Navien boilers are modern heating equipment equipped with automation and a protection system. Sensors for detecting problems of varying levels of complexity allow the user to eliminate many minor problems on their own, without resorting to the services of a service center. The accompanying instructions contain codes that characterize a particular problem in the operation of the boiler. Based on this list, the user can easily find information on solving many problems. In this material we will analyze error 03 and tell you how to fix it.

It is important to mention that for high-quality and long-term operation of the equipment, it is necessary to adhere to the universal rules for operating high-tech devices:

- Responsible approach to equipment installation, carried out in strict accordance with the instructions.

- Using high-quality components and materials that will ensure uninterrupted operation of the equipment for a long time.

- It is important to carry out preventive maintenance of equipment (inspection and cleaning of components).

- Do not forget to check the readiness of the equipment for operation (gas supply, sensor condition, water supply).

By observing these conditions, you can avoid rapid wear of equipment and frequent breakdowns.

The Korean company strives to minimize information on user intervention in fixing problems. This is caused by the manufacturer’s concern for the safety of customers who may make mistakes in fixing a technical problem and thereby harm themselves and their loved ones.

It is important to remember that Navien boilers are complex and explosive equipment. Therefore, troubleshooting on your own must be done with the utmost care, following the clear instructions of specialists.

Fault 03

Each malfunction characterizes a specific problem in the operation of the equipment. So error 03 on the Navien boiler model Deluxe Coaxial 16K indicates that the device has problems igniting the gas burner or gas is not supplied to the burner. This article will discuss fault diagnosis and repair.

If the Navien boiler gives error 03, you need to check the presence of gas in the house, and also whether the gas supply tap located near the boiler is open. Only after you are convinced that the cause of the error is a malfunction, should you start diagnosing the equipment.

Useful tips

- The instructions for Navien gas boilers note the stability of their operation when the supply voltage is unstable, hence the minimal list of errors.

This is ensured by the presence of a security chip in the microprocessor - one of the features of Navien models. But what to do if there is an emergency on the line? For objects located in rural areas, the question is far from idle. Experts recommend turning on the heating unit via a UPS. The unit contains a stabilization circuit, a group of batteries, and a charger. In the event of a power line break, problems at a substation, or with starting a backup generator, an autonomous source will ensure stable, continuous operation of the Navien boiler for several hours (the period is determined by the total capacity of the battery).

- When contacting a specialized organization, you need to clarify whether it is certified by the Navien boiler manufacturer. Otherwise, you will have to face a number of problems, and eliminating error 03 will be expensive. “Simply Workshop” pays for spare parts like everyone else: in retail outlets, via the Internet. And this is time and extra money. As for detailed instructions for testing and troubleshooting Navien boilers, the manufacturer supplies them only to its service centers. This means that specialists from a third-party organization will not be able to do the work really well.

[/vc_column][/vc_row][/vc_column][/vc_row]

Did you like the article? A repost will be the best thanks.

Diagnosis of the error

Let's diagnose and fix this problem. If this blockage occurs, you must try to restart the boiler. To do this, press the “power on” button on the remote control. Re-ignition is in progress. If error 03 occurs again, so now you need to:

- turn off the boiler;

- turn off its power supply;

- close the gas supply valve.

Let's remove the front panel. For these purposes you will need a Phillips screwdriver. It is necessary to unscrew two self-tapping screws located at the bottom of the boiler. And then unclip the two latches on top and remove the lid from the boiler. When a problem arises with igniting a gas burner, first of all, it is necessary to check what gas pressure is present in front of the boiler, and then the operation of the ignition electrodes. Check for spark.

Operating principle of the Navien boiler

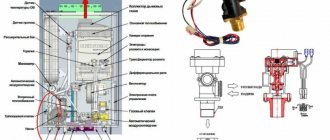

The operating principles of modern gas boilers are almost the same for all manufacturers, the only differences are in the configuration of the equipment and the internal arrangement of the actuators. The flow diagram of water in the boiler is shown in the figures. The Navien boiler works either to maintain the required temperature in the CO, when heated water from the first heat exchanger is pumped by a circulation pump in a large circle, or in the DHW preparation mode. The DHW mode is a priority, which means that if it is necessary to heat the water, a special three-way valve switches the circulation to the DHW plate heat exchanger, and the coolant flow through the heating circuit is blocked. The signal to switch the boiler to the DHW preparation mode comes from the flow sensor located on the hydraulic unit with the make-up tap.

Checking the operation of the ignition electrodes

At the next stage, we will check for the presence of a spark at the ignition electrodes. Using a Phillips screwdriver, you need to unscrew the two screws that secure the electrode block in the combustion chamber. And then carefully remove the electrodes and pull them out of the boiler firebox. Let's connect the power supply and put the boiler into operation. The pump starts up, the fan turns on, we hear the gas valve closing the coils open, but ignition does not occur. No spark. I'm guessing the problem is with the ignition transformer. It requires replacement. Let's turn off the boiler and turn off its power supply.

Check if the spark plug produces a spark

Differences between Navien Ace and Navien Delux

Navien Delux is a modified model that replaced Navien Ace. Navien Delux Coaxial is a series of boilers with two heat exchangers with a power from 10 to 30 kW with a closed combustion chamber and forced smoke removal using a turbine. The manufacturer notes the following features of Navien Delux:

- Frost protection system. Unlike boilers from other manufacturers, in addition to automatically turning on the burner when the temperature drops below 6 degrees, at temperatures below 10 degrees the boiler ensures continuous movement of the coolant by activating the circulation pump.

- Fan with variable speed. Navien Delux boilers are equipped with a turbine with adjustable blade rotation speed depending on the readings of a special air pressure sensor. This ensures an optimal gas-air mixture ratio and increases boiler performance.

- The heat exchanger is made of stainless steel. By using a fan with variable rotation speed and increasing combustion efficiency, it became possible to replace the copper heat exchanger with a stainless steel heat exchanger, which certainly has a significantly longer service life.

- It is also noted that the boilers are protected from the influence of mains voltage surges by a special protective chip and the ability to operate at low (up to 4 mBar) pressure of main gas and water. In other words, the manufacturer tried to make a product that is maximally adapted to the worst operating conditions.

Repair

To remove the transformer, you must:

- disconnect the connector by pressing the lock;

- Carefully remove the ignition electrodes.

Connection occurs in reverse order:

- first the electrodes are connected;

- then the connector is fixed.

Now you can reconnect the power supply and turn on the boiler in operating mode. The pump turned on, the fan started and a spark occurred.

Turn off the boiler again and turn off the power supply. We connect the electrodes to the boiler firebox. It is important to do this very carefully so as not to damage the gasket.

Navien boiler error 02

Error 02 is caused by the heating circuit flow sensor located at the outlet of the main heat exchanger. If nothing prevents the movement of water in the CO circuit, after turning on the pump, the sensor contacts close and the signal is registered by the control unit, otherwise error 02

.

The following main reasons can be identified:

- low pressure in the heating system (to control the pressure, Navien boilers are equipped with a dial pressure gauge located on the front cover - you need to check and, if necessary, feed the system to 1.2-1.5 bar)

- failure of the flow sensor (to check, measure the resistance of the sensor before and after turning on the pump)

- no circulation in the heating circuit

- control board is faulty

Lack of circulation means that for some reason the coolant cannot move normally through the heating pipes. Obstacles can be: clogged cleaning filters, freezing of a section of the pipeline, closed taps around the perimeter of the heating system, the presence of an air lock or a malfunction of the pump.

To remove air, you can try to start the boiler in a special test mode, after first opening the air vent valve on the pump. To activate the test mode, you need to turn off the boiler and move switch No. 1 on the DIP-Switch block of the board to the ON position. We will discuss the testing of actuators in more detail in a separate article.

We recommend watching a video in which one of the users simulates error 02 on a Navien boiler:

Rules of operation and timely maintenance

When purchasing a gas unit to heat your apartment or private home, you should remember that modern devices belong to the category of complex, high-tech, full of automation and protective systems. Therefore, in order to extend the life of the boiler and prevent its premature failure, it is necessary to follow certain operating rules.

- Firstly, this is installation in accordance with established requirements, according to the scheme recommended by the manufacturer, and not based on the advice of a familiar master.

- Secondly, these are high-quality materials and components: savings at this stage threaten to develop into financial costs for boiler repairs in the future.

- Thirdly, this is a thorough check of the condition of the sensors, chimney, water/gas supply before starting the boiler. Inspection and cleaning of main components should be done regularly, and not occasionally.

The automation will tell you the probable causes of problems by displaying coded messages on the display. Experience shows that following these recommendations will help avoid possible serious breakdowns and failures, which means that owners will not have to find out what typical malfunctions the Navienace boiler has and what will be required to eliminate them.

Design Features

Navien's products are quite widely represented on the heating equipment market. Its main advantages are versatility, high level of automation and quality of execution. The equipment of this brand is excellent for providing heat to both office, industrial premises and residential buildings.

Note! The main feature of gas boilers from this manufacturer is the presence of two heat exchangers, which allows for more efficient use of heat. In addition, the products are resistant to corrosion, since all metal components are made of stainless steel.

Both heat exchange circuits are resistant to various types of contamination, are not prone to fouling by small particles and are able to resist the formation of scale, which guarantees constantly high performance. In addition, all components are accessible and easy to operate and maintain.

Gas boilers of the Navien brand have numerous advantages, which makes them such a popular product in the domestic heating equipment market.

- The devices are fully automated, so they are able to function for a long time according to a previously specified program. This is very convenient for country cottages in which the owners do not live permanently.

- Navien boilers are environmentally friendly, since carbon dioxide is mainly released into the air, which is absorbed by trees.

- Reasonable cost - gas heating appliances of this brand have the most attractive cost-quality ratio.

- Easy to operate.

- The equipment is equipped with protective chips that neutralize the effects of voltage fluctuations in the network.

- The boilers are maximally adapted to difficult operating conditions, which is important for Russia.

- High power rating of fans installed in the equipment.

All of the listed advantages of Navien brand heating equipment enable users to receive the required amount of heat at low energy costs. Unique technical parameters also allow the use of boilers in extreme conditions of water and gas supply.

Error e03 in a Baxi gas boiler due to condensation in the pipes

One of the common causes of error e03 is condensation that accumulates in the tube. It hits the relay or affects the amount of discharge, and also prevents the relay from operating. More modern models are equipped with insulated tubes that prevent the formation of condensation or special expansions to collect condensate. If drops appear on the pipe, you can remove it and blow it out.

You can buy spare parts for Baxi gas boilers in our store.

MORA boiler and EFD-503 control units

Case from practice. Several EFD-503 units came in for repair. Such blocks are installed directly on the gas fittings and are used in boilers MORA, BERETTA, PROTHERM and others. So, specifically in this modification of the block, the error reset occurs through the closure of two contacts on the block itself, and the switching is displayed on the control panel with a button. The client says I change the blocks regularly once a year. Tired of replacing it (the price of 1 unit is approximately 10 thousand, and there are two of them in the boiler), he turned to us for repairs. In fact, faults were identified and corrected on the units provided - the units were sent back. Installation result: 1 unit works, two worked for 20 seconds, went into error and no longer work.

The probability that the control unit only worked for 20 seconds after repair is very small (even more so if there are two units at once). A more suitable description of the malfunction is “phasing error” - non-compliance with the polarity of the connection. I ask - what actions does the boiler perform before the error appears? The answer is none, just a mistake and that’s all. Let me explain that the error should be reset, maybe you have a bad contact on Reset. No, about the theory of contact - we know that the blocks are faulty. Okay, send it. The client sends two blocks after repair and two additional blocks from the “faulty” collection. We first install the blocks that were repaired on the stand. Blocks are in error. We reset the error - ignition is in progress, the valve opens, the unit sees the flame - it is working! We deliberately create an error on the block, reset it again - there is ignition, the board works according to logic. We check all four blocks in the same way - everything is in error, after a reset everything works. We provide information to the client about which contacts are closed on the block to reset the error, he takes the “faulty” block from the collection and voila! - works. All questions have been resolved.

Error code instruction

By introducing electronic circuits into the gas boiler control algorithm, manufacturers have made it easier for ordinary users to use the units at home.

Nowadays there is no need to call representatives of the service organization with which an agreement has been concluded for the supply of fuel, inspection and repair of equipment. Errors are displayed on the electronic display in the form of digital symbols, and instructions for correcting them are given in the technical manual.

Sample control panel. In modern electronic models, the display is located on the control panel, and the symbols are clearly visible even in the dark thanks to the bright LED backlighting in red, orange or blue.

Please note: for Navien boilers, information can be displayed in both digital and alphanumeric characters. This means that there is no difference between error “15” and “E15” - it carries the same information. So, let's move on to the symbols, their decoding and instructions for further actions.

Outwardly, it looks like this: the heating circuit is operating normally, and cold water suddenly starts flowing from the hot water tap. The information screen, however, displays information about heating the water to the desired temperature.

Error e03 in a Baxi gas boiler due to a faulty draft sensor

The draft sensor is a gray box that is connected to the fan by tubes. In the normal state, the contacts are open, but close when a vacuum appears, which is created in the outlet pipe. If there is no vacuum or it is insufficient, then the boiler stops and it will not be possible to start it.

In order to eliminate a malfunction of the pneumatic relay, you can perform the following actions: when the equipment is started, the fan begins to operate, after which a signal to the control unit should close the contacts of the pressure switch relay, therefore, you can close them yourself to simulate operation. If in this case ignition occurs, then it is necessary to look for another reason. For example, in connection with a discharge pipe or sensor.

To check the operation of the relay inside the sensor, create a vacuum using the supply tube by making a characteristic click. The pneumatic relay has two outputs. One of them remains open, and a tube is connected to the other. The connection must be made correctly.

The boiler does not light up

If a gas boiler does not ignite, then in most cases there will be an error signal on the information panel indicating its number or code, by which you can approximately find out in which boiler system the malfunction occurred and how critical it is. All double-circuit boilers provide switching between summer and winter operating modes. In summer mode, the boiler will not turn on to heat the room (the same is true when using weather-compensated automation or thermostats).

If the boiler does not ignite and does not make any attempts to turn on (stands idle) when necessary, this may be an electronic malfunction, but such cases are rare and concern specific boiler models.

Usually, if there is a malfunction that prevents the boiler from operating normally, the user will receive an error. That is, if the boiler does not ignite, you need to determine the error code and find its meaning in the equipment operating manual. Error codes with descriptions are always indicated there.

Next, we will consider the most common boiler malfunctions that users encounter. It is worth mentioning here that mostly all modern boilers have the same basic structure and operating procedure. However, to solve a specific problem on a specific boiler, you need to at least read the instructions for that boiler.

Several unsuccessful ignition attempts

This is the very first error code for most equipment manufacturers. For BAXI E01 boilers, for Arison 501 boilers, for Vaillant F28. Ignition of the gas-air mixture in the combustion chamber will occur under two conditions: the presence of gas at the burner nozzles and the presence of a spark. Gas enters the burner through the gas valve, the spark is generated by a transformer on the control board (or remote). A separate case should be noted when ignition occurs, but the boiler cannot detect the presence of a flame and goes out (closes the gas supply valve).

The most common reasons:

Phasing error

. Often, gas boiler boards require connection polarity. For the average user, this means that the position of the plug in the outlet matters. If the connection polarity is reversed, the boiler does not see the presence of a flame, continues ignition (electrode crackling) even when there is already a flame on the burner, then turns off due to an emergency. Even if you did not touch the plug, the polarity could change at the substation!

Ignition or flame ionization electrode

. It can be separate or combined. The main problems may be related to contamination (oxidation) of the electrode or its gap relative to the burner. A dirty ionization electrode prevents the board from detecting the presence of a flame and operation stops.

High voltage wire. High voltage is generated by a transformer and transmitted through a wire to the electrode, where it pierces the air gap between the burner and the electrode with a spark. If a characteristic crackling sound is heard, but a spark on the burner is not visually visible, it is possible that the breakdown is occurring somewhere else. For example, there is a microcrack in the insulation of a high-voltage wire, and a breakdown occurs at the point where the insulation on the housing is broken.

Electrical connection problems

. The presence of parasitic potentials on the boiler body, lack of grounding or low voltage of the supply network can cause problems with ignition. I often hear the argument: everything used to work without grounding. No one will understand how the boiler worked without grounding. According to the operating instructions, this must be done! For normal operation of the boiler there must be: a network voltage of at least 180 volts, a potential between the neutral and ground wires of up to 10 volts, and the presence of grounding.

No gas on the burner

. The gas valve controls the gas supply to the burner: it opens and modulates (gas dosing). The gas valves are regulated and controlled by a control board. Accordingly, the cause of the problems may be a malfunction of the valve (or the need for adjustment), its electrical part, or the control circuit on the board. This device should be checked by a specialist. The lack of gas can also be due to external factors: a faulty meter, dirty filters.

Control board.

In some cases, lack of ignition or flame control is caused by a malfunction of the boiler main board. This can be considered after the other possible causes as described above have been accurately checked.

Insufficient draft (fan does not turn on)

Also a popular problem. If there is a problem with the removal of combustion products, the boiler will not start and ignite until it is completely eliminated. Such malfunctions and their solutions are described in more detail in a separate article - chimney errors.

Insufficient water pressure (refill required)

Traditional gas boilers operate in a closed heating system; accordingly, to prevent the boiler from turning into a hydrogen bomb, there must be a minimum water pressure inside the heat exchanger (in fact, the presence of water and circulation there). The pressure is controlled by a special sensor - a pressure sensor. The boilers are provided with an additional mechanical pressure gauge for the user. Although the systems are closed, the pressure in them can drop over time (for example, water escapes through leaks in the connections). As soon as the water pressure in the boiler drops below the minimum level (0.5 - 0.7 bar), the boiler sensor detects a malfunction and blocks operation. In most cases, you just need to study the readings of the mechanical pressure gauge and recharge the system according to the instructions for the boiler.

How to repair a boiler with your own hands

- If error 02 appears on the display, first of all you need to remove the front panel. It is attached using plastic latches. All wires must be disconnected. Remove the control board. After this, study the location of all contacts. Perhaps they are closed. To do this, use a circuit tester. Then, reconnect the network. Check the boiler. If the situation has not changed, then the equipment needs repair.

- Check the operation of the circulation pump. To do this, remove the boiler lid. When electrical current is applied, the motor must run. Windings often burn out in circulation pumps. This is a common cause of the problem. The windings can be inspected using a special device. Their resistance should be the same and be in the range of 16 - 20 Ohms. If the windings are burned out, then the motor must be replaced.

- Check the flow switch. This relay is responsible for turning the circulation compressor on and off. The relay should operate at a pressure of 4 bar. Therefore it is necessary to measure the pressure in the boiler. To do this, use a pressure gauge. When current is applied to the motor, the relay should operate. Otherwise, it must be replaced. To avoid problems, buy equipment only from well-known brands, otherwise a problem will arise.

- Install the new sensor in its original location. Please note that all sensors have a certain polarity. Incorrect installation may result in malfunction of the boiler. To avoid this error, you need to familiarize yourself with the diagram supplied with the sensors. Be sure to check the integrity of the sensor wire. The wire must be clean and without kinks. Install the front panel last. It is attached with plastic latches.

- Check the functionality of the boiler. After this, you can conduct a test run. After the boiler has worked for 5 minutes, you need to check again the tightness of all connections. Then you can carry out a full check. See what the equipment display shows. If no errors are found, then the boiler can be considered fully operational. After this, you can begin daily use.

Checking chimneys for error e03

When inspecting chimneys, the first thing to do is inspect the chimneys. Often the head of a coaxial chimney is equipped with a fine mesh, which prevents large elements from entering. In the cold season, when frost forms on the mesh, the air intake completely stops.

In the instructions you can see the rules for installing chimney pipes for various buildings. If the chimneys are installed incorrectly in different weather conditions, the boiler may stop working. Reasons could be long pipe sections or lack of slope.

The formation of icicles and ice happens quite often, so it is recommended that when designing the location of a gas boiler, you should take into account the wind rose for a particular region.

In the warm season, the diameter of the chimney may decrease due to cobwebs or nests made by birds. If no problems were identified when inspecting the outlet pipe and air intake pipe, then you can proceed to consider the following reasons for the appearance of error code e03.