Until recently, the only prospect for pellet production was targeting private consumers. The market segment implied the consumption of products by owners of country houses and cottages equipped with solid fuel boilers with a capacity of 20-100 kW, more about which you can read in this article. However, already now the number of consumers using pellets in boilers with capacities of 200 kW and above reaches 50% and continues to grow. Accordingly, there was an increased demand for granular fuel, which in turn created a supply for inexpensive and efficient equipment for the production of pellets. Since there are a large number of wood processing enterprises in Russia, it would be advisable to produce fuel pellets from sawdust.

Description and characteristics of various types of pellets

The remarkable thing about fuel pellets is that their production does not require specific raw material sources; they are made from anything. They do not require any high-tech raw materials. They can be produced from ordinary waste. These may be residues from wood processing: sawdust, wood chips. Or even agricultural waste, such as straw. They are also called fuel pellets. Essentially, these are small cylindrical granules. Their production includes the use of specialized equipment. They are made under high pressure without any adhesives. Their thermal properties are not inferior to dry firewood. They take up much less space.

To put it into perspective, we can say that one kilogram of such granules produces up to 4.5 kJ of heat, which corresponds to the calorific value of 15% dry wood.

When burning pellets, less carbon dioxide is produced, less ash is produced, and virtually no sulfur is formed. Purpose of pellets:

- heat houses that have a stove or fireplace;

- used in boiler rooms;

- used as litter for pets;

- used as absorbents for liquids.

Types of pellets

If you plan to produce pellets for sale, then you need to buy equipment for the production of pellets that meet the standards of the countries where you plan to supply them. For example, ash content for the USA should not exceed 1%, but in Europe it is half a percent higher.

Technological process

Regardless of which machines are used for the production of fuel pellets, the production process consists of such technological operations as:

- Cleaning and preliminary grinding of raw materials, which are brought to such a state that the length of its particles does not exceed 2.5 mm.

- Drying sawdust mass, the humidity of which is brought to a level of 9–12%.

- Final grinding on a machine, which is carried out so that the maximum length of the particles that make up the sawdust mass does not exceed 1.5 mm.

- Mixing the crushed raw material with water or treating it with hot steam (this technological operation is used if the moisture level of the sawdust after drying and grinding has dropped below the minimum permissible value).

- Pressing the sawdust mass, as a result of which cylindrical granules are formed from it (for the practical implementation of this technological operation in a production environment, matrix installations of a cylindrical or flat type can be used; at home, homemade installations of a lever, screw or hydraulic type are suitable for the formation of fuel briquettes) .

- Cooling of finished pellets, which during their formation using high pressure spontaneously heat up to a significant temperature.

- Sorting of finished fuel pellets and their packaging.

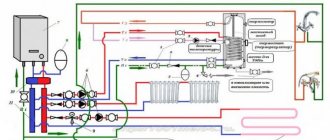

Pellet production line

Manufacturing technology

The production of pellets takes place in several stages. At first, the raw materials are crushed into small parts. Next it is dried. After drying, it is crushed again into smaller fractions. Next, preparation is carried out using water, that is, the residual moisture should not exceed 10%.

This is important, since pressing raw pellets will require more effort, and they are not suitable for boilers, since they burn worse and generate less heat.

At the next stage, production involves pressing the pellets and re-drying. The finished product is packaged in one kilogram.

Particular attention should also be paid to the water content of the granules. Because too dry raw materials stick together worse. Some moisture dosage is needed. Pellets need to be cooled after the molding press. After which they are packaged.

Equipment for the production of pellets

Equipment for the production of pellets includes:

- crusher for grinding raw materials.

- Dryer;

- pellet press;

- cooling equipment for finished raw materials;

- packaging equipment.

Pellet production line

A fully assembled pellet production line will not be cheap. Its complete set includes drying drums, conveyors, scales, fans for blowing material, and hammer mills. The main role here is played, of course, by the pellet machine. You won’t be able to make it yourself, since you will need a milling machine to create the matrix. Pelleting equipment may vary in the quality of the pellets produced. Processing accuracy may vary from standards.

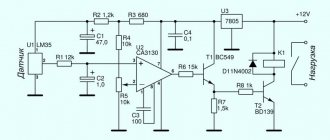

Homemade crusher

The production of pellets requires a crusher, which you can assemble with your own hands. If the raw material contains branches or other occurrences such as slabs, then additional equipment will be required to grind them. Of course, there are quite a few designs of such equipment. Some of them grind raw materials into not too large fractions.

Homemade crusher diagram

To make your own crushing machine, you will need one electric motor, quite powerful, and several circular saws. Such a machine will be a good helper to start your own pellet production. They are mounted on the same shaft. They are fixed in such a way that each subsequent saw tooth moves relative to the previous one. A pulley and a pair of bearings on the sides are placed on this shaft. The shaft is installed on the frame and fixed there. It should be borne in mind that the engine must have sufficient power to be able to crush branches and boards into the required sawdust size. The performance of such a unit is not the highest.

Sawdust dryer

Making pellets involves drying the raw materials. To prevent pellets from crumbling immediately at the exit from the pressing machine, it is necessary that the sawdust be of the required moisture content. In large production this is done in special chambers. At home, some craftsmen make drum dryers, since this design is the simplest.

Homemade sawdust dryer

Iron barrels are welded to each other. Next they are placed on the frame. Blades are welded to the inner walls, which interfere with the raw material during drying. Hot air is supplied from one side of the improvised drum, and this air leaves from the other. The drum rotates using an electric motor through gearboxes. The source of hot air can be a conventional heat gun.

You should know that this technological process is the longest and most energy-consuming. Therefore, expenses may exceed income.

Tips for choosing equipment

Equipment should be selected according to the volume of work that is expected to be performed. The largest units turn out to be more expensive in terms of cost and electricity consumption. If you intend to produce a small volume of pellets, from an economic point of view, medium-sized and low-productivity machines will be more profitable.

Dry raw materials in small quantities

Speaking of small volumes, it should be said that a cubic capacity of up to eighty cubic meters of sawdust is implied. Such pellet production is quite acceptable for private businesses. The cost of drying such raw materials is much less than for raw materials.

Basic equipment that will be needed first:

- hammer crusher for producing fine fractions of raw materials;

- unit for creating air flows;

- pressing equipment for pellets;

- cooling unit;

- separator;

- packaging line;

- transportation means;

- container or storage bin.

It is better to have equipment from one manufacturer, as this will save you from further problems if one of the components breaks down.

Raw sawdust in small quantities

Drying such wood processing waste is considered the most expensive, as it requires much more time and investment in terms of energy consumption. Although, with large volumes, the costs pay for themselves. Raw sawdust includes sawdust with a moisture content of up to fifty percent. Before making pellets, sawdust must be dried to a moisture content of approximately fifteen percent. To prevent your work from going to waste, after drying it must be stored in a dry and well-ventilated place.

Industrial pellet dryer

It is also necessary to provide for crushing the material after the drying apparatus. This will also help bring the raw material to the desired state, from which granules can then be compressed. For such tasks, powerful installations are more suitable, since small and cheap ones cannot always cope with the task.

A sufficient amount of raw materials with a moisture content of forty fifty percent

The volume sufficient for the production of pellets is considered to be from two thousand cubic meters. Such production will require. This also requires the availability of appropriate equipment:

- sieve for sifting out fine dust;

- dryer with electric heat generator;

- equipment for moving finished products;

- device for cooling finished products;

- pressing equipment;

- packaging machine;

- place for storage and warehousing of manufactured products;

- a place where you can store already dried raw materials. Warehouse or bunker;

- means for grinding initial raw materials.

Such volumes require serious preparation in terms of equipping workplaces. The most expensive item of all expenses is drying raw materials. In addition to the aerodynamic method, there are also other methods, for example, vacuum, infrared and microwave drying. This equipment is more expensive and requires more energy.

Dry raw materials in large volumes

To work with dry raw materials, you need the same equipment as for raw materials. The only difference may be the amount of pressing equipment.

When choosing equipment, you should take into account the performance of the equipment and the quality that the manufacturer is willing to guarantee for its equipment and final products.

Other materials

In addition to sawdust, other materials are used in the work:

- peat;

- agricultural waste;

- straw;

- branches.

All this must first be dried and crushed. The technology for working with this raw material is slightly different, since the composition is different.

Peat pellets

For example, peat needs to be dried, but does not need to be crushed. On the contrary, the husk will not need to be crushed, and depending on the condition, drying will most likely not be necessary either.

Granulator device

The granulator is similar in design to an electric meat grinder with one difference: the knife is located on the outside, behind the matrix grid.

During the granulation process, the raw material mass is loaded into a hopper, from which it is pushed under pressure through a mixture heated to 110 degrees. matrix. The movement of the screw ensures that the mixture is pushed, creating pressure and pressing the crushed and moistened raw materials against the matrix.

Upon reaching a critical volume value, the compressed raw material is forced through the holes of the matrix. A special cutter cuts the granules to the required size. Plastic capsules cool down, maintaining their shape.

You may also be interested in information about how to keep Indian ducks at home.

The operating principle consists of sequential operations:

- supplying crushed feed from the hopper to the rotating shaft;

- compression;

- pressing through the matrix;

- cutting with a knife;

- entering the receiving bowl.

The diameter of the holes in the grid determines the diameter of the capsules. Depending on the power of the electric motor, the diameter can be from 5 to 10-15 mm. The distance at which the knife is installed after the grate determines the length of the granules.

The video shows how the granulator works and works:

Main parts of the granulator:

- loading hopper;

- screw;

- matrix;

- knife;

- drive shaft;

- gearbox;

- electric motor;

- bed;

- receiving bunker.

But how to breed ducks at home for beginners and what you should pay attention to is indicated here. All parts of the device are made of metal. All parts of the device are made of metal

All parts of the device are made of metal.

The specific characteristics of the thickness and diameter of the matrix, the diameter of the screw, and the power of the electric motor are determined together.

The units offered by manufacturers can be used for preparing not only feed, but also pellets (fuel pellets made from sawdust).

Main characteristics of granulators offered by manufacturers:

The maximum power of manufactured units is 30 kW with a productivity of more than 1000 kg per hour. The weight of the installation is more than 500 kg.

But what the blue favorite duck looks like and how to properly breed it at home is indicated here.

Device cost

- with a 2.2 kW electric motor – from 53,000 rubles;

- 7 kW – from 83,000 rubles;

- 15 kW – from 190,000 rub.

Advantages of industrial granulators:

- reliability;

- duration of operation;

- versatility;

- efficiency;

- safety;

- convenient service.

The high cost of units manufactured in industrial conditions forces livestock breeders to make devices in a handicraft way, using improvised means.

But you can read here how broilers are raised without feed and what feed should be used.

Requirements for pellet production

Since wood and the production of wood materials do not harm the environment, there are not many requirements for it. Wood is a combustible and flammable material, so the workshop where production is carried out must have fire extinguishing equipment. First of all, these are fire extinguishers and an automatic extinguishing system. It is also necessary to consider how raw materials and finished products will be stored. The room must protect them from sources of flame.

Pellet production workshop

Since all equipment for the production of pellets works with a large amount of water, it is reasonable to provide a water supply and drainage system.

What is a granulator

A pellet granulator, also known as a pelletizer, is a machine used to produce pellets. The principle of its operation is very similar to a meat grinder. Only instead of an auger, it uses heavy rollers to push the wood flour through the matrix. The matrix is a steel pancake with through holes. In a meat grinder it is called a mesh.

What equipment is needed for the production of pellets

Today, manufacturers offer two types of pelletizers:

- A matrix in the form of a pancake, located horizontally at the bottom of the machine. Two or three rollers roll over it, squeezing the pellets down.

- The matrix is made in the form of a ring of a certain width and installed vertically. The rollers rotate in a vertical plane. The pellets are ejected along the entire length of the matrix.

Application of pellets

The main purpose of pellets is combustion in boilers as a heat source. Widely used in thermal power plants with a capacity exceeding 500 Megawatts. The specific heat of this product is not inferior to dry firewood or even peat. Depending on what raw materials the pellets were made from, their energy intensity may vary.

Application of pellets

The most commonly used raw material is sawdust, since it is available in sufficient quantities at all woodworking enterprises. The heat that can be obtained from their combustion is 4 kW/h/kg. This is enough to heat a small country house. In addition to heating, pellets are used as toilet fillers as a non-standard application. In fact, the scope of pellet application is very wide.

What are fuel pellets made of?

The raw material for the production of pellets, as a rule, is wood processing waste - wood chips, shavings, sawdust, bark, trimmings. Agricultural waste and other natural materials are also compressed into granules: straw, cake, dry manure, branches, husks, peat. It turns out that instead of problems with disposal, we have inexpensive, environmentally friendly heating. Abroad, there is a special term for pellets and fuel briquettes similar in composition - “solid biofuel”.

Note that pellets can be made from recycled wood. For example, plywood, MDF, chipboard, fiberboard, OSB are processed. However, due to the high content of binders, the use of such granules is somewhat limited, so usually recycled wood is mixed with natural fibers.

Depending on the raw material, the appearance of the pellets will differ