Area of use

Pellet boilers have high technical properties. This explains their widespread use in various fields. Today, experts distinguish between two main areas of application for such heaters:

- Industrial enterprises, restaurants, shops and other institutions and buildings that require heating and hot water supply.

- Such boilers are very popular among owners of country houses. With their help, you can create a productive heating system, the maintenance of which does not require large costs.

Before installing a pellet boiler, you need to familiarize yourself with the different types of boilers and choose the best option for yourself.

Gas-coal-wood

The advantage of a gas-wood-coal boiler is that it does not depend on electricity. This allows you to create autonomous heating systems. Fuel for such a unit is available in any locality and, moreover, at a low price. The wood-coal-gas boiler from the manufacturers listed in the table below is easy to service and has an attractive design.

| Manufacturer and model | Characteristic |

| Outbreak KSTG-10 (Russia) | This company has been on the market since 2003. It is a dynamically developing and reliable manufacturer. Boiler type: single-circuit. The combustion chamber is open. Installation - floor. Heating area - 200 m². Power - 20 kW. Gas is natural. Type of solid fuel - firewood, coal. Operating temperatures - 95 ºС. Heat exchanger material is steel. Efficiency - 77%. Weight - 70 kg. |

| Outbreak KSTGV-12.5 (Russia) | This “coal-wood-gas” boiler model is energy-independent and stable when operating at reduced gas pressure. Due to the optimal design of the combustion chamber, the boiler has high efficiency. Built-in water heater that provides hot water. Includes gas pressure regulator. The boiler body is resistant to temperature changes. Type - double-circuit. The combustion chamber is open. Installation - floor. Heating area - 125 m². Power - 12.5 kW. Gas is natural. Type of solid fuel - firewood, coal. Boiler - built-in. Operating temperatures - 95 ºС. Heat exchanger material is steel. Efficiency - 83%. Automatic shutdown - no. Weight - 120 kg. |

| Raton KS-T-12.5 (Belarus) | The boilers are designed for heating individual residential buildings, buildings and structures equipped with continuous water heating systems with natural coolant circulation and an open expansion vessel. Type - single-circuit. The combustion chamber is open. Installation - floor. Heating area - 130 m². Power - 12.5 kW. Type of solid fuel - firewood, coal, peat. Display - no. Heat exchanger material is steel. Ignition is mechanical. Efficiency - 77%. Weight - 138 kg. The service life of boilers is at least 15 years. |

| Brestselmash KST 12.5 kW (Belarus) | Based on the type of fuel, boilers produced by Brestselmash OJSC are multi-fuel boilers designed for burning solid and gaseous fuels through conversion that does not require dismantling the boiler. Installation - floor. Heating area - 125 m². Power - 12.5 kW. Gas is natural. Type of solid fuel - firewood, coal, peat. Display - no. Operating temperatures - up to 95 ºС. Heat exchanger material is steel. Efficiency - 90%. Weight - 180 kg. Designed for heat supply and hot water supply of residential buildings and public utility buildings equipped with water heating systems with natural circulation, with operating water pressure up to 0.1 MPa (1.0 kgf/cm²) and maximum water temperature at the boiler outlet up to 95 C°. |

| Boiler PARTNЁR 24 (Russia) | The advantages of this company's products lie in its own innovative, unique design developments. The manufacturer provides guaranteed quality components, raw materials and materials. This is a stable, high-tech production facility. The combustion chamber is closed. Installation - floor. Power - 24 kW. Type of solid fuel - firewood, coal. Efficiency - 80%. Weight - 108 kg. Height - 79.5 cm. Width - 42 cm. |

Operating principle of automatic pellet boilers

When starting the boiler from a cold state, pellets are loaded into the screw fuel supply mechanism manually. After which the automatic control system of the unit starts, the burner lights up and the automatic supply of granules to the combustion area starts.

When the coolant temperature reaches the set value, the flow of pellets stops. When the temperature of the heating water decreases, the supply of pellets in the combustion chamber is restored, followed by automatic ignition of the burner.

Pellet supply

Fuel supply of pellets to the burner is carried out using a conveyor-type screw feeder. Usually it is divided into 2 parts: if the one located closer to the unit runs out of pellets, the second conveyor starts and fills the first with fuel.

The presence of fuel in the feeder is monitored using special photosensors. The fuel supply of pellet boilers is equipped with a pellet storage complex; the volume of the bunker will depend on the thermal power of the installation.

If the built-in pellet bunker is empty, the lower tank sensor will work and send a signal to the safety automatic system, which will turn off the boiler. Many modern pellet burning devices are equipped with an automatic start system.

Boilers can set different fuel supply rates in minutes, that is, the user sets the time for the pellets to reach the combustion level, the default value is no more than two minutes, which is enough for automatic ignition. There is also a vacuum fuel supply speed setting for automatic filling of the fuel hopper.

In the absence of such a system, the automatic intake is controlled by the boiler hose from the external fuel storage.

Ignition and combustion

The pellets are ignited in the same way as any solid fuel. The best option is to use special substances for ignition, although the pellets ignite well even without them. In the case of using liquid kindling, pour it over the granules, wait a little for the liquid to be absorbed, and then set it on fire.

In automatic ignition systems, it is performed by thermal electric heaters through which air is supplied. After the pellets burn well and the flame becomes stable, begin adjusting the air supply to increase the thermal power of the unit.

In cases where it is necessary to increase the duration of fuel combustion and use it more economically, it will be necessary to limit the oxygen supply. In order to increase the combustion rate, air, on the contrary, is added.

Ash removal

In the automated mode, the combustion of granules occurs on the grate of the burner device, the flame is uniform and yellow in color. Then the fuel in the combustion chamber will burn completely, black smoke will not come out of the chimney, and there will be very little ash residue.

Based on the consumer quality of the solid fuel used, ash is removed at different intervals. In this case, it is necessary to ensure that the ash level does not rise to the top of the burner.

Usually the ash is removed before loading the fuel. Modern pellet boilers have an automatic system for cleaning and unloading ash, which prevents the build-up and slagging of internal surfaces around the burner device.

List of the best models of pellet domestic boilers

Despite the great popularity of pellets, the choice of equipment is not so wide:

- Valdai 22M. Russia. This is a single-circuit pellet heating boiler. Power 22 kW is the maximum, 4 kW is the minimum. The equipment runs on peat and wood pellets and can be heated with wood. Raw material humidity up to 35%. When laying firewood, additional grates are installed. Ash content 90%, built-in remote access control unit, overheat protection. Bunker loading up to 160 kg. Consumption 6.3 kg/h. The heat exchanger is made of steel, the unit operates for up to 26 hours on one load. Price from $1960 (RUB 13,800).

- Cooper PRO. Teplodar. Unit with one circuit and automatic burner. Power 4-22 kW. Heating with sawdust is acceptable, suitable for houses with an area of 20 m2 or more. It is possible to reconfigure it for gas supply; the basic configuration includes a 6 kW heating element. The universal device also works on electricity - this is convenient for off-season periods. The automatic control panel minimizes user participation. At the first start, you need to set the operating modes, then the equipment maintains the specified parameters. Hopper capacity 120 kg, consumption up to 9 kg/h, operating period on one load up to 14 hours. Efficiency 95%. Price from $1,330 (94,000 rubles).

- Stropuva P20. The Lithuanian manufacturer offers pellet units without a screw for feeding raw materials and an auto-ignition system. To start the device, you need to turn on the gas burner; the energy carrier settles into the chamber under the influence of gravity. Power 20 kW, ash removal frequency - once every 4-5 weeks. Efficiency up to 90%, steel heat exchanger, price from $2,200 (RUB 160,000). The device has 4 built-in temperature sensors - this allows you to fine-tune modes and control the operation of the burner. There is a forced-air fan - it is more convenient to change the intensity of heating of the coolant. The relatively small volume of the bunker compartment (90 kg), and low fuel consumption within 4 kg/h are advantages. On one load the device works up to 23 hours.

A wide range of Korean factories and Belarusian manufacturers are on sale. Prices vary depending on automatic filling and the type of device - it all depends on the capabilities and needs of the user.

Gas-firewood

The advantage of universal gas-wood heating boilers is their autonomy: a smooth transition of the system to burning wood in the event of a lack of gas. Also, if desired, you can connect a “warm floor” structure, because the necessary connections and pipes are included with the boilers.

Such universal gas-wood boilers can be single-circuit or double-circuit, so connecting a boiler to heat water or heating water using a flow-through method is not difficult.

The disadvantages include the large dimensions of such units. Most often, they require a separate room for installation, and involve complicated maintenance. Typically, such boilers are produced only of the floor-standing type.

Combined gas-wood boilers for the home imply increased requirements. Norms and rules of operation are described in PPB, SNiP and SP.

A gas-wood combination boiler for a private home includes the following elements:

- Fire chamber. It is made of cast iron or steel. The boiler can have one firebox or two (more convenient). In the double version, wood is burned in the upper section, and a gas burner is installed in the lower section.

- Hot water supply and heating circuits. They are produced by companies specifically for heating, or for heating the production of hot water (double-circuit). Heating of hot water using a flow-through method.

A universal gas-wood heating boiler implies savings. You can verify this by looking at the following table.

| Type of fuel | Approximate cost of 1 kW of energy, $ | Approximate cost of 1 m³, $ | Approximate cost of heating a house with a volume of 450 m³, $ |

| Gas | 0,01 | 0,00047 | 0,2115 |

| Firewood | 0,02 | 0,0094 | 0,423 |

| Coal | 0,055 | 0,002585 | 1,16325 |

| Electricity | 0,03 | 0,00141 | 0,6345 |

| Diesel fuel | 0,04 | 0,00188 | 0,846 |

High-quality equipment using wood and gas is produced in Russia: “Zota MIX”, “Kupper PRO” (“Teplodar”), “Karakan” (“STEN”), “PARTNЁR” (“KOSTYOR”), “STS” (“Steel Solid Fuel Systems"). As well as foreign companies: Austria and Germany (“Wirbel”), the Finnish concern “Jaspi” and others.

It should be noted that in foreign analogues it is less common to notice shortcomings in the assembly and automation of the unit. They boast reliability and quality. However, the domestic manufacturer is constantly improving in accordance with the wishes of customers.

Prices for combined wood-gas heating boilers depend on the country of origin and the popularity of the brand. For example, the model (“BONTER”) will cost an average of 23 thousand rubles. Much will depend on the configuration, power and other indicators. But “Jaspi” will cost 130 thousand rubles. The run-up is large, however, unlike the Finnish one, where everything is regulated automatically, in the Russian analogue you will have to carry out all the boiler settings yourself.

Popular models

The most famous suppliers of solid fuel units are the following brands:

- Lithuanian Stopuva;

- German Buderus;

- Czech Wattek;

- Belgian ACV;

- Austrian Wirbel;

- Russian NMK, Zota and TeploGarant LLC.

Among the models on the market from various companies, there are several popular devices.

Stropuva Mini S8

A power-independent unit serving an area of up to 80 square meters. m. Works with three types of fuel and is distinguished by its small size. Equipped with a convenient vertical firebox door.

The special design of the ash pan allows you to reduce the need to clean it to twice a month. One bookmark is enough for daily heating; the pellets burn out in 48 hours.

Advantages:

- high efficiency;

- quality of construction;

- safety;

- presence of a thermometer.

Flaws:

- heavy weight;

- The rough surface of the door makes it difficult to clean.

| Roman Oborin: | Igor Falaev: |

| “Economical and compact unit, burns for a long time. It consumes little fuel, heats the house well, and does not produce soot. The only negative is that it’s a bit heavy.” | “A small, convenient barrel, the device is immediately ready for use, you don’t need to assemble or screw anything in. The door handles are of high quality and reliable, they do not open spontaneously. It takes a long time to heat, it can burn for up to 20 hours.” |

Teplodar Cooper Expert-15

Russian model with the ability to install a burner.

In the upper half of the housing there is a fitting for air outlet. Compatible with firewood, coal and briquettes. Three air entry zones and top combustion ensure long-term heat maintenance. At the bottom there is a water reservoir that prevents excessive heating of the floor. A steel plate protects the door from heat. You can additionally attach a draft regulator.

Advantages:

- possibility of installing a pellet or gas burner;

- convenient door placed at an angle;

- continuous burning for 24 hours.

Flaws:

- complexity of installation;

- small firebox.

| Oleg Egorin: | Semyon Ivin: |

| “It’s a convenient boiler, you can buy an additional burner, it works for a long time and even after switching off the house remains warm.” | “It’s not a bad unit, it’s enough for almost a day of heating, but it consumes a lot of fuel. Convenient door design for stowage." |

ZOTA Topol-16VK

A device with a water circuit at an affordable price. The triangular shape of the pipe avoids blockages and increases the service life of the device. To refuel the boiler, you can use firewood, coal and pellets.

The model is distinguished by a spacious firebox and the possibility of top and side fuel storage.

Advantages:

- low price;

- ease of use and cleaning;

- efficiency.

Flaws:

low efficiency.

| Vladimir Kharitonov: | Alexey Zaitsev: |

| “A high-quality device at an affordable price for its segment. Works flawlessly." | “The device is pleasant to use, cleans without problems, you can load different types of fuel, both briquette and regular.” |

Teplodar Cooper Expert-22

The device is small in size, capable of operating in 4 modes: fast heating, classic, medium and maximum.

Combustion from top to bottom ensures uniform and longer combustion of the material and good heat transfer. The upper cleaning hatch is protected by a steel screen that prevents burning.

Advantages:

- two hatches for cleaning;

- inclined door for top loading;

- top burning function.

| Evgeny Zherdev: | Ivan Alaev: |

| “Sophisticated heating adjustment, you can adjust the burning duration from 30 minutes to a day. Easy to clean, special cleaning accessories included.” | “A high-quality model, the design allows you to connect heating pipes from either side. The device comes with a heating element and a thermomanometer.” |

Stropuva S30

Solid fuel boiler for placement in commercial and residential premises. Equally effective for year-round and seasonal use. It is characterized by high efficiency, is independent of power supply and is compatible with a variety of fuel materials.

The device has compact dimensions and is environmentally friendly. The duration of firewood burning is up to 30 hours, briquettes can smolder for up to 2 days.

Advantages:

- safety of use;

- high efficiency;

- durability;

- build quality.

Flaws:

high price.

Firewood-coal-pellets-gas

Currently, these units are offered by: the manufacturer of the universal boiler “Cooper” “gas-wood-coal-pellets”, and others.

A large selection (pellets, firewood, coal, gas) gives such a boiler a great advantage. In the absence of one type of fuel, you can always switch to another type and stay warm.

| Manufacturer and model | Characteristic |

| Teplodar Kupper OK15 (Russia) | Boiler type: single-circuit. The combustion chamber is closed. Installation - floor. Heating area - 150 m². Power - 15 kW. Gas is natural. Type of solid fuel - firewood, pellets, coal. Display - no. Efficiency - 78%. The diameter of the chimney pipe is 150 mm. Weight - 98 kg. Double-turn heat reservoir formed by a removable visor, which ensures complete flame extinguishing in the tube sheet. In addition to the standard water jacket, the firebox has a heat exchanger. Power adjustment from 30 to 100% (a combustion regulator can be installed on boilers). A spacious firebox that allows you to load firewood 400 mm long horizontally and 500 mm vertically, or two buckets of coal. The presence of a tubular electric heater allows you to maintain heating systems after the end of the fuel combustion process. |

| Raton KS-TG-35U (Belarus) | Boiler type: single-circuit. The combustion chamber is open. Installation - floor. Heating area - 340 m². Power - 35 kW. Gas is natural. Type of solid fuel - firewood, pellets, coal, peat. Display - no. Ignition is electric. Operating temperatures - 95 ºС. Heat exchanger material is steel. Efficiency - 77%. The boiler is intended for heating residential buildings that are equipped with continuous heating systems with natural or forced circulation of coolant. |

| Teplodar Uyut-10 (Russia) | “Uyut” are budget heating boilers for rooms up to 100 square meters. m. The firebox is in a horizontal position, which allows you to heat the boiler with wood up to 0.5 m long. The high efficiency of the boiler is ensured by the original design of the water circuit: stagnant zones are excluded, and the heat-removing surface area is increased to 1.1 sq.m. Possibility of installing a gas or pellet burner. Boiler type: single-circuit. The combustion chamber is closed. Installation - floor. Heating area - 100 m². Power - 10 kW. Gas is natural. Type of solid fuel - firewood, pellets, coal. Display - no. Ignition is mechanical. Efficiency - 72%. The diameter of the chimney pipe is 115 mm. Weight - 67 kg. |

Requirements for installation and operation of the boiler

Heating equipment operating on compressed wood pellets requires certain rules for installation and operation.

Installation:

- Installation must be carried out on a flat and hard surface.

- The boiler room must be heated and equipped with ventilation.

- Installation of equipment must be carried out in accordance with all standards and requirements of the manufacturer and fire safety.

- The boiler room must be supplied with oxygen for the unit to operate;

Exploitation:

- It is necessary to select the correct type of wood pellets.

- Low or high room temperatures may be due to incorrect temperature settings of the equipment.

- Based on climatic conditions, it is necessary to select the right boiler for each individual region of the country. This way you will ensure maximum efficiency of your heating equipment;

Quick tips:

- When switching to this type of heating, take into account the fuel delivery conditions.

- Do not give preference to unknown brands and do not skimp on cheap models, this may affect the quality.

- Correctly calculate the volume of the bunker.

- Do not use pellets with high ash content.

Solid fuel

Combinations may include the following types of solid fuel:

- pellets;

- wood chips;

- firewood.

Solid fuel boiler using wood or wood chips.

You can find out what fuel is used by a particular model from the passport.

Sectional design of a solid fuel boiler (wood pellets)

Types and design of heating systems with natural circulation

Each heating option without a pump consists of the following main elements:

A heat source, which can be represented in the form of a boiler with various types of fuel; Expansion tank used to stabilize the pressure in the system; Pipelines for coolant circulation; Radiators that heat living spaces.

Depending on the type of coolant, the natural circulation system is usually divided into the following two types:

Hot water preparation; Steam heating.

Let's take a closer look at all the features of these two types of household heating systems.

Electric boiler "Sputnik-6"

Yes, yes, although electricity is not cheap these days, sometimes there is no other choice and electric boilers are used for small rooms. Or... such a boiler can serve as an auxiliary boiler to the main one, say, for heated floors in the off-season.

Electric boiler "Sputnik-6"

Compact, reliable, easy to maintain. It is possible to switch to higher power by simply replacing the heating element, which, by the way, is made of stainless steel. The boiler design is designed for pressure up to 6 atm. and allows the use of non-freezing coolants.

Of course, you noticed that this is a review article, and it does not aim to provide calculations of boiler power for a particular room, their efficiency and economy depending on various types of fuel.

Fortunately, correct calculations are a job for specialists, since many factors need to be taken into account, and they are largely individual.

But you can always seek advice and help in choosing, by the way, not only regarding heating boilers, but also fireplaces, bath stoves and other things that can warm. The Teplodar website has very responsive support, I was convinced of this personally.

Automation

- compliance with the temperature regime in the system;

- control of pumps in the main and auxiliary (admixture circuit) circuits;

- maintaining the set temperature of hot water supply;

- control of coolant flows using a three-way valve.

If there is an automation unit, a person only needs to set the required temperature and load fuel, then the combustion process is controlled automatically according to the specified settings by controlling the supply of oxygen to the firebox. If heating is carried out using a pellet unit, then the fuel is loaded automatically.

Operating principle of three-way valve

If there is a three-way valve, the system works on the principle of mixing hot water from the boiler into the main flow when the temperature drops below the set one. This principle allows you to heat only the required amount of water. It can be supplied either directly from the boiler or from a buffer tank. At the same time, it can be heated by alternative sources, for example, a solar collector.

Device

A universal combi boiler involves a two-chamber design. One uses gaseous or liquid fuel, the other uses solid fuel. A heating element can also be built-in. Such devices can operate not only in one, but also in two heating circuits. This means that combination boilers can not only heat rooms, but also heat water. And thanks to the presence of an inflatable burner in the design, high efficiency is ensured.

Features of heating a house using a combination boiler

Principle of operation

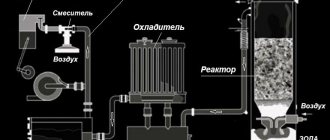

The principle of operation of a solid fuel boiler occurs according to the following cycle of supply and combustion of pressed wood pellets:

- From the hopper, an external screw conveyor delivers pellets to the preliminary combustion chamber.

- Depending on the model of the unit, fuel from the pre-furnace reaches the grate or burner nozzle through an internal auger or free fall. With the help of auto-ignition, ignition occurs.

- The primary air flow is directed under the grate, fuel is purged and the grate (retort) is cooled.

- The secondary air flow is directed to the burner, into the combustion chamber, through air channels in the boiler body or directly in the burner itself.

- In economy class units, ash spills into the ash pan through the gaps between the grates. More expensive models, with advanced functions, are equipped with movable (tipping) grates for removing ash from the firebox.

- In cheap series boilers, the ash pan is cleaned manually. To do this, you need to stop the operation of the device after filling the ash collection container. In automated analogues, waste combustion products are removed using automation. Using an auger, the ash moves from the container along the ash channel to the external ash pan. As it progresses, it is compressed, which makes it possible to produce an external ash pan with minimal dimensions.

Important: for boilers without automation: when using good quality wood pellets, the ash pan is cleaned every 6 - 7 days; when burning agropellets, cleaning must be done every 3 days; using coal requires removing ash daily.

Gas pellets

A pellet gas boiler is equipment that easily changes its operation from heating with one type of fuel to heating with another. This usually happens in about 15 minutes.

Here it is also possible to replace the burner in case of conversion. Many models have a tubular electric heater.

It is allowed to connect a liquefied gas cylinder.

The efficiency of a pellet gas boiler reaches 90%.

The unit has several combustion chambers. The kit includes two burners, as well as many control and shut-off devices. Has a high degree of security and automation. But despite this, a gas-pellet boiler, like any combined gas boiler, requires compliance with the standards of PPB, SNiP (some excerpts are described at the beginning of the article).

Don't forget to clean the boiler from time to time. During the maintenance process, it is necessary to remove accumulated wood dust and soot from the electric drive and moving elements.

What do you need to work with pellets?

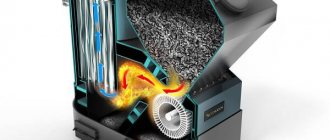

To convert the boiler to fuel pellets, you need to install a pellet burner, which is connected to the fuel hopper. After all operations, the boiler operates as follows:

- granules are supplied to the burner via a conveyor from the fuel bunker;

- electric ignition occurs immediately via a piezoelectric element;

- a built-in fan is activated in the burner, which increases the pressure, and the pellets burn at a high temperature, raised artificially.

Typically, gas-pellet boilers are made of cast iron, and due to their large dimensions and weight, the structure is placed on a concrete base.

What do you need to work on gas?

Pellet boilers with a gas burner are connected, first of all, to cylinders and gas holders. Such units are gaining popularity in the construction of houses and sites where natural gas is planned to be installed soon.

To connect a gas burner, you first need to close the unused firebox with an airtight hatch. Then you need to install a burner device in a place specially designated for gas equipment. After everything, set the switch to gas consumption. All. The modification took no more than 15 minutes.

Combination boiler Wirbel ECO-CK 20

Advantages of pellet equipment

Today, the advantages of boilers running on pellets are significant, which makes them in demand. One of the most important advantages is high efficiency, it reaches 80-97%. It is comparable to the most recognized heating equipment - gas boilers.

It is important that efficiency is ensured by cheap fuel - pellets are made from wood waste (shavings, pressed sawdust of various hardwoods or softwoods), thanks to which their cost is second only to gas. Moderate fuel prices coupled with high efficiency ensure the equipment is economical

In Russia, this is the cheapest type of heating after gas; in a number of post-Soviet countries (for example, Ukraine) it is even the most affordable

Moderate fuel prices coupled with high efficiency ensure the equipment is economical. In Russia, this is the cheapest type of heating after gas; in a number of post-Soviet countries (for example, Ukraine) it is even the most affordable.

For example, using a pellet boiler will cost 1.5 times less than similar equipment running on coal. And heating a building with an electric boiler is 2-3 times more expensive.

A pellet boiler differs from any other solid fuel boiler only in the presence of a special burner

An important advantage is autonomy in operation - it is achieved by a high level of automation. For example, the boiler itself is capable of supplying the required amount of pellets into the firebox, controlling the temperature regime set by the owner, and stopping and starting operation. Often the equipment is even able to clean itself of ash.

Autonomy ranges from 2-15 days, and if the automated boiler is provided with an uninterrupted supply of fuel, it can operate without human intervention throughout the cold season. Also, these units are independent of the presence of centralized heating and main gas pipelines.

We must not forget about environmental friendliness - pellets are compressed sawdust, they do not contain glue or other binders. This guarantees the absence of harmful substances (for example, sulfur) in the granules; their ash content is tens of times lower than that of firewood, as is the emission of carbon dioxide.

Another important advantage is safety. To ensure this, a multi-level fire protection system is used, which includes control sensors, electronics that interrupt the supply of pellets, automatic shutdown, a number of boilers are equipped with alarm systems

You will also be pleased with the cheap service - this is a guaranteed fact, explained by the fact that there is little work and any person who does not have special skills can cope with them

An important advantage is the simple installation - the boiler owner does not need to obtain any permission or draw up a project. Current rules allow the installation of such equipment in utility rooms, basements, corridors, and kitchens. In addition, you can do the piping of a pellet boiler yourself.

Universal solution

Suburban construction is ongoing, and as a result, the search for optimal solutions for heating private houses in winter is becoming increasingly urgent. Moreover, traditional heating devices become less efficient due to various circumstances:

- the need for constant attention to the process, adding fuel;

- unreliability of one source: failures in electricity supply, gas supply, etc.;

- high cost of fuel: gas, electricity or other options;

- difficulty of maintenance;

- other reasons.

Therefore, at some point, manufacturers decided to combine technologies to get a more advanced solution.

Combination boiler using wood or gas as fuel

Combination boilers are devices whose functionality is designed for different types of fuel. Moreover, they can be used in homes without restrictions, which is very important for many regions of our country. At the same time, you don’t have to rely on only one type of fuel, which can fail at the most inopportune moment, since there is always an alternative option. Such devices can use different types of fuel:

- gas;

Combination boiler using either gas or pellets

- electricity;

Combination boiler using either wood or pellets

- hard;

Model of a boiler using wood or gas as fuel

- liquid fuel.