What are solid fuel coal boilers?

A solid fuel coal boiler is a modern heating unit in which anthracite, stone, long-flame, gas, black, brown coal, pressed briquettes, as well as some other types of solid fuel can be burned to generate energy and subsequently heat the coolant.

Cutaway view of a modern Teplodar Kupper coal boiler.

In fact, direct (bottom-up) combustion boilers are the successors to the traditional Russian stove, but if a massive stone (brick) structure must be laid at the preliminary stages of building a house, then a more compact device can be connected to an already existing system.

Application and effectiveness

Coal boilers are installed in residential and commercial buildings (dachas, cottages, offices) located in areas where connection to the gas supply system is problematic. It is ideal to use a coal boiler for heating a private house with an area of up to 100-150 m2.

Comparison of the efficiency of boilers using different types of fuel:

| Type of energy resource | Calorific value, mJ (kW)/kg (m3) | Fuel price, rub./ton (m3) | Efficiency | Cost of kW of energy, rub. |

| brown (w ≈ 20–40%) | 12,9 (3,6) | 2700–3200 | 70 % | 1,71–1,27 |

| stone (w 7–15%) | 27,1 (7,5) | 6000–7000 | 70 % | 1,14–1,34 |

| anthracite (w ≈ 1–3%) | 31,1 (8,7) | 8000–8500 | 70 % | 1,31–1,40 |

| natural gas | 36,5 (10,3) | 5400–5700 | 90 % | 0,63–0,65 |

| firewood (w ≈ 60–50%) | 8,1 (2,2) | 1300–1500 | 60 % | 0,98–1,05 |

| firewood (w ≈ 30–20%) | 11,2 (3,1) | 1500–1800 | 60 % | 0,76–0,83 |

| granules (pellets) | 17,2 (4,7) | 7000–9000 | 85 % | 1,75–2,25 |

| briquettes (eurowood) | 16,1 (4,3) | 6000–8500 | 85 % | 1,65–2,32 |

As can be seen from the table, from a financial point of view, a coal boiler is far from the most economical option: it is inferior to gas and wood-burning units.

Compared to gas, which burns almost completely, coal leaves behind a lot of ash, which means it has lower combustion efficiency and part of the money spent on fuel will inevitably go to pay for “garbage waste”, in the literal sense of the word.

The second closest competitor to coal is firewood. They are obviously cheaper, but not so convenient to use: in addition to the fact that you will have to bring them to the desired fraction yourself (or buy chopped ones, but more expensive), you also need to add firewood to the firebox every 3–5 hours, while coal burns for 6–10 hours.

Design and principle of operation

Schematic representation of the operating principle of coal boilers.

The fundamental design of a coal boiler is no different from any other solid fuel unit, i.e. it consists of the following components:

- an outer capacious cylinder, which is also a body;

- a layer of heat-insulating material covered with facing panels;

- an inner cylinder located along the same axis (coaxially) with the first one;

- combustion chamber (furnace) located in the lower part of the inner cylinder;

- a hole (blower) adjustable by the sash to create and enhance traction;

- variable system of air exhaust and air supply pipes;

- ash collection compartment and instrumentation (optional).

Reference . The inner and outer cylinders cannot be adjacent to each other: there must always be free space (water jacket) between them for the unhindered passage of the coolant. Moreover, the size of this gap directly determines the amount of simultaneously heated water.

The principle of operation is extremely simple : due to the draft of the chimney, air enters the firebox, which causes the combustion of coal and the release of thermal gases. They, in turn, heating the inner walls, convert the heat into hot steam or transfer it directly to the water circulating in the heat exchanger system.

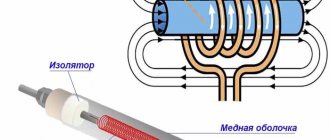

Some boilers, like TeplodarKupper Carbo 26, are equipped with heating elements for additional heating of the coolant.

The heated water supplies the pipes of the home heating system and/or hot water supply (DHW), and then, after completing a full cycle (circuit), it returns again to the boiler. The waste thermal gases enter the chimney, where, due to their energy, the temperature optimal for creating draft is maintained.

Reviews of household coal boilers: advantages and disadvantages

Coal boilers have been used for heating private houses for a very long time, therefore, thanks to many years of practice and feedback from owners, they can be assessed as objectively as possible:

| Advantages | Flaws |

| long operating time – coal burns slower than most other fuels (wood – 2–2.5 times, pellets – 2.5–3 times) | high cost - the price of even the most primitive coal boilers is quite comparable to the price of gas units |

| simple design - a regular boiler is designed quite simply, which guarantees protection against accidental breakdowns | allocation of a utility room - the unit itself and fuel reserves must be located separately from the living rooms |

| versatility - a coal boiler can burn any solid fuel, the only question is reducing the power (up to 20–40%) | constant monitoring and control - boilers without electronics can only be started manually and require supervision |

| independence from external factors - many models are completely autonomous (non-volatile) and do not require access to power grids | harm to the environment - coal dust and other particles of combustion products pollute the environment |

Users also note that over time, the pressure in the system drops, heating occurs more slowly and fuel consumption per month increases. This should not be considered a disadvantage, since the problem arises due to a banal accumulation of scale, which can be encountered not only by a coal-fired boiler, but by any hot water boiler unit.

Rating of solid fuel boilers TOP-9 boilers

- Types of solid fuel boilers and their features

- Rating of classic TT boilers for heating a private home

- TOP - 3 long-burning solid fuel boilers

- Rating of boilers with automatic fuel supply

- Conclusion

Modern solid fuel boilers for heating a private home or cottage are quite efficient and reliable heating devices, which, in the absence of natural gas, demonstrate the highest economic performance. Another common area of application for solid fuel boilers is as a backup heat source for a private home, the main heating system of which runs on natural or liquefied gas.

Many technological solutions, different types of solid fuel and different combustion principles create a lot of inconvenience for the unprepared consumer when choosing the optimal option for solid fuel heating equipment. Teplomatika engineers have prepared a small rating of the best solid fuel boilers, which will help the future owner of a private home make an informed and justified choice.

All modern solid fuel boilers, with a small degree of convention, can be divided into three main classes, each of which has characteristic technical differences:

- classic heating devices have an open combustion chamber for wood, coal or fuel briquettes. Boilers of this type operate on natural draft, and the regulator for changing the power is a mechanical valve control device. Boilers of this type are, as a rule, non-volatile, but the total combustion time of the fuel does not exceed several hours;

- a more advanced class of heating equipment is long-burning boilers. Increasing the time of complete combustion of fuel is achieved either by vertical loading of fuel, or by using pyrolysis of coal or wood during the combustion process. The operating time of such devices on one load can reach 12 hours;

- Fully automated solid fuel boilers operate on fine coal, for storage and supply of which a special bunker is installed on the boiler. The battery life of such devices is several days and depends only on the volume of the bunker. Pellet heating systems represent a separate type of heating equipment, the review and rating of which will be presented in a separate article.

Practical advice on choosing a boiler for heating a private home

- when calculating the required power, you can use the approximate formula - for 10 m² of heated area, 1 kW of heating device power is required;

- Do not blindly trust advertising indicators of the maximum burning time of one load of fuel. As a rule, the actual burning time parameters, at severe negative temperatures outside the window, are several times lower;

- when choosing a non-volatile boiler for systems with natural coolant circulation, it is better to exclude products with a cast iron heat exchanger. Cold return water, with the heat exchanger already heated, can lead to the formation of cracks at the point of its supply;

- long-burning heating equipment places very serious demands on the quality of fuel - the maximum moisture content of firewood should not exceed 15%;

- The volume of the ash box determines the frequency of its cleaning - the larger the volume, the less often it is necessary to remove ash;

- a small chimney and lack of ventilation in the boiler room often lead to smoke in the room due to the lack of sufficient draft. This feature determines a large number of negative reviews on various sites, but is in no way related to the quality of heating equipment;

- Not all heating devices allow the use of antifreeze as a coolant. In this regard, it is better to consult with a specialist or look for information on the manufacturers’ websites.

| Category | Place | Name | Country of origin |

Rating of classic TT boilers for heating a private home | 1 | ACV Radijator C25 | Belgium |

| 2 | Zota Topol-M 20 | Russia | |

| 3 | Bourgeois K MODERN – 16 | Russia | |

| 4 | Kentatsu Elegant 03 | Türkiye | |

TOP - 3 long-burning solid fuel boilers | 1 | ACV Radijator FK1 | Belgium |

| 2 | Zota Bulat 18 | Germany | |

| 3 | Bourgeois K MODERN – 16 | Russia | |

| Rating of boilers with automatic fuel supply | 1 | Kentatsu VULKAN PR-30P | Belgium |

| 2 | Zota Forta 20 | Russia |

The rating of classic solid fuel boilers is presented by models from both foreign and domestic manufacturers. Ways to improve this type of technology lie in the plane of improving the quality of the metal used and designing an original shape of the combustion chamber, the design of which increases the burning time of the fuel.

Rating of classic TT boilers for heating a private home

1. ACV Radijator C25 is a solid fuel boiler from Serbia from the Radijator plant, which has recently been part of the well-known Belgian ACV group. The device with a steel heat exchanger has an installed power of 25 kW, which allows heating rooms up to 250 m². A distinctive feature of the ACV Radijator C25 is the material of the three-pass heat exchanger - European quality steel, increased to 5 mm in thickness. Laser cutting of firebox elements and their welding using automated welding complexes guarantee the reliability of the heat exchanger, and European quality standards for welds will determine its durability.

Models in the line:

- Radijator C25

- Radijator C40

- Radijator C50

Advantages:

- the heating device includes a copper heat exchanger, which serves as a signal source for triggering the thermal safety valve;

- three-pass combustion chamber design increases heat extraction during fuel combustion and increases the performance of the heating device;

- ACV Radijator C25 is designed to work with all types of fuel (firewood, briquettes, coke, biomass), but shows maximum efficiency with coal;

- There is a technological hole on the bottom door of the heating device for installing a gas or diesel fan burner.

Flaws:

- The limited accuracy of mechanical traction control can lead to slight excess fuel consumption.

Expert opinion: an excellent boiler from Serbia, which implements the developments of a famous Belgian manufacturer. The only serious drawback of the ACV Radijator C25 is its price, which is significantly higher than its Russian analogues.

2. Zota Topol-M 20 - a domestic solid fuel model with a maximum thermal power of 20 kW allows you to heat rooms up to 200 m². The Topol series is already the third modification of solid fuel equipment from the Krasnoyarsk manufacturer, the development of which was based on the operating experience of previous series. Thus, in this series of heating devices, a horizontal heat exchanger with a removable cover is installed, which significantly increases the heat transfer area and increases the efficiency of the heating system. Two large doors make it easy to load different types of fuel - the top door is for coal, and the bottom door is for firewood. It is also convenient to clean the heating device and service it through the top door.

Models in the line:

- Topol-M 14

- Topol-M 20

- Topol-M 30

- Topol-M 42

- Topol-M 60

- Topol-M 80

Advantages:

- a thermometer on the front panel increases the convenience of controlling the operation of the heating device;

- in the Zota Topol-M body there is a technological hole for installing an electric heating element, which is purchased additionally;

- The optional TurboSet automation kit improves the combustion mode of coal or wood and almost doubles the operating time on one load.

Flaws:

- a mechanical draft regulator is available as an option. In normal mode, manual traction adjustment is provided using a screw;

- Many owners of Zota Topol-M 20 complain about the small volume of the ash box.

Expert opinion: a simple, reliable and inexpensive TT boiler, the capabilities of which are significantly expanded by installing additional heating and automation devices.

3. Kentatsu Elegant 03 - an inexpensive Turkish-assembled model with a power of 17 kW allows you to heat residential and industrial premises with an area of up to 170 m². Heating appliances of the Elegant series have a massive cast-iron heat exchanger, the production of which uses Amin Gas technology. The resulting very smooth surface of the heat exchanger qualitatively reduces hydraulic resistance, which has a positive effect on the uniformity of temperature distribution and the overall reliability of the equipment. A spacious combustion chamber increases the volume of loaded fuel, and a wide, convenient door makes loading it easier. The maximum power of the Kentatsu Elegant 03 is achieved on coal, but this unit also works well on other types of fuel - wood or fuel briquettes.

Models in the line:

- Elegant 03

- Elegant 04

Advantages:

- additional heat exchanger fins along the path of removing burnt gases increases the overall efficiency of fuel combustion;

- The included mechanical thermostat allows you to regulate the temperature of the coolant by changing the draft;

- a thermometer installed on the front panel improves the conditions for monitoring the parameters of the heating system;

- water-filled grates increase heat extraction and prevent their deformation under the influence of high temperatures.

Flaws:

- some buyers complain about the build quality of the outer casing and the insulation fastening.

Expert opinion: an inexpensive heating device of a classic design with a good price-quality ratio.

4. Lemax Forward - 16 - the cheapest model of the classic version of solid fuel heating appliances from the Russian manufacturer has a maximum thermal power of 16 kW, which is quite enough for heating a private house or cottage with an area of up to 160 m².

The Lemax Forward series is optimized for burning coal or coke, but firewood or fuel briquettes can be used as backup fuel. Top loading ensures uniform distribution of coal throughout the entire volume of the firebox by simply pouring coal from a bucket or appropriate container.

A distinctive feature of Lemax Forward - 16 is the alloy steel of the Magnitogorsk plant for the manufacture of the firebox, the thickness of which is 4 mm. Together with gray cast iron grates, this feature of the combustion chamber guarantees high reliability and durability of the heating device.

Models in the line:

- Lemax Forward-12.5

- Lemax Forward-16

- Lemax Forward-20

Advantages:

- treating the heat exchanger with inhibitory compounds eliminates the likelihood of its intense corrosion;

- with a full load of coal and its top ignition, the burning time increases to 8-12 hours, which is a very good value for boilers of this type;

- The upper large door for loading coal provides convenient access to all technological surfaces for their periodic cleaning.

Flaws:

- When heating with wood or fuel briquettes, the operating time on one load does not exceed 2-3 hours, which must be taken into account when planning a purchase. Expert opinion: a simple and reliable model at a very attractive price requires certain skills in working with solid fuel heating devices. Otherwise, the impressions of working with equipment of this class will be very negative.

TOP - 3 long-burning solid fuel boilers

Long-burning solid fuel heating devices were the first step in the development of this type of technology, the main advantages of which include a significant increase in the operating time of the device on one load of firewood or coal.

1. ACV Radijator FK1 - a long-burning heating device from a manufacturer from Serbia has a maximum thermal power of 23 kW, which allows you to heat domestic or industrial premises with an area of up to 230 m². A distinctive feature of the Radijator FK1 is a sealed combustion chamber and forced air supply for uniform and long-lasting fuel combustion. The boiler is optimized to work with all types of fuel, but produces the best results when using coal.

Another design feature of the ACV Radijator FK1 is the water-cooled grate and vertical heat exchange surfaces. Such features increase the efficiency of the boiler and increase its efficiency to 85%.

Models in the line:

- ACV (ATsV) FK1

- ACV (ATsV) FK2

- ACV (ATsV) FK3

- ACV (ATsV) FK4

Advantages:

- this series of TT equipment implements active overheating protection, the signal source for which is a copper heat exchanger inside the combustion chamber;

- a smoke cutter when loading coal or firewood increases the comfort of working with the heating device;

- the thickness of the steel walls of the combustion chamber increased to 5 mm increases the durability of the heating system as a whole;

- a built-in thermal catalyst for combustion products increases the environmental qualities of the heating device.

Flaws:

- This heating device is not a non-volatile device - for the automation and fan to work, you must be connected to an alternating current network. Expert opinion: a very high-quality and expensive Serbian-made model, the high efficiency of which fully justifies the money invested.

2. Zota Bulat 18 - a long-burning model from a well-known manufacturer from Krasnoyarsk has a maximum thermal power of 18 kW, which is enough to heat rooms up to 180 m². An increased combustion cycle is achieved using a large-volume two-pass firebox design and the use of fireclay bricks along the way to remove burnt gases. A secondary air supply system is also used to burn unburned solid particles. Maximum performance and burning time are achieved with coal, however, Zota Bulat also shows good results with wood. Maximum convenience and results can be achieved by installing the TurboSet kit on the Bulat 18, which makes the boiler semi-automatic. In this case, the burning time increases by 50%.

Models in the line:

- Zota (Zota) Bulat 18

- Zota (Zota) Bulat 23

- Zota (Zota) Bulat 28

- Zota (Zota) Bulat 35

- Zota (Zota) Bulat 45

Advantages:

- in non-volatile mode, the operation of the device is regulated by the blower damper, on which an optional draft regulator can be installed;

- a removable hatch above the shaft for the passage of flue gases simplifies periodic maintenance of the heating device;

- The Zota Bulat body has a technological hole for installing electric heating elements, which act as a backup heat source.

Flaws:

- In reviews, many consumers complain about the insufficient door seal for loading coal or firewood, which they have to modify themselves.

Expert opinion: a good TT boiler in the mid-price category, the maximum capabilities of which are optimized for the installation of a turbocharging kit and a chimney of sufficient height with very good draft.

3. Bourgeois K MODERN - 16 - a non-volatile pyrolysis type model from a well-known Russian manufacturer has been in operation on the domestic market for more than 10 years and during this time has established itself as a reliable and economical source of heat supply for country houses or summer cottages. The power of the device is 16 kW, which is enough to heat a house with an area of up to 160 m². Among the distinctive features of Bourgeois K MODERN, it is necessary to note two combustion chambers. In one, wood burns slowly with limited access to oxygen, and in the other, the pyrolysis gases released in the first chamber burn. For high-quality combustion of pyrolysis gases, the design of the device contains tubes and injectors for supplying heated air. The special design of the boiler with two combustion chambers ensures almost complete combustion of wood, an efficiency of about 90% and an operating time on one load of 6 to 12 hours.

Models in the line:

- Bourgeois K MODERN-12

- Bourgeois K MODERN-24

- Bourgeois K MODERN-32

Advantages:

- The energy-independent method of pyrolyzing firewood is a very rare type of boiler technology - foreign models require electricity;

- fireclay lining of the combustion chamber allows the use of firewood with a humidity of up to 50%, however, this will have to partially sacrifice efficiency;

- The staggered system of heat exchange surfaces allows you to significantly increase the heat transfer coefficient to the coolant of the heating circuit.

Flaws:

- the efficiency indicated by the manufacturer is achieved only when the moisture content of the firewood is less than 20%, which requires certain measures for their storage;

- The rather difficult period of the boiler reaching its operating parameters requires certain skills when lighting it.

Expert opinion: an excellent non-volatile pyrolysis boiler, the low price of which compensates for the occasional minor shortcomings of the assembly. It should be noted that non-volatile pyrolysis devices without forced air injection are practically absent on the heating equipment market.

Rating of boilers with automatic fuel supply

In the rating of solid fuel boilers with full automation of the heating process, there are two models from well-known manufacturers that operate on fine coal. The widespread use of heating devices of this type is hindered by the widespread introduction of pellet heating systems, the operation of which is not associated with dust and dirt from the coal fraction.

1. Kentatsu VULKAN PR-30P is a universal automatic boiler with a maximum thermal power of 35 kW designed to work with pellets or coal with a grain size of no higher than 30 mm. Structurally, VULKAN PR-30P is a solid fuel unit with a three-pass combustion chamber, automatic coal supply, manual ignition and an air supply fan to optimize the combustion process. To increase efficiency, heat-resistant pipes with specially designed turbulators are installed along the path of flue gases.

Models in the line:

- Kentatsu Vulkan PR-30

Advantages:

- a convenient and functional control panel helps the owner set and maintain the basic parameters of the heating system, and also gives a signal about the end of coal in the bunker;

- The sealed hopper lid prevents the occurrence of reverse draft and combustion of coal in the place of its storage.

Flaws:

- the automatic charcoal ignition unit is present only in models with the letters PE in the model name after the digital power designation.

Expert opinion: a good model of automatic coal-fired heating appliances, the widespread use of which is hampered by a decent price and a large minimum thermal power.

2. Zota Forta 20 - a relatively inexpensive automatic coal boiler from the Krasnoyarsk manufacturer is designed to work with fine coal (Nut) and is designed for continuous operation on one load for up to 6-7 calendar days. Zota Forta 20 has a maximum thermal power of 20 kW, which allows you to heat houses with a total area of up to 200 m². The supply of coal from the storage area (bunker) to the combustion zone is organized using a gear motor, and to remove combustion products, a large-volume ash box is installed on the Zota Forta 20.

Models in the line:

- Zota Forta 12

- Zota Forta 15

Advantages:

- the universal design of the heating device allows you to install a coal bunker on both the right and left sides;

- optional expansion of the bunker capacity allows you to significantly increase the operating time on one load of coal;

- double protection of the coal supply gear motor increases the reliability of the fuel path;

- The large and convenient design of the ash box does not require frequent removal of ash.

Flaws:

- operation of automation in a continuous cycle of coal combustion requires the presence of an uninterruptible power supply in case of loss of the alternating current network;

- The design of the fuel supply unit is very demanding on the quality and size of coal. Using coal with a diameter greater than 20 mm may stop its supply.

Expert opinion: a good solution for automating solid fuel heating. Before purchasing, it is advisable to analyze the local market for the availability of fine coal.

Conclusion

The constant technical development of solid fuel heating systems determines the appearance on the market of quite expensive and high-tech devices, the operation of which no longer requires the constant presence of a person. Among the general trends in the solid fuel equipment market, it is worth noting a serious increase in sales of technically complex TT systems for heating country houses, as well as an increase in the number of installations of simple and inexpensive heating devices as a backup source of heat supply.

Long-burning coal boilers

The operating principle of a long-burning coal boiler using the example of the Stropuva S20 model.

Long-burning coal boilers have a more complex design - the heat exchanger is located not above the combustion chamber, as in the classic version, but behind it or around it, which changes the combustion process itself: the coal burns very slowly (smolders without a flame) from the top layer to the bottom, which significantly reduces its consumption.

For better oxidation, a regular supply of air is necessary, therefore such boilers have an upper combustion system, in which air is supplied directly to the coal combustion zone using a pumping system. This combustion method reduces the frequency of refueling by approximately 1.5–2 times.

Efficiency and selection criteria for long-burning coal-fired boilers

Where are coal boilers installed?

Solid fuel coal boilers are installed in residential and commercial buildings - mansions, dachas, various offices located in areas where it is not possible to connect to the gas system.

An excellent option is to use a coal boiler to create heat in a mansion of 100–150 m2.

- Of course, when compared with gas, it burns without a residue, and after the combustion of coal, a lot of ash remains, which means that it has lower combustion efficiency and some of the funds paid for fuel will simply go to waste;

- The owners also use firewood. They are cheaper, but not very convenient to use. You will need to make them yourself to the required size, or spend money on sawing and chopping them, and you will also have to throw them in at intervals of 3-4 hours, while raw coal burns out in 6-10 hours.

Pyrolysis coal boilers

The operating principle of pyrolysis coal boilers using the Geyser VP model as an example.

The main feature of pyrolysis-type units is that they have two interconnected furnaces: in one, coal burns and hot gases are formed t = 1200–1300ºC, and in the other, these gases are “afterburned,” so they are cooled at the exit of the device t = 150–160ºC and produces virtually no smoke.

Thus, unburned particles of exhaust gases are oxidized and release additional energy used to heat the coolant. This increases the efficiency of the boiler and ensures complete fuel combustion, which extends the burning time of one fill to 24–30 hours, and taking into account the bunker to 4–7 days.

Is it profitable to heat a house with a coal boiler?

The use of a coal boiler is beneficial as a main and additional source of thermal energy. This is especially true for places not supplied with gas, or regions where coal remains the most affordable fuel. In the latter case, we are talking, for example, about settlements located near coal mines, where significant savings are achieved due to the low cost of delivering this energy carrier.

It should be noted that some modern coal boilers can also be heated with dry wood, which allows you to choose the most affordable type of fuel. However, it should be remembered that coal heat generators must not be heated with anything that burns, that is, garbage and so on, which is usually clearly indicated in the instructions for the equipment.

Bunker automatic boilers

Automatic coal boilers differ from previous versions in that all working processes are fully or partially (if we are talking about semi-automatic models) controlled by a programmable microprocessor controller connected to sensors and thermostats.

Long-term combustion is supported by forced air fans (superchargers) and a traction system for removing combustion products.

Model Zota Stakhanov 20. Coal is supplied by an automatic mechanism from a hopper connected to the boiler; supply volumes are regulated by the automatics of the boiler unit.

To ensure uninterrupted refueling, a loading hopper is provided - a metal box with a screw conveyor installed below.

The capacity of the built-in fuel tank in a bunker coal boiler is enough for an average of 2–7 days, and if the fuel is supplied from a separate mechanized storage facility, then depending on the area of its capacity it can last for 3–4 weeks or even for the entire heating season.

Features of heating with coal

Coal boilers have a number of advantages over other types of heat generators used for home heating. First of all, it is relatively low cost and simplicity of design. Compared to pellet options, coal models are 15-30% cheaper, but slightly more expensive than wood boilers.

Another advantage of a coal boiler lies in the duration of fuel combustion. Coal burns much longer than wood, so some models can operate on one load of the firebox for up to 24 hours or more, which is on average 3 times longer. The efficiency, by the way, is also higher, 75-90%, depending on the design features of the boiler.

Important! Coal heat generators can also use briquettes and firewood as fuel, although in this case there is a decrease in their efficiency by an average of 20%.

As for coal, the following grades are mainly used for solid fuel boilers:

- Long-flame gas (LNG).

- Anthracite.

- Brown coal.

The latter brand of coal is unstable, and its shelf life is a maximum of 6 months. This fuel is also sorted by fraction diameter, where small grades are well suited for automatic equipment.

To determine which coal is best to use, you should rely on the recommendations of the heat generator manufacturer, as well as the characteristics of a particular type of fuel.

The main characteristics of coal that you need to pay attention to include:

- Heat of combustion (calorie content) . The highest temperatures are produced by anthracite (8600 Kcal/kg) and coking coal (8700 Kcal/kg). The latter is not recommended for use in domestic boilers, as it is dangerous.

- Ash content is the percentage of ash in coal that will not burn. The higher it is, the worse the fuel; the boiler will have to be cleaned more often. Anthracite is the leader in this indicator.

- Internal moisture - unlike surface moisture, which is removed by drying, it is removed only by combustion. In addition, with an increase in internal humidity, the fuel gives less energy to heating the house, spending part of it on the evaporation of this very moisture.

Among the main features of coal boilers used to organize autonomous domestic heating at home, the following stand out:

- A wide range of capacities, which allows you to heat areas of 50 – 1000 sq.m.

- Even the best coal boiler requires periodic maintenance: adding fuel and cleaning.

- Release of dust and soot into the room when loading the combustion chamber. This is one of the reasons for the need for a separate boiler room, the area of which will be at least 6 sq.m.

- Dependence of the amount of waste on the ash content of the fuel.

- The need to allocate space for fuel storage.

To ensure complete combustion of coal in the combustion chamber, it is recommended to lay out layers of firewood, unless this is contraindicated for a particular brand of boiler, which is usually not the case. This simple move allows you to increase the overall performance of the unit.

Which one to choose: details about the characteristics worth paying attention to

The project will help you make the right choice; it specifies all the requirements for design parameters, communication connection options, installation details of the room, etc. Special attention in the documentation is paid to the operational characteristics of the device itself.

Direct, long burning or pyrolysis

Comparison of coal boilers using different combustion technologies:

| Direct combustion | Long burning | Pyrolysis | |

| Maximum efficiency | 65–75 % | 78–84 % | 85–92 % |

| Autonomous operation | no Yes | no Yes | Yes |

| Energy dependence | no Yes | no Yes | Yes |

| Refueling period | 6–10 h/—— | 12–18 hours/1–2 days* | 24–30 hours/4–7 days* |

| Fuel moisture | w ≈ 30–50% | w ≈ 20–30% | w ≈ 7–15% |

| Acceptable faction | up to 60–80 mm | up to 25–50 mm | up to 5–25 mm |

* refueling period taking into account the built-in automated bunker

We can conclude that there simply cannot be a more efficient combustion of fuel than in an automatic pyrolysis boiler, so if the homeowner’s plans do not include night refueling and constant supervision of the operation of the unit, then it is better to choose this option.

However, it is worth taking into account its demands on fuel quality and pre-emptively looking for a reliable supplier of fine-grained coal or purchasing a crusher. In addition, such a heater only works in conjunction with automation, i.e. it needs to provide uninterrupted access to power.

Primary heat exchanger (housing) material

The material from which the body of a coal boiler is made is an important factor determining the durability and maintainability of the heating system:

- steel is a lightweight plastic material that can easily withstand changes in pressure and temperature, but is prone to corrosion and burnout;

- Cast iron is a durable material that allows you to use high boiler capacities, but does not withstand shocks and sudden temperature fluctuations.

If there is slight damage to the steel heat exchanger, there is a high probability that the hole will be able to be welded, especially if high-quality “boiler” metal with a thickness of more than 4 mm was used, but if even the slightest crack forms on the cast iron, then the entire part will have to be replaced entirely.

The combined model Viadrus U22 is an excellent example of a combination of a cast iron primary heat exchanger and a steel secondary one.

Many manufacturers prefer to combine the strengths of both materials, so they produce boilers with a steel body, but with a cast iron firebox.

Single-circuit or double-circuit

The heat generated by the boiler is distributed depending on the number of circuits:

- single-circuit - designed exclusively for heating the room, connects to a system of batteries (radiators) and heats water only for them;

- double-circuit - used not only for heating the house itself, but also for heating water for sanitary purposes, as well as for “warm floors”.

Reference . In an instantaneous hot water heater, the heating output must be permanently adjusted in accordance with the water flow.

Since the combustion intensity of solid fuel cannot be changed in real time (dynamically), only a boiler that receives thermal energy from the combustion of gases, i.e., of the pyrolysis type, can be relatively profitable, and even then not always, given the difference in the price of coal according to regions.

It is possible to organize a hot water supply system with one circuit. To do this, you need to connect an indirect heating boiler, which will allow water to circulate not only through the pipes, but also pass into the storage tank (through the built-in heat exchanger), heating the water in it.

Minimum required power and heated area

The most commonly used method in non-professional environments to calculate the required power is the ratio of 100 W of heat per m² of room area:

Q = S × 100

- where Q is the required thermal energy to heat the room (kW);

- S – heating area (m²), 100 – specific power, norm per unit area (W/m²).

For example, for a room with an area of 17.6 m² Q=17.6×100=1760 W ≈ 1.8 kW

Usually the calculation is carried out in the direction “from small to large”. Simply put, the value for each room is determined separately, and then the resulting result is summed up. This allows you not only to find out the required power, but also to subsequently calculate the required number of radiators.

One more nuance: the power is calculated for the highest calorific value of coal that can be burned in the unit. When burning with other coal, such heat production cannot be achieved, therefore it is recommended to make a power reserve of 10–20%, then the equipment will not work at its maximum even in the most severe cold.

How and what kind of coal is best to heat a household solid fuel boiler

Efficiency

The efficiency factor (efficiency) shows the ratio of the volume of fuel consumed to the amount of useful heat generated by the unit.

This is the most important criterion for the performance of heating equipment, so it is obvious that the higher the efficiency, the better. For a coal boiler, as mentioned above, the figure varies between 65–92%, which depends on the design, type of combustion and degree of automation of work processes.

Other important selection criteria

Having decided on the choice of the main parameters of a coal boiler, you can pay attention to the additional characteristics of the unit of interest:

- smoke exhaust device - the degree of heat transfer by gases depends on the chimney elbows, therefore a three-pass system is more efficient than a one-pass system;

- volume of the combustion chamber - the larger the size of the firebox (calculated in l/kW), the less frequently fuel needs to be added and the longer the battery life;

- control and functionality - boiler equipment can be equipped with a thermostat, weather-dependent automation, a self-cleaning system and a mobile GSM module;

- external thermal insulation - good insulation allows you to reduce losses of useful energy, preventing sudden temperature changes and cooling of the boiler;

- presence of lining – combustion chambers with lining are more economical, because they consume 25–45% less fuel at the same power level;

- ensuring safety - to protect against overheating, an external heat exchanger or an independent cooling circuit and an emergency thermal valve are provided.

Reference . The most common type of boiler failure is deformation (folding) of its walls. Contrary to popular belief, this is not due to high pressure (it is released through a safety blast valve), but due to simple overheating, since not all units have built-in protection.

Which solid fuel boiler is better to buy?

There are many different types of solid fuel boilers on the modern market. Each type of equipment has its own technical characteristics and efficiency. To facilitate the process of choosing a solid fuel boiler, you need to have a clear understanding of each type of this equipment.

Natural combustion solid fuel boilers

This type of boiler is characterized by its simple design and affordable cost.

Any type of solid fuel is suitable for operation:

Coal.

Peat briquettes.

Firewood.

Waste from wood processing enterprises.

Pallets.

The best energy performance is achieved when working on coal, which has a high calorific value. Combustion is carried out due to the natural supply of outside air to the firebox. Modern models are equipped with thermostats that change the position of the damper at the entrance to the combustion chamber. During operation, it is necessary to regularly add fuel, remove ash and periodically clean the chimney of soot.

Obvious advantages of such boilers:

- ease of installation;

- fuel availability;

- no dependence on external networks (electric and gas).

Sectional view of a natural combustion solid fuel boiler.

Long-burning solid fuel boilers

Such devices represent the next step in the development of boiler equipment. They have an improved firebox shape, forced air supply, and an intelligent control system. The programs built into the control unit make it possible to increase the burning time of a single load of firewood by up to 24 hours, which is very convenient for residents. The relationship between the operation of the blower and the circulation pump, adjusted for temperature indicators, allows us to achieve optimal heating conditions for the building.

The peculiarity of these boilers is that the wood in them does not burn simultaneously throughout the entire volume of the firebox. The area of intense oxidation gradually moves from one end of the combustion chamber to the other.

Advantages of such equipment:

- adjustable combustion process with increased heating duration;

- economical fuel consumption;

- simplified maintenance;

- minimal soot formation.

Sectional view of a long-burning solid fuel boiler.

Pyrolysis boilers

Normal operation of boilers of this class occurs in the mode of high-temperature generation of combustible gases. In technology, this process is called pyrolysis. Wood is usually used as fuel, which, from a chemist’s point of view, is a complex mixture of high-molecular compounds. Under the influence of high temperatures and a lack of oxygen, they split into simple gases, which burn, releasing the main amount of heat.

The firebox of such a boiler is usually divided into two compartments. In the main chamber, the firewood smolders, intensely releasing flammable gases. Entering the afterburning zone, they mix with secondary air and burn out completely. The temperature of this stage reaches 1200o C, which guarantees the absence of harmful emissions in the exhaust mixture.

The heat generated in both chambers is generated by a water heat exchanger connected to the heating circuit of the building. Thanks to the complete combustion of fuel and controlled air supply, such boilers demonstrate the highest possible energy efficiency. The disadvantages include increased demands on the quality of the loaded firewood, the relative humidity of which in most cases should not exceed 16%.

Advantages of such equipment:

- high efficiency;

- lengthening the heating period on one fuel load;

- high level of automation;

- minimum of unburnt waste.

Sectional view of a pyrolysis boiler.

Pellet boilers

Pellet boilers operate on specially prepared solid fuel. Pellets are granules made from industrial waste: sawdust, agricultural plant residues, peat. They are distinguished by their convenient shape, low humidity and high calorific value.

Boilers of this category require almost no human intervention in the process of maintaining the fire. It may be enough to pour the granules into the bunker once a week. Automation will do the rest.

Given the availability of pellets, the advantages of such equipment are undeniable:

- economical operation;

- ease of operation and minimal maintenance;

- high level of automation;

- environmental Safety.

Sectional view of a pellet boiler.

Heat exchanger - steel or cast iron

The reliability and efficiency of the heating system largely depends on the material and design of the heat exchanger. Historically, there are two main types of heat exchangers supplied with solid fuel boilers.

Cast iron heat exchangers

Cast iron heat exchangers have a sectional structure. Their main advantages:

- ease of transportation and repair;

- resistance to chemical corrosion;

- ability to work at high temperatures;

- high thermal conductivity;

- acceptable cost.

But we should not forget about the shortcomings. Among them:

- high probability of destruction due to a sharp temperature change, which often happens when cold water is supplied to a hot apparatus;

- Such boilers take a little longer to warm up, but they retain heat for a longer time.

Steel heat exchangers

Steel heat exchangers are almost always manufactured as a single unit with the boiler. Steel is a more ductile material and is not afraid of temperature changes, but with intensive and careless use, thermal fatigue zones can form in the area of the welds, followed by the appearance of cracks. Unlike a cast iron heat exchanger, the design of which allows the replacement of a rejected section, high-quality repair of a steel block is only possible in a factory setting using welding and heat treatment.

Steel heat exchanger for solid fuel boiler.

What you need to know about power

The power of the boiler is its main characteristic. It shows how much thermal energy it is capable of generating per unit of time. This indicator directly depends on the type of fuel used, the size and design features of the equipment. It is laid down at the design stage and is confirmed by numerous tests of the finished sample. Household solid fuel boilers can reach a power of several tens of kW.

We must remember that most solid fuel boilers are adapted to operate on different types of fuel. The manufacturer usually indicates the maximum performance achieved under ideal conditions. When switching from using coal to raw wood, the loss of power can reach 25-30%.

Tips for choosing a boiler

The future owner of a solid fuel boiler should know the following before purchasing:

1. What type of fuel will be most simple and economical to purchase in your area of residence. This can be coal, peat, firewood, organic briquettes or pellets.

2. Determine the required power of the equipment used to heat the building. In general, to heat every 10 square meters of area of a well-insulated house, 1 kW of boiler energy is required. The calculation should be performed with a small margin, since the efficiency of heat transfer gradually decreases over the years of operation.

3. If you need not only to heat the building, but also to produce hot water for household needs, the boiler you purchase must be a double-circuit one.

4. The quality requirements for a boiler used in a cottage with continuous residence must be higher than for a country house visited periodically.

We gradually approached the selection of specific equipment. The proposed rating of solid fuel boilers for heating a private home should help you with this. When compiling it, the technical characteristics, reputation of manufacturers, reviews of specialists and users were taken into account.

The best known manufacturers and models: characteristics and prices

Recently, Russian coal boilers have become increasingly popular: their quality is constantly improving, and the cost remains quite low compared to foreign analogues. However, the most functional and automated boilers still remain from European manufacturers. Please note that almost all models have different power versions.

Direct combustion

ZOTA "Master" 20

ZOTA “Master” with a power of 20 kW is a very budget-friendly insulated (basalt cardboard) boiler that can withstand pressure up to 3 bar and runs on almost any fuel: coal, wood, pellets and gas (optional). It also uses electricity as an auxiliary heat source (TEH).

Country of origin: Russia, LLC TPK KrasnoyarskEnergoKomplekt.

Protherm “Beaver” 20 DLO

Protherm “Beaver” with a power of 20 kW is a non-volatile boiler with an operating pressure of up to 4 bar, which has an increased service life because it uses a high-tech (GG20) cast iron heat exchanger that is resistant to corrosion and thermal shock. You can only burn with various types of coal and wood.

Country of origin: Slovakia, Vaillant Group LLC (Vailant Group rus).

Bosch "Solid" 2000 B SFU 12

Bosch “Solid” 2000 B SFU with a power of 13.5 kW is a simple, reliable boiler designed for the use of brown coal, but can also burn coal, coke, firewood and wood waste. Equipped with a built-in pressure control device (no more than 2 bar), thermal protection and gas swirlers.

Country of origin: Germany, Bosch LLC (Bosch Thermotekhnika rus).

Long burning

Stropuva S15U

Stropuva S15U with a power of 15 kW - thanks to the volumetric firebox that can hold up to 240 kg of coal, this innovative boiler is an unsurpassed leader (among compact devices) in terms of burning time on one fill: up to 7 days. Consumes coal, pellets, briquettes and firewood, at a maximum pressure of up to 3 bar.

Country of origin: Russia–Lithuania, STROPUVA LLC (STROPUVA).

Cost: 81,500–99,778 rubles.

Boilers with a burning duration of one load of fuel up to 7 days

Buderus "Logano" S181-15 E

Buderus “Logano” S181-15 E with a power of 15 kW is one of the best automatic bunker coal boilers for heating a private home, with built-in water and gas temperature sensors. The improved heat exchanger design ensures long-lasting combustion of coal/pellets and can withstand pressures of up to 3 bar.

Country of origin: Germany, Bosch LLC (Bosch Thermotekhnika rus).

Cost: 252,000–258,840 rubles.

LIEPSNELE L20U

LIEPSNELE L20U with a power of 20 kW is an almost “omnivorous” solid fuel unit that consumes coal, firewood, coal briquettes and pellets, peat, wood shavings, other wood waste, etc. When fully loaded with coal, it maintains combustion for up to 7 days. The pressure level is limited to 1.5 bar.

Country- UAB (Vakaro Rasa).

Galmet "CARBO" 21

Galmet “CARBO” 21 with a power of 22 kW - a Polish semi-automatic coal-fired boiler already in the basic configuration has quite a lot of equipment: a smart PID controller that controls all components of the boiler and controls the combustion process, a flue gas sensor, a thermometer and a pressure gauge. Pressure limit – up to 2 bar.

Country of origin: Poland-Russia, GALMET LLC (GALMET-RUS).

Cost: 113,890–116,759 rubles.

Prices: summary table

Price rating of popular models of coal-fired boilers:

| Coal boiler model | Cost, rub. |

| ZOTA "Master" 20 | 34 000 |

| Protherm “Beaver” 20 DLO | 79 000 |

| Bosch "Solid" 2000 B SFU 12 | 80 000 |

| Stropuva S15U | 81 500–99 778 |

| Buderus "Logano" S181-15 E | 252 000–258 840 |

| LIEPSNELE L20U | 110 000 |

| Galmet "CARBO" 21 | 113 890–116 759 |

| ZOTA "Carbon" 20 | 47 900–53 290 |

| Teplodar "Kupper" OVK 10 | 23 050–25 680 |

| Thermocraft "Uragan" Prof 22 | 28 640–34 641 |

Poll: For what reason did you prefer a coal boiler?

How to properly fire a coal boiler

Before putting the boiler into operation, it is necessary to configure its operation:

- test the heating system for strength by increasing the pressure × 1.25;

- check the draft by holding a strip of paper to the air supply damper;

- turn on the heating at 80°C and correlate the thermometer data with the draft regulator;

- adjust the damper position to achieve the required temperature;

- test the draft at 90°C, at 95°C at the outlet the damper should close by itself;

- after calibration, a constant temperature of ≈ 80–85°C is established.

Due to prolonged firing, the efficiency of the boiler decreases, so it is recommended to first burn lighter fuel with lower efficiency, and only then add fuel with higher efficiency. For example, you can start kindling with paper and small dry firewood, and after they are completely burned out, add coal.

Subsequent maintenance comes down to performing cyclic actions:

- timely loading of coal into the firebox or bunker if the boiler is automatic;

- removal of the upper crust layer, sintered and fused pieces of coal;

- cleaning the combustion chamber from slag and the ash pan from accumulated waste.

Ash pan of a pyrolysis boiler fired with coal.

To save raw materials, sift the contents of the ash pit through a sieve; the unburnt coal fractions remaining in the sieve can be sent for re-firing! Classic boilers are not demanding on fuel: they are heated with almost any solid fuel, even household waste, but high performance can only be achieved by using coal with a moisture content of up to 30% and an ash content of up to 25%. Otherwise, the efficiency will be much lower than that declared by the manufacturer.

But the design of pyrolysis boilers and long-term combustion was initially developed to a certain standard, therefore their requirements for fuel quality are higher: coal must not only be low-moisture - up to 20% and low-ash - up to 15%, but also have a fixed size - from 5 to 25 mm.

Where to buy a coal boiler for heating a private house

In Moscow

- Comfort-Eco, Dmitrovskoe shosse, 100, building 2, tel. +7 (495) 921–37–61.

- My Boiler, Volokolamskoe highway, 116 building 2, tel. +7 (495) 221–56–79.

In St. Petersburg

- TechnoDom, Stachek Ave. 57, Komsomolskaya Square, tel. +7 (812) 671–00–88.

- Kit-Teplo, st. Litovskaya 8, +7 (812) 295–00–05, +7 (812) 248–18–88.

To summarize, it is worth saying that coal boilers are the “golden mean” between ease of use and fuel costs, so if the house is not connected to the gas main, then its installation is completely justified. Even better is the automatic version: it will help you survive even the harsh winter in comfort.

InstructionsLong burning boilersPyrolysis boiler unitsSolid fuel boilersCoal boilers