Before we look at our rating of the best solid fuel boilers of 2022, I would like to answer a number of important questions that will help many novice users decide on a purchase. First, you need to decide what to choose: a single-circuit boiler paired with a boiler or column, or a double-circuit analogue, equipped with an additional heat exchanger for organizing hot water supply. Due to the fact that our list contains an overwhelming number of affordable and budget-friendly models, we focused on single-circuit solutions (mainly) for several reasons: they are cheaper; in the event of a breakdown, the entire house will not be left without heat; the boiler and boiler provide quick access to heat and hot water. On the other hand, dual-circuit models provide space saving, as they combine two types of equipment.

In turn, according to the principle of operation, all solid fuel solutions for the home can be divided into several categories:

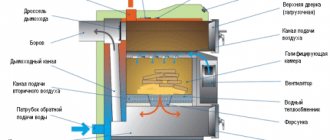

- Pyrolysis - in such equipment the fuel smolders and does not burn, as is the case with analogues, as a result of which only gases are released, which, in turn, are saturated with heat. It is important that the firewood and processed products have high humidity for pyrolysis;

- Classical - in such systems, heat is released during the flaming combustion of solid materials, and to maintain the temperature it is necessary to regularly replenish reserves with coal, firewood and processing waste, including stumps;

- Long burning - in such devices heat is generated slowly, which is due to the name of the equipment. The main advantage is the burning time of firewood, up to several days.

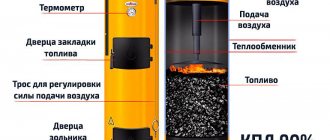

Description of design

As a rule, long-burning boilers are not used for heating water , that is, they are mainly made single-circuit. They are used in systems with forced circulation of water media. Even if heating the water is possible, its temperature is no more than 80 degrees. The design is equipped with a control unit that allows you to regulate the intensity and performance of room heating. If an emergency occurs, the regulator will signal about it.

Advantages and disadvantages

Among the main advantages are the following:

- ease of maintenance;

- affordable cost of equipment and fuel;

- positive reviews;

- autonomy;

- possibility of choosing different types of fuel;

- environmental cleanliness;

- excellent efficiency;

- intuitive controls;

- safety.

Heating a private house with a solid fuel heater, especially an automatic one, does not require large amounts of time spent servicing the equipment. It is enough to add fuel once every couple of hours (and probably even a day).

The disadvantages can probably be attributed to the fact that the entire heating procedure is a kind of vicious circle: loading fuel, ignition, combustion, extinction, cleaning.

We also note that most models are very sensitive to the quality of fuel and barely regulate the temperature.

Due to the fact that solid fuel devices have recently gone through many stages of improvement, they have become very economical and quite effective, which is the reason for their increase in popularity. There are also automatic long-burning boilers. Modern equipment can operate with a one-time load from 5 to 36 hours. The size of the firewood used has also changed. Now it is possible to load firewood up to 1 meter long and up to 20 cm thick. Such a large fuel size saves material and time costs during procurement.

In order to most accurately understand what we are talking about, we will describe the technical data of one of the devices - KT-2E (made in Ukraine):

- heating area - 250 sq. m;

- power - 25 kW;

- loading chamber volume - 62 cubic meters. m;

- fuel capacity - 56 kg;

- burning time on one tab is around 8-46 hours (this depends on the type of fuel);

- firewood size - 46 cm;

- dimensions of the loading opening - 230x370 mm;

- water in the boiler - 117 l;

- Efficiency - 83%;

- chimney size - 170 x 170 mm;

- water pressure - no more than 3 bar;

Review of famous models

Among modern pyrolysis boilers, the companies BUDERUS, VIESSMANN and VIADRUS are especially popular and reliable. This is due to the fact that the quality fully corresponds to its price. Manufacturers take a responsible approach not only to the selection of materials, but to the assembly of devices itself. The boilers are fully automated, and this also applies to the ignition process itself.

Let's look at each manufacturer in more detail:

- Vitoligno 100-S from VIESSMANN – premium class (Germany). These units have a power rating from 25 to 80 kW, the efficiency level reaches 88%. The line of such models has a working pressure of no more than 3 Bar. The temperature of the supply pipe is 95 degrees, and the return pipe is 55 degrees. You can use logs up to 50 cm long. Vitoligno 100-S has automation, which consists of a controller and a set of sensors. There is a fan in the chimney duct, which provides draft as it serves as a smoke exhauster. The controller regulates the operation of not only the fan, but also circulation and network pumps, as well as three-way boiler piping valves.

- BUDERUS – premium class (Germany). Such boilers also have a number of their advantages, in particular, their efficiency is 88-90%, despite the fact that their power varies between 20-40 kW. The working pressure here is the same as in previous analogues - 3 Bar. The supply temperature is 95 degrees and the return temperature is 55 degrees. But in this boiler you can use logs 10 cm longer. Such boilers can be made of either cast iron or steel. Perhaps one of the most pleasant features of BUDERUS models is their aesthetic appearance, because not everyone has the opportunity to hide the boiler out of sight.

- VIADRUS Nefaistos P1 – middle class (Czech Republic). You can use pellets for refueling. This is convenient because the boiler is loaded only once a week and no longer requires refueling. Although, to be fair, it should be said that the duration of the work largely depends on the volume of the bunker. The entire system is controlled automatically. For safer operation, the burners are equipped with a fire extinguishing system connected to water. VIADRUS products are in no way inferior in their technical characteristics to the Germans, but at the same time they cost an order of magnitude cheaper than their counterparts.

Of course, there are many different models on the modern market, both domestic and foreign. When preparing to purchase, it is worth studying the general technical characteristics of pyrolysis boilers, and then, focusing on your finances, choose a specific model.

Principle of operation

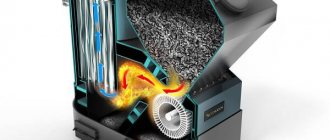

Solid fuel boilers consist of the following parts:

- heat exchanger;

- fan;

- fuel bunker;

- combustion chambers;

- smoke exhauster.

Solid fuel is placed inside the bunker and set on fire.

Limited air and high temperature create the formation of pyrolysis gas. The resulting gas enters the combustion chamber of the boiler through ceramic nozzles, where it interacts with secondary air. In the chamber, the gas burns completely, and CO2 is formed. High-temperature gases that exit the combustion chamber enter the heat exchanger and then into the chimney. In this case, the fan creates an air flow that blows across the heat exchanger. Then the heated air enters the grilles, which are located inside the heat generator or through a ventilation duct system connected to it. According to this scheme, the air in the room is heated. With the help of an electronic unit, the air temperature at the exit is in the region of 50-110 degrees. With approximately one load, a heat generator can operate for 6-9 hours, but these figures can vary significantly depending on the manufacturer. We must not forget, in order to preserve the walls of the combustion chamber, it is not advisable to allow the device to operate in critical mode if the temperature is more than 110 degrees.

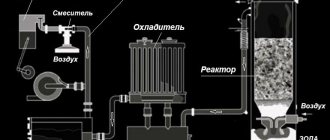

Pyrolysis: what is it?

Even in ancient times, people realized that burning wood was not the best way to release energy. The most effective was the use of charcoal . At that time it was not yet known that the process of burning coal was called pyrolysis. Essentially, this is the breakdown of organic substances, possible under the influence of high temperature. To prevent such decomposition from becoming simple combustion, it is necessary to limit the access of oxygen. Coal pits were previously used for this, but an important disadvantage of this method was the loss of energy that is released during the burning of coal. To avoid this, special pyrolysis boilers were created.

Types of solid fuel boilers

Solid fuel boilers can use various substances. By type of fuel they are divided into:

- who use firewood - any trees will do (birch, oak, maple, alder, ash). In this case, it is necessary to take into account the calorie content , since the higher it is, the longer the wood burns. For combustion, it is best to use wood with a moisture content of no higher than 25%;

- who use coal - coal of any fraction and class is suitable. It is advisable to choose coal with a calorie content of no more than 7000 kcal per kilogram. Burning a kilogram of coal with a calorific value of 7000 kcal, the result is 8.15 kW/h, and this figure is close to what natural gas creates;

- pyrolysis - work on wood, molecularly decomposing the wood during combustion at elevated temperatures. The wood must be dried for at least a year before burning;

- that use pellets - you can use any pellets (straw, sunflower husk, wood). This is the most profitable type of fuel. Pellets are characterized by low ash content and high calorie content. Devices that run on pellets are, according to reviews, some of the most popular today due to their advantages;

- universal - used on all different types of fuel.

In addition, depending on the type of fuel, they can be divided into those where manual loading and automatic feeding are carried out using a piston or auger.

Flaws

If you want to purchase a pyrolysis boiler, be sure to pay attention to its disadvantages .

- First of all, it is worth noting the high price. Naturally, the costs will pay off as you use the equipment, but before that you will need to make a large investment.

- To use the unit, you will need fuel of a certain moisture content. If this figure is 30% or more, the material must be dried independently. Otherwise the boiler will go out.

- Extinguishing of the pyrolysis chamber can occur due to insufficiently high coolant temperature. To avoid this, in some cases it is advisable to install a bypass pipe. Such a solution will complicate the design and make the system less efficient.

- Many models use air pumps to create forced draft. Accordingly, the boiler will have to be connected to the electrical network.

Reviews of solid fuel boilers

Many people have been using these devices for years and they know exactly about all the advantages and disadvantages.

Therefore, before buying a solid fuel boiler, it would be good to consult with someone just to find out consumer feedback. According to our statistics, the owners of these boilers say that it is necessary to carefully select fuel, find out what kind of fuel is available in your case, determine how much it burns and how much energy it produces, and then compare it with the cost of them and select the most profitable type of equipment . In this case, you need to carefully take care of the exhaust system, because sometimes some of the heat simply flies into the air. The overall result suits everyone. Users in our country, as a rule, burn wood; they are harvested from the beginning of summer and sometimes until the end of autumn. Many of the consumers in their reviews recommend choosing birch , because when it burns, the largest amount of heat is generated, which is the advantage. Here are reviews on whether it is worth buying a solid fuel boiler.

Is it worth buying a solid fuel boiler?

If it is not possible to connect gas, yes.

Is a solid fuel boiler profitable?

Much cheaper than electric.

How often do you need to add firewood to a solid fuel boiler?

Maximum twice a day.

Tips from the experts

The future owner of a solid fuel boiler should know the following before purchasing:

- What type of fuel will be easiest and most economical to purchase in your area of residence. This can be coal, peat, firewood, organic briquettes or pellets.

- Determine the required power of the equipment used to heat the building. In general, to heat every 10 square meters of area of a well-insulated house, 1 kW of boiler energy is required. The calculation should be performed with a small margin, since the efficiency of heat transfer gradually decreases over the years of operation.

- If you need not only to heat the building, but also to produce hot water for household needs, the boiler you purchase must be a double-circuit one.

- The quality requirements for a boiler used in a cottage with continuous residence must be higher than for a country house visited periodically.

A question of cost

The cost range for solid fuel boilers is very large. The cost depends on how much area will need to be heated, but the manufacturer is even more important.

So we can buy a domestically produced Ogonyok KOTV device for 15 thousand rubles, while the Polish SAS ECO will cost much more, about 160 thousand rubles. Boilers made in Turkey by Caldera and Germany by Roda are in excellent demand, the cost of which will also not greatly please the consumer. But, not forgetting about saving in the future, you need to think carefully.

Exploitation

Judging by the reviews, operation does not create any issues. Apart from downloading after a certain time, the rest does not require much labor. Due to the well-thought-out design, cleaning from combustion products and raw materials is quite simple. The owner of the house only needs to load fuel into the fuel container, light it and set the desired temperature (when installing a temperature control device). Then you can enjoy the comfort and warmth of your home , only breaking away from time to time to refuel.

Prices: summary table

| Model | power, kWt | Efficiency,% | Peculiarities | Cost, rub. |

| Burzhuy-K "Modern-12", Russia | 12 | 92 | Non-volatile, with mechanical control, the interval between adding firewood is 12 hours, coal is 15 hours. | 59 000-62 000 |

| Trayan TB-10-2KT, Russia | 10 | 85 | Non-volatile, dual-circuit, with mechanical control, the period between fuel additions is 10 hours, the ability to connect a 3 kW heating element. | 43 000-53 000 |

| Buderus Logano S171-22W, Germany, Bosch Thermotechnik GmbH | 22 | 89 | Energy-dependent, highly automated, environmentally friendly, loading period - 3-4 hours. | 179 000-198 000 |

| Atmos DC 18S, Czech Republic | 20 | 90 | Volatile, with built-in smoke exhauster, long burning, one load – up to 12 hours. | 127 000-159 000 |

| Suvorov-M" K-10, Russia | 12 | 92 | Non-volatile, long burning. The burning time of one coniferous bookmark is up to 14 hours, hard wood – up to 17 hours, fuel briquettes – up to 36 hours. | 62 000-64 000 |

| Suvorov Ultra" K-15U, Russia | 15 | 94 | Mine, long burning, firewood - up to 65 hours, fuel briquettes - up to 120 hours. | 93 000-96 000 |

The technology of converting solid fuel into heat and hot water has seriously advanced from stove heating. In terms of cost-effectiveness of use, abundance of innovative solutions, environmental safety and affordable comfort, pyrolysis boilers are quite competitive compared to gas and electric appliances, and the market provides a choice for every taste and budget.

BoilersPyrolysis boiler unitsSolid fuel boilers

How to choose a solid fuel boiler?

Most people associate solid fuel devices with the stoves that once heated the entire country. With the creation of electric and gas boilers, the popularity of solid fuel heating systems has greatly decreased. It was believed that a heating boiler using solid fuel - peat, coal or wood - was more difficult to operate and needed constant monitoring. In some ways this was true. A classic solid fuel boiler has a small firebox and to heat your home you need to add fuel 6-8 times.

This is actually quite a big drawback, in contrast to gas devices running on liquefied or main gas. Another disadvantage is the need for high-quality fuel. This was especially true for gas generator or pyrolysis boilers, which are quite sensitive to fuel moisture. Such disadvantages, or more specifically features, must be taken into account when choosing a heating boiler.

And now about the advantages of solid fuel boilers.

Solid fuel boilers are safer, unlike electric and gas ones, since there is always a danger of gas explosion and leaks, not even in the boilers themselves, which have an increased degree of protection, but usual in the gas supply system.

These boilers are economical - you can buy firewood in places far from the city quite cheaply, and the design of today's devices is such that they have a fairly good efficiency.

Environmental friendliness - today in solid fuel boilers the fuel burns completely , leaving a little ash, which, as a rule, serves as fertilizer, although little of it is obtained.

We mentioned above that heating requires 6-8 refuelings daily. In fact, modern boilers now operate on one refill for up to 36 hours, which significantly increases their attractiveness to buyers.

And the main thing is convenience, durability and unpretentiousness - it is now quite expensive to install gas into a house, and using electricity for heating is also not cheap. Choosing liquefied gas can be inconvenient and it may not be easily and quickly delivered to every area. Often a solid fuel boiler is the best option , and sometimes the only one. As already described, you can choose any fuel for heating - coal, firewood, briquettes, coke, European firewood, and so on.

Design features

The latest developments in the field of thermal energy have been introduced into the designs of such solid fuel boilers. They significantly increase the operating efficiency of heating devices, increase periodic maintenance time, have high efficiency and allow operation with various types of solid fuels.

They are made from high-strength steel or ductile iron, ensuring long-term use without the need for repair or replacement. The level of automation of such boilers ensures regulation of combustion modes without human intervention and complete safety during operation.

The main thing !, the use of long-burning technologies allows you to increase the periodic loading time to 48 hours, and in some models even up to 10 days. As a result, the operation of the heating boiler becomes very simple and not burdensome for its owner.

Types of heating boilers

There are two types of boilers:

- with manual loading;

- with automatic loading.

Manual loading boilers

As a rule, long-burning boilers from BuderusLogano are recommended.

The choice of this particular brand is due to the excellent quality of production, ease of operation and reliability. Long-burning boilers BuderusLogano G221 are manufactured in a number of modifications with a power of 25-50 kW. This is the best option for heating a country house or a small industrial premises. This boiler runs on briquettes, wood or coal. This is a traditional cast-iron heating boiler, the combustion duration of which is ensured by the volumetric loading chamber and modern technologies used in the manufacture of this device.

Automatic pellet boilers

This is a type of boiler that runs on granular fuel - pellets. These devices are absolutely unpretentious in operation , but they are energy dependent and need to be connected to electricity for the device’s automation to operate.

Recommendations for choosing equipment

If you are sure that you can constantly buy dry firewood or dry it yourself at home, then you can safely buy a pyrolysis boiler. Otherwise, preference should be given to modern equipment, the furnace of which is designed for pyrolysis and traditional combustion of fuel. Such a device can operate on wood, the humidity of which reaches 35–45% .

If there are no problems with fuel, pay attention to the loading chamber. Firewood measuring 55–65 cm in size should be placed here. Both chambers should have a coating of expanded clay concrete. Thanks to it, an optimal temperature regime is maintained inside the device, which ensures high-quality combustion of the selected fuel and protects the walls of the product from burnout.