In a heating system, a very important element is the heating expansion tank. Such a device serves to accept excess coolant at the moment when it expands, thus preventing rupture of the pipeline and taps.

Heating expansion tank

The principle of operation of an expansion tank for heating is as follows: when the temperature of the coolant rises by 10 degrees, its volume increases by about 0.3%. Since the liquid is not burned, excess pressure appears that needs to be compensated. This is precisely why an expansion tank is installed.

Types of expansion tanks

Different types of expansion tanks are used in different heating systems. Previously, systems without circulation pumps used an open expansion tank for heating. But such tanks had many disadvantages, so nowadays they are used very rarely. Due to the fact that air gets into such an expansion tank for heating, corrosion appears, and the liquid evaporates faster and must be constantly replenished. Such a tank must be placed at the highest point of the heating system, and this is not always easy to implement.

Open expansion tank for heating

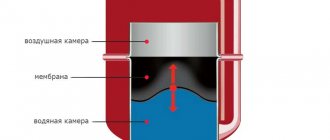

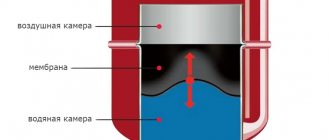

In such heating systems, where the coolant circulates using a pump, a closed expansion tank for heating is installed; the calculation here is that it is a sealed container that has an elastic membrane inside. A membrane (balloon or diaphragm) divides the tank into two parts. Air or inert gas under pressure is pumped into one part, and the other part is intended for excess coolant. The membrane inside the tank is elastic, so when the coolant enters there, the volume of the air chamber becomes smaller, the pressure in it increases, thus compensating for the high pressure in the heating system. When cooling, the reverse process occurs.

Construction of closed expansion tanks

A closed expansion tank for heating, a flat tank can be flanged (have a replaceable membrane) or with a non-replaceable membrane. The second type is in quite high demand due to its relatively low cost. But flanged expansion tanks are better in many ways - the pressure here can be higher, and if the membrane ruptures, it can be replaced.

The flanged expansion tank of the heating system can be either vertical or horizontal.

Here, the liquid, when it enters the tank, has no contact with the metal surface, since it is located inside the membrane. If the membrane is damaged, it can be replaced through the flange.

Vertical and horizontal flanged tanks

Tanks that do not have a replaceable membrane are fixed rigidly around the entire perimeter. From the very beginning, the diaphragm is pressed against the inner surface, since the volume of the expansion tank for heating is completely filled with gas. After this, the pressure in the heating expansion tank increases, and the liquid goes inside. When the system starts up, the pressure can rise sharply, so this is when the membrane can be damaged.

Diaphragm expansion tank

Installation and configuration of the hydraulic accumulator

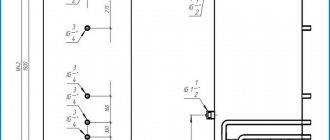

The tank is installed in the water supply system together with a pressure switch, dry running (when using submersible electric pumps) and a pressure gauge. In most cases, to connect these devices, a five-inlet fitting with bends of standard diameters and threads is used to connect: a pressure pipeline from an electric pump, an in-house water main, a pressure switch, a pressure gauge and a hydraulic accumulator. When installing the hydraulic accumulator piping, perform the following operations:

- A coarse sand filter is placed in the pipeline coming from the electric pump. Many professionals and craftsmen from specialized companies install a fine cleaning device instead of or after the sand filter, citing the fact that with this arrangement the membrane of the pressure switch, which is the main executive element in the automatic control system, will not be contaminated. However, such a connection to the water supply system leads to the fact that the electric pump is forced to work on a fine filter with low throughput - this will require the application of more power and can lead to premature failure of the unit due to overload (overheating).

- Next, a five-inlet fitting is placed in the line behind the coarse filter. A pressure switch and pressure gauge are screwed to it. For ease of use in the event of failure, for example, of a hydraulic accumulator or any automation elements, shut-off valves are installed in the system. One of them is installed at the outlet of the five-piece intended for connection to the hydraulic accumulator, the second is installed at the inlet of the intra-house pipeline.

Rice. 8 Scheme of piping a hydraulic accumulator with a surface pump

- Sometimes it is necessary to drain the water from the hydraulic accumulator, in this case the flexible line is unscrewed from the shut-off ball valve and the reservoir is emptied; they do the same with the internal plumbing system, draining water through an additional valve in the line or through the entire pipeline into the well.

- For normal operation of the submersible electric pump, it is necessary to install a dry-running relay. To do this, a tee with a side outlet is placed in front of the five-inlet fitting, into which the relay is screwed.

- Many people install a ball valve in the pressure pipeline from the electric pump at the inlet of the five-inlet distributor. This action is not entirely clear from a logical point of view (why a tap is needed) - usually a check valve is installed in the water main at the outlet of a submersible electric pump or the suction pressure pipeline of a surface pumping station, which prevents water from flowing back into the well through the electric pump or pipe. And if you need to drain water from the external underground pipeline back into the well, this can be done by opening a check valve (additional valve) - due to the slope of the laid pipeline to the source, it will flow away by gravity. In addition, if the ball valve is accidentally closed, clogged, or inoperable, the pump will pump water into a closed system without automation and will fail.

- A hydraulic accumulator and an intra-house pipeline are connected to the shut-off ball valves using a flexible connection.

- The assembled unit, together with the five-piece and automation elements, is usually attached to the wall of the room in which the surface electric pump and hydraulic accumulator are located. If this is not possible for some reason, the five-piece is screwed to the inlet pipe of the hydraulic accumulator directly or through a transition section of the pipe; proceed in the same way when connecting the unit to an electric pump.

Related article:

Water supply pumping stations for a private home. Perhaps, reading what an expansion tank for water supply is, it will be interesting to know what it is, what elements it consists of and how a pumping station for water supply works, as well as characteristics, how to choose, manufacturers and prices.

Rice. 9 Expansion tank for water supply with piping in a caisson well

Setting up the hydraulic accumulator

Any hydraulic accumulator has a fitting on the back of the housing designed to pump air with a hand pump at a certain pressure. This is done to ensure that the elastic balloon functions optimally without critical changes in its physical condition.

That is, if the air pressure inside the hydraulic tank between the walls of the elastic cylinder and the metal body is higher than the minimum in the system, the membrane shell will shrink, lose its shape and quickly fail. Therefore, the air pressure inside the accumulator is set so that it never exceeds the minimum in the system; for approximate calculations, a 10% decrease is taken. The second method of calculating the required pressure inside the hydraulic accumulator is to multiply the lower threshold of the relay operation by 0.9, for example, with a limit value in the relay of 1.7 bar, after multiplying by 0.9 we obtain the required pressure inside the hydraulic tank of 1.53 bar.

There are two ways to adjust the required pressure difference in the accumulator and the system: in the first case, change the lower threshold of the relay response, in the second, change the air pressure in the accumulator tank membrane.

For example, consider the typical values of the hydraulic relay thresholds of 1.4 - 2.8 bar and the pressure inside the accumulator of 1.5 bar. In the first case, we set the relay to turn off when the system pressure is about 1.7 bar. If it is necessary to adjust the expansion tank for water supply with a change in internal pressure, proceed as follows:

- Open the shut-off valve or unscrew the flexible line, draining the water from the accumulator.

- Remove the protective cover from the back, release the nipple and insert a car pressure gauge into it, measuring the pressure.

- If it needs to be reduced, simply bleed the air until the required pressure gauge readings are obtained.

- To increase the pressure inside the hydraulic tank, connect a regular car pump to the nipple and pump air to the required value, periodically checking the readings with a pressure gauge.

Selection of expansion tank

Choosing an expansion tank for heating is a responsible matter. In this case, you should definitely pay attention not only to its type and size, but also to the membrane - the following indicators are important: resistance to the diffusion process, operating temperature range, durability, compliance with sanitary requirements.

Today there is a wide range of expansion tanks for heating systems on the market.

In addition, it is necessary to determine the ratio of the boundaries of the pressure range, which is extremely permissible. Before purchasing a tank, be sure to check whether it meets existing quality and safety standards.

Calculation of tank volume

First of all, let’s determine the relationship between the required volume and the parameters that influence it. When making calculations, it must be taken into account that the larger the capacity of the heating system and the higher the maximum temperature of the coolant in it, the larger the tank should be. The higher the permissible pressure in the heating expansion tank, the lower it can be. Of course, the calculation method is quite complex, so it is better to consult a specialist. After all, a mistake in choosing an expansion tank can cause frequent operation of the safety valve or other troubles.

The volume is calculated using a special formula. Here the main quantity is the total volume of coolant that is present in the heating system. This value is calculated taking into account the power of the boiler, the number and types of heating devices. Approximate values: radiator – 10.5 l/kW, floor heating system – 17 l/kW, convector – 7 l/kW.

To make a more accurate calculation of a device such as a vacuum expander for heating, the formula is used: Tank volume = (Volume of water in the heating system * Expansion coefficient of the coolant) / Efficiency of the expansion tank. The expansion coefficient for water is 4% when it is heated to 95 degrees. To determine the efficiency of the tank, another formula is used: Tank efficiency = (Highest pressure in the system - Initial pressure in the air chamber) / (Highest pressure in the system + 1).

Expansion tank useful volume coefficients

Thus, the vacuum expansion heating tank is selected taking into account the strength and temperature characteristics, which should not exceed the permissible values at the connection point. The volume of the tank can either be equal to or greater than the result obtained as a result of the calculations.

Place of the tank in the heating system

Open system

In open heating circuits, the expansion tank should be installed at the highest point (possibly in the attic, under the roof of the house), not far from the boiler.

This arrangement promotes good circulation and removal of air accumulated in the pipes.

The overflow pipe of the unit is connected to the sewer system so that the liquid drains automatically.

Outside the heated room, the container must be insulated. This can be done with ordinary glass wool or polystyrene foam.

Closed system

A closed tank can be installed almost anywhere in the system. Traditionally, it is installed in the return line in front of the boiler.

If you place the tank after the circulation pump so that water is “pressed” into it under pressure, this will create excess pressure on the diaphragm. It is better for the pump to “suck” liquid from the expander. As the coolant moves, you should get: an expander, a pump, a boiler.

Any stove, be it Russian, Swedish or Dutch, is capable of heating only a small room. If the area of the house is large, then stove heating with a water circuit is used. We will consider the system elements and installation rules in the article.

Read about how to make a heat exchanger with your own hands here.

To install a chimney, a coaxial chimney for a gas boiler is increasingly being used. How is this chimney different from a regular one? Here https://microklimat.pro/otopitelnoe-oborudovanie/kotly/koaksialnyj-dymoxod-dlya-gazovogo-kotla.html you will learn about the features of this system, and you can also read the installation instructions.

Installation of expansion tank

Installation of the expansion tank of the heating system is done in accordance with the project and instructions. Your best option would be to have a specialist do this. If this is not possible, then at least consult with him. The installation of an expansion tank for heating, if it is an open type, is carried out at the highest point of the heating system. A closed tank can be placed almost anywhere, but not directly after the pump.

Closed heating system

One of the options for installing an expansion tank in the heating system

It is necessary to pay special attention to such an issue as fastening the heating expansion tank, since the mass of the tank, which is filled with water, increases significantly. Another important point is the possibility and convenience of servicing the tank and free access to it.

Advantages of a closed heating system

- The first advantage of a closed heating system is that the tank can be installed wherever it is convenient for you, but in an open one, only in the attic or at some other high point in the system. And due to the tightness, the coolant practically does not evaporate.

- The coolant is always saturated with air in an open heating system, which leads to corrosion in heating pipes and radiators. In a closed environment, as you understand, this cannot happen.

- In a closed system, there are fewer losses in the tank than in an open system, which heats up very quickly and has increased sensitivity. Plus, the temperature difference in a closed system is smaller, which allows you to use heating equipment longer.

- The closed system is suitable for a wide variety of radiators, convectors and air curtains; you can connect a “warm floor” system. Plus, you can add an indirect heating boiler for domestic hot water to a closed system.