principle of operation, types of electric boilers, advantages and disadvantages of electrode boilers

The selection of an electric boiler that will provide heat in cold weather must be approached seriously. Among the variety of manufacturers of electric boilers, one can highlight the domestic company Galan, which produces high-quality equipment. Let's take a closer look at what makes Galan boilers remarkable.

Electric boilers Galan: basic information

Galan electronic boilers for heating attract attention as high-quality products with reliable characteristics and small dimensions. It is worth saying that such wonderful units are produced by a family company of the same name located in Russia

This family enterprise began its business in 1994 and over the subsequent years has gained fame and respect.

It is worth saying that such wonderful units are produced by a family company of the same name located in Russia. This family enterprise began its business in 1994 and over the subsequent years has gained fame and respect.

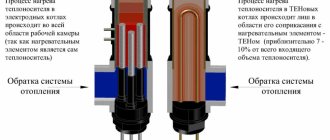

Galan boilers heat the coolant not by heating the heating element, but by passing electricity through it. Electrodes that are energized are connected to the heating elements. They make direct contact with the coolant and heat it.

The main part of the electric boiler is the ionization chamber, in which basic heating occurs. The camera itself is small in size. Due to the sudden heating, the coolant pressure increases to 2 atmospheres. Thanks to this effect, the unit can act as a pump.

The electric heating unit consists of:

- heat exchanger;

- tank with heating elements;

- regulation and control units.

The coolant in electric boilers can be either water or antifreeze. The best coolant is a specialized liquid called Argus-Galan.

The operation of this electronic heating equipment is no different from the operation of similar devices from other manufacturers. The water is heated in the generator, and then flows through the main piping and into the radiators. Here it gives off its heat and the air in the room heats up.

In addition to heating the room, the Galan electric unit can provide the house with hot water for household needs. Most Galant devices are equipped with external storage boilers.

Types of electric boilers Galant

Galan electrode boilers for autonomous heating systems are available in several types.

Electric boilers of the Ochag series

- Ochag-2;

- Hearth-3;

- Ochag-5;

- Hearth-6.

Electric boilers of this series have low power (from 2 kW to 6 kW). Mainly used for heating rooms with small volumes of 80–250 cubic meters. m. Boiler weight is about 1 kg.

Units in this series have the following dimensions:

- length: 25–33.5 cm;

- diameter about 35 mm.

The electrode unit operates from a network with a voltage of 220 volts.

Electrode boilers Galan Geyser series

- Geyser-6;

- Geyser-9.

Galan. Electrode boilers of the Vulcan series

The weight of the boilers is 5.7 kg. They have a power of 25 kW. They can heat a room with a volume of up to 850 cubic meters. m. They are powered by a three-phase electrical network with a voltage of 380 volts.

Galant electric boilers of the SELS series

Models in this series are considered the largest. The unit is applicable both in residential buildings and cottages. Operates from a three-phase network. Can only work in closed-type heating systems.

The unit is equipped with automation. The equipment has three power levels that are manually adjusted. It is possible to connect a circulation pump. Operating the heating unit of this series is convenient and simple.

The equipment has a power of 9–27 kW and weighs about 17 kg.

Pros and cons of Galan electric boilers

- For installation, Galan electric boilers do not require any additional costs, only for the purchase of a heat source.

- Installation of units will cost less than installation of liquid fuel devices.

- Galan electrical units are unpretentious; they do not require cleaning or constant maintenance.

- This is safe and environmentally friendly equipment. Does not emit odors during operation.

- No need to install a chimney.

- Heating units are light in weight and have moderate dimensions. To install the boiler, a separate specialized room is not required.

- Installation of Galan devices can be done with your own hands.

- This is fireproof equipment.

The disadvantages of Galan devices include:

Conclusion

Galan equipment for heating systems has recently become increasingly popular. And this is not surprising, since the devices have excellent characteristics, both technical and operational.

Types of Galant electronic heating boilers

The existing market of Galant electric boilers for individual heating systems offers three types of designs, which differ in their technical characteristics.

Hearth Series

The Ochag boiler series is available in four modifications:

- Hearth-2.

- Hearth-3.

- Hearth-5.

- Hearth-6.

Hearth Series

They have a low power of 2 to 6 kW and are designed for heating small rooms with a volume of 80 to 250 cubic meters. These boilers weigh about a kilogram. In this case, the volume of coolant in the general heating system can range from 20 to 70 liters.

The overall dimensions of the Galant Ochag series of boilers range from 25 to 33.5 cm in length and 35 mm in diameter. They operate from a regular 220 W network.

Geyser Series

The Galant Geyser boiler series is available in two modifications:

- Geyser-6.

- Geyser-9.

These heating boilers are designed to heat rooms with an internal volume of 250 to 340 cubic meters.

Geyser Cross

To install Geyser heating boilers, a three-phase network with a voltage of 380 W is required.

With proper thermal insulation, Galant Geyser boilers consume from 2.5 to 4 kW of electricity per hour. They weigh about 5 kilograms and are made about 40 centimeters long. The volume of coolant in the heating system where these heaters are installed can be from 50 to 200 liters.

Vulcan Series

The largest Galant electronic heater is its modification called Vulcan. These heating devices weigh 5.7 kilograms, have a power of 25 kW, operate on a three-phase network of 380 W, and heat rooms up to 850 cubic meters.

The operating principle of all types of electric boilers

Simple control unit with display for an electric boiler.

It is clear that manually controlling the operation of the heater is nonsense; after all, we live in a time of high technology. Therefore, almost all types of electric heating boilers are equipped with electronic controls with a different number of options. The “brains” of the device may not be provided by the manufacturer. Some models have the simplest and most necessary sensors; in expensive devices the number of functions is much wider. What should be in the control unit of all types of electric heating boilers:

- temperature sensor;

- separate fuses;

- time relay;

- load relay;

- two-tariff meter.

Depending on the temperature outside the window, with the same heating of the coolant, the house will be either warmer or colder. It is more convenient when the room temperature is kept at the same level by increasing or decreasing the heating of the liquid in the circuit.

The load relay will prevent the heater from turning on when the home network is overloaded. For example, when the washing machine is running. Thus, the wiring will not be overloaded and will not burn out. To save on electricity bills in houses that are heated by electrical appliances, you need to install double tariff meters.

They calculate how much energy is spent during the day and night, and divide the cost per kilowatt used. Electricity is cheaper at night. The installed time relay will turn on the heater when it is more profitable, that is, at night. While during the day the boiler will work as little as possible.

Boiler selection criteria

When purchasing a Galan boiler, you must immediately select a coolant

In order for the heating system to function without breakdowns and ensure a comfortable temperature in the house, it is necessary to determine the basic characteristics of the boiler before purchasing. When choosing a model, the following criteria are taken into account:

Electric boiler power - this parameter is the main calculated value of the heating system. The average is 1 kW per 10 sq. m area. For more accurate calculations, you can use an online calculator. Experts recommend choosing equipment with a power reserve of up to 10-15%. Unit dimensions - the size of the boiler will help determine the installation location

It is important to know the mass of the unit and the placement method. Lightweight compact Galan models are installed near radiators; it is difficult to recognize them as a boiler. Degree of automation – a mechanical control unit is suitable for temporary premises

The electronic regulator precisely controls the system parameters, ensuring economical electricity consumption. Reliable automation turns off the unit if it overheats or has a short circuit.

The cost of equipment is another significant criterion. The Galan electric boiler is offered at an affordable price.

Coolant

Electrode boilers are sensitive to the composition of the coolant. In accordance with the requirements of the manufacturers, only distilled water should be used, to which table salt is added, approximately 80-100 grams for every 100 liters. The difficulty lies in the fact that the final density and conductivity of the solution must be in strict accordance with the manufacturer's requirements. It is impossible to determine the exact amount of salt, and it can give different results depending on its composition.

The final preparation of the solution is carried out locally, based on the actual current values in the electronic boiler. The instructions for the device provide a table of the required values depending on the boiler power, coolant volume, etc. By adding distilled water or salt, the coolant resistance is brought to ideal.

Only compounds provided by the boiler manufacturer are used as antifreeze. When they are used, the proportion of salt in the solution also changes.

Galan Navigator Basic automation for the Galan boiler

Digital temperature controller Galan Navigator Basic consists of a housing, an electronic unit with connected temperature sensors (red - supply pipe and blue return pipe); heating stage operation indicators; indicator for turning on the circulation pump; indicator for turning on the external room temperature regulator; return (blue) and supply (red) channel indicators; temperature indicator; control knobs; switch; adapter block for connecting the circulation pump and power supply to the control unit 220 V; relay contactor (in version H2 there are two contactors, 4 in version H3 - three contactors); current controller 12 (for tubing version); zero bus.

Temperature control is carried out through two channels from the supply sensor (red) and the return pipe sensor (blue). The return sensor is the main control sensor. The supply sensor is an emergency sensor to prevent boiling and a backup sensor in case of failure of the return sensor. Adjustment range: Recommended values: Return: 10–80°C. Return: 35–40°C. Feed: 10–85°C. Serve: 70–75°C. Hysteresis: 1–9°С Hysteresis: 3–5°С By hysteresis in this Manual we take the temperature difference between turning off and then turning on the boiler. When the unit is turned on, an indication of the current return temperature appears on display 7, blue LED 6 lights up. The glow of the dot in the upper left corner of the indicator means a signal is given to turn on the circulation pump. To reduce the peak load on the network, the heating stages are switched on in series. 30 seconds after turning on the pump, the first heating stage is connected, 10 seconds after turning on the first stage - the second, then after another 10 seconds the third heating stage. As the heating system warms up, the heating stages are switched off one by one to improve the efficiency of the system. At a temperature set minus hysteresis, the third stage will turn off, and at a temperature set minus half of the hysteresis, the second stage will turn off. Controls and displays of the “Navigator” temperature regulator 5 When the set temperature is reached, the heating will turn off completely. To cool the boiler, after turning off the heating, the circulation pump runs for another 30 seconds and turns off. During the cooling period of the system, to equalize the temperature field, the circulation pump is turned on for 30 seconds every 5 minutes. When the system cools, the stages are also switched on one by one. When the maximum set supply temperature is reached, the heating is completely switched off until the temperature drops by 9°C. Thermal sensors are installed on metal parts of the heating system at a distance of 30-50 cm from the boiler. The thermostat has two 6P4C type sockets for connecting external devices for regulating the air temperature in the room. When these devices are connected and the set air temperature is reached, the heating is completely turned off, and the signal dot in the middle upper part of the indicator lights up. The KT series of thermostats is designed for electrode boilers and includes a current controller, which, if the rated current value is exceeded, turns off the heating for 3 minutes, after which the heating cycle is repeated. When the current controller is activated, the color of the LED changes from green to red.

The maximum permissible electrical power at the “pump” output is no more than 200W. If it is necessary to use a circulation pump of higher power, make the connection through switching equipment. The Navigator digital temperature controller is available in three versions. Option H1 (Basic, Basic KT), designed for single-stage boilers, only the first stage is used. Option H2 (Basic +, Basic KT+) is provided for heating systems with two heating stages. Option H3 (Basic T, Basic TT) uses all three heating stages.

Electric boilers "Galan" on heating elements

In this group of heating equipment, two types of boilers are produced: new heating boilers “Standard” and “Lux”.

Group "Standard"

"has a structure unusual for electric boilers: it is a small cylinder, sealed on both sides, to which the coolant supply and return pipes are welded. They are distinguished by a very low price, high efficiency and decent economy, which requires automation. "Galan" recommends its automation "GAlan-Navigator".

Electric boilers "Galan" on heating elements have an unusual design

Boilers of this group operate in closed heating systems with natural or forced circulation. They have very small sizes and a fairly large set of capacities:

- Hearth Turbo

. There are 7 modifications in this line with power increments of 1.5 kW. Powers from 3 kW to 15 kW, length from 350 mm to 1050 mm, weight from 2.5 kg to 10 kg. - Geyser Turbo

. There are only two models in this line: 12 kW and 15 kW, 500 mm long, weighing 8 kg. - Vulcan Turbo

. There are three modifications with powers of 18 kW, 24 kW and 30 kW. The length of boilers in this series is 490mm, weight 10kg.

The boiler bodies are made of AISI 316L stainless steel, which has an increased load capacity, a long service life and can withstand temperatures up to 1300 o C. The boilers produced today are equipped with new heaters and blocks of them, which have smaller dimensions and a longer service life. The boilers have three power levels, which allows you to save energy without sacrificing comfort. Also, the new boilers have less weight and reduced inertia of the boilers. All this allows you to save up to 20% of electricity compared to conventional boilers of similar power.

Characteristics of Galan heating element boilers (click on the picture to enlarge the size)

Three-stage power gradation and more reliable elements do not create excessive load on the network, so many boilers can be powered from a 220V network. All electrical connection data is given in the tables.

In the group of heating element boilers " Lux"

there are two lines. Their appearance is already more familiar: wall-mounted, painted steel casing, control panel on the boiler. Boilers are used only in closed-type heating systems with forced circulation. There is no water treatment for hot water supply, the control is automatic (built-in automation).

Line "Stealth"

. Boiler efficiency is 98%. Such indicators were achieved thanks to the use of new type heating elements. When using these boilers, you can achieve decent savings - up to 40-60%. This is facilitated by modern built-in automation, programmable thermostats, which allow, while maintaining a comfortable temperature, to minimize energy consumption. It is possible to connect a remote control that transmits signals via cellular communications.

The Galan Steals heating boiler has a more familiar design

This line includes six modifications of boilers with power from 9 kW to 27 kW. Technical data of the equipment are presented in the table.

Technical characteristics of Galan Steals boilers (click on the picture to enlarge the size)

"Galax" line

. A three-stage power control system allows you to save energy and not create excessive load on the network. This equipment is connected to a three-phase 380V network and has a protection class of IP40.

Heating element boilers "Galan Galax". Internal organization

There are built-in safety systems: monitoring the presence of coolant flow and a safety valve. It is possible to connect programmable temperature sensors.

Heating element boilers "Galan Galax". Internal structure (click on the picture to enlarge)

There are eight modifications in the line with a power from 9 kW to 30 kW, their technical data is summarized in the table.

Technical characteristics of Galan Galax boilers (click on the picture to enlarge the size)

Currently, there are a large number of manufacturers of heating equipment. Most boilers are installed by specialists and will require numerous permits before installation. But there are alternative solutions that somewhat simplify the entire procedure. We will talk about electric heating. Let's look at helpful reviews. Galan boilers - that’s what we’ll talk about in this article.

Advantages of electrode boilers

The main advantage of the Galant electrode electric boiler is its unique simplicity and high efficiency, reaching, like other types of electric boilers, 98%.

Electrode boilers are compact and can be installed in places convenient for owners with good access.

The design of the device is so simple that there is nothing to break in it. If high-quality materials that are resistant to corrosion are used, the service life of the electrode boiler is practically unlimited. The reliability of the product is confirmed by reviews of an electric heating boiler for the home, posted online by owners who have already installed this device in their home.

Electrode boiler GALAX 15 N

1,781.54Br Add to cart The head of state signed a Decree that should stimulate the consumption of electrical energy in Belarus. From January 1, 2022, it will become 3 times cheaper for heating and hot water supply needs. As the press service of the Ministry of Antimonopoly Regulation and Trade reported, Decree No. 492 “On setting tariffs for housing and communal services for the population for 2022” comes into force on January 1, 2022. Part of the provisions of the decree concerns an increase in tariffs for basic housing and communal services for the population, and the other concerns a reduction. Thus, tariffs for electricity and gas for food preparation purposes were increased by 21.8% and 25.6%, respectively, which ensures a 100 percent reimbursement level for these services. But the tariff for electrical energy for heating and hot water supply has been reduced three times in order to stimulate electricity consumption in the republic.

From January 1, 2022, the cost of electricity for heating and hot water supply for houses that are not connected to central heating and gas supply is set at 0.0335 rubles per 1 kWh. Heating appliances will need to be equipped with a separate meter.

Disadvantages of electrode boilers

In an electrode boiler, one electrode is the housing, and the other is an electrode immersed in the coolant. To protect against electric shock, the boiler body must be reliably grounded. But at the same time, the coolant is constantly under voltage. This is the main disadvantage of the electrode boiler. The second drawback, which is often written about in reviews, is the high cost of such a simple design. But if you buy a heating element electric heating boiler for your home, its price will be almost twice as high as an electrode one. And another significant drawback is the high and constantly growing price of electricity.

The best Russian electrode heating boilers

"Galan" Vulcan 36

was one of the first to begin developing such a family of heating devices, using developments in the military space industry and patented engineering solutions. For a quarter of a century, even the first line of devices has not failed and continues to function.

"Galan" Vulcan 36

Model power 36 kW, suitable only for three-phase network. The maximum current for three phases is 27.3 A. The control is mechanical; the boiler is installed only on the floor.

This model “Vulcan” 36 has many advantages, let’s highlight the main ones:

- ease of maintenance and operation.

- safety and reliability - if an electric short circuit occurs, the current supply wires overheat, the set temperature is exceeded, or a coolant leak occurs, the boiler turns off.

- the coolant volume is 600 liters, the volume of the heated room is 1700 cubic meters.

- affordable cost - the average price is 11,000 rubles.

Operating instructions "Galan" Vulcan 36

"Galan" Geyser 15

A safe and productive single-circuit electrode boiler, which is often preferred by owners of country property. Equipment power 15 kW, suitable only for three-phase network. The maximum current for three phases is 22.7 A. The control is mechanical; the boiler is installed only on the floor. As an additional option, it is possible to connect external control.

"Galan" Geyser 15

It is bought due to the following advantages:

- Simplicity and ease of use - even a beginner can understand the device.

- light weight of the structure and compact dimensions - only 5.3 kg.

- large heating area - up to 180 sq.m.

- electronic automatic control - the presence of a control unit that allows you to create an interval for heating the coolant.

- ability to connect to a room temperature indicator.

- The average price of the device will be 7800-8000 rubles.

Operating instructions "Galan" Geyser 15

RusNIT 208M

, Ryazan. Can be used as the main or backup heat source in a house or domestic premises with an area of up to 80 sq.m. Power 8000 W.

RusNIT 208M

Specifications:

- three-stage power adjustment - 30%, 60% or 100%;

- the heat exchanger and heating element are made of stainless steel;

- antifreeze or distilled water can be used as a coolant in the system;

- the presence of a thermal switch that prevents heating of the coolant above 90°C;

- can be connected to a circulation pump;

- Manufacturer's warranty – 2 years.

Among the disadvantages, we note the manual selection of power, difficulties during connection, requiring certain skills.

The cost of the unit is from 15,000 rubles.

Operating instructions RusNIT 208M

Features of installation of ion boilers

A prerequisite for installing ion heating boilers is the presence of a safety valve, pressure gauge and automatic air vent. The equipment must be placed in a vertical position (horizontal or at an angle are not allowed). At the same time, about 1.5 m of supply pipes are not galvanized steel.

The zero terminal is usually located at the bottom of the boiler. A grounding wire with a resistance of up to 4 ohms and a cross-section of over 4 mm is connected to it. You should not rely solely on RAM - it cannot help with current leakage. The resistance must also comply with the rules of the PUE.

If the heating system is completely new, there is no need to prepare the pipes - they must be clean inside. When the boiler crashes into an already operating main, it is necessary to flush it with inhibitors. The markets offer a wide range of products for removing deposits, salts and scale. However, each manufacturer of electrode boilers indicates those that it considers best for its equipment. Their opinion should be followed. By neglecting flushing, it will not be possible to establish the exact ohmic resistance.

It is very important to select heating radiators for the ion boiler. Models with a large internal volume are not suitable, since 1 kW of power will require more than 10 liters of coolant. The boiler will constantly work, wasting some of the electricity in vain

The ideal ratio of boiler power and total volume of the heating system is 8 liters per 1 kW

The boiler will constantly work, wasting some of the electricity in vain. The ideal ratio of boiler power to the total volume of the heating system is 8 liters per 1 kW.

If we talk about materials, it is better to install modern aluminum and bimetallic radiators with minimal inertia. When choosing aluminum models, preference is given to primary type material (not remelted). Compared to the secondary one, it contains fewer impurities, reducing the ohmic resistance.

Cast iron radiators are the least compatible with an ion boiler, since they are the most susceptible to contamination. If it is not possible to replace them, experts recommend observing several important conditions:

- The documents must indicate compliance with the European standard

- Installation of coarse filters and sludge traps is required

- Once again, the total volume of coolant is produced and equipment suitable in terms of power is selected

Types of equipment

Galan electronic boilers are represented by three lines of models:

Electrode boiler Galan Ochag 6, 5 and 3

The numbers at the end of the model name indicate the power of devices that are very similar in appearance. The weight of Hearth boilers is from 0.9 to 1.1 kg, and the length depends on the model:

- Galan Hearth 6 has a length of 335 mm;

- Galan Hearth 5 – 320 mm;

- Galan Hearth 3 – 275 mm.

These are the most compact devices that operate on 220 volts and can heat rooms with an area of 80–250 m2.

You can buy boilers of the Ochag model on the official website of the Galan company, where equipment with a capacity of 6 kW costs 4,050 rubles, and equipment with a capacity of 2 kW costs 3,900 rubles.

Heating boilers Geyser

Equipment with high power (from 6 to 15 kW) and medium dimensions is capable of heating a room of up to 200 m2. Geyser devices weigh 7 kg and operate from a single-phase and three-phase power supply system. When operating boilers, it is recommended to use about 300 liters of liquid. The price for a 15 kW boiler is 8,000 rubles, and for a 6 kW heater is 7,100 rubles.

Electrode equipment Vulcan

The most powerful system with which you can heat several houses at once, the total volume of which is no more than 800 cubic meters. The equipment can be installed in small rooms, since it has small dimensions and weighs 7 kg. The devices operate on three-phase current and have a power of 25 to 50 kW. Their cost is higher than other models. On the official website, the Vulcan 25 heating boiler can be purchased for 8,200 rubles, and the price for the Vulcan 50 model is 13,200 rubles.

The features of electrode boilers include their reliability, which is explained by the fact that there is practically nothing to break in such equipment. Even if a coolant leak occurs, the currents will drop to zero and the device will simply turn off. The automation built into the heating system will take care of everything else.

Models of heating element boilers Galan

Devices operating on the basis of heating elements come in two varieties:

- Hearth Turbo, Geyser Turbo, Vulcan Turbo are created on the basis of electrode models, from which they differ in design and dimensions. With a power of 3 to 30 kW, they are capable of heating a room with a volume of up to 750 m3. They can operate from both single-phase and three-phase electrical networks. The price of heating element models differs slightly from electrode ones and ranges from 6,500 to 13,800 rubles.

- Monoblocks Galax and Stealth are devices similar to ordinary heating boilers, which in their design have a hanging metal rectangular cabinet. Stealth models have a tank and a control unit equipped with heating elements. Boilers with a power of 9 kW cost 24,900 rubles, and 27 kW - 27,100 rubles. Galax models are additionally equipped with equipment for monitoring coolant flow, a safety valve, a pump for forced circulation, and a pressure gauge. In this regard, their cost is higher - a Galax with a power of 30 kW costs 37,500 rubles, and the price for a model with a power of 9 kW is 33,000 rubles.

All Galan heating equipment is equipped with automatic equipment, with the help of which the consumer can set the desired air temperature and radiator temperature in the room, change it automatically in accordance with needs at a certain time of day, turn the device on and off with a special contact thermostat.

Equipment Features

The main feature of Galan heating boilers is the principle of their operation. After all, heating of the coolant, for example, in electrode devices occurs due to its ionization. In this case, the equipment simultaneously acts as a water heater, circulation pump and heating device.

Other units of this brand, such as electric or heating elements, work in the same way as electric boilers of other brands, but in comparison they have a lower cost.

The power line of Galan units is represented by equipment with a capacity of 2 to 50 kW, which allows it to be used for heating 20-500 sq. m area.

The use of any Galan boiler does not require permission from government authorities. And the Galan electric boiler weighs quite little and takes up very little space. It does not require a separate room - you just need to hang the device in the kitchen or bathroom, after which you can not pay attention to it.

We assemble an electric boiler with our own hands

If you are going to make an electric boiler with your own hands, you will find drawings and operating principles in our review. Before assembly, make sure you have the necessary tools and equipment. First, let's understand the operating principles of electrode boilers - there is nothing complicated about them, the technology is simple and proven.

The operating principle of a heating element boiler is quite simple; the heating element heats the water that comes into direct contact with it.

In classic electric boilers, the heating medium is heated using heating elements with or without a thermostat. The heating elements are somewhat slow - a lot of time passes from switching on to reaching operating mode. In addition, they are unsafe, as fires often occur due to their fault. In standard boilers, heating elements are located inside a small-diameter pipe through which the coolant passes - it heats up and heats the heating system.

Also in the design of heating element boilers there are temperature sensors that determine the degree of heating of the coolant - adjustments are made using them. Another control method is possible, using an air temperature sensor. Both types of sensors are connected to external automation systems responsible for starting and stopping equipment.

Description of the operating principle

The operating principle of electrode boilers is different:

Electrode boilers heat water using ions formed in the water as a result of alternating current being supplied to the electrodes.

- Instead of heating elements, one or three electrodes are located in the pipe (for single-phase or three-phase boilers);

- When electricity is supplied, ion exchange begins in the pipe;

- The coolant heats up and transfers heat to pipes and radiators.

Many of our readers are familiar with the military boiler, which consists of two razor blades and two wires. It quickly warms the water, after which it is used for making tea and other food needs. But this boiler consumes a huge amount of electricity - its operation often triggers the RCD in the panel. A similar principle is used in electrode boilers.

In order for the electrode boiler to work more efficiently, salt, soda or special additives are added to the coolant. They increase the electrical conductivity of water and improve heating of the system.

Electrode boiler assembly

Scheme of a simple electrode boiler for heating systems.

Now we will try to assemble an electric boiler for heating a house with our own hands. With the indicated dimensions of the pipe used, we will get a device whose power will be about 4-5 kW - this is enough to heat rooms up to 40-50 square meters. m. We take the pipe and begin to inspect it - it should be intact, without cracks or traces of rust. If there is rust, it should be removed with fine sandpaper.

We weld two bolts to the pipe - zero and ground will be connected to them. Thus, the pipe body will become our outer electrode. Next, we weld the inlet and outlet pipes - they will serve to connect to the heating system. The inlet pipe is located at the bottom, and the outlet pipe is located at the top. The top cover can be welded, or you can make an internal thread in the pipe and make the cover removable.

The removable top cover will ensure ease of maintenance of the boiler - it is likely that in the future it will have to be cleaned of accumulated salts and slags. If you don’t want to deal with removable covers, then you can weld them.

When assembling the electrode boiler, be careful not to allow the electrodes to come into contact with each other.

The most difficult thing is to make the bottom cover and insert the electrode into it. We recommend making the cover removable so that the electrode can be easily removed and replaced. The internal electrode should not come into contact with the internal walls or the cover itself. To create insulation, you should use ready-made insulators made of fiberglass or fluoroplastic. The procedure may seem labor-intensive, but if the assembler has “straight hands”, he will cope with this task.

Both covers, top and bottom, should be sealed with rubber gaskets. The length of the internal electrode should be such that it does not touch the opposite wall (aka the top cover).

General information

The operating principle of electrode boilers differs from traditional electric ones. Heating in them is carried out not by heating elements (heating elements), but by flowing electric current through the coolant.

To be more precise, thermal energy arises as a result of the chaotic movement of ions from the anode to the cathode, i.e. coolant molecules are split into positively and negatively charged particles. This is essentially the same principle that home experts often use to quickly heat water by dipping two electrically connected blades into the water.

It should be noted that such a heating system is not new. Back in Soviet times, it was used on nuclear submarines and ships. In 1992, the Russian company, based on military equipment standards and conversion developments, began manufacturing household flow-type electrode boilers.

Structural diagram

In 1994, the first production model went on sale, the operation of which showed the promise of the chosen direction. Below we will take a closer look at why the Galan heating system is attractive.

Electrode boiler in the heating system

About the benefits

Before talking about the advantages of an electrode boiler as a heating system at home, it should be noted that this option is only possible if there is reliable electrical wiring and a stable network condition. When frequent power outages and sudden voltage drops occur, it makes no sense to install such equipment, since the unit will not be able to function normally.

But even here you can find a way out if you promptly purchase a diesel generator or a UPS - an uninterruptible power supply. It accumulates a certain amount of electricity, and it can be enough for several hours of operation of the electrode boiler in the event of an accident. Some UPS models can regulate voltage using a built-in stabilizer.

In addition, in small suburban villages there is a certain quota for electricity consumption by a private home. Otherwise, special permission will be required, provided that this issue is resolved from the technical side.

If the described problems do not concern the owner, he will be able to appreciate all the advantages of an electrode boiler:

- High level of security. The equipment is designed in such a way that there is no possibility of electric current leakage, which means sparking and other similar phenomena. During operation, the occurrence of a dangerous fire situation is practically impossible, which allows the unit to be used to maintain a minimum temperature without outside supervision.

- Compact dimensions and the ability to be integrated into a heating network running on gas. As a result, the electrode boiler comes into operation when the gas supply stops.

- Fast heating of the heating system, silent operation of the unit and the ability to replace heating elements without changing the entire device.

- Installation in residential premises is possible without installing a boiler room or chimney. In addition, installation of the unit is very simple and can be done by hand.

- High efficiency - up to 96% during operation, and when heating, about 40% of electricity is saved. There is absolutely no contamination - soot, fumes, ash or smoke.

Connecting electrode boilers

Each equipment box contains detailed instructions for connecting and preparing the equipment for operation. The installation is not difficult, but there are a few things you need to know. To ensure sufficient circulation in the system, the boiler must be installed vertically. Below is the electrical connection diagram.

Installation diagram of the Galan boiler in a system with natural circulation. Nothing complicated, you can do it yourself (click on the picture to enlarge the size)

You can use electrode boilers in systems with heated floors: both where this is only part of the system, and where Galan works only on a low-temperature circuit. Of course, there is a difference in the scheme and it is visible in the photo below.

Electrical diagram for connecting the Galan boiler to a system with heated floors (click on the picture to enlarge)

In addition to these nuances, it is also worth considering a number of provisions that are necessary for efficient and economical heating:

If you are installing a boiler into an existing system and do not want to modernize/remodel it, then when selecting a boiler, pay attention to the system’s displacement. In general, 1 kW of power will normally “heat” 10 liters of coolant

In principle, each system is designed for a specific boiler, and only in this case can savings be expected, because you need to select pipes, shut-off valves, heating devices, and pumps. Before installing boilers in an existing system, flushing with the Protector inhibitor is mandatory, otherwise the existing salt deposits in the system will not make it possible to adjust the system. Like any electrical equipment, Galan boilers are demanding on power supply parameters. For their normal operation, a stable voltage is required. If the voltage or frequency on the line is unstable and often “jumps,” it is necessary to install the appropriate equipment at the input: a stabilizer and/or an inverter. The efficiency of operation depends on the mode in which the boiler operates more. There are only two of them: active - when the coolant is heated, and passive, when the heater is in a standby state. The longer the boiler is in the standby state, the lower the energy consumption. A ratio of 1x2 is considered good (in passive mode it is twice as much as in active mode); operating mode 1x1 is acceptable. All others are uneconomical. The time spent in active and passive mode depends on the rate of heat loss in the room: the longer the heat lasts (better insulation), the less time Galan works in active mode. Connection diagram of the Galan boiler to a system with radiators and heated floors (click on the picture to enlarge)

In general, there are debates about the efficiency of electrode boilers: it will not be possible to bypass the law of conservation of energy and how much energy is consumed is how much is released (a little less, taking into account the inevitable losses). But there are still savings when using electrode boilers. And it is formed due to direct heating: heat is directly transferred to the coolant, without being lost to the heating of a foreign body (heating element). Because of this principle, the inertia of the boiler is also less, that is, heating/shutdown occurs almost instantly.

One of the features of electrode boilers is their demand for coolant. As long as it can't be used. Can:

- drinking water that complies with GOST;

- distilled water, to which add regular salt at the rate (5g salt per 100 liters);

- special coolant - not general purpose and not automotive.

Coolants suitable for use in electrode (ion) boilers are provided by Galan itself. There are antifreezes "Potok" and "Argus". “Argus” has a freezing point of -40°C, has a quality certificate, is safe for human health, and inert towards the elements of the system.

Features of Galan electrode heating

First of all, it should be said that the Galant heating system is a closed structure, i.e. The coolant circulates in a closed circle. In other words, electrode boilers cannot be used in systems where the coolant comes directly from a well or other source.

As for the radiators that can be used, there are practically no restrictions; they can be:

- Steel;

- Bimetallic;

- Aluminum.

The only thing that is not recommended for use with such boilers is:

- Large-sized radiators;

- Cast iron radiators for home heating;

- Large diameter pipes.

There are also no special requirements for electrical connections. The only thing is that you must use cables of the appropriate cross-section, and the connection diagram contained in the instructions for the equipment must also be followed.

Electrode boiler Ochag-3

Advantages

The Galan heating system has many advantages, among which the following points can be highlighted:

- Energy efficiency that the manufacturer managed to achieve thanks to new technology for converting electrical current into thermal energy.

- Energy saving - electrode boilers working in conjunction with digital electronic control units consume 30-40 percent less electricity compared to traditional heating elements.

- Thanks to the use of modern technologies and high-quality materials, as well as the use of automatic devices, these devices are completely energy and fire safe.

- Galan heating systems operate in a fully automated mode. Thanks to this, human intervention is not required to ensure a stable and comfortable temperature regime, regardless of weather conditions. Automation from Galan is capable of maintaining the temperature background with high accuracy (± 0.2 degrees). The equipment can be equipped with a climate control system for weekly programming of the operating mode. In addition, when using non-freezing coolants, such as “Potok”, there is no need to drain them from the radiators, even in the case of long-term downtime of the boiler.

Electronic control units

- The Galant heating system is an excellent option for those settlements where the network voltage is unstable. Even if the voltage drops to 180V, the boiler will continue to operate.

- Electrode boilers do not require a permit for installation.

- If a leak occurs in the system, the device immediately turns off, since the electric current cannot be closed in the circuit.

- The liquid heating chamber has a small volume, and during ionization, the coolant in it heats up sharply, as a result of which the pressure rises to two atmospheres. Thus, the boiler serves not only as a heater, but also as a circulation pump for heating. This allows you to reduce the cost of purchasing equipment, as well as the cost of operating the heating system.

- Low price.

Thus, the popularity of these devices is well founded.

Replacement electrodes for Galan boilers

Flaws

Like any other heating equipment, electrode boilers also have some of their disadvantages, which are listed below:

Demanding requirements for water - the fact is that not just any water can be used in the system, but with certain characteristics. When starting heating, it is necessary to prepare the coolant according to the manufacturer’s recommendations. As a rule, to do this, add a few teaspoons of soda and salt per liter of water. You can also use special liquids.

Coolant Galan

- Electric current circulates in the water, therefore, the possibility of receiving a strong electric shock if you touch the heating radiator is possible. To prevent this situation, it is necessary to perform grounding in accordance with PUE and GOST 12.1.030-81.

- Periodically it is necessary to clean the system and change the electrodes, which become thinner over time, resulting in reduced heating efficiency. Thus, in terms of durability, electrode boilers do not have any advantages over traditional heating elements.

As we can see, the shortcomings are not critical, but they should still be remembered.

In the photo - electrode boilers Geyser-9

Abilities[edit | edit code]

Galan, as a Greater Demon and member of the Ten Commandments, is a very powerful character, capable of fighting members of the Four Archangels or facing a large squad of Holy Knights alone.

See Demon Clan

- Physiology of Demons

- being a representative of the Demon Clan, Galan has seven hearts, the destruction of one or more of which is not a fatal wound for him, although very painful. - Soul Manipulation

- like any other demon, Galan is capable of extracting, absorbing and simply physically contacting the souls of any living beings.

See Hellfire

“Hell Flame”「獄炎 (ごくえん) (ヘルブレイズ) Gokuen (Herubureizu)」 is the dark and mysterious power of the Demon Clan. It allows the user to create and control black flames that cannot be extinguished. This fire nullifies all regenerative abilities, and is also capable of leaving a wound immortal.

See Dark Matter

“Dark Matter”「暗黒物質 (あんこくぶっしつ) Ankoku Busshitsu」is an innate ability of all demons that allows them to manipulate an unknown dark substance. Dark Matter allows you to regenerate damage, create any structures and use some other abilities.

See “Critical Limit”

Critical Limit

Rinkai Toppa (Kuritikaru Ōbā )

」 is Galan's personal ability, allowing him to increase his physical strength through magic for an indefinite period of time. When using his ability

muscles grow

, and

spines appear on the body

. On top of everything else, his voice takes on a “monstrous” sound. Thus, his Strength Level rises to 40,000 units, but the skill of restraining oneself completely atrophies.

Level edit | edit code

| Before magic is restored | |||

| General | Magic | Force | Spirit |

| 26 000 | 24 000 | 2 000 | |

| Base | |||

| General | Magic | Force | Spirit |

| 27 000 | 1 000 | 24 000 | 2 000 |

| Critical Limit | |||

| General | Magic | Force | Spirit |

| 40 000 | ? | ? | ? |

Equipmentedit | edit code

Halberd

「ハルバード Harubādo」- Galan is excellent at wielding a halberd, which, despite its size, he always carries with him. The weapon itself is very durable and allows

play golf with big boulders

And

destroy cities with one blow

- “Chaotic Judgment”

「紊粗断 (ざんばらざん) Zanbarazan」 is a technique that involves quickly delivering a large number of slashes in different directions at different angles around you. - “Deadly Strike”

「紊粗断 (ぶんざらだん) Bunzaradan」 is a technique that involves delivering one concentrated slash with all possible force to cut an opponent in half. - “Rapid Merciless Strike”

「伐裟利 (ばっさり) Bassari」 is a technique that involves quickly delivering a large number of stabbing blows in different directions. The force of the blows is enough to destroy a large part of the city in a couple of moments.

Preparing the coolant and starting the Galan boiler

Galan heating boilers require a special coolant; they do not work with ordinary water, since its resistance is not strong enough. To increase resistance, table salt is added to the water. For 100 liters of distilled water you need 5-8 mg of salt (the edge of a teaspoon). The salt is diluted in a small amount of water and poured into the general circuit.

Then the circulation pump is turned on, which will mix the coolant until it has a homogeneous structure. You can check the correct preparation of the coolant using current clamps. The readings must coincide with the table values indicated in the boiler passport. If the voltage is too high, you need to make the water less salty; if the voltage is not enough, you can add more salt. There is no need to rush into making changes, as the system will fully stabilize only after three days.

In addition to salted distilled water, non-freezing liquid produced by the boiler manufacturer Galan can be used as a coolant. This is a specially designed coolant that does not freeze down to -40 degrees.

The issue of heating is acute for any buildings and premises. Many devices are used for these purposes, but electric boilers and systems still have undeniable advantages. The Galan electric boiler is an excellent assistant in this matter. The Russian company was founded more than 25 years ago, and initially produced only electrode heaters. Now heating elements have also been added to the range.