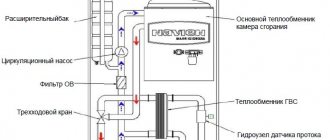

To understand the situation more clearly, you need to understand the principle of operation of the boiler. Double-circuit gas wall-mounted boilers such as Baksi or Ariston consist of several components. In the gas part, the incoming fuel is burned, the water part ensures the supply of heated water from the heat exchangers to the heating system, and the smoke removal part is responsible for removing combustion products outside the home.

Depending on the user settings, temperature sensors adjust the water heating mode. A sensor on the return pipeline turns off the boiler, depending on the achievement of the required temperature set for the return. However, the system pump does not stop running until the heat exchanger temperature drops.

Error E01. Incorrect boiler power supply connection

In BAXI boilers, according to the operating instructions, it is required to observe the polarity of the phase and zero connections, and if the boiler is connected incorrectly, the user will also receive an E01 error. This can be checked either at the corresponding connectors on the board, or simply by turning the connection plug over in the socket. The second is usually the easiest to do.

An important point is grounding the boiler. All metal parts of the boiler must be reliably grounded according to the PUE standards! Improper grounding is often the cause of problems with electronics.

FULFILLMENT OF WARRANTY OBLIGATIONS.

If malfunctions occur during the warranty period, warranty work is performed by the organization that commissioned the product (in the absence of other warranty agreements). BAXI SpA provides compensation for the cost of failed boiler components under warranty through official dealers of BAXI SpA. In turn, official dealers of BAXI SpA compensate the cost of these components to trading companies. To compensate for the cost of a failed component, the service organization must provide, along with the faulty components, a completed “individual repair report form” of the established form or provide the same data in electronic form (using a template file from BAXI SpA). Spare parts are purchased by trading companies or service organizations from official dealers of BAXI SpA for products or spare parts.

Flame control sensor fault (baxi e01)

In general, some manufacturers claim that the “igniter” is a consumable item. Personally, I have a baxi eco four boiler in my apartment and I have never changed it (the boiler is already six years old). But nevertheless, everything depends on the specific operating conditions, gas quality and air pollution. Therefore, you need to carry out an inspection, if necessary, clean the electrode with an alcohol solution and check its correct position and gap relative to the burner body according to the instructions (this may be different for different models). Case from practice: a client complains about the Baxi boiler error E01. We changed the board - the boiler worked for a day and again the same error. What did you do with the boiler before the error appeared? We bent the electrode and made a gap of 1 mm. On what basis? Somewhere someone told, showed...

In Baxi boilers, the ignition electrode also performs the function of flame control. Flame control is one of the most important functions of the boiler safety system. It is needed so that the boiler immediately shuts off the gas supply if the flame on the burner goes out for some reason. The gap must be set exactly as specified in the operating manual for the device!

The fact is that the principle of flame control is to register a small current that begins to flow through the electrode during combustion. And the flame structure has an air gap at the base, and if the gap is too small, the flame will not be registered and the boiler will fail when operating at certain power modes.

We do not recommend bending the electrode under any circumstances - it is very fragile and will most likely break off.

As an option, carefully bend the attachment point.

The boiler does not heat water for heating

So, let's look at the main reasons why a gas boiler does not heat water for the heating system and what to do about it:

- airlock. It is necessary to inspect the heating system for the presence of air in the radiators. To eliminate this problem, you need to install an air vent. Its operating principle is similar to that of an expansion tank, but it is capable of maintaining pressure in the system. Using an air vent, you need to bleed air from the system. It is important to inspect the valve itself for mechanical blockages - scale may be present there;

- corrosion in radiators. Clogging of heating devices can be determined by draining water from the system. If the water flows dirty, then you need to flush the system until visually clean water appears;

- connection errors. Hot water may not flow if the diameter of the pipes is not as specified in the project or instructions. It is necessary to check the compliance of the pipeline, the correct connection and the quality of installation of shut-off valves;

- insufficient pressure in the network. You should try adding water to the heating system, as there may not be enough pressure to trigger the automatic ignition of the burner;

- presence of scale in the heat exchanger. The first sign is prolonged heating of the coolant and heating of the batteries. It is necessary to get rid of sediments and carry out boiler water treatment. To do this, you need to disassemble the boiler and remove the heat exchanger assembly.

Before doing this, you need to shut off the flow of gas and water to the device. Then flexible connectors from the pump are connected to the heat exchanger and it is washed with a composition containing a special cleaning agent, which can be purchased over the counter. After which the parts are washed with water.

Some manufacturers allow the use of antifreeze instead of water in the heating system. This substance can be used in the following boilers: “Baxi”, “Vaillant”, “Proterm”, “Beretta”, “Korea Star”. However, it should be understood that each manufacturer recommends using its own antifreeze;

- filter clogging. If the filter screens are clogged with mechanical debris, the radiators may also have poor heating. Therefore, the filter should be checked and cleaned regularly by rinsing with water. If clogging occurs too often, then such a part must be replaced;

- incorrect setting. First of all, if there is weak or no heating, you need to check the settings of the control unit. The temperature may be set insufficiently and the gas does not heat the water;

- malfunctions of pumping equipment. If the pump power is not enough to ensure good circulation, it may turn off if it overheats. This can happen when the DHW circuit is turned on;

- incorrectly selected heating devices. If the system has radiators with unsuitable heat transfer and design parameters, this can also lead to low heating;

- incorrect slope of pipelines. Most often this problem occurs in systems with natural circulation. Regulatory documentation specifies that the slope of pipes should be 10 mm per meter of pipe. If these requirements are not met, circulation may be disrupted and, as a result, there may be no heating due to low coolant flow.

BAXI error e01. Control board fault

As a rule, if the above checks have been performed and do not reveal a problem, then diagnostics and repair of the boiler board will be required. In the case of Baxi boilers, the ignition unit and modules responsible for modulating the flame are located on the board itself, so their breakdown can lead to error E01. Diagnostics of the control board can only be carried out by a qualified specialist.

You can also watch a short video that shows in detail and clearly the checks discussed.

If you still think that the cause of error 01e

is a breakdown of the electronic board - contact us, we have everything you need to diagnose and repair the boards of BAXI gas boilers: specialist, experience, spare parts, equipment for professional installation. It is possible to deliver boards to other regions of Russia and organize repairs by agreement.

Instructions for many BAXI boiler models are also available for download on our website.

If you are interested, we have posted an article on our website with a complete list of error codes for Baxi boilers.

Description and advantages of the technology

In the offer of the Italian company Baxi you can find various gas, electric and solid fuel heating boilers, which are intended for both small country houses and full-size country buildings. Such equipment is technologically advanced. It is efficient and economical, characterized by reliability and complete safety in operation.

The range of Baksi gas boilers has different capacities

The advantages of this brand’s equipment include:

- ease of maintenance of Baksi boilers;

- high degree of automation;

- affordable price;

- Possibility of choosing units of different power.

The Italian manufacturer produces equipment that can operate on various types of fuel, including pellets, wood, coal, electricity or natural gas.

You can choose both installations with a capacity of several kilowatts, which will be an excellent choice for a summer residence, and equipment that can quickly heat a house with an area of 200-300 square meters.

This video will help you get acquainted with the Baxi brand:

Do-it-yourself cleaning of heat exchangers

To clean the primary circuit, drain the water from the heater. For these purposes, unscrew the tap on the body (usually located on the right).

Cleaning is carried out using Jelly using special liquids. The device is connected to the boiler through pipes, liquid is poured into it and connected to the network. Cleaning takes two hours, changing the direction of fluid movement manually. After this, the liquid is drained and the boiler is restored to its original state.

The secondary circuit is also cleaned using special liquids. Only in this case the gas tap is turned off and the hot water tap remains open. The cleaning liquid passes in a short circle.

Practical recommendations

You can eliminate the appearance of “random” errors (and they are regularly displayed as a result of instability of the power supply) by connecting the gas Baxi to the network via a UPS. Various modifications of blocks are available for sale, designed to work together with household boilers.

The stabilizer and UPS are connected to the Baxi boiler

Unlike a stabilizer, this device will supply voltage to the heating unit even in the event of power line breaks and a malfunction of the backup generator. The autonomy of the UPS is ensured by built-in (or attached external) batteries. Users note that after its installation at the site, the number of Baxi boiler errors that appear is sharply reduced.

AUTHORIZED SERVICE CENTERS AND AUTHORIZED SERVICE PARTNERS OF BAXI SPA

Service organizations can enter into service contracts and thus become authorized service centers and authorized service partners of BAXI SpA. BAXI Authorized Service Partners (ASP) are organizations that have the right to perform first start-up, service maintenance and warranty on behalf of BAXI SpA. repair of BAXI equipment. BAXI Authorized Service Centers (ASC) are organizations that have the right to perform the first start-up and service maintenance of BAXI equipment on behalf of BAXI SpA and assume the following additional obligations: - upon contact, perform the first start-up and carry out subsequent warranty and service maintenance of any BAXI equipment purchased from any trade organization or installed by another organization; - sell BAXI spare parts to all applicants.

Authorized service centers and service partners of BAXI, in agreement with the representative office of BAXI SpA, have the right to extend the warranty period. Also, during warranty repairs, BAXI SpA, in addition to compensation for spare parts, pays the cost of travel and work (according to the contract). BAXI SpA carries out compensation under the warranty through official BAXI dealers, or through direct payments. Authorized service centers and service partners of BAXI are created either on the basis of trading companies that regularly work with BAXI products, or on the recommendation of these trading companies.