Here you will learn:

- Description and principle of operation of a hydrogen generator

- The main advantages of hydrogen heating

- Application area

- Hydrogen generator design

- How to make a generator

- Making a simple hydrogen generator with your own hands step by step

- Heating the house with Brown gas

- Installation safety

- Industrial generator

- Economic expediency

Before making a hydrogen generator, it is necessary to study all the details - economic feasibility, safety. We offer several simple circuits and designs of a hydrogen generator.

Description and principle of operation of a hydrogen generator

There are several methods for extracting hydrogen from other substances; we list the most common:

- Electrolysis, this technique is the simplest and can be implemented at home. A direct electric current is passed through an aqueous solution containing salt, under its influence a reaction occurs that can be described by the following equation: 2NaCl + 2H2O→2NaOH + Cl2 + H2↑. In this case, the example is given for a solution of ordinary kitchen salt, which is not the best option, since the released chlorine is a toxic substance. Note that the hydrogen obtained by this method is the purest (about 99.9%).

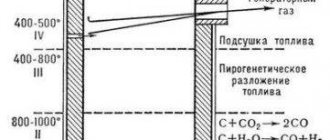

- By passing water vapor over coal coke heated to a temperature of 1000°C, under such conditions the following reaction occurs: H2O + C ⇔ CO↑ + H2↑.

- Extraction from methane by conversion with steam (the necessary condition for the reaction is a temperature of 1000°C): CH4 + H2O ⇔ CO + 3H2. The second option is methane oxidation: 2CH4 + O2 ⇔ 2CO + 4H2.

- During the cracking (petroleum refining) process, hydrogen is released as a by-product. Note that in our country it is still practiced to burn this substance at some oil refineries due to the lack of necessary equipment or sufficient demand.

Of the listed options, the last one is the least expensive, and the first one is the most accessible; it is the one that forms the basis of most hydrogen generators, including household ones. Their principle of operation is that in the process of passing current through a solution, the positive electrode attracts negative ions, and the electrode with the opposite charge attracts positive ones, resulting in the splitting of the substance.

Example of electrolysis using sodium chloride solution

A little history

The principle of operation of hydrogen energy was noted in ancient times. The famous healer Paracelsus, while conducting his scientific experiments, noticed that when certain elements were combined, bubbles were formed, which at that time he mistook for air. It was later discovered that it was hydrogen, which is a colorless gas that exhibits explosive properties under certain conditions.

Currently, they have learned to use hydrogen for various purposes, including heating a residential building or any other structure. These technologies are being actively developed and implemented in many industries. As an innovation on the scientific development market, hydrogen heating has already attracted the interest of many consumers and continues to gain popularity among the general public.

It has been proven that hydrogen is considered not only a fairly common substance, but also an easily accessible substance. The only difficulty is that it has to be extracted from chemical compounds, most often water.

The main advantages of hydrogen heating

This method of heating a house has several significant advantages, which are responsible for the growing popularity of the system.

- Impressive efficiency, often reaching 96%.

- Environmental friendliness. The only by-product released into the atmosphere is water vapor, which is not capable of harming the environment in principle.

- Hydrogen heating is gradually replacing traditional systems, freeing people from the need to extract natural resources - oil, gas, coal.

- Hydrogen acts without fire; thermal energy is generated through a catalytic reaction.

Application area

Today, an electrolyzer is as common a device as an acetylene generator or a plasma cutter. Initially, hydrogen generators were used by welders, since carrying a unit weighing only a few kilograms was much easier than moving huge oxygen and acetylene cylinders. At the same time, the high energy intensity of the units was not of decisive importance - everything was determined by convenience and practicality. In recent years, the use of Brown's gas has gone beyond the usual concepts of hydrogen as a fuel for gas welding machines. In the future, the possibilities of the technology are very wide, since the use of HHO has many advantages.

- Reducing fuel consumption in vehicles. Existing automotive hydrogen generators allow the use of HHO as an additive to traditional gasoline, diesel or gas. Due to more complete combustion of the fuel mixture, a 20–25% reduction in hydrocarbon consumption can be achieved.

- Fuel savings at thermal power plants using gas, coal or fuel oil.

- Reducing toxicity and increasing the efficiency of old boiler houses.

- Multiple reductions in the cost of heating residential buildings due to the complete or partial replacement of traditional fuels with Brown gas.

- Using portable HHO production units for domestic needs - cooking, obtaining warm water, etc.

- Development of fundamentally new, powerful and environmentally friendly power plants.

A hydrogen generator built using S. Meyer’s “Water Fuel Cell Technology” (that’s what his treatise was called) can be bought - many companies in the USA, China, Bulgaria and other countries are engaged in their production. We propose to make a hydrogen generator yourself.

Expert advice

Qualified craftsmen believe that making homemade hydrogen generators for cars at home is a risky endeavor.

They explain this by the fact that an electrolyzer for a car has a complex and unsafe system of devices.

The manufacture of such units requires the use of special materials and reagents.

Please note: in the case of self-installation of an electrolyser that was made by yourself, it is recommended to strictly exclude the possibility of gas entering the combustion chamber when the engine is turned off. When the engine is turned off, the hydrogen generator must automatically disconnect from the vehicle's electrical power supply.

If you still decide to make a car hydrolyzer yourself, then you should definitely equip it with a bubbler - this is a special water valve. Using it will significantly increase safety when driving a car.

Hydrogen generator design

To build hydrogen generators with your own hands, they usually take Brown’s classic installation scheme as a basis. This medium-power electrolyser consists of a group of cells, each of which contains a group of plate electrodes. The power of the installation is determined by the total surface area of the plate electrodes.

The cells are placed inside a container well isolated from the external environment. The tank body has pipes for connecting the water main, hydrogen outlet, as well as a contact panel for connecting electricity.

Hydrogen generation apparatus designed according to Brown's scheme. By all calculations, this installation should fully provide the household with heat and light. Another question is what dimensions and power will allow this to be done (+)

The Brown generator circuit, among other things, provides for the presence of a water seal and a check valve. Due to these elements, the installation is protected from hydrogen backflow. According to this scheme, it is theoretically possible to assemble a hydrogen installation, for example, to organize heating of a country house.

How to make a generator

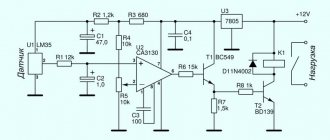

A lot of Internet resources publish a variety of diagrams and drawings of a generator for producing hydrogen, but they all operate on the same principle. We present to your attention a drawing of a simple device taken from popular science literature:

Here the electrolyzer is a group of metal plates bolted together. Insulating gaskets are installed between them; the outermost thick plates are also made of dielectric. From a fitting built into one of the plates there is a tube for supplying gas to a vessel with water, and from it to the second. The purpose of the tanks is to separate the steam component and accumulate a mixture of hydrogen and oxygen to supply it under pressure.

Advice. Electrolytic plates for the generator must be made of stainless steel alloyed with titanium. It will serve as an additional catalyst for the splitting reaction.

The plates that serve as electrodes can be of any size. But you need to understand that the performance of the device depends on their surface area. The greater the number of electrodes that can be used in the process, the better. But at the same time, the current consumption will be higher, this should be taken into account. Wires leading to a source of electricity are soldered to the ends of the plates. There is also room for experimentation here: you can supply different voltages to the electrolyzer using an adjustable power supply.

As an electrolyzer, you can use a plastic container from a water filter, placing electrodes made of stainless steel tubes in it. The product is convenient because it is easy to seal from the environment by removing the tube and wires through the holes in the lid. Another thing is that this homemade hydrogen generator has low productivity due to the small area of the electrodes.

Independent construction

Due to the fact that there is currently no mass production of such units, purchasing them is not an easy process. Most likely, you will have to place an individual order or negotiate the supply of equipment from Italy, where such devices were first developed and put into operation.

But not all consumers can afford such a solution to the problem. In this case, it is worth considering the possibility of building a boiler with your own hands.

How does a homemade hydrogen heating boiler work?

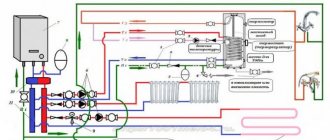

The hydrogen heating system consists of a generator, burner and boiler.

At the moment, no source can provide accurate and success-guaranteing instructions for constructing a hydrogen boiler. But according to the skills and experience of practicing chemists and technicians, such a unit should consist of the following components:

- Heat exchanger.

- Electrolyzer.

- The combustion chamber.

- Safety block protecting against “return” (with 2 stages).

- Container with electrolyte and produced hydrogen. It should be made of alloy or stainless steel, and also be equipped with a valve with which you can relieve pressure in the system.

Operating principle of the boiler

Hydrogen begins to be produced after the electrolytic solution enters the electrolyzer. Under the influence of a catalyst with O2, the element is divided into heat and water. The resulting heat, which has a temperature of about 40 degrees, goes into the heating system, first passing through a heat exchanger. Very often, this temperature is enough to fully heat the house using heated floors.

The water released as a result of the chemical reaction enters the tank (with the electrolyte), and then a certain part of the solution undergoes spontaneous ignition due to the recirculation process.

Making a simple hydrogen generator with your own hands step by step

We'll tell you how you can make a homemade generator to produce a mixture of hydrogen and oxygen (HNO). Its power is not enough to heat a house, but for a gas burner for cutting metal, the amount of gas produced will be sufficient.

Rice. 8. Gas burner diagram

Designations:

- a – burner nozzle;

- b – tubes;

- c – water seals;

- d – water;

- e – electrodes;

- f – sealed housing.

First of all, we make an electrolyzer; for this we need a sealed container and electrodes. As the latter, we use steel plates (their size is chosen arbitrarily, depending on the desired performance), attached to a dielectric base. We connect all the plates of each electrode to each other.

When the electrodes are ready, they must be secured in the container so that the connection points for the power wires are above the expected water level. The wires from the electrodes go to a 12-volt power supply or car battery.

We make a hole in the lid of the container for the gas outlet tube. Ordinary 1-liter glass jars can be used as water seals. We fill them 2/3 with water and connect them to the electrolyzer and burner, as shown in Figure 8.

It is better to take a ready-made burner, since not every material can withstand the combustion temperature of Brown gas. We connect it to the output of the last water valve.

We fill the electrolyzer with water to which ordinary kitchen salt has been added.

Apply voltage to the electrodes and check the operation of the device.

Heating the house with Brown gas

Scheme of operation of a hydrogen generator.

Hydrogen is the most common chemical element, so it is economically profitable to use it.

For many owners of houses and summer cottages, the question often arises of how to obtain “clean” and cheap energy for household needs. The answer can be found in innovations such as a water generator for home heating.

Scientists, thanks to their developments, have allowed many to use such a device to produce gas. The installation is capable of generating hydrogen (Brown gas) and this gas will be used to generate energy.

This compound can be represented by a chemical formula like hho. This gas can be obtained from water using the electrolysis method. There are many examples in life when people want to heat their home with oxyhydrogen. But in order for this type of fuel to gain popularity, you must first learn how to produce it (Brown’s gas) in domestic conditions.

There is not yet a technology for hydrogen heating of a private home that would be sufficiently reliable.

Watch the video in which an experienced user explains how to make a hydrogen generator with your own hands:

Brief theoretical part

Hydrogen, also known as hydrogen, the first element of the periodic table, is the lightest gaseous substance with high chemical activity. During oxidation (that is, combustion), it releases a huge amount of heat, forming ordinary water. Let us characterize the properties of the element, formatting them in the form of theses:

- The combustion of hydrogen is an environmentally friendly process; no harmful substances are released.

- Due to chemical activity, the gas does not occur in free form on Earth. But its reserves in water are inexhaustible.

- The element is extracted in industrial production by a chemical method, for example, in the process of gasification (pyrolysis) of coal. Often a by-product.

- Another way to produce hydrogen gas is by electrolysis of water in the presence of catalysts - platinum and other expensive alloys.

- A simple mixture of hydrogen + oxygen gases explodes from the slightest spark, instantly releasing a large amount of energy.

For reference. Scientists who first separated the water molecule into hydrogen and oxygen called the mixture an explosive gas due to its tendency to explode. Subsequently, it received the name Brown's gas (after the name of the inventor) and began to be designated by the hypothetical formula NHO.

Previously, airship cylinders were filled with hydrogen, which often exploded.

From the above, the following conclusion suggests itself: 2 hydrogen atoms easily combine with 1 oxygen atom, but part very reluctantly. The chemical oxidation reaction proceeds with the direct release of thermal energy in accordance with the formula:

2H2 + O2 → 2H2O + Q (energy)

Here lies an important point that will be useful to us in further debriefing: hydrogen reacts spontaneously from combustion, and heat is released directly. To split a water molecule, energy will have to be expended:

2H2O → 2H2 + O2 – Q

This is the formula for an electrolytic reaction that characterizes the process of splitting water by supplying electricity. How to implement this in practice and make a hydrogen generator with your own hands, we will consider further.

Installation safety

Many craftsmen place plates in plastic containers. You shouldn't skimp on this. You need a stainless steel tank. If it is not there, you can use a design with open plates. In the latter case, it is necessary to use a high-quality current and water insulator for reliable operation of the reactor.

It is known that the combustion temperature of hydrogen is 2800. This is the most explosive gas in nature. Brown's gas is nothing more than an “explosive” mixture of hydrogen. Therefore, hydrogen generators in road transport require high-quality assembly of all system components and the presence of sensors to monitor the progress of the process.

A working fluid temperature sensor, pressure sensor and ammeter will not be superfluous in the design of the installation. Particular attention should be paid to the water seal at the outlet of the reactor. It is vital. If the mixture ignites, such a valve will prevent the flame from spreading into the reactor.

A hydrogen generator for heating residential and industrial premises, operating on the same principles, is distinguished by several times greater reactor productivity. In such installations, the absence of a water seal poses a mortal danger. In order to ensure safe and reliable operation of the system, it is also recommended to equip hydrogen generators on cars with such a check valve.

Industrial generator

At the level of industrial production, technologies for manufacturing hydrogen generators for household use are gradually being mastered and developed. As a rule, energy stations for home use are produced, the power of which does not exceed 1 kW.

Such a device is designed to produce hydrogen fuel in continuous operation for no more than 8 hours. Their main purpose is to supply energy to heating systems.

Installations for operation within condominiums are also developed and manufactured. These are already more powerful designs (5-7 kW), the purpose of which is not only the energy of heating systems, but also the generation of electricity. This combination option is quickly gaining popularity in Western countries and Japan.

Combined hydrogen generators are characterized as systems with high efficiency and low carbon dioxide emissions.

An example of a real-life industrially manufactured station with a power of up to 5 kW.

In the future, it is planned to make similar installations for equipping cottages and condominiums. Russian industry has also begun to engage in this promising type of fuel production. In particular, Norilsk Nickel is mastering technologies for the production of hydrogen installations, including household ones.

It is planned to use a variety of fuel cell types during development and production:

- proton exchange membrane;

- orthophosphoric acid;

- proton exchange methanol;

- alkaline;

- solid oxide.

Meanwhile, the electrolysis process is reversible. This fact suggests that it is possible to obtain already heated water without burning hydrogen.

It seems that this is just another idea that, if you grab onto it, you can launch a new round of passions related to the free production of fuel for your home boiler.

Hydrogen project with an investment of 300 million dollars

Australia is set to see a massive expansion of renewable hydrogen production after a $300 million project earmarked for Western Australia was able to secure investment funding.

The project is being developed by Infinite Blue Energy, which plans to build Australia's largest hydrogen production facility using wind and solar power.

The Arrowsmith Hydrogen project, which will be built at a site in Dongara, 320 km north of Perth, is expected to produce 25 tonnes of green hydrogen per day, powered by wind and solar.

The project will include its own dedicated renewable electricity reserves on site, and an Infinite Blue Energy spokesperson told RenewEconomy that the Arrowsmith plant will receive around 85MW of solar power, complemented by 75MW of wind capacity. Work on the project is expected to begin by mid-year. First production from the site is scheduled for the last quarter of 2022.

Infinite Blue Energy hopes the giant project will help transform Australia into a world leader in the production and supply of zero-emission hydrogen fuel.

With the completion of the Arrowsmith project and IBE's innovative business model, Australia can advance its interests on the global stage as a leader in the development of innovative Green Hydrogen energy solutions and accelerate the creation of a major jobs and industry strategy for Australia in the near future.

Ultimately, Infinite Blue Energy hopes to see the integration of large-scale energy storage and generation using hydrogen, which can provide 24/7 power supply.