Here you will learn:

- Operating principle of traditional boilers

- How do pyrolysis boilers work?

- A little chemistry and physics

- Ensuring long burning

- Advantages and disadvantages of pyrolysis boilers

Traditional solid fuel heating boilers are distinguished by their simplicity. There is practically nothing in their design except a firebox, doors, a thermometer and a heat exchanger. This simplicity leads to low efficiency and rapid combustion of wood. Therefore, in this review we will consider the operating principle of a pyrolysis boiler - it is more complex structurally, but it has a higher efficiency. This unit will also delight you with long-lasting combustion from just one load of firewood. Our review will tell you how this is implemented.

Briefly about pyrolysis combustion

The process of pyrolysis is the slow decomposition of carbon fuel, which occurs under the influence of high temperature and lack of oxygen. The output is flammable gas or liquid fuel, depending on the feedstock and the conditions of the chemical reaction.

Pyrolysis heating boilers produce and burn gas, hence the second name – gas generator or gasifying. Initial raw materials are dry firewood, coal, fuel briquettes.

Diagram of a gas generator plant that produces fuel for an internal combustion engine

Reference. For pyrolysis combustion, a wide variety of solid fuels containing hydrocarbon compounds are used. An example is the production of liquid fuel from old car tires or the combustion of waste in industrial gas-generating furnaces.

How wood pyrolysis occurs:

- A certain volume of chopped wood or sawdust is loaded into a closed tank (reactor).

- The metal vessel is heated from the outside to 500...900 °C, and air is supplied to a limited extent through the tuyeres (blown holes).

- The tree smolders and decomposes into its components - hydrogen, methane, carbon monoxide, water vapor, carbon dioxide. At the end of the reaction, some ash remains at the bottom.

- The resulting gas mixture is cooled, purified, and then pumped into cylinders for further use.

Before loading into the gas generator, the wood is dried. Otherwise, the heating energy will be spent on water evaporation, the pyrolysis reaction will slow down greatly, and the output will be a bunch of water vapor.

Note that any process of burning solid fuel is accompanied by the release of wood gas, even in a fire (see photo). Pyrolysis is described in more detail in our other publication.

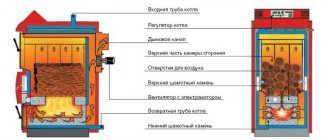

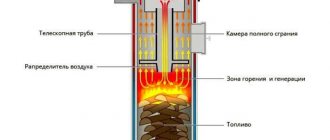

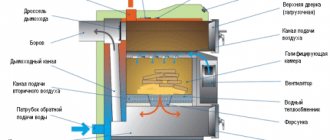

Device

The huge chamber is designed for storing solid fuel: coal, firewood and other flammable substances. Firewood or other fuel flares up, then the air is automatically shut off. For the flame to be intense, air is needed. There is not enough oxygen for intense combustion, and the wood begins to smolder. Wood gas and a lot of carbon are released - ash particles. Air and ash particles are mixed in another chamber and the afterburning process occurs. Both chambers are separated by a special grid on which fuel is stored. The peculiarity of fire in such a device is that it has a reddish tint due to the reaction with carbon.

Operating rules

To get good heat transfer from a gas generator heater with minimal fuel consumption, manufacturers recommend adhering to the following rules:

- use only dry firewood, permissible humidity 12...20%;

- when installing and piping the boiler, be sure to use a three-way mixing valve or the Laddomat-21 complex device to maintain the temperature in the return line at 65 °C;

- operating coolant temperature at the supply – 80…90 °C;

- the heat generator must operate at a power close to maximum; the unit cannot be operated for a long time in low productivity mode (less than 50%);

- It is very advisable to burn with large logs, but not with round logs;

- Together with pyrolysis boilers, it is strongly recommended to use a buffer tank, which will accumulate excess thermal energy;

- The requirement for the minimum volume of the heat accumulator is 25 liters for each kilowatt of heater power.

Explanation. If cold coolant with a temperature below 65 degrees enters the boiler tank, then during the gasification of the fuel, condensation and tar will form in the primary chamber. Read more about correct piping in a separate guide on connecting TT boilers.

The supply of coolant to the boiler must be regulated by a three-way valve.

After the buffer tank, another mixing unit is installed to lower the water temperature. The use of a buffer tank is due to the efficient operating mode of the boiler - intense combustion, outlet temperature 80...90 degrees. It is under these conditions that a high efficiency of 86–87% is achieved. You cannot “choke” a heat generator with air; the combustion efficiency will drop to 40–50%, like a homemade potbelly stove.

Scheme of operation of the pyroboiler

The pyrolysis boiler circuit consists of the sequence of the following processes:

- loading fuel into the boiler furnace, ignition;

- after the fuel has ignited, the damper is closed, the combustion process gradually enters the smoldering stage;

- through the primary channel, outside air is supplied to the loading chamber, part of which is used to maintain the smoldering process and achieve the required gasification temperature;

- pyrolysis gases enter the combustion chamber through the grate;

- to ensure the combustion process of pyrolysis gases, air is supplied to the afterburning chamber through a secondary channel;

- volatile products burn, releasing a certain amount of heat, part of which is directed under the grate and used to maintain pyrolysis, the second goes directly to heating the boiler;

- waste combustion products pass through a water heat exchanger and are discharged into the chimney;

- maintaining the optimal combustion temperature is supported by a thermal control system.

Additional information about the operation of a pyrolysis boiler can be found in the video

Real advantages of pyrolysis heaters

Let's list the advantages of gasifying boilers declared by sellers, and then weed out outright stories:

- pyrolysis heat sources are full-fledged gas generators that produce flammable synthesis gas;

- the units are very economical and environmentally friendly due to their high efficiency;

- boilers completely burn coal and wood, with virtually no residue;

- burning duration is over 10 hours (the most modest indicator is 8 hours).

Note. Advertisers and not very conscientious manufacturers always compare gas generating units with conventional direct combustion boilers, “forgetting” about equally efficient pellet heaters. But even this comparison is not very advantageous.

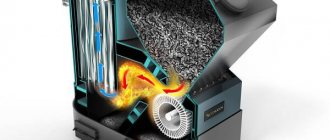

The first statement is too bold. Let's remember: intense pyrolysis begins from strong heating and lack of oxygen, but what happens in the boiler? The fan pumps air into the firebox in excess, there is no smoldering. Synthesis gas, of course, is released, but direct combustion of fuel is also present.

On the left is the flame torch in the afterburning compartment during boiler operation, on the right is the fire tube heat exchanger (top view)

Let's look at the other advantages:

- Statements about efficiency and environmental friendliness are not fairy tales. Due to decent efficiency, the boiler better utilizes fuel energy and emits much less toxic compounds into the atmosphere - nitrogen oxide and carbon monoxide. Under 1 condition: recommendations for operating mode and moisture content of firewood are fully observed.

- The reasons for more complete combustion are dry wood and forced air injection. If you put sawdust briquettes or dry acacia into a traditional turbocharged boiler, the ash residue will also be zero. A lot of light ash is simply blown by a fan into the chimney. This means that this fact is not an advantage.

- The duration of combustion depends on 2 factors: efficiency and capacity of the fuel compartment. In terms of efficiency, solid fuel boilers are inferior to pyrolysis boilers by 10%, which is a small increase in operating time. The main factor is the volume of the combustion chamber; if it reaches 80 liters or more, the firewood burns out in 6–8 hours.

Reference. The Czech manufacturer Atmos describes the advantages of its heat generators (literally): large fuel bunker – long burning time. Hence the conclusion: the statement about the duration of work is true, only the reason is different - the capacity of the firebox, and not the fact of generating wood gas.

There are also many tales told about the economical smoldering mode, which is simply absent in pyrolysis units. The Atmos DC15E operating instructions say so - a decrease in flame intensity leads to a decrease in efficiency and an increase in fuel consumption.

The newest heat generator “Atmos” of pyrolysis type at the exhibition “Aquatherm-2019”

Installation specifications

Industrial pyrolysis equipment allows you to process tens of tons of material per day, but its disadvantage is its large size.

Main parameters of the units:

- productivity (kg/hour or cubic meters per day);

- installation weight (mobile units weigh 3-8 tons, stationary units weigh more than 10 tons);

- dimensions;

- power;

- type of power supply (required fuel/electrical network parameters);

- mobility (is disassembly required for transportation);

- number of floors of the installation (number of levels).

Sometimes the manufacturer of pyrolysis plants indicates additional parameters: payback, reactor volume, etc.

Significant disadvantages of boilers

If you visit any online store of heating units and ask how much pyrolysis heat generators cost, you will immediately see their main drawback. Not the most expensive Russian boiler “Suvorov M” K-20 (20 kW) will cost 1320 USD. e., and identical in power ATMOS DC 20 GS – 2950 cu. e. For comparison: the price of the expensive traditional heater Buderus Logano S131-22 H is 1010 USD. e.

Let us outline other disadvantages of gasifying heat sources:

- 2 chambers, a brick or ceramic lining plus a water jacket in the lower part of the body - the listed design solutions significantly increase the weight and size of the units;

- high requirements for fuel quality;

- coolant with a temperature of 80 °C is rarely used when heating private houses, which means that you cannot do without an expensive heat accumulator + piping elements;

- Ceramic lining parts do not last forever - the nozzle may crack due to overheating and will have to be replaced.

It must be said that pyrolysis boilers attract home craftsmen. But making such a unit with your own hands is very difficult; you need experience and investment in purchasing materials. It is not possible to make a heater for free. It is much easier to weld a regular or mine boiler.

Note. Judging by the reviews of boiler owners on thematic forums, it is still possible to use raw firewood. The algorithm is as follows: the unit is melted and warmed up with dry logs, then wet wood is added. But the share of such fuel should not exceed 30%, otherwise soot and soot will form. Let's listen to the expert's opinion in the video:

With your own hands

Below is a 25-minute video of designing and making your own pyrolysis boiler. The author describes the assembly process step by step and also talks about the difficulties encountered.

Possible mistakes:

- Wrong alloy. The most common mistake, which, by the way, is typical not only for home-made models, is the use of the cheapest materials from ferrous metals. They do not belong to the category of heat-resistant materials, which ultimately leads to burnout of the structure and difficult, or even simply impossible, repairs. It is necessary to carefully select the steel grade and use special heat-resistant alloys. For example, 20Х23Н18 and the like.

- Small thickness of steel. Another mistake is the incorrectly selected thickness of the steel sheet. This parameter is determined based on the temperature distribution throughout the boiler, but the minimum value is about 5 mm. The thicker it is, the more expensive it is, but then the boiler will work longer.

Blueprints

An attraction of unheard of generosity – there’s no other way to describe it! From us you can download drawings of pyrolysis boilers completely free of charge. This will allow you to assemble the heart of the heating system in your backyard or garage if you wish.

We present long-burning boilers, which you can find under the Bourgeois K brand. Drawings of a 20 kW boiler can be downloaded for free from the link below.

- .

- ;

See examples of graphic materials in the images below.

You also have a unique opportunity to order a set of drawings for one of the models at a very attractive price. Of course, this is an option for those who are going to make a boiler with their own hands, not only for themselves, but also to order. To contact, use the form below.

Conclusions and recommendations for selection

It makes sense to choose a pyrolysis boiler from all existing boilers in this situation:

- you are willing to pay for efficiency and environmental protection;

- the budget allows you to purchase a heater and heat accumulator of the required volume;

- there is enough space in the boiler room for equipment;

- It is possible to prepare high-quality firewood, buy briquettes or dry freshly cut wood.

The heat generator model is selected according to power and functionality. How to choose the right wood-burning heat source for your home, read our instructions.

Initially, pyrolysis domestic boilers are designed to install a storage tank and use good fuel. This is a Western European practice, where solid fuel units cannot be operated without a buffer tank.

Our incomes are not so high, which is why homeowners save on everything - equipment, fuel, combustion method. Hence the conclusion: at the moment, gas generator installations are incompatible with the needs and expenses of most homeowners, because they cannot be operated correctly.

Suitable waste for recycling

The advantage of pyrolysis plants is that they are suitable for the safe disposal of a wide range of materials, including difficult to decompose substances.

- Solid waste: paper, plastic, glass, bones, etc.;

- wood processing waste: chips and sawdust;

- plastic and polymer-containing waste (bottles, plastic bags);

- silt layers formed in sewers and sewers;

- slate and peat;

- car tires, rubber waste;

- waste from the agricultural and industrial complex;

- agricultural waste (husks of grains, shells of nuts, etc.);

- waste from medical institutions

- oil sludge;

- plant waste, including algae.

Technological process

Before starting calculations, it is advisable to decide on a suitable heater model:

- what functions it should perform (only heating or also as a home kitchen);

- what fuel is most available;

- intended installation location.

Large stoves allow you to heat spacious rooms. Metal units are mobile and can be easily transported from place to place. The brick kiln is always stationary.

If these issues are resolved, you can begin to make a pyrolysis oven with your own hands.

The body of a potbelly stove type can be made from scratch using high quality steel sheets. It is easier to make the furnace body in the form of a rectangle with double walls, filling the opening with sand or water (you will get a water circuit). Another option is to use an existing steel container such as a barrel or gas cylinder.

In the case of a brick building, you will need the skills of a masonry master.

In any case, you will have to make two combustion chambers. One is the combustion chamber, where solid fuel is processed; in the second, processed products are burned, coming into contact with air. Grate bars are installed between the chambers. It is advisable to make the chimney removable, so it is easier to clean.

The dimensions of the future installation depend on the required power. The main element is the combustion chamber. When calculating its volume, it is based on the combustion rate of the proposed fuel and its mass. The load factor is generally considered to be 0.63 (by which the mass of fuel is divided).

Suppose you need to create a metal furnace. You will need the following materials:

- steel sheets grade st. 20 4 mm thick (cutting is best left to specialists);

- steel corners with identical shelves 4x50 mm;

- steel reinforcement with a cross section of 8 mm;

- pipe with a diameter of 60 mm for the blower;

- 120 mm pipes for the chimney;

- one and a half dozen bricks.

You also need tools for the job:

- welding machine with a set of electrodes;

- grinder, drill;

- building levels, tape measure, pencil;

- hammer.

Output products

After heat treatment of polymer materials, char ash, pyrolysis liquid and gas remain.

Some of the gases condense and turn into a liquid state. The liquid is purified to turn it into synthetic oil. It is used as a replacement for natural fuel.

Dry pyrolysis method

Gas that has not undergone condensation is sent for afterburning or sold to third-party consumers. It can be used as fuel to generate electricity at thermal power plants.

After the tires are processed, fireproof steel cord remains; it is sent to a warehouse for further processing into metal products. The carbonized (turned into coke) residue is used in industry:

- in the production of new tires and rubber products;

- as a dye in the manufacture of paint and varnish coatings;

- used as a sorbent instead of activated carbon;

- serves as a component of liquid fuel or is itself used as a solid fuel.

What is pyrolysis

Pyrolysis is the process of high-temperature decomposition of organic materials and inorganics in the absence of oxygen. The processing method is low-waste or completely waste-free. Allows you to create a cyclic recycling technology.

During pyrolysis, the processed materials do not burn completely. They break down into solid residues releasing pyrolysis gases. After complete processing, the output will be new products. Their composition, consistency and nature depend on the method used and the type of raw material.