An automatic coal boiler requires less maintenance than a classic one. Fuel loading and ash removal are carried out once every 7 days. Due to the large number of components and systems, high demands are placed on their reliability, therefore it is necessary to pay special attention to the choice of manufacturer.

Description of coal boilers with automatic feed

Fuel continuously enters the firebox in small portions . A similar principle is implemented in pellet boilers. The feed rate is regulated by a microprocessor controller taking into account the temperature of the coolant or air in the room (thermal sensors are connected).

The scheme has the following advantages:

- user participation is required less often;

- coal burns completely (efficiency 90%);

- power is regulated (up to 30% of the nominal);

- there is no inertia - productivity can be sharply reduced to zero.

Due to their ability to operate for a long time on one load of fuel, units of this type are called long-burning boilers. The ability to change heat transfer over a wide range allows them to be used in low-temperature mode, which is necessary in the off-season or for floor heating.

Due to the lack of inertia, the heater turns off at any time. This prevents boiler water from boiling and excessive consumption of coal.

Solid fuel pellet boilers

If you purchase an automatic solid fuel coal boiler for a heating system that is inexpensive to operate, nothing will come of such an undertaking. But with a little ingenuity, TKDGs can save you a lot of money. To do this, we must remember that Moldova is an agricultural country. With a large amount of agricultural waste, especially sunflower husks.

Today the market offers an abundance of cheap husk pellets at a price of 2 rubles per 1 kg. But the main advantage of fuel from waste is its high heat transfer:

- on average, the calorie content of this raw material is 4500 kcal;

- if you compare husks with gas, then for 1 lei spent you get 2250 kcal of energy (from gas 1592 kcal);

- 30% - this is the saving you get if you heat with husk pellets.

The only problem is that not all coal boilers burn agropellets effectively due to the high ash content of this fuel. The units operate effectively on several types of solid fuel:

- fractional coal;

- fuel with a high composition of coal dust;

- agro-pellets;

- biomass of sunflower and corn.

The burner is independent of the fuel composition and copes well with the afterburning of pyrolysis gas and coking of the fuel. Unlike coal, agropellets produce 5-10 times less ash, and the kindling temperature does not go beyond acceptable limits.

Design and principle of operation

The automatic solid fuel boiler is designed on the basis of a classic unit: in the body there is a combustion chamber with a heat exchanger, below there is an oil pan.

The following components have been added to the design:

- Fuel bunker.

- Electric feeder.

- Special burner with ignition mechanism.

- Rotary grate.

- Electronic automation.

- Fans for air supply. When burning coal, large amounts of oxygen are consumed. Natural draft is not able to provide such a volume; the fuel will not burn completely.

The user pours coal into the container and turns on the control unit. He activates the feeder motor and commands the burner to ignite the incoming portion of fuel. Ignition is carried out by an electric arc. If the fuel extinguishes in the future, the automatic system will generate a spark again based on a signal from the flame sensor.

By controlling the feeder motor, the controller regulates the supply of coal. The grate bars rotate periodically to dump the ash into the box. There are models with the function of removing soot from the walls of broken smoke channels. It is cleaned by springs, then dumped into the ash pan by a rotating auger.

If necessary, automatic coal boilers are switched off, stopping the supply of fuel and air. The heat exchanger located away from the burner does not receive energy from the smoldering coal. After the water in the pipes has cooled, the temperature sensor signals the controller to resume air injection. Fuel ignites; The smoke entrained by the fan is directed to the heat exchanger and heats the working environment.

Internal structure

A solid fuel boiler for heating a private house with automatic fuel loading differs from semi-automatic boilers in having a more complex internal structure. Thus, the fuel combustion process is carried out in a special burner, and waste in the form of ash is gradually poured into the ash pan. With the help of grates you can heat the boiler in semi-automatic mode.

In order for the equipment to work efficiently and without failures, you need to prepare coal with the correct fraction. The heating fluid heating procedure is carried out in a heat exchanger.

To extend the service life of the boiler installation, it is important to correctly adjust the return temperature. If the return is cold, the heat exchanger will undergo cracking or severe deformation.

In large-sized systems with long circuits, 3-way thermostatic valves are placed, which will automatically mix hot coolant with cold.

Coal hopper design

The container is a steel box with a flange for connection to the feeder.

Installed inside:

- crusher;

- fuel disintegrant (prevents large caked lumps from jamming the mechanism).

Bunkers are available that do not require connection to a feeder.

The product is located above the burner and is a horizontally rotating drum with a rectangular hole in the wall. With each revolution, a portion of coal is poured into an even layer onto the grate.

This solution has two disadvantages:

- danger of fuel ignition in the bunker;

- inability to load fuel manually (necessity arises during power outages).

The owner of such a device is recommended to acquire a low-power diesel generator for backup power.

Varieties by type of fuel bunker

Reservoirs differ in volume and location . There are two types.

Built-in

It is part of the boiler, attached to the body.

Advantages:

- quick installation;

- there is no need to allocate an adjacent room for storage.

Disadvantage: small volume. Coal reserves last for 3-7 days.

Mechanized

A spacious bunker installed in an adjacent room. It must be separated from the boiler room by a wall made of non-combustible material.

The advantage is large volume. Loads only once per heating season.

Disadvantage: installation takes 2-3 days.

How to choose?

When choosing, you need to look at the following points:

- fraction of the coal used - less demanding equipment that works on fractions up to 80 mm;

- possibility of using different types of fuel;

- dimensions, volume and rated power of the tank;

- voltage of the electric motor - for the home it is best to use systems operating on a voltage of 220 volts;

- System efficiency - for industrial equipment it is up to 81% with simultaneous heating of areas up to 3500 m2.

Automatic fuel delivery options

There are two types of feeders.

Feeding by pneumatic conveyor

The device consists of the following parts:

- compressor;

- receiver;

- dispenser with piston drive.

Once every 24 hours, air with excess pressure is pumped into the storage tank, after which the system goes into a non-volatile mode.

Automatic feeding is carried out due to the action of compressed gas on the pistons, so power outages lasting less than a day do not affect it in any way.

Conveyors of this type have two disadvantages:

- relatively high energy consumption (compressor engine power is 1.5-2 kW);

- make a loud noise.

Therefore, they are used only in conditions of unstable power supply.

Screw transmission

The mechanism resembles a meat grinder. The spiral turns of the auger move the coal forward as they rotate.

The feeder operates silently and consumes relatively little electricity (motor power is 130-180 W).

The disadvantages of the mechanism are as follows:

- energy dependence;

- with a length of more than 2 m, the coal has time to crumble during the journey.

Most household units are equipped with such feeders.

Pellets and their effectiveness as solid fuel

Pellets are cylindrical granules compressed under high pressure, obtained by processing waste from agriculture (husks of grain seeds, hay or straw) and wood processing (sawdust, chips, shavings or bark). Peat and coal pellets are less popular.

This is what different types of pellets look like.

The calorific value (specific heat of combustion) of pellets is 17.2–19.5 mJ/kg = 4.7–5.4 kW/h, which is significantly higher than, for example, wood, pure peat and even fuel briquettes . Burning 2 tons of pellets provides the same amount of energy as 960 cubic meters of gas, 1000 liters of diesel fuel or 3.2 tons of firewood.

In Russia, the production of pellets of the “Premium” and “Standard” varieties is permitted, which have an insignificant degree of ash content of 0.4–1% and 1.5–3%, respectively.

Reference . Contrary to popular belief, pellets are produced without the addition of synthetic substances: and although there are standards that allow chemicals in the composition, most pellets do not contain binding substances and improvers, and gluing occurs due to lignin released during heating.

The disadvantages include, perhaps, storage conditions - they cannot be left simply under a canopy, but must be stored in a closed room or container.

Which coal is suitable for heating automatic coal boilers?

Fractional fuel of the Eco-pea variety is used. The grain size is determined by the design of the feeder and is given in the product data sheet. In most cases it is 5-50 mm. It is advisable to use fractions of no more than 25 mm, since large pieces do not burn completely.

Requirements for coal quality depend on the type of burner.

There are two of them:

- Retort.

- AKM.

The first option is designed for clean fuel that does not contain coal (coal chips less than 5 mm in size). It is obtained by sifting on sorting sieves, packed in bags and sold at a relatively high cost.

The second type is unpretentious in terms of fuel quality . The share of shtyba is allowed up to 60%. Such fuel is obtained from cheap assorted fuel using a built-in crusher. This generates a large amount of dust, which is a significant drawback.

What to look for when choosing a boiler unit

The efficiency factor (efficiency) is the most important point that is worth paying attention to, since it is it that shows the efficiency of the heating device. Manufacturers usually indicate an efficiency of 85–98%, but in reality it depends on the correct settings, the quality of the granules and design features.

Main characteristics of automatic pellet boilers:

| Burner type | |

| retort (meat grinder) - “omnivorous” vertical burner, but the use of less heat-intensive fuel reduces efficiency | stoker (flare) – horizontally directed burner, efficient, but demanding on fuel quality |

| Heat exchanger material | |

| steel is durable, but (with a thickness of up to 6–8 mm) material subject to burning | cast iron is a durable, but fragile material if used improperly |

| Control system | |

| built-in controller - a control unit located on the boiler controls the processes of loading granules and heating | full automation - options for feeding, ignition, heating, self-cleaning, thermal and photosensor, timer and protection system |

| Maximum power | |

| The boiler power required for heating a house is calculated individually, but in any case it is recommended to buy the device with a small margin of 10–20% | |

| Heating circuit | |

| single-circuit - intended only for heating the space of the house itself | double-circuit – allows you to heat water for sanitary and domestic needs |

Reference . If there are several heating systems, such as radiators, water supply and heated floors, or it is necessary to create climatic zones, then it is better to purchase dual-circuit equipment with additional automation that allows you to control several temperature conditions at the same time.

It is also worth paying attention to equipping the boiler with a device for swirling fuel gases: thanks to it, part of the heat does not go into the chimney, but is transferred as much as possible to the heating system, which increases efficiency, and also prevents ash formation, because The pellets burn out almost completely.

How to choose a room thermostat for a heating boiler and save up to 30% every month

Requirements for arrangement in a private house

The room in which the boiler is supposed to be placed must meet the following conditions:

- Minimum area – 7 sq. m.

- There is at least one opening window.

- Provides fresh air. The quantity depends on the heater power.

- There is a separate entrance from the street for fuel delivery.

According to the standards, for natural ventilation the total area of the inlet openings is determined at the rate of 8 square meters. cm per 1 kW of boiler rated output. These can be open transoms or valves or channels in the walls.

If it is not technically possible to provide the required area with inlet openings, forced ventilation is used.

Automatic boiler "Yamal" long burning

Anyone who has heated their own home with coal knows about the main problem with this fuel, which prevents it from organizing its automatic supply to the high-pressure boiler. In most cases, its fractions differ in size, hence the automation of supply in the form in which it is implemented, for example, in pellet boilers, becomes impossible. Manufacturers of the Yamal coal machine have solved this problem by using an absolutely modern feeding method that can work perfectly even with fractions of various sizes.

Photo 1: Domestic coal-fired heating boiler "Yamal" with automatic feed

The meaning of this method, like everything talented, is not complicated. In the middle of the bunker with inclined walls there is a conveyor that picks up pieces of coal and raises them higher and higher. At the highest point there is a gear crusher, which passes fractions of suitable size, and those that are larger either prick against its teeth or fall back into the hopper. As you can see, the mechanism does not have complex structures, and even if it fails, everyone can adjust its operation with their own hands.

Photo 2: Automatic loading of coal into the combustion chamber of the Yamal boiler

The operation of the Yamal boiler is fully automated. Fuel supply, ignition, slag discharge, power adjustment - all these processes occur automatically under the supervision of an electronic control unit. When the fuel bunker is completely filled and the diesel burner is charged, a coal heating boiler can heat the room itself for 20 days.

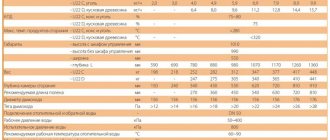

The production company produces three Yamal models of varying power. Their key technical data is shown below:

Choosing an installation location

A coal boiler for heating a private house is placed in a separate room.

The installation location must meet the following conditions:

- The minimum distance from the device to the wall is 50 cm.

- The floor is made of non-combustible material (ceramic tiles, concrete).

- For a unit with a power of over 50 kW, a separate foundation is erected on the ground, not connected to the building structures and screed.

The wooden floor is protected with a sheet of tin on a fireproof heat-insulating substrate. It is recommended to use basalt cardboard for this purpose - the material is inexpensive and environmentally friendly. Previously used asbestos was recognized as a carcinogen.

On the sides and rear, the flooring protrudes beyond the boiler by 50 cm, from the side of the combustion door - by 1 m.

If the heater is installed near a wooden wall, it is also protected with a tin screen with a backing or covered with vermiculite plaster.

Which chimney is better to install?

The exhaust from a coal boiler is characterized by:

- high temperature – 650 ˚С versus 300 ˚С for wood;

- a large amount of sulfur and other elements that form a caustic mixture of acids when moisture condenses.

In such conditions, special requirements are placed on the chimney. In the case of using a sandwich type structure, the internal (working) part must be made of heat-resistant and acid-resistant steel. Ceramic chimneys have similar properties. Brick ones need to be lined.

The cross-section of the smoke exhaust duct is selected in accordance with the rated power of the heat generator. The manufacturer provides it in the instructions. You can focus on the smoke exhaust pipe: the diameter of the channel should be the same or exceed it.

Wood briquettes for the boiler

At the moment, the production technology has been changed. Consumers began to be offered cylindrical fuel, up to several centimeters long, which made it possible to use wood fuel briquettes in automatic boilers.

How and from what are wood briquettes made?

Heating wood briquettes for boilers are produced in three different ways, each of which has its own characteristics and markings:

- Rectangular RUF briquettes - received the marking due to the fact that the first compressed fuel was created on equipment manufactured by the German manufacturer RUF. In shape, the finished product resembles a small brick. The production principle is based on pressing sawdust and waste using hydraulic presses at a pressure of 300-400 bar.

Cylindrical briquette – pressing of briquettes for solid fuel boilers of this type is carried out using hydraulic or shock-mechanical equipment. When pressing, the pressure increases to 600 bar. The disadvantage of the cylindrical type of fuel is the fear of moisture and susceptibility to mechanical damage.

Pini&Kay – pressing of wood briquettes for heating boilers is carried out using mechanical screw equipment. The difference between production is the simultaneous use of high pressure (up to 1100 bar) and thermal firing. The resulting “logs” have edges and a characteristic dark brown color.

- The washers are similar in structure to Pini&Kay, have four or six edges and a radial hole in the center. The length of the briquette is only a few centimeters.

- Coniferous briquettes flare up quickly and create a high temperature in the firebox, but quickly burn out due to the large amount of resin released. Heating with pine briquettes is not profitable due to high fuel consumption, but it is advisable to use them to light the boiler.

- Pressed hardwood slabs have a high calorific value, are difficult to ignite and burn out slowly. The average consumption is 10 kg for 6-7 hours.

The briquette production technology used affects the quality and cost of fuel. Pini&Kay have the highest calorific value; they are resistant to moisture and mechanical stress, and also burn longer when fired.

Briquette consumption in the boiler

Solid fuel for boilers in briquettes is made from various types of wood. The burning time and fuel consumption depend on the type and type of wood:

Another type of briquettes that has not found widespread use are slabs made exclusively from bark. This type of fuel burns hard, but during combustion it has practically no flame and smolders slowly. At the same time, the temperature is maintained until the slabs burn out. The average burning time is 12 hours.

Cost of wood briquettes

It is economically profitable to use fuel briquettes due to their high calorific value and low content of non-combustible residue.

Which heating system to choose

The preferred option is with forced coolant circulation.

Its advantages:

- heat is distributed throughout the house evenly;

- the boiler operates in a gentle mode (the difference between the thermometer readings at the flow and return is small);

- Low temperature mode and connection of heated floors are possible.

The system is designed so that in the event of a power outage or pump failure, the coolant circulates naturally.

For this:

- use pipes of increased diameter;

- install them with a slope of 3 mm/m;

- the supply pipe from the boiler begins with a vertical section (acceleration manifold);

- the pump is installed on the bypass.

A two-pipe scheme is optimal.

Long burning units

A less expensive option for a heating unit than bunker models is a coal boiler that burns fuel for a long time. It has an enlarged firebox, which is densely filled with coal. Then the fuel is ignited, but not from below, as in a classic boiler, but from above. The air needed to support combustion is also supplied from above. Thus, combustion does not involve the coal mass, but gradually, as the mass burns out, it descends from top to bottom along the combustion chamber.

A long-burning coal boiler is capable of maintaining uniform heating of the coolant for 8-12 hours, i.e. per day it requires only 2-3 loads of fuel. A coal-wood boiler , which uses coal and firewood with equal efficiency, is very popular among consumers The disadvantage of long-term combustion thermal installations is that they are demanding on the composition and quality of the fuel used: it must be dry and homogeneous. Sintering of burnt particles, which impede further combustion, is unacceptable.

Choose, based on your capabilities, which coal boiler to buy for your home - an expensive but fully automated one, or an affordable long-burning unit. Now you have the information to make an informed choice of heating unit.

User manual

The user is required to comply with the following rules:

- In the same room with the boiler, it is allowed to store a supply of coal for no more than 24 hours of operation. The rest of the fuel is contained in an adjacent room behind a wall made of non-combustible material.

- The chimney and internal surfaces of the boiler should be cleaned of soot every year before the heating season. Otherwise, it may ignite, which can lead to a fire and shorten the service life of the pipe.

- Liquid removed from the condensate collector must not be drained into an autonomous sewer system. This will cause the death of bacteria in the drive. Condensate is disposed of separately.

During operation of the automatic fuel supply system, coal dust is generated. In concentrated form, it can ignite and even lead to an explosion. To avoid this, you should equip the boiler room with dust collectors and regularly perform wet cleaning.

What are the dangers of using unsorted coal?

In batches of unsorted coal, there is an excess of coal dust, huge pieces of rock the size of a fist, which jam the auger of an automatic solid fuel long-burning boiler, tearing off the keys between the engine and the gearbox. As a result, the boiler fails or simply malfunctions. To correct the situation, you will have to tinker with it a lot and spend money on replacing faulty parts and components.

In Russia, sorted coal intended for solid fuel boilers is rarely sold anywhere, so suppliers recommend using coal with a fraction of 6 - 13 mm (seed coal). As a rule, this is anthracite with high calorie content. However, due to the high calorific value and extremely high temperatures during combustion, anthracite fuel deforms the burners. Over time, these parts have to be changed.

Even if you use fine-grained anthracite, which will have a calorie content acceptable for combustion in a TKDG, you cannot expect effective operation:

- with a 70% probability the boiler will not burn out the coal;

- the rated power will drop by half;

- a 25-kilowatt boiler can “turn” into a 15-kilowatt one

- the coal will have to be reseeded and used in a second round.

In order for an automatic long-burning boiler to produce the declared power, it is necessary to supply a certain amount of fuel to the burner in 1 unit of time:

- Long-flame coal has a calorific value of 6100 kilocalories per 1 kg (7 kW). In order for the boiler to produce a power of 28 kW, it is necessary to supply 4 kg of coal per hour. During this time, the coal should burn completely, but it is unrealistic to effectively burn 4 kg of coal in an hour. That is, burn in such a way that the efficiency of the device reaches at least 75%, not to mention the 85% declared by the manufacturer.

- If you reduce the fuel supply by 2 times, the boiler power will decrease in proportion to the amount of fuel supplied. That is why if the boiler does not “raise” the temperature above 50 degrees, the reason must be sought in incorrect settings.

In order for a boiler with automatic fuel supply to work without failures and problems, you need to buy long-flame coal. According to the manufacturer, its calorie content is 6100 kcal per 1 kg (in practice, the figure is 15-20% lower). It is worth considering that long-flame coal, which is sold in Russia, has a fraction of 13 - 50 mm, while for boilers with automatic fuel supply in most cases the fraction should not exceed 30 mm.

Criteria for choosing heating equipment

When purchasing a heat generator, pay attention to the following:

Rated power.- Bunker volume. It is selected so that at maximum productivity the fuel reserve is enough for 3-4 days.

- Functionality.

- There are two varieties: one works only for the heating system, the other is also capable of heating water for household needs.

- Control.

- Automation type.

The first criterion is the main one. The rated power is equal to the heat loss of the heated object in the coldest period. The exact value is determined using a complex calculation. The methodology is set out in SNiP “Heating, ventilation, air conditioning”.

A simplified version of the calculation allows you to approximately estimate the power.

The procedure depends on the ceiling height:

- Up to 3 m. Heat loss is assumed to be 100 W per square meter. m area.

- More than 3 m. Calculate the volume in cubic meters. m and multiply it by 40 W.

Boilers with the function of preparing hot water are divided into two types:

- Dual-circuit. They operate in flow heating mode. They are compact, but with low power they serve only one water point.

- With the ability to connect an indirect heating boiler. The storage tank takes up a lot of space, but even with minimal heater power, any number of water points can be serviced simultaneously.

Based on the control method, there are three types of devices:

- Simple. There are only keys on the front panel of the boiler.

- With remote control.

- With GSM module. Receive commands over a cellular network from anywhere in the country.

There are 3 types of automation installed on heaters:

- Simple. Thermal sensors are attached to the pipes. The system supports user-specified temperature conditions, for example, 90/80 (flow/return).

- Room thermostat. Sensors are installed indoors. The boiler maintains the temperature in the room set by the user, choosing the optimal mode (90/80, 70/60, etc.).

- Weather-sensitive. Sensors are located indoors and outdoors. The heater receives information about warming or cooling and manages to promptly adjust the operating mode in order to maintain a stable temperature in the room.

Reviews of household automatic pellet boilers: advantages and disadvantages

Reviews from owners of automatic pellet boilers indicate that this technique has both strengths and weaknesses, or rather, nuances:

| Advantages | Flaws |

| autonomy – equipment with a GSM module can remain unattended for weeks | cost – the price of even the most modest options is 100–120 thousand rubles. |

| versatility - work on wood chips, husks and sawdust | energy dependence , a backup generator is needed for operation |

| Convenience – self-cleaning and auto-feeding minimize manual maintenance | service - many foreign companies simply do not have a representative office in Russia |

| safety – the body does not heat up, which is especially important for children and animals | granule consumption - often real figures differ from theoretical calculations |

| cleanliness - there are no traces of use in the room, i.e. soot, dust and smoke | fuel price - the cost of pellets exceeds the cost of firewood or coal |

Reference . An unexpected increase in pellet consumption is often associated with inadequate quality of the product itself: if they contain foreign impurities or their moisture content is more than 10–12%, then in order to maintain a given regime it becomes necessary to compensate for the loss of heat capacity in quantity.

Rating of the best manufacturers

Due to the complexity of the design, the likelihood of an automatic boiler breaking down is higher than a classic one. Taking into account the fact that such an event complicates the operation of the unit and threatens the destruction of the heating system due to freezing of the coolant, the issue of choosing the brand of the unit deserves special attention.

Users consider boilers from the following companies to be the most reliable:

- “Thermorobot”, “Zota Stakhanov”, KAZ Kordi, TIS Eko, Altep, Faci (Russia).

- Roda, Buderus (Germany).

- Metal-Fach (Czech Republic).

- Pereko, Galmet, Heiztechnick, Defro, Stalmark (Poland).

- Vulkan (Ukraine).

- Termodinamic, Emtas (Türkiye).

High-quality boilers with a drum hopper (without feeder):

- "Auto-30".

- "Ugleavtomat"

- "Master."

- "Prometheus".

- Carborobot (Hungary).

Russian boilers, which are not inferior in quality to imported ones, are more profitable to purchase due to their cost and speed of repair.

The working process

So, the process of heat supply using an automatic boiler and coal as fuel consists of several stages:

- coal is poured into the bunker manually. The number of bookmarks and the time of continuous operation of the system depend on the capacity of the bunker;

- The auger feeds fuel into the chamber automatically. The gearbox does not stop working from the electric motor;

- fuel is squeezed into the chamber and air is supplied under pressure;

- combustion occurs in thin layers, reducing the amount of soot and unburned particles, but if necessary, the boiler will automatically remove ash.