Even a quick glance at a standard heating scheme gives the average person an idea of how intricate and labor-intensive the process of implementing a heating system in a house is. Any heating circuit is a complex set of interconnected components, which are selected on the basis of detailed hydraulic and thermal calculations. An important part of the circuit is the expansion membrane tank of the heating system, which ensures reliable operation and integrity of all heating devices.

Design and functions of the expansion membrane tank of the heating system

The basic membrane heating tank has a rather complex design. If the owner can make a regular open-type expansion tank himself using a welding machine, an angle grinder and sheet metal, then an expansion membrane tank for heating is often purchased ready-made in a store. This can be an expansion tank for heating Reflex, characterized by decent consumer characteristics, or an expansion tank from another trusted manufacturer, the operating parameters of which satisfy the requirements of the circuit. You can read about choosing a heating circuit and installing heating in a private house here.

Traditionally, the membrane expansion tank of the heating system, the price of which is about one hundred dollars for a model with a capacity of 80 liters, has the following design:

- steel body;

- a membrane dividing the expanzomate into two parts;

- fitting (used for pumping air under pressure);

- flange (used to connect the coolant supply line to the hydrophore body).

With the proper level of operation and correct selection, the heating expansion tank will serve in the system for quite a long period of time. However, in the event of a breakdown, membrane expansion tanks for heating systems can only be repaired if they are equipped with a replaceable membrane. Thus, in terms of maintainability, they are superior to an open expansion tank for heating, because in the event of a leak, it can be quickly sealed and restored.

However, in terms of functionality, an expansion tank for open-type heating, which you can buy in a specialized store, is inferior to a membrane expansion tank. In the circuit, a membrane heating tank, the operating principle of which is to compensate for the thermal expansion of water, performs the following functions:

- protection of the circuit from water hammer;

- preventing leaks of radiators, pipelines and connections as a result of pressure surges;

- ensuring the durability of heating devices;

- regulation of coolant pressure in the system;

- air release;

- promoting uninterrupted and reliable operation of the boiler.

Expanzomat for heating or switching to a closed heating system - Do-it-yourself home heating

A heating system with natural circulation, or, otherwise, gravitational heating, always has, by design, an open expansion tank, into which air escapes from the pipelines when they are filled with water and the thermal expansion of the water is compensated.

But the openness of the tank, during heating operation, has disadvantages in the form of evaporating water (coolant) and saturation of the coolant with oxygen from the air. Evaporation of water from the tank leads to the need to frequently add water to the system, and saturation of water with oxygen leads to oxidation of the metal surfaces that make up the heating system (pipes, radiators, heat exchanger), which reduces the service life of the system as a whole.

The way out of this situation is a simple conversion of open heating into a closed system. The very principle of natural circulation will remain, that is, the coolant will circulate due to the physical properties of heated and cooled water, but only this process will take place through a closed pipeline with excess pressure.

This modernization is very good to carry out in conjunction with the installation of a circulation pump, which will give all the advantages of modern heating on an old system.

Conversion to a closed heating system

Conversion to a closed system involves dismantling the open expansion tank, installing a safety group, as well as an expansion chamber for heating. Before starting work, you need to select an expanzomat for heating of the required volume, which is required for efficient heating operation, having correctly calculated the volumes of all elements (pipes, radiators and heat generator).

Expanzomat for heating

The safety group kit includes: a pressure gauge, a safety valve and an automatic air vent, but it is quite expensive and, to reduce costs, this group can be assembled from separate units.

Security group assembled

Let's look at each of them:

1. Safety valve. Serves to protect sealed containers, including heating systems, from exceeding the permissible pressure.

Safety valve

They are produced with different factory calibration limits, which allows them to be used in different conditions.

This is also interesting: How to choose heating pipes

For work in heating systems, “explosives” are usually used, with a limit of 3.5 bar, but when choosing a valve you need to pay attention to the recommendations of the boiler manufacturer. Many manufacturers of steel boilers do not recommend (even prohibit) the use of steel heat generators at hydraulic pressures above 1.5 bar.

Therefore, if a steel boiler is selected for heating, then a safety valve should be selected with an operating limit of 1.5 bar.

2. Pressure gauge. Serves to indicate liquid or gas pressure. Since heating operates with excess pressure, its value is monitored using a pressure gauge.

Pressure gauge

3. Automatic air vent. This device is used to automatically remove air from a sealed container or pipelines.

Automatic air vent

We have dedicated a separate article on how to connect an expansion chamber for heating. Read here.

Save

Save

Save

Save

Save

practikaotoplenia.ru

Membrane type

When choosing a membrane heating tank in a hardware store, instructions for which are provided by the manufacturer at the time of purchase, the buyer should pay attention to the membrane. This element of the expansion tank is the main functional part of the tank and can be made of various types of rubber. High-quality membranes are made of elastic and durable rubber, which is not subject to high loads and temperature changes.

The type of membrane integrated in the tank matters.

Currently, manufacturers equip expansion chambers with diaphragm and balloon type membranes. The first type of membranes is used in small-volume tanks. The design of the diaphragm membrane does not allow the device to be repaired in the event of a breakdown, so tanks with balloon membranes are often used in circuits, which protect the walls of the buffer vessel from contact with the coolant. They are reliable, efficient, wear-resistant, and, importantly, have a high level of maintainability.

Step-by-step instruction. Different connection methods

Expanzomat is another name for an expansion membrane tank. It makes more sense if a specialist does the installation. If you decide to install it yourself, then in unclear moments, contact him and get advice. The tank can be installed both on the supply side of the line and on the return side.

Installation sequence and features:

- location of the expansion tank in space. In principle, as already mentioned, the tank can be positioned in any way you like. But from a rational point of view, the air chamber should be located at the top so as not to be affected by gravity. This will increase the already significant impact on the membrane from the coolant and air. Replacement or repair will be required after a shorter period of time than specified in the warranty;

- On the installed diagram of the heating system, select a place free from turbulence. This is usually the section of pipe in front of the recirculation pump. This is the best option;

- attach the tank to the wall and connect it to the system with a flexible hose.

It doesn’t matter where you place the tank: for supply or return, it is important that it is located at a minimum distance from the suction side of the centrifugal pump.

Application of expanzomats

Proper installation of a membrane expansion tank in a heating system allows you to solve a number of critical functional problems. The expansomat helps protect the system from overheating and heating devices from accidents. Therefore, a heating buffer tank of the appropriate size has a wide range of applications.

According to the heating schemes, the buffer tank for the heating system can be used in the following circuits:

- heat pump systems;

- circuits with solar collectors;

- autonomous heating systems;

- centralized heating systems;

- closed contours.

Such versatility in the use of devices is possible due to the wide variety of expanzomats supplied by manufacturers involved in the development of hydrophores of various types. Depending on the hydrophore model, the purpose of the expansion tank in the heating system may be different. In order for the connection of the expansion tank to the heating system to meet the expectations placed on the device, the owner needs to choose the right expansion tank.

Buffer tanks for solid fuel boilers - purpose and characteristics

If your house is heated using a boiler, and not from a central heating system, then the question arises: what to do if the boiler turns off? Solid fuel boilers operate as long as the fuel is burning, gas and electric, respectively, as long as gas is supplied and there are no power outages. But what if the power goes out?

The design of the buffer container is very similar to a thermos, a giant thermos. Its volume can be different and varies on average from 500 to 1000 liters.

The operating principle is based on increased capacity of the working fluid. When connecting a buffer tank, the amount of liquid circulating through the system increases several times. At the same time, when heated as much as possible by the boiler, the liquid in the buffer tank retains its temperature for a long time and releases it gradually, which makes it possible to maintain heat in the pipes even after the boiler is turned off.

Let's give a simple example. Let's assume that the volume of water circulating through the pipes is about 100 liters. An additional storage buffer tank with a volume of 500 liters is installed. Total 600 liters. Those. it turns out 6 times more coolant, which, accordingly, will cool 6 times longer and the radiators will cool down not 2-3 hours after the boiler is turned off, but after 14-18 hours! Actually, this is the main benefit of installing a buffer tank for heating.

Why is it profitable to buy buffer tanks for boilers in the SantekhMir online store?

- The SantekhMir store is an official dealer of leading companies specializing in the field of plumbing engineering.

- We provide permanent discounts for all clients of our online store.

- Fast and reliable delivery to all regions of Russia.

- Prompt order processing.

- Experienced consultants with many years of experience will answer all your questions and help you choose the best option based on the optimal price-quality ratio.

- You can pay for your purchase online without leaving your home.

- Our store offers only high-quality official products from leading manufacturers!

Expansion tank calculation

First you need to calculate the optimal volume of the expansion tank for the heating system, on the basis of which the choice of a specific expansion tank model will be made. It is better to entrust this process to heating specialists who will thoroughly approach the calculations and give clear recommendations regarding the choice of a specific model of the expansion tank.

To carry out the calculation, specialists will use the following values:

- total volume of water in the circuit;

- nominal hydrostatic pressure;

- specific density of liquid;

- the amount of thermal expansion;

- performance characteristics of the valve designed to bleed air from the system.

The calculated values are substituted into formulas that are used to determine the volume and other operating characteristics of the expanzomat.

There are also more primitive schemes for calculating the volume of the tank. They can be used by private property owners with simple contours. The calculation is based on using the total amount of coolant in the system. Ten percent is calculated from this amount. The result obtained is an approximate value for selecting a tank.

For example, if 800 liters of water are used in all the pipes and radiators of the house, then the approximate capacity of the tank should be 80 liters, that is, a tenth of the total coolant volume.

How to install an expansion tank (expanzomat) for heating - Do-it-yourself home heating

When installing a heating system operating under pressure (closed system), it is necessary to install an expansion tank that will compensate for the expansion of the liquid when heated. If it is not there, then when the liquid is heated, there will be an increase in pressure in the closed system, which will lead to its damage (leakage, in the form of ruptures of pipes or boiler).

What is an expansion tank for?

This device, designed to compensate for the expansion of liquid in the heating system, is called an expansion tank - a loose translation of the English word “expanse” (expand) or, to put it in a more familiar version, an expansion tank.

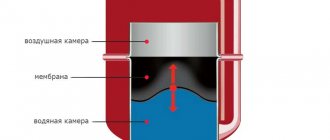

The expansomat is structurally designed as a metal container divided into two parts: one contains air or gas under pressure. These parts are separated from each other by a rubber pear-shaped membrane, which contains the heating system fluid.

When the coolant expands from heating, the membrane stretches, its volume increases, which allows the tank to accept additional volume of coolant. When the liquid cools and the pressure decreases, the membrane contracts under the influence of the back pressure of the gas located in the other cavity of the tank, pushing the coolant into the heating system.

For trouble-free operation of the heating system, it is necessary to install an expansion tank of the required volume, which should be at least 10-12% of the total volume of liquid in the heating system. You can calculate the volume of coolant in the heating system according to the recommendations given in the article: calculating the expanzomat.

How to properly install an expansion tank

If you install an expansion tank of a smaller volume, this can lead to improper operation of the entire system or even to emergency situations. When installing a larger volume expansion machine, this will not affect the operation of the system, but the cost of the system as a whole will increase.

Installing an expansion tank with a smaller capacity can lead to improper operation of the entire system or even to emergency situations: rupture of pipelines or heat exchanger. When installing a larger volume expansion machine, this will not affect the operation of the system, but the cost of the equipment as a whole will increase.

This is also interesting: How to choose heating pipes

The expanzomat can be installed either on the supply pipeline or on the return line, there is not much difference - only the pressure settings of the air and hydraulic cavities of the tank will change. But, since the temperature of the coolant in the return pipeline is lower, the expansion tank installed on the return line will operate under less severe conditions, which will extend the service life of the device.

If there is a circulation pump on the return line, then the expansion tank should be connected to the system in front of the pump, thereby protecting the pump from cavitation.

Now about the method of placing the membrane tank. It can be positioned horizontally or vertically, with the hydraulic outlet upward: this is necessary to prevent air accumulation in the hydraulic compartment:

Incorrectly installed expansion tank

The expanzomat is installed incorrectly: air will accumulate in the hydraulic compartment:

During installation, an installation tap must be installed on the membrane, designed for dismantling and installing the tank on an existing heating system.

When installing a closed heating system, you need to remember that the higher the pressure in the system, the less likely it is to become airborne through automatic air vents or other elements of the system.

practikaotoplenia.ru

Advantages of using the device

A high-quality membrane expansion tank for a heating system, the operating principle of which allows for stability and durability of the entire circuit, has a number of advantages that distinguish it from primitive expansion tanks. Therefore, owners who responsibly approach the issue of choosing key circuit elements analyze its consumer qualities before purchasing a device.

Among them, the following advantages are worth highlighting:

- ease of installation due to the possibility of a convenient flange connection;

- minimal costs during operation;

- the device does not reduce the quality of the coolant and does not pollute it with impurities and scale;

- The expanzomat is safe to operate and does not require any precautions on the part of the user;

- no heat loss;

- protection against water overflow;

- minimum volume of supplied air;

- extending the service life of boilers and radiators of any type;

- creating minimal hydraulic resistance;

- increasing the reliability of the circuit.

By choosing a closed expansion chamber, owners achieve excellent performance of the heating circuit. At the same time, it is recommended to use an expansion tank for an open heating system, which can be purchased on the manufacturer’s website, in rare cases, since such expansion tanks cannot boast of perfect design and wide functionality.

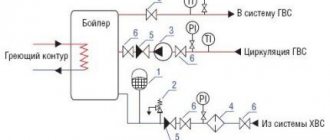

Features of installing heat accumulators

All installation work is carried out according to a previously approved project in accordance with the recommendations of the heating equipment manufacturer.

Connection diagram

In this case, it is necessary to take into account the features of installation work:

- The surface of the storage tank must be insulated from heat loss without fail.

- Thermometers should be installed on the pipelines through which water circulates (outlet and inlet).

- Battery containers with a volume of over 500 liters in most cases do not fit through the doorway. In such cases, you should use collapsible structures or install several smaller batteries.

- It would not hurt to install a drainage channel at the lowest point of the container. It will come in handy when you have to completely drain the water.

- It is advisable to install mesh filters on the pipelines through which water enters the container. They will prevent large inclusions from getting inside (welding scale, minerals trapped in the system, etc.).

- If there is no air vent valve at the top of the container, it should be installed at the top point of the outlet pipe.

- It is necessary to install a pressure gauge and a safety valve on the line next to the battery.

If you are the owner of a solid fuel boiler and have not yet purchased a heat accumulator, think about it. You will not only extend the life of your heating equipment, but also significantly save on fuel.

Read further:

Choosing a solid fuel boiler - what to pay attention to

The use of solid fuel boilers: weighing the pros and cons

Types, advantages and disadvantages of solid fuel boilers

How to properly operate a solid fuel heating boiler

What kind of piping can be used for a solid fuel heating boiler - a simple and complex diagram

Closed

Let's move on to closed expansion stores. A closed tank is a special container made of metal, oval or spherical in shape. The peculiarity of this equipment is that inside it is divided into two chambers - air and liquid - using a sealed membrane. It is for this reason that such expansion mats are called membrane ones.

The principle of operation of the tank is as follows: the air compartment is equipped with a valve, the task of which is to release air when the pressure level increases significantly. Thanks to this, the coolant is able to fill the internal volume of the chamber. As water pressure increases, the membrane, made of heat-resistant rubber, bends and releases air from the compartment.

After the pressure is completely normalized, the membrane returns to its initial position, allowing air to re-enter the heating tank.

It is worth noting that membrane-type expansion tanks are available in various configurations. In some cases, the tank has one of the chambers filled with nitrogen under high pressure, while the other compartment is designed to be filled with water or other coolant. The peculiarity of such a system is that the liquid chamber is connected to the heating system.

After this, the pressure in each of the compartments tends to be established at the original level. The closed expansion tank is configured at the factory, so when purchasing this product, the buyer receives a product completely ready for use.

Installation and placement are also simple, but a lack of free space may be a problem, so if there is not enough free space, you can use a flat tank, the dimensions of which are optimized for installation in small spaces.

Depending on the type of membrane, there are two main types of closed tanks.

Expansomat with non-replaceable diaphragm membrane

To create the carbon body of this unit, the deep cold stamping method is used. A membrane is firmly fixed around the perimeter of the compartments. The internal surface of the case is coated with epoxy moisture-resistant paints that protect the surface from the harmful effects of water.

Enamel is used to cover the outer part of the body. In the initial stage, the vacuum tank is 100% filled with air, which presses the membrane to the inner surface under high pressure.

As the temperature inside the tank increases, pressure begins to increase and coolant flows in, which pushes the membrane in the opposite direction. At the same time, the air in the second compartment begins to compress.

Flange with replaceable diaphragm

Such devices are manufactured in both horizontal and vertical versions. One of the key design features of the model is that the coolant does not come into contact with the metal part of the expansion tank, since it is completely located inside the membrane.

As a result, there is no need to use a special coating to protect its surface from exposure to liquids. In addition, it is possible to replace the membrane if necessary.

Often closed devices are installed near boilers. You can install a second expansion tank in the heating system, placing it next to the boiler if the circuit also supports a hot water supply.

Open

Those belonging to the first group are most often installed in attics, that is, above the top point of the heating system. An open expansion tank is a rectangular or cylindrical container, for the production of which sheet steel is used. After their installation, it is necessary to provide thermal insulation. No setup required before turning on.

Example: a circulation pipe is used to drain liquid. Adjacent to the sink is a control pipe on which a shut-off valve is installed to regulate the water level in the container. It is impossible not to note the expansion pipe, through which the liquid enters directly into the tank. All these and other pipes are connected using special pipes.

Open expansion stores have certain negative qualities.

For example, owners of this auxiliary system will constantly have to replenish the volume of liquid, since it has increased volatility.

Before checking the coolant level, you must lift the protective cover of the open tank. In addition, additional monetary costs will be required for its installation, since the tank will have to be mounted at the top of the heating system.

It is also necessary to first insulate the place where the installation will be made. Due to the fact that an open expander operates at reduced pressure, it is somewhat difficult to control such a system.

And lastly, air enters the expansion machine, which has the device described above, which leads to an increased level of corrosion of the main elements.