First of all, when organizing heating for a private home, you need to decide on the type of fuel used. This is the main criterion for choosing a boiler, on which further operating costs, autonomy and stability of the heating system depend.

Having decided on the type of fuel, you need to select the minimum required power, pay attention to the number of circuits, installation method, heat exchanger materials, method of air intake and exhaust of combustion products. Let's consider the entire process of choosing a boiler for a house with an area of 100 m2 one by one.

Gas, solid fuel, liquid fuel or electric

For domestic use, 4 sources of thermal energy (4 types of fuel) are used:

- Gas. Gas boilers are the most widespread, accounting for more than 60% of demand. Using natural gas as fuel is one of the most profitable options. The gas has high heat transfer, when burned it produces a minimal amount of toxic combustion products, and its storage does not require large areas and tanks. At the same time, gas boilers are distinguished by affordable prices (the best models in the middle price segment range from 19-28 thousand rubles), have high efficiency (on average 88-94%), the most developed and functional automation, and work for weeks without human intervention. In general, the gas boiler industry is the most developed and competitive: for the buyer this means the availability of increasingly affordable, high-quality, economical models, as well as a developed service structure (both in Moscow and St. Petersburg, and in the regions).

- Solid fuel (wood, coal, pellets). Solid fuel boilers occupy about 7-15% of the market and are still widely used in places where there is no gas mains or regions with access to solid fuel for a nominal price. The disadvantages of solid fuel boilers are known to everyone - this is the unstable release of thermal energy, the need to procure fuel, organize a place for its storage, constant kindling and cleaning of the boiler unit. To maintain the combustion of wood-burning boilers, human intervention is required on average every 2-4 hours, for coal boilers - 5-10 hours, depending on the type of coal. However, there are also more autonomous and more comfortable to use long-burning models, and there are also pellet boilers with fully automated fuel supply.

- Liquid fuel (diesel, waste oil, fuel oil, kerosene). Diesel boilers and boiler units operating in exhaust gases occupy about 10% of the market and are universal. Liquid fuel boilers are installed exclusively in a separate room under the boiler room, require a fuel storage tank (in the boiler room or outside the house), but at the same time they have high efficiency, are able to work completely autonomously, produce a minimum of toxic emissions when burned, and the cost of fuel is often significantly lower than gas . The most affordable and profitable models are the diesel Navien and Kiturami, which differ from their gas counterparts only in the burner design.

- Electricity . Electric boilers are almost ideal in terms of operating comfort and functionality, however, the cost of electricity is the highest for full heating of a house of 100 square meters. m. can cost from 7 to 10 thousand rubles. per month. It is most rational to use an electric boiler when temporarily living in a house, then the low cost of the boiler and heating system will pay off operating costs for a long time. There are also options for using it in tandem with a buffer tank that accumulates the heat generated by the boiler at a reduced night rate, or using it as a backup boiler unit.

Efficiency and selection criteria for energy-saving electric heating boilers

To summarize, if there is a gas main near the house, we recommend choosing a gas boiler without hesitation. If there is no gas main, you should choose based on personal preferences for the method of maintaining combustion, the availability of fuel in the region, requirements for autonomy, the cost of the boiler and its installation.

Review of the best 100 kW boilers

Most units from different manufacturers have a similar design. It includes shut-off valves, a burner block and automation with main sensors. When gas is supplied from the main line and there is water in the system, the gas mixture is ignited using an ignition device. The burners heat the working fluid in the heat exchanger (water), which is supplied through the heating circuit to the radiators.

Automation is needed to prevent ignition in the event of a lack of water or low gas pressure, as well as timely shutdown in an emergency. Complex units may contain a pump to create gas pressure on the nozzles, as well as a special device for forced pumping of water through the system: this increases the performance of the heating installation. In addition, there is a temperature regulator (it can be displayed by an analogue or digital indicator), electric or piezo ignition.

Popular boilers include products from the Slovak company Protherm: reliable, high-quality, unpretentious in operation. They can compete with the French De Dietrich with high efficiency, low power consumption and a 5-year warranty from the manufacturer.

The boilers are equipped with electric ignition with 2-stage adjustment; indicators show the temperature and pressure of the coolant in the system. The equipment is economical and has low emissions into the atmosphere. The automatic mode allows you to set comfortable working conditions; it is also responsible for maintaining the set temperature.

Several units can be combined into a large network (when heating large areas, for example, warehouses). The manufacturer ensures high productivity - at the level of 90-95%, a guarantee is provided.

The minimum required boiler power for a house is 100 sq. m.

Power requirements depend on the heat loss of the house, the boiler simply must replenish them. For an average house in the climatic zone of the Moscow region with a masonry of 2 bricks and a ceiling height of 2.7 m, the heating capacity is calculated according to the rule: 1 kW of power for every 10 m2 of heated area. We also recommend a power reserve of 10-30%, depending on the type of fuel used.

For example, the minimum required boiler power for a house with an area of 100 square meters. m. = 10 kW * 1.2 = 12 kW.

Often manufacturers do not produce 12 kW versions, limiting themselves to 10 and 15 kW boilers, so you can choose a 14 or 15 kW model, but no more. A boiler unit of too high power will cycle more frequently (on/off), which reduces its service life.

Standard simplified calculations are sufficient for more than 95% of cases. If the house is well insulated, is located in the extreme southern or northern point of the country, has high ceilings or a large glazing area, more accurate calculations are made. You can do this using the calculator below.

Calculator for accurate calculations

The heating boiler must provide the total power of the radiators (boiler power ≥ total power of the radiators), so first you need to use a calculator to calculate the power of the radiators for each room separately. By summing up all the obtained values, you will get the minimum required boiler power.

How to calculate power correctly

Firstly, it is worth mentioning that all our efforts to heat the house are aimed at heating the air in the interior to a comfortable temperature.

If we talk about comfortable temperature indicators, they are different for each individual person.

Some people feel great at a temperature of +19C, while others are already freezing at +22C.

However, +19C is considered the “healthiest” temperature for indoor living spaces.

So, our heat generator heats the coolant, which transfers this heat to the air in the premises of the house through underfloor heating pipes or through radiators.

The greater the boiler power, the more the coolant is heated and the more the air in the rooms heats up.

In this case, heat loss occurs - the air in the interior gives off heat through doors, windows, walls and ceilings. Warm air also escapes through the ventilation system.

How to choose a boiler for heating a private house

Floor or wall

Gas wall-mounted Vaillant with the necessary elements and components of the heating system built into the body.

Floor-standing models are more resourceful and versatile, most of them are non-volatile, i.e. not requiring connection to the electrical network (with the exception of electric boilers). Wall-mounted models are more compact, and from the factory they already contain an expansion tank, a circulation pump, a safety valve, an air vent and other elements of the heating system.

Wall-mounted models are equipped with lightweight steel or copper heat exchangers, which, even despite special coatings, are susceptible to corrosion and last no more than 12-16 years. Floor-standing models are not limited in weight, so heavy cast iron heat exchangers with thick walls are often installed in them; cast iron is practically not subject to corrosion, and the service life of such heat exchangers is more than 25-30 years.

Please note that solid fuel and liquid fuel models are presented only as floor-standing models due to technical features.

Single-circuit or double-circuit

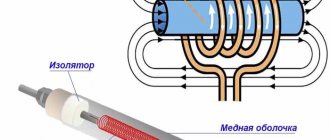

A visual principle of operation of double-circuit boilers with priority for hot water supply (DHW).

Single-circuit boilers are intended exclusively for heating. Double-circuit models are equipped with an additional heat exchanger, with the help of which sanitary water is also heated for hot water supply at home. Sanitary water from the DHW circuit does not mix with technical water from the heating circuit.

The cost of double-circuit boilers is only 10-20% more expensive than single-circuit versions, so this is the most profitable way to solve the issue of hot water supply.

Heat exchanger material

The heat exchanger that transfers the thermal energy of combustion to the coolant can be made of:

- steel is the lightest and most inexpensive option to produce, used primarily in wall-mounted models and boilers in the low and mid-price segment. Steel heat exchangers have thin walls and are susceptible to corrosion, so their resource is limited by physical properties, service life is 12-14 years;

- Copper is a more corrosion-resistant, more thermally conductive, but also more expensive metal. Copper heat exchangers are used in models of the middle and high price segments, their service life is about 13-17 years;

- cast iron - resistant to corrosion, retains heat for a long time, but is heavy and fragile. The service life of cast iron heat exchangers is at least 25-30 years.

How to choose a room thermostat and save up to 30% per month on heating

Combustion chamber design and types of smoke removal

There are several options for organizing fuel combustion:

- an open combustion chamber and natural draft through a vertical chimney is a standard option used in floor-standing models, when air for fuel combustion is taken from the room, and combustion products are naturally discharged into a vertical chimney. For fuel combustion, proper ventilation must be provided in the boiler room;

- a closed combustion chamber and forced draft through a coaxial chimney is a simpler option to organize; it is used in wall-mounted and some floor-standing models. Air intake and combustion products removal are carried out through a compact coaxial (side) chimney. The chimney itself comes complete with the boiler.

Electric boilers do not require air intake and exhaust of combustion products, and therefore no chimney.

Types of gas burners by flame regulation

The criterion applies exclusively to gas boilers, the burners of which can be of 3 types:

- single-stage – works in on/off mode;

- two-stage - operates in off, 50 and 100% power modes. This reduces the load and increases fuel economy;

- modulated – smoothly regulates power within 10-100%. This is the best, but also more expensive type of burner, since the boiler automation can achieve the most economical and gentle mode of operation of the burner - continuous burning at the lowest possible power.

Efficiency

Efficiency factor (efficiency) is the ratio of the volume of fuel consumed by the boiler to the volume of heat generated, i.e. efficiency. Average normal values:

- for gas - 88-94%;

- for solid fuels – 82-89%;

- for liquid fuels – 86-91%;

- for electric ones – 99%.

Accordingly, the lower the efficiency, the less thermal energy is accumulated by the coolant. If for liquid fuel boilers during testing this is an insignificant indicator due to the symbolic cost of fuel, then for gas boilers every additional % efficiency contributes to tangible savings.

Additional criteria

Having decided on the main selection criteria one by one, you can turn to additional ones:

- condensation of combustion products – used in long-burning gas and solid fuel boilers, when an additional heat exchanger accumulates the remaining heat of combustion products. Thus, a significant part of the heat does not “fly down the drain”;

- automation functionality - modern models can be equipped with a programmer that allows you to set the boiler operating mode for the next day or week, for example, by setting the temperature to 15°C during working hours when the owners are not at home, which will significantly reduce fuel consumption. Also important is the ability to connect a room thermostat, the presence of protection against overheating and stopping the circulation pump, and a frost prevention mode. Solid fuel boilers, as a rule, are not equipped with functional automation;

- the presence of heat and sound insulation - a layer of thermal insulation reduces heat loss through the boiler itself, and sound insulation used in gas, diesel and electric models makes their operation almost silent.

What characteristics should you pay attention to when choosing a gas boiler?

The modern gas equipment market offers three boiler options according to installation method

- Floor-standing

- Wall mounted

- Parapet

By number of circuits

- Single-circuit - heating only.

- Double-circuit - heating and water heating.

By type of burner

- Atmospheric - air comes naturally.

- Supercharged - a fan is used in operation.

- Combined.

By type of power control

- single-stage - after heating to the desired temperature, the boiler switches to igniter mode.

- two-stage - operates in two modes, during heating to the desired temperature 100% of the power, and after heating it switches to 40% power mode, the switching process occurs automatically using an automation unit.

- smooth two-stage - 2 operating modes of 100% and 40% power, but the transition process occurs more smoothly.

- modulated - operate in 3-4 power modes.

By type of combustion chamber

- open - air is taken naturally from the room in which the boiler is installed

- closed - air is taken from the street through a separate coaxial pipe.

By type of traction

- Natural - in a natural way

- Forced - a fan is used in the boiler, which forcibly takes in air from the street through a coaxial pipe, and also removes combustion products.

By ignition method

- Electric - ignition.

- Piezo - ignition.

- Manual.

According to the material from which the heat exchanger is made

- Steel

- Cast iron

- Copper

The best known manufacturers and models: characteristics and prices

BAXI ECO Four 1.14 F

One of the best boilers for heating a private house with an area of 100 m2. The Italian gas wall-mounted single-circuit boiler with a power of 14 kW is known for its high reliability and efficiency - efficiency of 92.5% with a maximum gas consumption of 1.6 cubic meters. m/hour. It also features a copper heat exchanger, virtually silent operation and functional automation with the ability to connect a room thermostat. During the installation practice, no serious deficiencies were identified; according to reviews from the owners, the model has been working without problems for more than 7 years.

Baxi SLIM 1.150i 3E

Floor-standing double-circuit Italian model with a power of 14.9 kW. It is distinguished by the presence of a cast iron heat exchanger, functional and reliable automation, the presence of a circulation pump and a modulated burner. The boiler efficiency is 90.3% with a maximum gas flow of 1.74 m3/hour. The only disadvantages are heavy weight, vulnerability to voltage surges (connection via a stabilizer is recommended) and high price.

Buderus Logamax U072-12K

One of the most affordable reference German models with a capacity of 12 kW (heating and hot water supply). Characterized by good efficiency - efficiency of 92% at a maximum flow rate of 2.1 m3/hour, convenient and functional controls, aesthetic design and compact dimensions. The main advantage over analogues is the price.

However, there are also disadvantages in the form of an insufficiently strong plastic make-up tap and vulnerability to voltage surges. The main advantage over analogues is the price.

Teplodar Cooper Praktik 14

A common budget solid fuel boiler made in Russia with a capacity of 14 kW. It is distinguished by a simple and reliable device, a block of heating elements (6 kW) pre-installed from the factory, which are capable of maintaining an acceptable coolant temperature for a long time, for example at night, after the firewood has burned out. You can also use coal and peat briquettes as fuel.

It has disadvantages typical for the budget price segment: a steel heat exchanger, a small combustion chamber, and is picky about the size of firewood.

Combined electric gas boilers: their efficiency, best models and prices

Stropuva S15U

Lithuanian solid fuel boiler with long burning, power 15 kW is more than enough for a house of 100 sq. m. Mine-type model (air supply from above), which, when heating with coal, ensures the burning duration of one bookmark up to 7 days. The boiler efficiency is 85%, which is optimal for a solid fuel model. According to installation practice and owner reviews, no serious malfunctions have been noticed for more than 6 years.

When burning with wood, it has significant disadvantages: high requirements for dry wood and a high level of tar formation on the walls of the firebox. The manufacturer recommends using coal as fuel.

Cost: 99-100 thousand rubles.

Poll: what type of boiler did you choose?

One circuit or two

This parameter only affects ease of use. The standard configuration (single-circuit boiler) is intended only for heating - taking a shower or even washing your hands in this case will not work for one simple reason: the absence of an additional circuit for heating water. Therefore, this option will have to be supplemented with a gas water heater or an electric boiler.

But there is a combined solution - a double-circuit boiler: it simultaneously performs the main function and uses excess heat to heat the water supply. And already such 100 kW gas boilers are recommended for wide use in a wide variety of conditions - from a city apartment to a detached mansion.

You might be interested >> How to choose the right boiler for heating in a private home

Read the link about the pros and cons of single-circuit and double-circuit gas boilers.

Prices: summary table

| Model name | power, kWt | Efficiency, % | Gas consumption, m3/h. | price, rub. |

| BAXI ECO Four 1.14 F | 14 | 92,5 | 1,6 | 47 000 |

| Baxi SLIM 1.150i 3E | 14,9 | 90,3 | 1,74 | 83 000 |

| Buderus Logamax U072-12K | 12 | 92 | 2,1 | 41 000 |

| Teplodar Cooper Praktik 14 | 14 | — | — | 20 000 |

| Stropuva S15U | 15 | 85 | — | 99 000 |