Often, a solid fuel boiler becomes the only option that can be seriously considered as the main source of thermal energy for heating a home. The standard situation for many small settlements and countryside villages is that gas mains have not yet reached every consumer, or laying them directly to the house is associated with prohibitive costs. Electric heating, due to the high cost of electricity, seems unprofitable. But local conditions are characterized by the wide availability and low price of firewood or coal. The solution comes naturally...

Buffer tank for solid fuel boiler

But here’s the problem: the operation of solid fuel equipment is always associated with a certain cyclicity - peak production of thermal energy, even in excess quantities, during the main phase of combustion of the fuel load, with a gradual decrease to almost zero during periods of inactivity. Constantly replenishing fuel in the boiler is inconvenient for a number of reasons, it is unprofitable, and in many models it is completely technologically impossible. Is it possible to make sure that the efficiency of the heating system does not suffer from this pronounced unevenness of energy supply, so that during the burning of the fuel fill a reserve of excess heat is created, which can then be usefully used, and not “thrown down the drain”? Yes, this is quite possible - a similar problem is successfully solved by a buffer tank for a solid fuel boiler.

What is a buffer tank

The equipment is a container with an installed heat accumulator. The container itself accumulates excess thermal energy. The container is equipped with a small coil covered with heat-insulating fabric.

The operation of the equipment begins with loading firewood into it. In this case, the container accumulates excess thermal energy, and then this heat is redirected to radiators. Another very important feature of the device is the support of warm liquid in the radiators.

System nuances

Important! Each heating system with a buffer tank implies the presence of a powerful electric pump, which is necessary for continuous cycling of warm air into the batteries.

- When the power supply is interrupted, the thermal system of the buffer tank stops operating.

- At the same time, the burnt material continues to be processed in the furnace, releasing heat.

- As for the water in the pipes, it begins to heat up even more and reaches a maximum boil.

- If the system is not equipped with a powerful pump that sucks out air, an explosion may occur, which poses a direct threat to human life.

It is also worth noting that the buffer system does not require constant fuel supply. This gives the advantage of not defrosting this system due to sudden extinguishing of the boiler.

System operation

Automatic operation of the buffer unit provides the following advantages:

- Timely transfer of thermal energy to the coolant;

- Automatic operation system without human intervention;

- Continuous heat accumulation;

- The liquid does not boil if the power supply is interrupted.

Video description

Video example on how to calculate a heat accumulator:

Next, you need to calculate the mass (volume) of water that would be capable of holding such an amount of thermal energy, using the following formula:

- M = Ke / 0.0012 Δt

- M – mass of water, kg,

- Ke – amount of stored energy, kW,

- Δt – temperature difference between the heated coolant and cooled coolant in the system, °C,

- 0.0012 – heat capacity of water, kW/kg °C.

Substituting the input data into the formula, we get:

100/0.0012 (90-70) = 4166 kg or approximately 4 m³.

However, in practice such large containers are rarely used. Therefore, in order to reduce the costs of their installation and maintenance, downtime can be reduced by half, and the coolant cooling level can be reduced to an acceptable 500C. Then, to maintain comfortable heat in a house with good thermal insulation, a capacity of 1000 liters will be sufficient.

What does the buffer tank consist of?

The buffer tank for a solid fuel boiler is represented by a metal barrel equipped with an external thermal insulation system. The design of the device is quite simple, but the efficiency of heat transfer is at a high level. Which gives a significant advantage in ideal heating of the room.

Buffer equipment design:

- Heat exchanger in the form of a spiral. Made from stainless steel. It is provided for models that perform several functions in the heating system (solar collectors, heat pump);

- Tank. It is a capacious container, which is made of sheet material coated with enamel. And there are also options for creating a stainless steel tank. In this case, elements intended to connect the heating system with the heat generator depart from the container. The material used to make the container affects the longevity of all equipment;

- Built-in system coil. Helps maintain a constant temperature in the coolant and heats water for domestic needs.

Calculation of heat storage volume

A volume that is too small is ineffective, a large volume is impractical in terms of costs and loss of usable area of the room. An accurate calculation cannot be performed due to the lack of information about the heat loss of the building, especially if it is at the design stage.

However, it is possible to calculate as approximately as possible. The initial data is the boiler power and the total area of all heated premises. Calculations are made as follows:

- The heater power in kilowatts is directly related to the area. 1KW is capable of heating 10 m2. If the house is 120 m2, then the boiler should produce 12 kW. It is necessary to provide a reserve so that the equipment does not operate at maximum load (average coefficient - 1.5). It turns out that you need to install an 18 kW boiler.

- Neglecting the volume of liquid in pipes and radiators, it is assumed that every kilowatt of power is spent on heating 25 liters. coolant in the heat accumulator. Multiplying the two values, we get 450 liters. This value is not the maximum, because at the last step a power reserve of 50% was included.

Pros and cons of a buffer tank

Before purchasing, you should also pay attention to customer reviews about this equipment.

pros

- The equipment is protected from overheating;

- The boiler releases its full thermal energy;

- Smooth operation of the equipment, which allows you to warm up the room in an equal proportion;

- Constant hot water;

- Automatic heating system;

- Increasing the efficiency of equipment by installing its system.

Minuses

- The tank takes up a lot of space in the room;

- A separate room is required for mounting the container;

- Problematic delivery of equipment due to the above symptoms;

- It takes time to establish stable operation of the equipment;

- High cost of equipment compared to the boiler itself.

Installation of a heat accumulator

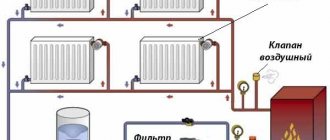

Regardless of what type of storage tank you install, you will need the following in any case:

- Ball Valves;

- Circulation pumps;

- Polypropylene pipes of various diameters;

- Check valves;

- Thermal sensors;

- Pressure relief valve;

- Wiring;

- Electronic pump control unit;

- Thermal accumulator;

- Expansion tank;

- Tools (various wrenches, pipe soldering iron, FUM tape, and so on).

Important advice! It is recommended to install the heat accumulator closer to the boiler. This will save you some money, and heat loss will also be significantly reduced.

All water or antifreeze is poured out of the CO (it is usually poured into a special container, since buying a new one would be too expensive).

- A container for thermal expansion of water is connected to the upper open part of the storage circuit, and a safety valve must be connected to it in case the pressure in the system is exceeded.

- Taps are mounted on the tank nozzles. In general, you don’t have to do this, but if you want to carry out repair work without draining the coolant, then you will have to install ball shut-off valves.

- A pump is connected to the lower outlet pipe of the heat accumulator.

- The pressure terminal of the heating system is connected to the upper terminal of the heat accumulator.

- In the same area, a temperature sensor and an electronic control unit for the thermal storage system are installed. If you do not know how to configure the unit’s operation, you should seek help from a specialist.

- The main part of the CO through which the coolant circulates is connected to the adjacent terminal, located at the top of the thermal tank.

- A second pump is connected to the return line of the battery to circulate water. This device is needed to move the main heating circuit.

- Then automation is built in to regulate the normal functioning of the second circulation pump.

- If your heat accumulator has a second storage circuit inside the tank, then it is also connected in parallel to the CO.

- If additional equipment and temperature sensors do not have standard power cables, then work is carried out to connect the power supply.

- Lastly, the system is connected to ground, after which the advanced heating system is diagnosed and started for the first time.

Note! All security systems and additional equipment are best installed through quick-release fittings, which are usually called “American” fittings.

Boiler capacity

The amount of heat that will be supplied at the appropriate power of the heating device depends on the parameters of the equipment’s capacity. If the equipment produces 35 kW/hour, then the volumetric capacity data must be exceeded up to 30 times. It is worth paying attention to additional factors when calculating capacity.

- Firstly, the heating battery in the buffer tank is installed in such a way that it does not affect the system in any way at a temperature of -30 degrees.

- In this situation, the boiler will continue to operate, but only bypassing the buffer installation.

- When the external temperature rises, the heat accumulator begins to work, which accumulates all the excess heat.

Power is calculated based on natural conditions. If we take a temperature of -29 C, then the device will lose 33 kW in one hour and the power must correspond to this temperature regime.

The size of the room also affects the buffer heating boiler. For large areas, appropriate container sizes are purchased. For small rooms it would not be advisable to buy a large boiler.

Criterias of choice

When choosing a heat accumulator for a home heating system, the following criteria should be taken into account:

- Capacity of the container. It is calculated taking into account the characteristics of the system, the power of the unit, and the consumption of domestic hot water.

- Dimensions and weight. They must correspond to the strength of the base on which they will be installed, as well as the characteristics of transportation and installation work.

- Limit pressure level. It must be no lower than the same parameter in the system. They determine the thickness of the walls, the material from which they are made, as well as the geometry and design features of the tank.

- Case material. Products made from carbon steel alloy are cheaper, but also have a shorter service life due to their susceptibility to corrosion. Stainless steel models are more expensive, but are durable.

- Additional heat exchangers. The number is determined by the presence of connected circuits and the complexity of the circuit.

The main feature of the difference between heat accumulators is capacity Source termico.com.ua

- Functional. Depending on the capabilities, manufacturers equip their products, in addition to the basic parameters, with various additional functions - installation of heating elements, installation of control and measuring equipment, installation of automation and safety devices, such as, for example, air valves, thermostats, etc.

- The quality of the thermal insulation layer. Not only the thickness of the coating is taken into account, but also the type of material used. The longer the tank stores heat, the more cost-effective it is in a private heating system.

On a note! It is better to purchase a thermal storage device only at a specialized retail outlet. The product must be branded, have a certificate, a guarantee and a full instruction manual.

Tips for buying a buffer tank

Before purchasing, it is advised to contact professionals who work with heating devices. They will take into account the nuances of the room for which the buffer boiler is purchased. And they will help you make the right and optimal choice on all counts.

If you have to make a purchase yourself, it is recommended to pay attention to such components of the buffer unit as:

- Container volume;

- Heating system pressure;

- Availability of an auxiliary heat exchanger;

- Weight and external characteristics;

- Functionality of the device in case of installation of additional elements.

Prices: summary table

| Model | Volume, l | Allowable operating pressure, bar | Cost, rub |

| Sunsystem PS 200, Bulgaria | 200 | 3 | 38 000 |

| Hajdu AQ PT 500 C, Hungary | 500 | 3 | 33 000 |

| S-TANK AT PRESTIGE 300, Belarus | 300 | 6 | 39 000 |

| ACV (ATsV) LCA 750 1 CO TP, Belgium | 750 | 8 | 178 000 |

Connection rules

Buffer equipment will delight you with its long service life if the following rules were taken into account when connecting it:

- Availability of water purification filters;

- For main heat supply, a locking mechanism is required;

- Connections in the system must be flanged or threaded;

- The presence of a valve for air removal;

The presence of a pressure gauge and a safety valve on the heat exchanger.

Online calculator

*If the calculator shows 0 (zero), it means you have no excess energy to accumulate.

Explanations:

The rated power of the boiler is indicated by the manufacturer. If the documents for the equipment have not been preserved, you can find the specifications on the Internet.

The power needed to heat your home. It is calculated by specialists using a complex form, which includes: the volume of the room, the heating system, and the energy efficiency of the entire house.

Supply and return temperatures. If the system does not have thermometers installed, it can be removed with any heat remover.