In modern heating systems, a three-way valve is used quite often, since it is a means of high-quality regulation of the coolant - by temperature, and not by flow. After all, supplying optimally heated water to radiators is the best way to save energy.

Thermal mixing taps also have other useful functions, which you will learn about in this article. But first, it’s worth considering how a three-way valve works, and also understand its internal structure.

Types of 3-way valves

All thermostatic three-way valves for heating are divided into 3 types according to their design and operating principle:

- mixing;

- dividing;

- switching.

The purpose of each of the 3 varieties can be judged by its name. The first type of valve mixes two coolant flows with different temperatures, the second one separates, the third switches water between 2 lines. It is not difficult to recognize them externally; usually the principle of operation is depicted on the body in the form of a picture. Here's what a three-way mixing valve looks like:

The nameplate from Herz clearly shows the mixing of 2 flows, which means this is a mixing valve

A similar designation appears on the separating element. As for switching taps, there may not be an image on their body, but there are significant external differences in shape.

Separating (photo left) and switching (right) 3-way valve

By mixing or separating flows, the optimal temperature of the coolant supplied to the radiators of the heating system or underfloor heating circuits is achieved. Switching is used in gas double-circuit boilers, when heated water must be alternately directed to different heat exchangers.

Thermal heads for heated floors

Chinese automatic equipment for warm water floors! Test!

Heating in a private house has already been done. But we decided to add a warm floor in the washing room. Room area

Correct connection of the heated floor to the boiler.

Warm floor (working principle)

Anyone who has been following my work for a long time knows that I am not a stranger to any simple methods of adjusting the floor.

Automatic water heated floor. After watching the video, you will learn: - how to choose a room regulator, - which ones.

How to make a heated floor? Connecting a heated floor to a heating system without a collector

How to make a heated floor with your own hands? In the house I made 3 circuits with heated floors: in the kitchen, bathroom.

How to assemble a three-way mixing unit for a heated floor yourself. Pressure testing of your own underfloor heating.

Design and principle of operation

To understand what the thermo-mixing three-way valve of the most common saddle type consists of and how it works, you should study the diagram below. Inside the brass body with three nozzles, 3 chambers are arranged using the casting method, the passages between which are blocked by poppet valves. They are fixed on one axis - a rod coming out of the body on the fourth side.

In a 3-way mixing tap, the outlet pipe (from where the mixed water comes) is always open, the remaining 2 fittings are alternately closed with a thermal head

The operating principle is as follows: when you press the rod, the passage for one flow will begin to open and gradually close for another, resulting in water of the required temperature in the mixing chamber of the valve. It leaves the brass body of the element through the third pipe. The pressure on the rod is adjusted using a thermal head with a remote temperature sensor installed in accordance with the diagram.

The whole process is worth explaining in more detail:

- Imagine that an insufficiently heated coolant comes from the hot water side. Then the mechanism passes it further, and the third pipe is closed. The remote sensor is filled with a heat-sensitive liquid and is connected through a capillary tube to a reservoir (bellows) inside the thermal head.

- When the sensor heats up, this liquid expands, its volume in the tube and bellows increases, as a result of which the latter begins to press on the three-way valve rod. The moment of pressing is determined by the adjustment on the scale of the thermostatic head, set to the required temperature.

- After this, cold water from the third pipe is mixed into the flow of heated water and the temperature of the water at the outlet of the thermal valve remains unchanged, although heating of the coolant at the inlet continues.

- If the incoming water continues to heat up above normal, then to maintain the set outlet temperature, the thermostatic valve can completely close the inlet and open the side flow. In this case, the rod lowers to its lowest position.

- As soon as the sensor detects cooling of the coolant, the head slightly releases the stem, the valve seat on the hot side opens and the addition of heated water begins.

The method of adjusting a three-way tap using a thermostatic head with a sensor is the most popular because it is quite accurate and simple, and does not require electricity.

If we are talking about a dividing valve, the principle of its operation is almost the same, only when you press the rod, one flow begins to divide into two. But in the switching element, the direction of movement is changed by the electric drive, which is described in detail in the video:

Type #1 - non-adjustable bypass pipe

An uncontrolled bypass in a heating system is a regular bypass pipe without any additional equipment.

The lumen of the pipe is constantly open and the movement of liquid through it occurs in an uncontrolled mode. The main application of such bypasses is when connecting radiators.

When designing a heating system, it should be taken into account that the liquid will pass along the path with the least hydraulic resistance.

Therefore, the diameter of the flow area of an unregulated bypass installed vertically must be smaller than the diameter of the flow area of the main line. Otherwise, under the influence of gravity, the coolant will flow into a nearby bypass.

In horizontal wiring, different laws apply. A hot medium tends to rise upward because it has a lower specific gravity. Therefore, the bypass of the lower wiring is usually made equal to the main line, and the pipe going to the radiator is smaller.

Using drives

In addition to the thermostatic head, the valve can be controlled in other ways. The first of them is manual, when the depth of pressing of the rod is determined by turning the handle outside the body. Not the best option and is only suitable if the temperature of the water entering the pipes is constant. Another option is control using a servo and electric drive, receiving commands from the controller. To work together with different drives, another type of valve is used - rotary valves, whose device is shown in the figure:

This 3 outlet valve is very similar to a regular motorized ball valve

There is a certain similarity here with a ball valve, only the working rotary element has a different hole shape to allow coolant to flow in two directions at once. The operating principle here is simple: the axis rotates to the required angle, rotated by the drive. The latter is controlled by a controller that receives impulses from one or more sensors. Typically, valve actuators are installed in complex or automated heating systems with weather control.

Three way hydraulic valve

This hydraulic valve has three passages. Of these, two serve to supply water flows, the third conducts the boiler into the water circuit structure. To prevent metal corrosion, the block body is made of stainless metal. During operation, the thermal floor reacts perfectly to the environment, changing the position of the axle boxes and controlling the degree of heating of the liquid at the outlet. The thermal head is equipped with a meter that transmits signals to the actuator (close or open the valve).

Features of Three Way Valve:

- it is easy to install;

- it allows mechanical and automatic adjustment;

- it is durable;

- it has an average price;

- it contains chemical and water protection.

Schemes for connecting the valve to the heating system

Once you have an understanding of what a three-way valve is and what its work is, you can consider various connection diagrams, depending on the purpose and role of the element in heating the house. Installation of a thermomixing 3-way valve is carried out in 4 cases:

- To protect a solid fuel boiler from the effects of condensation and temperature shock after sudden power outages.

- The coolant in the underfloor heating circuits should warm up to 45 °C, the temperature is maintained by a mixing unit with a three-way valve.

- To maintain the required water temperature in different branches of the system.

- When you need to connect an indirect heating boiler to a single-circuit gas boiler.

To protect a solid fuel heating unit from the formation of condensation, it is impossible to allow cooled water from the radiator network to be supplied to the boiler tank during its heating. To do this, use the following boiler connection diagram with a bypass and a three-way mixing valve:

The scheme works like this. Until the heat generator warms up, water circulates in a small circle through the bypass. When the coolant in the return heats up to 50-55 °C, the valve begins to open and mix in cold coolant from the system. When the heater reaches operating mode, the bypass is closed and the entire flow goes through the radiators. This topic is covered in more detail in the video:

In a heated floor system, this element performs the same functions. The circulation pump circulates the coolant through the heating circuits until it begins to cool. As soon as this happens, the sensor and thermal head will operate, after which the three-way valve will begin to add hot water coming from the boiler to the closed circuit. How to correctly install a heated floor manifold, pump and valve with your own hands is shown in the diagram:

The pump forces water to circulate along the contours of the heated floor, and the valve maintains its temperature at 35...45 degrees

The next example of the use and connection of this important part is the connection of a solid fuel heat generator and a buffer tank with a heat accumulator. To warm it up completely quickly enough, the temperature of the supplied coolant must be from 70 to 85 ° C, which is not at all necessary in a radiator heating system. A three-way valve installed behind the container along with a separate circulation pump helps to lower it.

In the scheme with a heat accumulator and a TT boiler, 2 mixing valves are used, each one regulates the temperature in its own circuit

Important. When installing the mixing valve, remember that the pump should be located on the side where the three-way valve is always open.

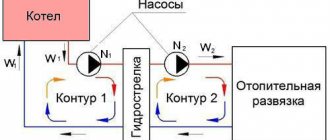

A complex heating system of a large cottage can have many consumers connected via a hydraulic valve and a distribution manifold. Moreover, coolant with a different temperature must be supplied to each of the circuits. The highest is needed for an indirect heating boiler, so there are no control valves on the supply line to it. The remaining consumers need a colder coolant, and therefore they are connected through three-way valves.

There is a three-way valve in each circuit of the circuit, since it is necessary to prepare water at different temperatures. Only the DHW boiler is connected directly to the comb

In a scheme with an indirect heating boiler and a single-circuit gas boiler, you also cannot do without a 3-way valve. The element’s task is to switch the coolant flow to the DHW boiler coil at the command of the controller (the electric drive is activated).

While the coil is heating the boiler, the heating is inactive as the valve switches the flow between 2 lines

How to choose

How to choose the right mixing valve, Warm floors from A to Z, part 3

Warm hydrofloor is a modern heating system, the efficiency of its operation is ensured by various devices, these include a thermostatic valve.

When choosing a mixing unit, its flow capacity should be taken into account. It is necessary that it can process the water produced by the heating system. These data are indicated in the documentation for the boiler.

For sexual pipelines, pipes measuring 26 mm are most often taken. The diameter of the thermostatic valve pipes must correspond to their size. Otherwise, you will need to install an adapter, which is not recommended, since the seams will be under constant pressure, and their tightness will need to be monitored.

In addition, the equipment should be selected depending on the temperature of the coolant in the floor line, from 55 to 35 degrees.

If you choose from manual or automatic equipment, then the presence of automation will facilitate the process of operating underfloor heating, create an acceptable microclimate in the house, and save resources, but it is more expensive. The use of a programmable device will allow you to adjust temperature indicators depending on the time of day and day of the week.

When installing warm water floors in a small room, you should not buy expensive equipment; a simple two-way valve will do.

When purchasing a device in a store, check for a certificate, warranty, and manufacturer’s instructions for installation and operation.

Budget elements with fixed water temperature

In simple heating systems of country houses that receive thermal energy from a TT boiler, it is allowed to install a three-way valve of a simplified type that operates autonomously. To operate, it does not need a thermal head with a temperature sensor, and there is no rod there. The control thermostatic element is installed inside the housing and is set to a certain outlet water temperature, for example, 60 or 50 °C (indicated on the housing).

Operating diagram and design of a valve with a built-in control element

A thermal mixing valve of this type always maintains a fixed temperature of the coolant at the outlet; this setting cannot be changed. This gives rise to the pros and cons of using such fittings:

- The advantage is a lower price than the cost of a unit with a thermal head. The difference is significant - about 30%.

- Disadvantage - it is impossible to regulate the heating of the exiting coolant. When the element is set at 55°C from the factory, it will always supply water at this temperature ±2°C.

Advice. Before purchasing a valve of a simplified design, carefully read the technical documentation for the solid fuel boiler; it often indicates the minimum temperature of the return coolant. You will find more information on the use of mixing fittings in a separate publication.

Our range

The Santekhkomplekt online store offers a wide range of thermostatic mixers from leading European manufacturers. From us you can buy products from Danfoss (Denmark), Esbe (Sweden) and Giacomini (Italy), known throughout the world for their meticulous attitude to quality.

All products are made from corrosion-resistant alloys that can withstand highly acidic water, which is typical for Moscow. Quality control of the control rod allows the listed manufacturers to achieve its high precision and durability, providing it with stable reliability for many years.

Electronic thermostats

There is a minor numeric display and a row of keys. The display shows the current characteristics of the system, or those being set. The keys (often with up and down arrows) are designed to change the temperature. Programmable temperature controllers make it possible to maintain a stable floor temperature; you can automatically change it on specific days of the week or time of day.

There are modifications that, along with the stationary control unit on the wall, have a portable control panel. Certain models make it possible to manage work via a personal computer or tablet, which is quite convenient. These devices can control floor heating.

A water-insulated floor is the best heat resource; with its help, convenience and comfort are introduced into the atmosphere of the home.

Selection criteria

When choosing a mixing valve, it is advisable to focus on several indicators.

- Room area.

For small rooms - bathroom, toilet, it is not always recommended to purchase a more expensive thermo-mixing valve, since it is enough to install a familiar valve. Large rooms with warm water floors will require mixers that automatically regulate the temperature of the heating fluid. Esbe three-way valves model VTA320 - Cross-sectional dimensions. This indicator must be taken into account when selecting a thermostatic valve, ensuring precise connection to the heating system. If there is no device with the required diameter in the assortment offered in the store, then special adapters are purchased.

- Possibility of obtaining an automatic operating mode.

- Bandwidth. This parameter is calculated at the design stage of the heated floor. Based on the obtained values, a mixing valve is selected that can withstand the required load.

Checking water heated floors when using cross-linked polyethylene pipes

For these pipes, the test mode for water heated floors is different.

The system must be loaded with pressure twice the operating pressure, but not less than 6 bar. After such a load, the pressure begins to drop. After 30 minutes, restore test pressure. This must be done 3 (Three) times. After increasing the pressure three times, bring the pressure to test pressure (twice the working pressure) and leave the system for 24 hours. After 24 hours, check: If the pressure in the system has dropped by less than 1.5 Bar and there are no leaks, then the test (pressure testing) of the water heated floor system was successful. Date: September 25, 2022

Tips for choosing

The selection of a thermostat model for a water floor depends on several circumstances: the volume of the building, boiler connection, floor covering, environmental climate, availability of additional or main heating systems.

Purchase criteria:

- Price. The most profitable varieties are mechanical type products. They perform better and are almost impossible to damage due to carelessness. Such thermostats are suitable for those who have children.

- Multifunctionality. Electronic products are excellent at controlling heat in rooms.

- Programmability. This criterion allows us to provide the most comfortable conditions in every room of the house.