Solid fuel boilers, despite all the obvious advantages and disadvantages, have another hidden aspect that over time has to be paid attention to. Heating systems on solid fuel boilers with manual loading mode do not operate in support mode. If the fuel in the furnace runs out, the boiler stops working, and accordingly, the coolant begins to cool. This problem is well known to residents of the private sector and owners of country houses.

It is not always possible to constantly add coal or firewood to fill the firebox, and stopping the boiler in winter is fraught with a sharp drop in temperature in all living areas.

The best option to prevent such a situation would be a heating system in which an electric boiler is connected to a solid fuel boiler.

Functions of an electric boiler in a heating system with a solid fuel unit

Connecting an electric boiler to the system together with a solid fuel heating device is a fairly common engineering solution. This option eliminates the possibility of the heating system cooling down, prevents overcooling of the main heating unit and maintains a comfortable temperature in the house. An electric boiler often acts as a backup heating device, the task of which is to equalize the temperature of the coolant in the heating system.

Layout of solid fuel and electric boilers when used together in a heating system

The operation of solid fuel boilers requires periodic human supervision - all models of such units require fuel loading.

Note: for traditional boilers, the number of loads can reach up to 2-6 times per day. The situation is different with pyrolysis boilers and long-burning units. Frequent human intervention is not required here. One load of fuel is enough for 12-24 hours of boiler operation, and for some models - for 48 hours of operation.

The main task for the home owner when the heating is on is to prevent the boiler and heating system from cooling down. An electric boiler paired with a solid fuel boiler successfully solves this problem. Let us consider in detail the combination of a solid fuel boiler with a heating device powered by electricity.

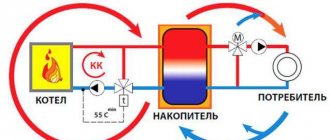

The working scheme is as follows: a solid fuel unit with a power of 50 kW must be combined with an electric boiler whose power is 28 kW. The operation of the electric heating device is periodic. The unit must be on standby - ready to be turned on immediately after the main equipment is stopped. The electric boiler starts when the fuel in the solid fuel boiler runs out and the temperature of the coolant in the system drops to 50 0C. In this case, the circuit must have a water tank for the hot water supply system, which in this case acts as a heat accumulator.

The main circuit elements that consume the power of autonomous heating boilers are:

- heating radiators - require 30 kW;

- heating system "warm floor" - up to 15 kW;

- storage capacity for the hot water system - on average 300 liters.

Attention! Automation for adjusting the switching of circuits in this situation - a bunch of units is not required.

An electric boiler, working together with a heat accumulator, is a group that prevents coolant with a temperature that has fallen below a critical level of 50 0C from entering the main heating unit.

* The pump installed in the system periodically circulates the coolant through the pipeline, signaling the temperature in the heating circuit. When the coolant temperature drops to a critical level, an electric boiler equipped with heating elements comes into operation, taking on the task of heating the house. A thermostat and three-way valve control the temperature of the hot water tank. When the water temperature in the DHW system circuit decreases, the coolant enters the coil to heat hot water. A correctly connected electric boiler and proper connection with a solid fuel boiler will make your system fully controllable.

In the described design of the heating system, all heating equipment, including the pipeline, when the main heating device is stopped, is reliably protected from defrosting and does not cause interruptions in heating of residential premises and hot water supply.

Completion of the heating system installation

At the stage when the connection of the electric boiler to the heating system and electrical network is completed, perform the following actions:

- check the serviceability of the pipeline fittings located in front of the device. To do this, it is switched from the “closed” to “open” position and back;

- The pipeline fittings of a heat generator powered by electricity are moved to the “closed” position. In the same mode, the fittings of water supply and heating systems should be installed;

- On the pipelines supplying cold water to the heating boiler, it is necessary to open the shut-off valves. When using an electric heating system, do not use non-freezing coolant fluids, as they will negatively affect the functioning of the equipment. They contain components that over time lead to wear of the rubber elements. For the heating system, water with a minimum hardness level should be used;

- before entering the device on the return pipeline, it is necessary to install a sump filter or a filter or both of these parts;

- After filling the heating system with coolant, you need to check its tightness.

Combined heating boilers

Another, less expensive option is to install a combined unit, which is a solid fuel boiler and an electric unit at the same time.

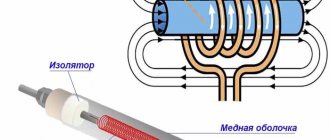

Such devices use solid fuel and electricity to heat the coolant, being designed for the interchangeability of these energy carriers during operation. A special feature of such units is the installation of electric heating elements in the tank of a solid fuel boiler - heating elements provide the necessary heating of the coolant passing through the heat exchanger. The idea of combining an electrical device with a solid fuel unit is not new, but it became possible to launch the production of appropriate heating equipment only after the advent of combined automation devices and new generation materials.

The principle of operation of combined heating mechanisms is that while the combustion chamber is free from the main type of fuel (wood, coal, peat, etc.), the main work of heating the heating fluid is performed by electricity. Thanks to the installed control sensors, the equipment independently responds to changes in temperature conditions, turning on and off as needed.

In practice, it looks something like this: the fuel supply has already completely burned out, and accordingly the boiler has gone out. The boiler water accordingly begins to lose its temperature. Electric heating is replacing solid fuel. Now the heating mechanism works like a regular electric boiler until the firebox is filled with the next batch of firewood or coal.

After the main unit reaches the optimal operating mode, the control unit turns off the electric heating elements, and the heating operates on solid fuel again.

Advantages and disadvantages of combined heating equipment

*

Despite the high cost, combination boilers have undeniable advantages. These include not only complete control over the state of the entire home heating system, but also a number of others:

- the device does an excellent job, heating rooms with low energy consumption;

- Combination boilers are environmentally friendly heating units;

- absence of condensation, since the first heating of the device is carried out in both modes - main and auxiliary;

- the entire heating complex is constantly in working order, which is important when the owners of the house are absent for a long time.

However, this technique also has disadvantages.

A significant disadvantage for combined heating devices is their energy dependence. If there is no voltage in the network, the system loses its efficiency and versatility.

Important! When installing equipment, it is necessary to take into account the potential of home electrical wiring, which may not be designed for the power of the equipment being installed. The presence of low-amperage circuit breakers will lead to constant power outages in the house. Before installation, make sure that the power consumption limit allocated for you is capable of satisfying the operation of the heating equipment.

Unlike traditional solid fuel devices, whose efficiency reaches 70-80%, combined products have a lower coefficient - approximately 3-5%.

Electrical connection

The power supply circuits are the same for all electric boilers, the only difference is the number of phases. Devices with a power of up to 12 kW are connected to a single-phase 220 V network, more than 12 kW - to a three-phase (380 V). What you will need for installation:

- power cable with copper conductors;

- differential circuit breaker or combination of RCD + conventional circuit breaker;

- ground loop.

A VVG cable of any type is used as a power line; the number of cores depends on the number of phases - 3 or 5. Select the cross-section of the current-carrying part according to the power of the heat generator, usually this parameter is indicated in the product’s operating instructions. To simplify the task, we present the data for different boilers in the form of a table.

The rating of the differential circuit breaker also depends on the power consumption of the heater; the operating current is 30 mA. For example, to protect the power line of a 3 kW (220 volt) unit, you will need a device rated at 16 A; for a power of 16 kW (380 V), you need a 32 A difavtomat. The exact ratings are indicated in the product data sheet.

To independently connect a wall-mounted electric mini-boiler room, you need to remove the front panel, run the power cable inside and connect the wires of the corresponding colors to the terminal block contacts. As a rule, the neutral wire is indicated in blue, grounding in yellow-green. The control box of the induction and electrode boiler is connected in the same way.

Electrical connections between the control cabinet and the heating block of an electrode or induction boiler are made according to the individual diagram presented in the instructions. As an example, we give a connection diagram for the popular Galan electric boiler.

Automation diagram for single-phase 220 V network

The temperature of the coolant here is monitored by overhead sensors installed on the metal sections of the supply and return pipelines. The devices are connected in series with the contacts of the thermal relay that controls the magnetic starter. When the upper temperature threshold is reached, the circuit breaks and the starter turns off the heating.

Connection diagram for connecting the boiler to a three-phase 380 V network

How to achieve joint operation of electric and solid fuel units

*

If you are faced with a choice of which individual heating option to give preference to - a solid fuel boiler, an autonomous electric unit or a combination of these two devices, the latter option has advantages. To install the circuit, you will need a connection diagram for both units, similar to a gas-solid fuel heating system. Properly done equipment piping is a guarantee of the efficiency and safety of operation of this equipment.

The proposed video describes in detail how and in what way to connect solid fuel heating devices together with electric heating elements

What you need to pay attention to during installation:

- both devices must have a reasonable power ratio, the coal or wood heating device is the main source of heat, so its power must be twice the power of the electric boiler;

- both units are connected in parallel, which makes the operation of one independent from the other;

- the solid fuel unit is the main one and is connected to the large circuit, while the electric boiler is responsible for the temperature in the small circuit;

- the main heating unit is equipped with a three-way valve;

- to save energy resources and ensure heating safety, installation of a heat accumulator is mandatory;

- each heating device is set to a certain heating temperature - for solid fuel equipment the operating temperature should be 60-70 0C, while on an electric unit the temperature value is set to 40-50 0C, since due to the presence of a heat accumulator, the water for heating will cool more slowly, and the electric boiler will start with a time delay.

Features of the purchase and installation of electric boilers

When installing electric heating equipment, a number of nuances should be taken into account:

- In order to properly connect the electric boiler to the electricity and heating system, it is necessary to resort to the services of employees of organizations engaged in this type of work on a professional basis.

- The device itself should be purchased from specialized retail outlets, where the relevant documents are attached to it. The equipment must have original packaging, which should preferably be opened in the presence of a specialist from the service department. Together with it, the boiler is inspected to ensure that there are no mechanical damage or other defects on the surface.

- Before installing the electric boiler, you need to remove the plugs from the pipes and make sure that there is no dirt in them and the communications. With this electric boiler connection scheme, sealing materials and gaskets are used.

- When choosing a place to install a thermal electric boiler, it is advisable to give preference to non-residential premises. The best option is the kitchen (see photo). The device should be positioned so that it is convenient not only to use, but also to carry out its maintenance. In accordance with the standards, the gap between the sides of the boiler and the walls should be 5 centimeters. The free space in front of the appliance cannot be less than 70 centimeters, above it - at least 80 centimeters, and below the boiler - at least 50 centimeters.

- Heating equipment must be installed on a wall made of non-combustible material. To install the device, use a special fastening element - a mounting plate. Usually it is included in the basic package of an electric boiler. The plank is secured to the wall using 4 dowels.

Eventually

In each case, the homeowner himself decides how to organize an autonomous heating system. The proposed technical solutions will not only eliminate the unpleasant consequences of the main heater fading during severe winters, but will also provide some savings in energy resources.

The efficiency of operating solid fuel units and electric boilers in pairs has been proven by practice - the interaction of these devices provides greater comfort and guarantees reliable heat supply.