A heating system is not just a set of pipes and radiators connected to a heat source. For correct operation, auxiliary components are used, which include a balancing valve. Let's figure out what principles its work is based on, what capabilities it has, what types exist and how they are installed.

Valves provide access to water of the same temperature to all radiators Source pechky.ru

When you can't do without a balancing valve

A situation often arises when the radiators in different rooms heat differently, although the design calculations and installation of the system were correct. When one room is warm and the other is much cooler, the reason most often lies in the uneven distribution of heat throughout the house. A balancing valve for the heating system will help correct the situation.

This type of water shut-off valve is capable of redistributing hot water (adjusting the system) so that each radiator receives the required amount of heat. Redistribution is carried out by monitoring the pressure and temperature of the coolant. Adjustment of hydraulic resistance is carried out by changing the diameter of the pipe. The need for balancing arises in the following cases:

- During the design, errors were made in the calculations.

- The installation was carried out with deviations from design calculations.

- Batteries were replaced; The characteristics of the new batteries do not correspond to the design.

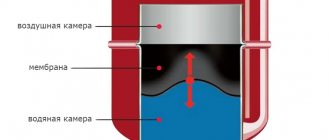

Balancing valve design Source s-proms.ru

- The configuration of the pipes has changed.

- During operation, the system was cleaned and flushed irregularly.

When at least one of these factors comes into play, the balance of the system is upset. This is reflected in the formation of air pockets, due to which some rooms do not receive enough heat. Violation of the temperature regime established in the project is accompanied by excessive energy consumption, and you spend more on heating water than planned.

Visible signs of imbalance are the following inconveniences:

- The launch is accompanied by difficulties; for example, the system is not drawing rated power.

- The heating system is operating normally, but there are significant temperature fluctuations in different rooms.

- It is not possible to achieve a comfortable temperature, although the boiler is operating at maximum and the taps on the radiators are fully open.

Valve model for single-pipe distribution Source rmnt.ru

Application options

The balancing valve is also activated

:

- In a small circulation circuit of a solid fuel heating boiler closed to a heat accumulator. The regulator makes it possible to do without installing a mixing unit to maintain the temperature of the coolant in the circuit at a level of at least 60 degrees. The balancing valve on the supply pipe is responsible for ensuring that the coolant flow in the boiler circuit is higher than in the heating circuit.

- To regulate the operation of an indirect heating boiler. The balancer regulates the supply of heated coolant directly from the boiler to the coil installed in a container with water for domestic hot water.

Working Application of Balancing Valve

How the valve works and what it helps to improve

A balancing tap (or valve) is a type of ordinary water valve, the body of which has connections for connecting a pressure gauge (pressure measurement), sometimes there is an addition in the form of a flow meter.

It works on the same principle: it changes the size of the flow area, however, this can be done more discretely. A spool (spool valve) is designed for this, which is actuated by rotating the handle and shuts off the flow. When the cross-section decreases, the hydraulic resistance in a given section of the pipe increases, which makes it possible to equalize the flows in different pipes.

The balancing valve has a special feature - a spring, the rigidity of which is adjusted by rotating the handle. By increasing or decreasing the spring stiffness, the flow pressure in a particular pipe can be controlled. The mechanism makes it convenient to adjust using a balancing valve for any heating system; the operating principle makes it possible to use it not only in heating operation, but also, for example, in the design of a heated floor.

Spring location in valve body Source ytimg.com

See also: Catalog of companies that specialize in engineering systems (heating, water supply, sewerage and others) and related work

Using a valve allows you to obtain the following advantages:

- Saving. After balancing the system, the amount of fuel consumed is reduced.

- Flexible microclimate adjustment. You can set a comfortable temperature for each room independently.

- Simplifying system startup. The launch proceeds without complications.

- Versatility. The fittings are equally successfully used in private and apartment buildings. In private housing, it flexibly regulates heat transfer in each room. In buildings, it is convenient to balance risers.

The principle of operation of the balancer in the heating system

Operating principle of the balancer

The principle of operation of the balancing device is that the valve seat is capable of changing the internal passage. Rotating the handle sets the corresponding nut and spindle in motion. When unscrewing, the valve rises to the upper operating position, which ensures maximum fluid flow; when tightening, the spindle presses on the valve seat, lowering it to the lower position, thereby reliably blocking the passage of fluid through the radiator.

The radiator modification, used for mechanical adjustment of the thermal and hydraulic modes of the heating circuits, is made of the following elements:

- The body is made of brass with threaded pipes for installation of intra-house pipelines.

- Molded round seat located inside the body.

- A device for adjusting the cross-section of the coolant passage is a regulating spindle, which rests against the saddle when screwed.

- Rubber sealing ring.

- Protective and safety cap made of metal/plastic.

Varieties

Balancing valves in the heating system are manufactured in two versions according to the control method: manual (static) and automatic. Manual varieties have the following features:

- They are suitable for installation only in private houses when the wiring diagram is single-pipe.

- At a budget price, they do a good job of regulating pressure and make it possible to configure the entire system or individual sections.

- Records the characteristics of the working environment at control points.

Types of manual and automatic valves Source s-proms.ru

Mechanical

The devices in question are used in utilities to achieve pressure balance instead of washers and throttle diaphragms. Using a mechanical balancing valve, you can adjust the system to the desired parameters at constant fluid pressure.

Mechanical balancing valve device

These devices are used for more than just network balancing. They allow you to turn off individual consumers, for example, heating radiators, or drain water from them through a special tap.

The devices in question are often equipped with measuring nipples that allow you to measure the pressure in the system in the area where the valve is located, as well as the actual flow of the working medium (this can be water, steam or glycol solution). The main advantage of the devices described is their low cost.

Features of installing a balancing valve

Installation of balancing valves for the heating system is necessary if you notice irregularities in the distribution of heat across the radiators of different rooms. Balancing fittings are also installed in new buildings where they are provided for by the design. Installation is carried out in compliance with the following features of the device:

- The fittings are inserted into the pipe taking into account the direction of flow, which is indicated on the body.

- Automatic models are sensitive to water contaminants, so a filter is placed in front of the device.

- It is necessary to exclude the influence of turbulence on the operation of the valves. It is enough to leave a straight section of pipe in front of the valve, then the water flow will move without turbulence, and the operation of the device will be more correct.

Before installation, it is necessary to flush the pipe and check its integrity. Installation of a balancing valve for heating consists of the following steps:

- Select a piece of pipe suitable for inserting the valve. For stable operation, it will be enough if the straight section in front of the valve is five pipe diameters, after which two or three diameters will be enough.

Procedure after installing the valve Source ytimg.com

- The device is screwed into the pipe; For sealing, flax fiber with lubricant is laid in advance. The minimum number of threads is seven.

- The tap is screwed onto the pipe at one end, and the other is connected to the battery, observing the direction of coolant flow. Spatial placement does not affect the work; it can be anything.

How to install

When performing installation, it is very important to ensure the required position of the valve. In this case, the arrow on the body must coincide with the direction of movement of the coolant

This position will ensure not only the required design resistance of the valve, but also the required flow. At the same time, it is worth noting that some manufacturers allow the possibility of installing the valve not only in the direction, but also against the flow. The rod, in most models, can occupy a different spatial position.

During the installation process, it is worth protecting the working parts of the fittings from various mechanical contaminants. To do this, you need to install a sump filter or a special filter in front of the valve. To eliminate turbulent fluid movement, it is necessary to provide straight sections of sufficient length before and after the valve. This requirement must be specified in the documentation for the valve.

A heating system equipped with a balancing valve must be filled in a special way. To do this, in systems equipped with dynamic valves, it is necessary to provide filling connections, which must be located in close proximity to the valve on the return pipeline. And the valves mounted on the supply pipeline must be carefully closed. To set the balancing valve, a special flow meter or differential pressure and flow tables are used. However, in any case, the initial calculation is performed at the stage of calculating the heating system.

Radiator network balancing

To carry out balancing, it is necessary to calculate the so-called adjustment step (correction step). To do this, the number of revolutions of the balancing valve for the heating system (it depends on the model) is divided by the number of batteries. For example, if the spindle has 4.5 turns and there are 10 radiators in the house, then for that particular system the adjustment step will be 0.45 turns.

Adjustment scale for 7 turns Source zerocreation.ru

The adjustment is carried out starting from the last (furthest from the heat source) battery. Moving from there to the beginning, each subsequent radiator is tightened by 0.45 turns. This calculation is approximate, as it does not take into account battery power. To configure the system more accurately, use the following method:

- The system is heated to 80°C, leaving all valves open.

- Measure the temperature of each radiator; it will be different.

- The temperature is equalized using valves: the middle one is opened by 1-1.5 turns, the middle one by 2.5 turns.

- After 20-30 minutes, when the heat has time to redistribute, another temperature measurement is taken. The difference in values between the outer radiators will be minimal.

Professional methods determine the correct valve position based on operating parameters: water supply volume and pressure drop. Configuration is carried out using diagrams and tables attached to the device passport.

Balancing is carried out for each battery Source ultra-term.ru

Types and differences

Ballorex balancing valves and taps can be considered quite stable equipment, in terms of the availability of many varieties.

To a greater extent they repeat each other's design. The main division occurs due to several details.

First of all, they are divided according to the type of drive or control into:

The former require manual configuration and control, the latter are complete automatic machines, mainly capable of organizing into a single system. The price difference between them is very significant.

Fitting with adjustment and flow meter

Equally important is the presence of additional details. Cranes are often equipped with :

There are plenty of variations. You just need to understand that you don’t have to buy the most expensive and sophisticated option. It is quite possible that you will not need the same pressure gauge or flow meter at all. And it costs a fair amount of money.

Connection methods

Something else worth paying attention to is the method of connecting the balancing valves.

This connection must be reliable, but at the same time mobile. That is, it is necessary to be able to remove the device at any time, replace it or repair it. The best option in this case is the flange method.

The flange connection method is widely used in industry. The flanged valve is equipped with its own flanges and is connected to the same counter products at the ends of the pipes.

Industrial balancing valve with flanges

The flange valve is easy to install by tightening just a few bolts, it is just as quick to remove, but it has one important feature. It is understood that a flanged valve, when equipped with a dismountable assembly, has an amazing level of tightness.

A flanged valve does not need to be tightened or inspected from time to time, and the likelihood of flanges becoming loose is extremely low, provided you have installed them correctly.

Briefly about the main thing

A balancing valve is needed to prevent or correct disturbances in the operation of the heating system (less often hot water supply). There are manual and automatic versions of the device used for systems of varying complexity.

Balancing allows you to save heat consumption and distribute it evenly, but for this you need to install the valves according to the rules, and then check and adjust the temperature in the radiators. Professional balancing is based on measuring the operating parameters of the system.

Purpose of the device

All branches of the heating system must receive the calculated amount of coolant. Previously, simple systems were controlled by using pipes of different diameters. In complex ones, special washers were installed, by moving which it was possible to change the cross-section of the pipeline. Today, a special valve is used that operates on the principle of a valve.

The balancing valve is equipped with two fittings, thanks to which

:

- the pressure of the coolant flow is measured before and after passing through the valve;

- a capillary tube is connected to allow adjustment.

Based on the readings of the device, it is possible to determine the pressure drop when water passes through the regulator, and calculate, according to the instructions, how many turns of the handle are required to optimize the operation of the heating system.

Note! A number of manufacturers offer balancing valves with a digital display, but such devices are more expensive.

What is the pressure difference between two points

When the master adjusts the flow rate using a balancing valve, the pressure loss on the pipes and on the valve becomes different, which changes the pressure drop on the balancing valves.

The calculation of this difference is worth considering using an example. Thus, pressure gauges are installed on the supply and return pipelines, which show the pressure level at these points. The difference will be considered a value that is equal to the difference between two pressure gauges. In other words, if one device produces a value of 1.5 Bar, and another - 1.6 Bar, then the difference is 0.1 Bar. If the valve is automatic, it independently corrects the difference between the points. This element always comes in pairs, since feeling the deviation is very important.

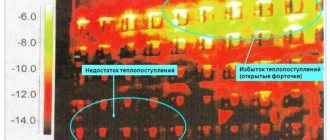

Reasons for uneven heat distribution in rooms

Modern high-rise buildings and private houses are heated using a heating system consisting of radiators and piping. Both elements form one structure through which a flow of hot water spreads evenly to heat the living space.

However, despite the fact that the water supply pipes are made of durable metal, and professionals design the heating system, problems often arise with an uneven supply of hot water through the pipes. Additional reasons may also be low pressure, high water flow speed or a large amount of cold air inside the pipes.

Figure 1: Pipe pressure measuring device

Final Conclusion

If you install heating yourself, you will probably encounter balancing problems. When all radiators, except the last one, have balancing valves, the procedure will not cause much trouble. It is better to take valves that are adjusted with a key or a screwdriver, rather than with a plastic handle, so that children cannot reach them. It is possible that in winter the position of the spindles will have to be adjusted, because heat loss in rooms varies. The only caveat: do not make sudden movements and open the taps in cold rooms slowly, ¼ turn at a time.

Source