An indirect heating boiler allows you to make maximum use of the heat produced by the heating system. Indirect heating of DHW systems is energy efficient and economical, which is why such units are becoming increasingly popular. However, like any other heat exchange equipment, such boilers are susceptible to the formation of corrosion, scale and blockages. To prevent this and ensure long service life of the equipment, it must be cleaned regularly. On the HitEnergy website you can buy a highly effective boiler flushing product at an attractive price.

How to drain water from an Electrolux boiler?

The Electrolux water heater must be drained in accordance with the following sequence:

- Shut off the supply to the container.

- Open the hot water tap.

- Unscrew the drain knob on the safety valve.

- Drain the water from the tank through a pre-prepared hose connected to the drainage hole.

Interesting materials:

Why is it difficult to hear on a mobile phone? Why doesn't it see it when I connect my phone to my computer? Why did the sound disappear on my Samsung phone? Why won't my phone charge? Why doesn't my phone read the memory card? Why doesn't my phone accept Wi-Fi? Why doesn't my phone see the flash card? Why can't my phone see the flash drive via the otg cable? Why can't my phone see my Android memory card? Why doesn't my phone see the microsd memory card?

DIY indirect heating boiler repair

There is almost nothing to break in the boiler; it’s not a water heater. Therefore, along the way, we will consider what can fail regarding the fittings that work for this tank. There really is a lot of it, there is something to break.

Repairing Ariston boilers is in many ways similar to repairing Electrolux boilers, because the device is essentially similar. Let's consider what equipment should be in the general case and indicate typical symptoms of a malfunction.

Anyone who knows the hardware and knows how to weld metals can repair a boiler with their own hands.

Inputs and outputs of an indirect heating boiler

The boiler is an indirect heating equipment. No self-respecting manufacturer would call other products that way. First of all, water heaters, storage and instantaneous, gas and electric.

These are not boilers! The water heater is different in that it cannot do any work without a spiral or burner. The boiler is another matter; it has a coil, and sometimes even two, for circulating coolant. The heating element is built in as an option. (Cm.

See also: How to replace heating elements in a boiler with your own hands)

Here is a typical set of inputs and outputs of an ordinary indirect heating boiler:

Drain hole for emptying the tank. Unlike what we have in water heaters, this element most often does not coincide with the intake pipe.

It is good practice to leave a hole in the ceiling area of the tank for air bleed, where a Mayevsky valve can be built in. This will help empty and fill the boiler.

There is not always a hole for the Mayevsky tap. In this case it is built into the hot water recirculation outlet. And the pump is connected to the inlet through a check valve.

The coil recirculation is usually connected to a boiler, solar collector or heating system. Where exactly is indicated in the instructions.

A separate bypass valve can be built directly into the boiler wall, but this is a fairly rare case.

There are even two holes for the thermostat - for the upper coil and for the lower one. This allows you to flexibly control the operation of the equipment. But most often there is only one thermostat.

This is an approximate set of portals for an indirect heating boiler, now compare it with an electric water heater that is hung on the wall. There is only an entrance and exit for water. Does this look like a boiler? Well, we have already discussed the origin of the term.

We recommend going to the website of some serious manufacturer, like Ariston or Bosch, and see what a boiler is and what a water heater is. Now about the fittings.

Let us immediately make a reservation that in this sense we are using terms from shipbuilding, so fittings in a broad sense are equipment: pipes, connections, taps, taps, valves and even pumps. Although the latter are more likely to refer to aggregates.

Fittings for connecting an indirect heating boiler

Typically, two recirculation pumps are connected to the boiler. For hot water and coolant from a boiler, heating system or solar collector.

Both of them work in suction mode and are separated from the indirect heating boiler by a check valve. It is common practice to shut down the pump and service it.

In this case, there is no need to empty the boiler, because the non-return valve holds the water. The location of the outputs and inputs is as follows:

Recirculation of hot water begins at the very top, and can end anywhere, usually in the middle part.

The coolant recirculation is located at the level of the coil, which is usually located in the lower half. Unless there are two coils.

The hot water recirculation pump must be purchased separately and must be equipped with some kind of control mechanism. This is a built-in thermostat or timer. Recirculation of hot water helps keep heated towel rails warm, in addition, when taking a shower, a person will immediately have real settings.

It won’t happen that hot water from the boiler will come a little later and burn your skin. As for the pump that runs on the coil, it can also be part of a single-circuit boiler. Double-circuit ones are usually not designed to work with a boiler at all.

In this case, if there is a strong desire, it is recommended to take the coolant for the coil from the heating system, and the pump will have to be purchased separately.

The coolant recirculation circuit is controlled by the boiler thermostat. Sometimes it is not included in the kit, in this case, prepare another thousand rubles.

The thermostat can be controlled either by an external pump, which pumps water from the heating circuit through the coil, or by a boiler, which has special terminals for such a signal. They go directly to the three-way boiler valve, which switches the operating mode as required.

With this one it's all about recycling. Do not forget that there must be purified water in the heating circuit. (See also: Sitemap 2)

Cleaning the indirect heating boiler and draining the water

An important point is drainage. Some boilers have a special technological hatch for cleaning, but more often there is no such luxury. That is why the problem of how to repair a boiler worries many minds.

In this case, it is quite difficult to remove scale, and the matter is complicated by the fact that it is impossible to visually control the result. On top of everything else, another problem looms on the horizon - obtaining a large volume of cleaning solution.

For example, a 180 g bottle of 70 percent vinegar costs about 20 rubles. To obtain a normal concentration, a content of at least 4.5% is required. It is not difficult to calculate that to satisfy the conditions you need to take 2.8 liters of water. Yes, plus 180 g per bottle.

It turns out that every three liters of solution costs 20 rubles or so. A little expensive if the full volume is 300!

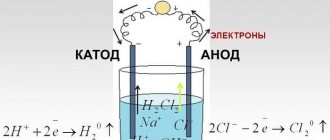

That is why the task of cleaning the boiler is not trivial. Hydrochloric acid is often used in industry. Its disadvantage is that it cannot process austenitic steels.

The concentration is approximately the same as that of acetic acid (about 3 - 5%), but the cost of the substance is about 25 rubles per liter of a 35% solution. This is about 2 times cheaper than acetic acid. The water temperature should be between 20 ºС.

The technique involves pumping through coils at a speed of about 1 m/s.

It is important to remember that if the tank is made of stainless steel, or the enamel is damaged, then the tank cannot be cleaned with hydrochloric acid. In addition, you will need personal protective equipment: clothing, a respirator, goggles, etc.

How to protect your water heater from odor

Get rid of the unpleasant odor of water from the water heater, prevent pollution and its consequences through prevention and proper operation:

- replacing the anode - the element attracts salts and similar substances, reduces oxidation and scale formation. If the magnesium device is “eaten”, the tank is exposed to these factors with increased force, creating an environment favorable for microorganisms;

- correct selection, replacement/cleaning of filters from hydrogen sulfide, iron, impurities. This is especially true if H₂O is hard. But first you need to do the cleaning, rinsing;

- If you haven’t drained the water or cleaned the boiler for a long time, germs will appear. Experts' recommendation: flushing at least once every six months, as well as cleaning an open (wet) heating element.

Some models of water heaters have an antibacterial internal coating (silver particles, etc.).

Pathogenic processes are slowed down, but purifying water from bacteria by washing is still recommended, since the described protection is ineffective if there is a lot of plaque and scale - an environment favorable for the constant proliferation of microbes.

If the water has a specific composition with a high concentration of sulfates, then they interact with the magnesium anode and hydrogen sulfide is released. To check, unscrew the heating element and disconnect the anode. Insert again, if the rotten smell of hot water has disappeared - the cause has been found. An expired anode can be replaced with “eternal” ones - titanium, nickel, aluminum, zinc varieties - they do not have this property.

Cleaning the tank

If there is dirt inside the tank, it can be removed mechanically. That is, wipe it with your hands. Suitable for this:

- Soda;

- Vinegar;

- Lemon acid;

- Detergent.

Cleaning a removed tank is a more reliable and economical way than pouring solutions into it and heating it. You will need very little active substance and a regular sponge or dish brush with a long handle. But remember a few rules:

- If the inside of your boiler is painted with enamel, do not use hard or metal brushes or sponges;

- Perform all work wearing gloves;

- If there is a thick deposit of scale, you will have to install the water heater in place, pour the active substance into the boiler and warm it up;

- If corrosion appears on the inner walls, the best option is to sand it off and paint the tank with enamel.

How dangerous are bacteria in a boiler?

- H₂S and its vapors are toxic, leading to nausea, vomiting, cramps, abdominal pain. Irritating mucous membranes. In large quantities, death can occur. Rapid absorption after entering the body, concentration in the brain, liver, kidneys, pancreas, intestines;

- Legionella bacteria in the boiler are dangerous to health and lead to infectious diseases;

- exposure to low concentrations inhibits hematopoietic function; toxicity to the fetus was noted in tests on pregnant rats;

- Destructive oxidative reactions increase: corrosion, formation of sulfur and sulfides. When certain factors coincide, weak solutions of acids (for example, sulfuric acid) appear. Hydrogen sulfide slowly corrodes metals, so stainless steel tanks with poor-quality seams have an increased risk of corrosion;

- slows down the action of water softeners.

There are several types of microbes.

Those that convert sulfate in water into hydrogen sulfide are of little harm to health, but there are also dangerous pathogenic bacteria legionella , which decompose organic matter and in the process produce H ₂ S, causing intoxication. The type of microorganisms can only be determined by having the water analyzed in a laboratory.

Principle of operation

Gas single-circuit boilers with an indirect boiler operate according to two main connection schemes. The principle of operation of the first is as follows:

- The three-way valve dominates here. A pump is installed directly into the outlet of the gas boiler, which provides circulation and creates pressure. The next step is to install a three-way valve, which is connected to the boiler thermostat. When heating tap water or other coolant, its flow is directed to the heating system, with priority for the hot fluid entering the boiler coil. This happens with the help of an additional, second pump. And it turns out that in this case the hot water supply and the heating system are connected in parallel, and they can form two circuits, precisely in this closed chain. And after the boiler, an additional pump is installed, which helps regulate the operation of the thermostat. The principle of starting and stopping the process is also regulated by a thermostat, namely, when the heating is strong, the fuel supply is forced to shut off, when the coolant cools down, the fuel is passed through again, and the burner is automatically ignited.

- If there is no double circuit and priority is not given to heating hot water, the boiler is mounted in a common system, installed in a convenient location, and water is heated along with all radiators.

You might be interested >> The operating principle of a floor-standing gas boiler

Types of water heaters and do-it-yourself boiler repairs

Many modern people cannot imagine their life without water heaters. Often, devices serve their owners for quite a long time, but sooner or later they fail. The simplest, but most expensive method of repair is calling a specialist.

As an alternative, you can repair the boiler yourself. The procedure is not particularly difficult; you just need to understand the design and examine possible malfunctions.

First you need to study the design of this unit.

Device structure

The classic design of a water heater is presented in the form of a sealed tank. Inside the container there are elements that are needed to heat water and ensure long-term and safe operation of the device. Typical products consist of several main elements:

- frame;

- insulating coating;

- tank;

- magnesium anode;

- inlet tubes;

- temperature sensors.

In this video you will learn everything about water heaters:

There is always water inside the container, so there is a risk of bacterial growth. Because of this, device manufacturers make tanks from stainless steel or treat products with titanium coating. The cheapest material is glass porcelain, and such structures quickly become unusable. There are two types of heating elements:

- Wet. Are in direct contact with water. They are often presented in the form of hollow structures, inside of which there is a heating coil. The space around the element is filled with sand or other substances with high thermal conductivity.

- Dry. Placed on the side of the tank. It is separated from contact with water by a ceramic casing. These elements are considered much safer than wet ones. This is due to the absence of scale on them, which minimizes the likelihood of a short circuit.

The fastening of heating elements can be flanged , when the elements are pressed using bolts, as well as nut - the parts are equipped with threads, the fixation is carried out by screwing. Often heating elements are steel or copper.

https://www.youtube.com/watch?v=7bGJPFrcP-s

In our case, steel parts

Features of various designs

Before you start repairing a water heater with your own hands, you need to figure out what type of device it is. There are several varieties:

The word "boiler" means "boiler". It follows from this that such products include not only storage devices, but also flow-through devices.

Electric heaters

This type of boiler is considered the most popular. The design consists of a tank, a thermal insulation layer (polyurethane foam is often used), and an upper casing.

The heating element is located at the bottom of the device. The water is heated to a certain temperature, which is pre-set on the thermostat, the maximum value is +75°C.

If no water is drawn, the device maintains temperature readings by turning the heating element on and off. It is equipped with overheating protection, so when the maximum performance is reached, the device turns off.

The optimal temperature value is +55°C; it is in this operating mode that the structure will last longer and save electricity.

This device is the most common

Hot water is drawn through a tube located at the top of the device. The cold liquid inlet is located at the bottom of the device. The metal tank is protected from corrosion by a special magnesium anode, which has a certain working life. The element must be replaced once or twice a year, depending on the hardness of the water.

Indirect heating systems

Such products do not independently generate thermal energy; water is heated using a coil in which the coolant is located.

Cold water comes from the bottom of the device, hot water comes out from the top. Indirect heating devices can provide large quantities of hot water, which is why they are often installed in large houses. The operating principle is to exchange heat between liquids at different temperatures. In order for the output to be +55°C, heating is carried out to +80°C.

The process takes a lot of time, this feature must be taken into account when choosing a suitable device. Like their electrical counterparts, indirect ones are equipped with a magnesium anode.

The structures can be wall-mounted or floor-mounted; in addition, they can be connected to a double-circuit gas boiler.

More expensive models are equipped with additional electric heating elements, which reduce heating time as needed.

Gas and flow structures

Gas-powered appliances are only wall-mounted. There is a thermal insulation layer inside the structure. There is a chimney pipe at the top, and a gas burner at the bottom.

The latter is a source of heating, in addition, it is helped by the heat circulation of combustion products. An automatic electronic system monitors and extinguishes the gas as needed.

The column is equipped with a protective anode.

Gas water heaters produce large amounts of hot water in a short period of time.

Flow systems do not accumulate liquid inside. The heating process occurs at the moment the tap is opened, when the devices allow water to flow through them. The structures operate on both gas and electricity. Gas products are modern modifications of popular geysers.

Electrical systems carry out heating using heating elements of increased productivity. Despite their small dimensions, the products are high-power, so their scope of use is limited. Hot water flows regularly without interruption for heating.

Gas water heaters have greater efficiency

Types of malfunctions and their causes

There are many reasons why boilers fail. Most of them can be fixed on your own. Main problems:

- The device does not heat water. The reason may be a failure of the heating element or the electrical system. If the heating procedure takes longer than usual, this indicates multiple scale that needs to be removed. In addition, due to deposits, the boiler may turn on/off more often.

- Overheating of water is a consequence of a broken thermostat.

- A leak from under the flange indicates damage to the container due to mechanical action or metal corrosion.

- If the device is constantly noisy, there may be a lot of scale on the heating element, or the check valve is broken.

- The display shows an error. Some devices are equipped with an electronic system that may malfunction due to power surges or module failure.

- Lack of hot water supply indicates a breakdown of the heating element or thermostat.

- Dark-colored hot water indicates the presence of corrosion, which can be caused by hard water. If the tank is damaged, you will likely need to purchase a new unit.

- The heater produces an electric current. This situation can happen due to damage to the cable or rupture of the heating element.

- The device does not turn on or off - the reason is burnt out contacts or melted buttons.

- Constant burnout of heating elements is caused by a large amount of scale or improper installation of the device.

- If air appears in the water heater, it means the gaskets are worn out or the check valve is broken.

To identify the cause of malfunctions and eliminate them, it is necessary to carry out a number of standard procedures, namely: turning off the device and the network, draining the water and dismantling the product.

Replacing the heating element or anode

If the temperature sensor or heating element has burned out, it is time to replace the magnesium anode. First you need to disconnect the device from the power supply, then:

- Remove the plastic cover and disconnect the wires.

- Turn off the cold water supply and disconnect the pipes.

- Unscrew the mounting screws and remove the protective cover.

- Remove the temperature sensor and flange.

- Remove the heating element carefully so as not to damage the rubber gasket.

- Remove the appliance from the wall, place it in the bathtub, and then run a water hose inside to remove any remaining scale. To clean the heating element, stir 50 g of citric acid in 2 liters of water. Keep the heating element in the resulting solution until the deposits dissolve (10-12 hours).

- Unscrew the magnesium anode and assess its condition. If one pin remains, replace the part.

- After cleaning, return the parts to their place. If necessary, install a new temperature sensor.

- Reassemble the structure in reverse order. Particular attention should be paid to the condition of the rubber gaskets. If they become unusable, it is recommended to replace them with new ones to avoid leaks of the product after assembly.

- The product must be connected to the electrical network after it is completely filled with water.

Repairing leaks

If water drips from the device, the reason may be worn sealing gaskets or damage to the container. In the latter case, repairing heating tanks does not make sense; the purchase of a new device is required. If the problem is in the rubber seals, you need to replace them with new ones.

During installation of the water heater, specialists install shut-off elements. A check valve is installed at the cold water inlet, which is adjusted during operation of the system.

The safety valve is placed on the cold water supply pipe, following certain recommendations:

- It is forbidden to install shut-off valves between the valve and the boiler.

- For a flexible hose, you need to make a special hole in the sewer pipe.

- To quickly drain water from the device, it is permissible to install a ball valve with a tee.

- A leaking valve may indicate its failure. Complete replacement of components will help correct the situation.

- Another cause of leakage can be excessive water pressure. To prevent this, it is optimal to install a regulator that reduces the readings to normal.

Assembly technology

We will describe step by step how to make an indirect heating boiler with your own hands - the whole complex of work will consist of the sequential assembly of different parts of the structure.

Water heater tank

The volume of the container into which water will flow for subsequent heating depends on the needs of the homeowner: the standard consumption is up to 70 liters per household per day, so for a family of 4 people 200 liters will be enough.

The material of the tank should be selected from an aluminum alloy, as well as other non-ferrous metals that are not subject to corrosion, if finances allow - stainless steel. A good alternative is a gas cylinder, but the inner walls must be treated with a special primer, otherwise the hot water will have an unpleasant rotten smell.

You need to cut at least 5 holes in the tank body with your own hands: two on either side - they are intended for inserting a coil, at the bottom there are also 2 - for water supply and a drain tap, at the top there is only one - hot water extraction.

Making a coil

This element, made of a copper pipe of small diameter but thick-walled, can necessarily have different dimensions - it depends on the volume and height of the container. Experts say that for every 10 liters. water requires 1.5 kW of coil thermal power.

To save money from your home budget, you can use pipes made of a different material, but always with excellent heat transfer. During manufacturing, it is necessary to carefully monitor the formation of turns:

- they do not touch under any circumstances - there must be a gap between the turns;

- do not make excessive efforts - this will make it very difficult to remove the finished product from a special mandrel;

- the number of turns is strictly calculated and depends on the dimensions of the tank.

For the mandrel, use a pipe of the required diameter or a round wooden log without knots. After manufacturing, the spiral is carefully coated with a protective heat-resistant varnish.

We insulate the structure

The outside of the tank must be covered with thermal insulation to reduce losses and increase the efficiency of the product - this can be special foam for installation or other material with excellent thermal insulation properties, for example, polystyrene foam.

It is secured with wire, special ties or glued on. Craftsmen recommend strengthening sheets of foil on top of the insulation or using insulation with one foil side. Some craftsmen insert the boiler into a larger container for insulation, and fill the space between it and the inner walls with insulation of any kind.

How to Remove Bacteria in a Water Heater

Removing bacteria by washing and disinfecting the storage boiler:

- Shut off the main pipeline in the apartment, turn off the water heater from the network, and drain it.

- Remove and disassemble the container; to do this, unscrew the heating element (flange connection) and its casing - you can stick your hand with a sponge on a long holder into the hole. Clean the tank from dirt, plaque, and sediment with a sponge and detergent. Use soft material to avoid scratching the inner surface. Rinse the container and drain the liquid.

- You don’t have to unscrew the heating element if deep cleaning is not required. Disconnect the supply tube, pour white through it (50 liters - 1 liter of product), fix it in position above the tank. Instead of the specified solution, you can use scale solvents.

- Connect the hose to the pipeline and open the valve.

- After filling, turn on the boiler and warm it up.

- Open the taps, wait for the liquid with bleach to flow, close them - this will additionally disinfect and protect the section of pipes from the tank to the tap from bacteria.

- For a recently cleaned container, it is enough to wait 3 hours, but if cleaning has not been carried out for more than a year - 6 hours;

- Fill and, bringing the heating to maximum temperature, drain 3-4 times to remove all traces of detergent.

Ways to drain water:

- A pipe (hose) with cold water (blue on the valve) goes from the source to the boiler, and hot water (red on the valve) goes from the tank to the tap points. There is also a release safety valve on the tank body; it is activated automatically if the pressure inside exceeds the norm. To drain, you need to open the valve tap - the liquid will flow out, you can connect a tube to the spout. The disadvantage of this method is its low speed: an 80-liter boiler will empty in 2 hours.

- The second method requires a wrench. The hot tap at the washbasin should be closed; place a container under the tank. Unscrew the nuts of the tube and the safety valve fastenings with an adjustable wrench, and disconnect the assembly completely. The hot tap is opened, air begins to flow into the tank, and the contents begin to flow out of the cold pipe of the tank. The speed is adjusted using the specified tap or shut-off valve, if there is one at the outlet of the hot pipe of the water heater.

- Uncontrolled, but the fastest and easiest way: unscrew the cold hose, safety valve, and hot tube at the outlet of the boiler in order. Water will flow out with pressure, so it is important to place a large container (basin) for collection.

During the process

of servicing and washing the storage water heater, it is advisable to clean the heating element, which is important for open-type devices (wet, submersible); for dry devices, the procedure is not required - they do not come into contact with water.

The heating element is removed, washed and placed in a solution of citric acid (20 g per 1 liter) or in a special solution for dissolving scale for several hours. If there is not a lot of scale, then you don’t have to unscrew the heater: fill one third with the mixture described, wait several hours, drain, repeat several cycles.

Source

What is meant by flushing heat exchange equipment?

Chemical in-place flushing of the boiler involves pouring a cleaning composition into it, which destroys accumulated deposits. The basis of the process is circulation. It is necessary not only for the effective removal of crushed deposits, but also for reducing the washing time.

If you simply pour the flushing liquid into the circuit and leave it for some time, it will quickly go from acidic pH to neutral, since chemical reactions will take place inside between it and the deposits. Because of this, only part of the contaminants will be removed and time will be lost for repeated refilling of the product.

By connecting a pump that provides circulation, the operator, who monitors the pH, can always add concentrate on time without temporary downtime. The cleaning solution continuously moves through the flushing circuit and enhances the effectiveness of deposit removal due to the hydraulic cleaning effect. Thus, when choosing the right product, it takes about 4-8 hours to wash industrial units.

Expert advice

Sometimes the cause of the smell may be a poor-quality heating element or anode. If the smell or taste in the water reappears after cleaning, this may be the problem.

To avoid problems with scale, perform maintenance on your boiler once a year.

If you have dirty water from a water supply system, a well, or a borehole, place a filter in front of the boiler entrance and periodically change or clean it.

Do not heat the water below +55 degrees. At a lower temperature, microorganisms will multiply in it, especially the dangerous Legionella.

If your water heater tank is made of stainless steel, paint the welds with enamel. This is the weakest point of such boilers.

Install a back pressure valve. It will bleed water if the pressure in the system is too strong or a water hammer occurs. This way you will protect yourself from surprises.

Completeness

In a dual-circuit system, everything is there.

As a rule, a double-circuit floor-standing gas heating boiler is already equipped with everything necessary: a circulation pump, a safety valve, a membrane expansion tank and fittings. All that is needed to install such a mini-boiler room is to supply gas, water pipes and a pipe for removing combustion products.

In single-circuit - everything is separate.

Not only do you need to buy additional equipment, but you also need to install it in a boiler room, which requires a considerable area. Wall-mounted single-circuit boilers are more convenient in this sense - they already have some of the necessary components, all that remains is to connect a water heating boiler for the hot water system with protection elements.

Single-circuit.

You need space - both for the boiler itself and for the expansion tank, pump, safety valve. Considering not only the dimensions of the system, but also its unaesthetic appearance, it is better to place it away from the eyes. At the same time, the installation itself of both boilers will not be difficult for a good specialist.

Article Rating

Why does the water go out in the water heater?

The type of water heaters, storage tanks - electric, gas, indirect heating - is not important. The unpleasant smell of hydrogen sulfide from the boiler can appear with any version of the product.

The mode of use matters - high intensity reduces the likelihood of

rotten water appearing in the water heater.

Reasons why water from a water heater smells of hydrogen sulfide, as well as other contaminants:

| Sign of a problem | Cause |

| Musty smell of hydrogen sulfide, stale scent, same taste | The reason is microbes. The appearance and vital activity is determined by: · stagnation, lack of water flow due to infrequent use of the water heater; · not timely cleaning (scale, plaque, sediment); · warming up only to +40 °C, this is the optimal environment for the proliferation of microorganisms; · hydrogen sulfide is already present inside the water supply, which can be determined by drawing cold water from the tap and smelling it; · interaction of the magnesium anode with special impurities. |

| Cloudiness, foreign particles | · the above reasons; · breakdown or absence of filters due to poor quality water from the pipeline. |

| Metallic taste | · depletion of the magnesium anode, untimely replacement of the element. For “eternal” varieties of devices - titanium, nickel - the aftertaste is not typical; · may occur if the water heater is made of stainless steel, but such cases are rare, corrosion-resistant material usually has no effect; · corrosion around the welds of metal containers. |

| The smell of gouache, anise plastic, medicine | The tank material releases hazardous substances, including phenol and formaldehyde. Cases are rare. All boilers are necessarily certified according to sanitary and hygienic standards, but the possibility cannot be excluded if a fake, counterfeit tank is purchased, especially one made of plastic. |

The reason

why the water from the water heater stinks of rotten eggs may also lie in the tubes and hoses, so they are also checked, washed, and disinfected.