The use of gas fuel is ineffective without the use of special burners. Today the market offers a considerable selection of designs, from professional ones that create temperatures of up to 1500 degrees and above, to household devices that are needed for heating and cooking.

Nevertheless, it is common for home craftsmen to make these devices themselves. The reason is simple - a do-it-yourself gas burner, adapted to a specific task and working conditions, is more convenient, even if it costs more than a factory one.

Types and classification

Based on their intended purpose, devices are divided into professional and household.

The first include:

- Burners for work related to metal processing: soldering, forging, welding.

- Devices for general construction, road work, roofing, wood burning, and removal of old paint.

- Technological equipment for various purposes. For example, drying chambers, food industry tools.

For household purposes, this includes a gas stove, nozzles for home stoves, heating boilers, and gas convectors.

Household devices include home workshop devices . This is where you most often find do-it-yourself burners, not only manufactured, but initially designed to perform specific tasks.

They are arranged according to two main schemes:

- injection or injection;

- with complete preliminary mixing of the working mixture, or ejection.

In the first type, air (or oxygen) is captured by the supplied gas stream. In the latter, the gas-air mixture is obtained in a preliminary chamber.

DIY gas burner: manufacturing instructions

In this article we will look at how to make a gas torch for soldering with your own hands. This device is often in demand both in private households and for commercial purposes - for individual technical creativity and various types of construction tasks. In particular, gas burners are used for soldering, metalsmithing, forging, roofing, jewelry work, and for other purposes they produce flames whose temperature exceeds 1500°C.

In metalworking, using a gas torch, you can heat a metal workpiece so that in the end it turns out to be sufficiently hardened. When carrying out welding work with some metals, the areas of future seams must be heated.

How to improve flame control

For the normal operation of our homemade unit, we will install a divider and a tap on it. It is better to mount the faucet near the handle, at a distance of about 2–4 Washing machine, but it can also be attached to the supply pipe. As an option, take a burner tap from an old autogen or another similar tap that is attached with a thread. To seal the connection, take FUM tape.

The divider is installed on a pipe with a nozzle; it is made of brass, diameter 15 mm. The best option is a cylindrical part with a hole for a tube with a nozzle. If there is none, we do this: 1. Take a brass pipe with a diameter of 35 mm and cut a piece of 100–150 mm.2. Take a marker, step back from the end and mark 3-5 points, with an equal distance between them.3. We drill 8–10 mm holes in the pipe, take a grinder and make straight cuts to them.4. We bend everything to the center and weld it to the burner pipe.

Choosing a nozzle for bottled gas

As already mentioned, the propane nozzle has a shortened body and a smaller outlet diameter. It is not recommended to try to reduce the hole yourself, since even fractions of millimeters are important here. By eye you can only improve the operation of the stove, but not achieve its ideal operation.

It is important to understand that standard jets simply do not exist. They are designed for each specific model

Modern kitchen stoves are equipped with a set of jets designed to operate on propane. Some models are even produced specifically for bottled gas.

What needs to be done?

First the tools. Although for the most part the assembly is made from ready-made elements, the following are required:

- Hacksaw for metal.

- Drill with a set of drills.

- Pliers, screwdriver, personal files, velvet or appropriate needle files.

- Set of dies and taps with holders.

- Bench vice.

Basic materials you will need:

- Rubber or silicone hose for connecting the device to a gas cylinder.

- Two gas valves: the main one, which opens the gas supply, and the regulating valve, which serves to change the amount of gas supplied to the combustion zone.

- A tube with a thin hole at the outlet is a jet (nozzle).

Often, a gas nozzle is called a nipple, which is incorrect and contradicts the principle of operation of the device. Nipple - a threaded tube, often with a built-in valve. Used to connect parts. The jet ensures the injection of the required amount of fuel into the mixing chamber (for example, a carburetor jet).

- Tubes for the body of the product, injector chambers with a nozzle.

- Lever.

The exact list will be determined by detailed study of the drawings of a homemade gas burner, based on the blanks available.

How fuel is used:

- propane or propane-butane mixture;

- methane or natural gas;

- acetylene;

- hydrogen.

Each gas has its own characteristics. For household and home-made systems, the most convenient are acetylene, propane, and its mixture with butane.

It is quite difficult to get a hydrogen cylinder; methane has a higher pressure than household gas; it requires a reducer.

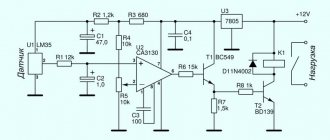

Scheme

A homemade soldering torch is extremely simple. Its body is a tube with a nozzle at the end. At the other end there will be a tap with a pipe for connecting the gas supply hose.

To make it easier to adjust the power of the torch, we will equip the nozzle with a divider.

Gas burner diagram

Work safety

The main traumatic factor when using and setting up a burner is temperature.

Gas, even household gas, is also dangerous, as evidenced by accidents involving explosions or poisoning.

The power of a propane torch depends on the diameter of the injector and nozzle . We must remember: it is not the gas itself that burns, but its mixture with air (oxygen).

The larger the volume that reacts, the stronger the torch. At the same time, the danger of getting a dangerous proportion of propane with air in the injection chamber increases, and as a result, a small explosion - cotton.

Therefore, a homemade burner does not need to be too large. As a rule, the injector diameter does not exceed 3-5 cm, and the nozzle opening is 0.5 mm.

Important! Work in a ventilated area or outdoors. Use gloves to protect your hands.

Gas nozzles for furnaces: purpose, types, features of choice

What is a stove? Surely most people will immediately imagine a brick analogue of a radiator, powered by wood and intended for heating a house. However, instead of the usual firewood, stoves can easily run on gas, although this will require a special device - a gas nozzle.

Purpose and advantages of nozzles

Gas burners (or nozzles) are designed to operate the stove on gas. Like other similar devices, the nozzle mixes fuel - natural or liquefied gas with air. As a result, the temperature in the oven increases.

Most often, such gas products are installed in baths , where high temperatures are required for a long time. However, nothing prevents you from installing a nozzle in your home in order to save yourself from the usual methods of kindling. In addition, such products have a number of significant advantages:

- Safety. Since such products work with explosive material, they are subject to strict requirements regarding reliability. You can verify this by reading the quality certificate.

- Availability of automation. Most gas products are equipped with automatic temperature control , which provides not only economical fuel consumption, but also protection from overheating or explosion of the furnace.

- Economical. As you know, gas is much cheaper than the cost of firewood, coal or electricity.

- Variety of fuels used. Many devices can operate on natural or liquefied gas.

- Ease of operation. The operation of gas devices for furnaces does not require any specific skills. In addition, some models can be operated from a special remote control.

- Ergonomics. Storing coal, firewood or other flammable materials requires a lot of space. The supply of fuel to the injector comes from the gas column.

Types of gas burners

All such devices are divided according to 2 criteria:

- operating principle;

- the type of fuel used.

Principle of operation

There are 2 types of such devices on the gas burner market:

Atmospheric nozzles draw air from the room where the stove is located. In addition, the operation does not require the use of complex automation. Thanks to this, the product has a simpler and more uncomplicated design. The main drawback is the requirement for good air circulation. Therefore, atmospheric burners should be installed in well-ventilated areas. However, some models have special sensors that monitor the oxygen level and, if its content is low, turn off the gas supply.

Supercharged products are equipped with complex automation , due to which they have a more complex design. Such products operate on the principle of forced air injection. Fans are responsible for this, regulating the pressure and volume of supplied oxygen. The main requirement for use is that air must be taken from the street.

Type of fuel used

Everything is much simpler here - the device can run only on gas or use several types of fuel. The first option is the simplest type of gas injectors and is the most popular in comparison with its “competitor”. As a rule, such products are installed in houses or apartments where there is a gas supply.

The second option has a more complex design, but can work with several types of fuel:

- liquefied gas;

- natural gas;

- diesel fuel.

Which one should I do?

Before we begin manufacturing, we will select the appropriate type of burner from the following list:

- atmospheric injection;

- ejection;

- supercharged.

The second and third types are more difficult to manufacture. And to organize pressurization you will need compressed air or oxygen, which means a compressor or another cylinder.

The easiest way to do it yourself is the first type; it’s the one you should prefer..

The atmospheric burner process is controlled by a control valve. Therefore, the choice of type, as well as the model of the device itself, largely depends on which one turns up.

It must be remembered that the combustion of a particular gas depends on the diameter of the nozzle hole. The hydrogen jet has slightly less of it, the propane jet has more.

Designs, diagrams, drawings, assembly technology

First of all, you will need a drawing of the future device, a sketch or diagram of the burner, with dimensions.

It’s easy to find a ready-made one using the Internet . If you understand the general principles of the device’s operation and know how to calculate it, you can develop the project yourself.

An easy option is to use a valve from a propane or oxygen cylinder, known as model VK-74 (see diagram).

A fitting is machined into the side thread, which will also serve as a handle. You can use a pipe of suitable size. On one side, cut an internal thread, on the other, make a shank for putting on the gas hose.

We screw a plug onto the thread with which it is attached to the cylinder. We drill a hole in its end and cut a thread for the jet. We weld a nozzle to the plug on steel spokes, which will also serve as an injection chamber.

It's even easier if you come across an old acetylene cutter or gas cutter. Essentially, this is a finished burner . It is enough to remove the parts connected with the oxygen supply so that they do not interfere, replace the gas nozzle with a nozzle, and attach the injection chamber-nozzle above it.

Design of a device with piezo ignition

A portable gas torch with piezo ignition for soldering is characterized by the formation of a stable flame torch. The device consists of a cylinder containing gas. A nozzle is installed on top. It is attached using an adapter hose.

This design does not require heating, it does not become clogged and odors do not accumulate in it. It has small dimensions, weight and cost.

The purpose of piezo ignition is to automatically ignite the fuel. This is convenient if you don't have matches. However, this is also the most vulnerable part of the structure. With proper care it will last a long time.

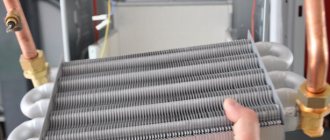

A gas torch for soldering at home is a necessary thing. It can be used to repair copper and brass items. These are parts that make up radiators and heat exchangers. The device is of great help during car body repairs, when high temperatures can cause warping of the metal.

Mini

A very tiny gas burner can be made from a fitting for inflating basketballs, a syringe needle and a couple of droppers , or as they are called medical “systems” for drip administration of drugs. The homemade product can even work from a lighter refill can.

Adjusting roller clamps will act as valves.

True, we will need a forced air supply for this device; the nozzle diameter is too small for injection of atmospheric air. For this purpose, you can use the compressor of an aquarium or an old refrigerator.

Carefully grind off the tip of the syringe needle and fitting. After this, bend the syringe needle slightly and insert it into the side hole of the fitting, so that the end comes out slightly from the cut tip.

We wrap the needle insertion site with copper wire and solder it well with acid.

The burner is ready. All that remains is to connect gas and air to it.

Recommendations

The principle of operation of the device is what you should understand before making the device. You can consider it using the example of a burner for roofing work. How does the burner work?

- The device is connected to the reducers of oxygen and propane cylinders by a system of supply hoses.

- Reducers are placed on the cylinders to create working welding pressure.

- A diagram for gas and oxygen is assembled, the tightness of the connections is checked, the nodes are secured, after which the gas can be opened with valves.

- The gas pressure is set to the operating value and the valve opens.

- The fuel is supplied through hoses to the propane appliance.

- The injector carries out the mixing process to form a gas-air environment.

- A working flame with a temperature reading above 2000 degrees comes out of the device.

Making a burner is one thing, using it correctly is another. A simple burner can cause an explosion or fire.

When performing any welding work, you must wear personal protective equipment: gloves and goggles, special shoes. You can work with propane cylinders only in a well-ventilated area, and at sub-zero temperatures, any actions with the burner are excluded.

What you should absolutely not do:

- work near open fire;

- keep the cylinder tilted;

- place vessels under the sun;

- carry out work without a gearbox;

- Warm up the gearbox over an open fire.

If you can clearly smell the gas, work with the burner should be stopped by closing the valve on the cylinder. Homemade burners, depending on the purpose of use, can be different: burners with a VK-74 valve, devices converted from an acetylene gas cutter and mini gas burners. It is realistic, profitable, and useful to build every homemade device. Only initially you need to decide on the type of structure and its parameters. The gas burner is also used in private households and for commercial purposes. In plumbing, a metal workpiece is heated with a torch, which ultimately comes out quite hardened.

Nozzle and handle - manufacturing options

If you look from the outside, the handle and nozzle are, in fact, the entire unit .

The rest is pipes and valves supplying gas. For the nozzle, you can purchase a brass nozzle from gas appliances. They sell without problems and cost pennies.

If you need a special design, you can proceed as follows.

We clamp a suitable workpiece with a vice.

To avoid crushing the thread when clamping the part in a vice, first use a regular wooden clothespin.

Carefully drill a hole with a drill of a suitable diameter, not reaching the end about a millimeter. We grind down the remaining metal until the point left by the very tip of the drill appears.

After this, using a thin drill or a hardened awl, we punch a hole of the required diameter from the inside.

Any suitable object can be used as a handle. A handle from an old soldering iron, a piece of thick-walled hose, or a drilled piece of wood will do.

To fix parts and hoses, we use clamp clamps and hot glue gun.

The burner flame is adjusted and adjusted in the following ways:

- gas control valve - current;

- moving the nozzle (nozzle) along the axis of the injection chamber, changing its opening.

- changing the size and shape of the supply window through which atmospheric air enters.

The last two methods are used when setting up . They do not need to be changed during operation. However, if you are not sure of the accuracy of the design calculations, you should take care of the possibility of adjusting them.