For the construction of cottages, country houses, dachas, and garages, you can use inexpensive wood concrete. Its production technology differs depending on the conditions in which the material is located. Wood concrete is made both at the factory and with your own hands. When making it yourself, certain proportions of raw materials must be observed in order to achieve its high strength. Arbolite has a number of advantages, among which it is worth highlighting low cost, minimal thermal conductivity, ease of production, and natural ingredients. From such building material it will be possible to construct a block, panels and slabs of the required shapes. By pouring the mixture into the formwork, you will receive a monolithic wood concrete, which is used for the construction of external load-bearing walls of low houses of two or three floors and partitions, and also as a heat and sound insulating building material.

In this short review we will look at the nuances of the production and use of wood concrete blocks at home.

Sawdust concrete is made from three main components:

1. Portland cement or sulfate-resistant mixture (its pozzolanic type cannot be added);

2. modifying additives and organic filler, which is supplied by the forest processing industry. This can be sawdust, small shavings, pine needles, wood chips, crushed bark and hard stems of agricultural crops;

3. chemical additives that regulate the porosity of wood concrete, accelerate hardening, increase bactericidal properties and make the material more durable.

Arbolite - composition and manufacturing technology

To make your own products, you should choose the right composition, as well as carefully study the technology. Despite the availability of the ingredients used and the simplicity of the recipe, there are certain subtleties. Let's look at them in detail.

Filler used

Wood chips, shavings or sawdust generated during wood processing are used as the base of the blocks.

Wood concrete is perfect for the construction of residential buildings, bathhouses, garages and other utility structures. As you can see, the scope of use is quite wide

The filler should be carefully prepared:

- clean from inclusions of foreign origin;

- grind to a size not exceeding 5x10x40 mm;

- dry thoroughly for three to four months;

- treat with lime mortar to prevent rotting.

Per cubic meter of wood chips you will need 0.5 tons of 15% lime solution. Wood waste is soaked for 3–5 days with periodic stirring. This reduces the concentration of sugar in the wood, which creates favorable conditions for the development of rot. You can use purchased material or grind it yourself at home using a wood chipper or crusher.

Components used

The production of high-quality wood concrete is possible by ensuring incoming control of raw materials and following a proven recipe.

The following components are used for the production of blocks:

- Portland cement, which is a binder. Its content is 12–16%. This concentration is sufficient to bind the ingredients and ensure the strength of the products after removal from the molds;

- mineralizers that reduce water absorption and increase biological stability. Lime is used after slaking and settling, calcium chloride, liquid glass, and alumina.

Arbolite is a good, warm, environmentally friendly and durable material

Providing the required consistency of the wood concrete composition is achieved by adding water, which is absorbed by the aggregate, saturating it with the mineral substances included in the mixture. Depending on the brand of wood concrete composition, the ingredients are introduced in different ratios. In this case, the specific gravity of the blocks varies from 0.3 to 1.3 t/m3.

Wood concrete production technology

The standard technological process involves performing the following operations:

- Preparation of aggregate of required sizes.

- Dosing and mixing of components.

- Pouring the finished composition into molds and compacting.

- Drying in natural conditions.

- Removing products from molds.

- Settling for 14–20 days.

The finished products have the shape of a square parallelepiped with a side of 0.25 m and a length of 0.5 m. The increased dimensions of the blocks make it possible to quickly lay walls.

Equipment

To make wood concrete, you need the following equipment:

- feeding conveyor. It is a screw that provides accelerated supply of aggregate during the production of wood concrete in increased volumes;

- magnetic separator. It is installed after the auger and separates various metallic inclusions from the continuous flow of chips supplied for crushing;

The manufacturing technology of wood concrete involves its production in the same way as fiberboard, by mixing Portland cement with low-grade wood shavings

- chipping plant. Designed for preliminary grinding of wood chips to the required size using a rotor equipped with knives for cutting large raw materials;

- separating device. Sorts pre-shredded wood chips into fractions. Conditioned material is fed into the bunker, and coarse material is fed for additional crushing;

- crushers. Units are used in which repeated grinding is carried out with special hammers. They are hinged on a rotating rotor;

- dosing device. Provides portioned supply of components specified in the recipe to the mixing unit. Performs volumetric dosing;

- mixing mechanism. A conventional cyclic concrete mixer is used, in which the initial components are mixed for 10–15 minutes;

- special forms. They are a structure made of wood or steel. After hardening, the blocks can be easily disassembled for reuse;

- manual rammer. Allows you to quickly compact the wood concrete mixture poured into molds. During the compaction process, air escapes from the massif and the density increases.

To produce blocks on an industrial scale, a vibrating machine or vibrating table is used. They allow you to obtain products of increased density and excellent quality. Accelerated supply of raw materials into molds during the industrial production method is carried out by special concrete distributors.

Requirements for organizing a workshop

Before looking for premises for a workshop for the production of wood concrete, you need to think over a business plan , when drawing up which you should definitely:

study the demand for this building material;- available assortment;

- find where to purchase raw materials (wood waste);

- analyze information about competing companies;

- become familiar with taxation;

- study the sales market.

After the business plan is drawn up, the next stage of business organization begins:

- business registration;

- mastering the technological process for the production of wood concrete;

- search for premises for a workshop;

- acquisition of equipment, its installation and commissioning;

- recruitment and training of working personnel;

- searching for suppliers of raw materials and purchasing them with a reserve for a month in advance.

The workshop area should be 100-300 sq.m. The workshop should have space for drying blocks, as well as for storing finished material. For the business to be profitable, the minimum productivity of the wood concrete production line must be at least 150 pcs. per shift. Gradually, the production of wood concrete should increase to 300 pieces.

The best option for a business is to purchase a ready-made wood concrete production line. Such equipment is programmed to perform a full cycle of the production process.

Properties, advantages and disadvantages

For a private developer, when choosing a building material, the technical characteristics of the material are important. Let's look at wood concrete blocks from this side. So, the characteristics and their brief explanation:

- Thermal conductivity - 0.08 - 0.14 W/m°C (depending on density, the higher the density, the higher the thermal conductivity). Characteristics comparable to wood. It has this indicator of 0.14 W/m°C, for ceramic brick it is 0.6-0.95 W/m°C. That is, a building made from arbolite blocks will be warm, and the width of the walls will be small. For central Russia, in permanent residences, it is recommended to make walls 30-40 cm thick.

- Frost resistance - 25-50 cycles. This parameter means that the walls can freeze/thaw from 25 to 50 times without compromising their qualities (depending on the manufacturer). If the house is a permanent residence, then it will not freeze at all. For unheated dachas, a service life of 25-50 years is quite acceptable.

- Compressive strength - 0.5-5 MPa. This is one of the most attractive features of wood concrete - it is difficult to destroy. Another point: it restores its shape after removing the load. That is, hitting with a sledgehammer can make a dent, but after a while it will level out - partially or completely depending on the “severity” of the damage caused.

Technical characteristics of arbolite blocks

- Bending strength 0.7-1 MPa. This means that if any distortions appear in the structure (the foundation has settled unevenly), the wood concrete blocks will not burst and will compensate for a sufficiently large load.

The properties are very good. Another thing is that they will only be provided that the proportions and technology are strictly observed. This is why arblite blocks are dangerous: you don’t know how well they are made.

Performance characteristics

As you can see, the characteristics of the arboblock are quite good. The advantages also include light weight, large size and good ability to absorb sounds. A very big plus is that the blocks are easy to cut and can be easily given the desired shape. Another positive point is that wood concrete holds nails and screws well. There are no problems on this side either.

- Shrinkage - 0.5-0.6%. This parameter shows how much the geometric dimensions of the wall will change under load. Wood concrete has one of the lowest rates.

- Water absorption 40-85%. This figure is very large. If you put an arbolite block in water, it can absorb a lot of water. For the developer, this means that care must be taken to ensure good waterproofing between the foundation and the first row of blocks. An arbolite house also needs exterior finishing that will protect the material from moisture. It's not all that scary. It is much more important that the hygroscopicity of wood concrete is low (the ability to accumulate vaporous moisture). Even with very humid air, it does not become damp, but allows vapor to pass through itself, regulating the humidity in the room.

- Fire resistance - class G1. Arbolite refers to materials that do not support combustion. This is their undoubted advantage.

If we talk about technical characteristics, then there is essentially one serious disadvantage - high water absorption. There is one more drawback, but it is from the field of operation. Mice love arbolite very much. The material is natural and warm. The problem can be solved by making a high base - no lower than 50 cm.

Features of arbolite blocks

The performance properties and area of use of wood concrete are influenced by:

- composition of the material;

- recipe used;

- production technology.

Made from high-quality raw materials and in compliance with technology, wood concrete has a complex of serious advantages:

- strength. The strength characteristics of the material allow it to maintain its integrity, accepting the acting loads from the building elements;

- frost resistance. Arbolite blocks are able to retain their properties after multiple cycles of freezing with further settling;

Arbolite is a building material made from sawdust, shavings, Portland cement and chemical additives

- reduced thermal conductivity. Walls made of wood concrete maintain a comfortable temperature in the living space and reduce heat loss;

- soundproofing characteristics. Arbolite solid wood absorbs external noise, providing sound insulation to the room;

- ease. Thanks to the reduced weight, the load on the base of the building is reduced, which increases the duration of its operation;

- harmlessness to others. The building material is made from environmentally friendly raw materials and does not have a negative impact on human health;

- long service life. Buildings can be safely used for 4–5 decades;

- ease of use. The building material can be easily drilled, cut, and plastered without the use of additional reinforcement mesh;

- cheapness. Lightweight blocks are made from inexpensive ingredients and can significantly save on pouring the base.

In addition, due to wood chips being the main ingredient, the material is easy to process. It is easy to screw screws and hammer nails into it. Due to these advantages, the material is popular among developers.

To get a complete picture of the properties of building materials, let’s look at the weaknesses. Disadvantages of wood concrete:

- significant deviations in dimensions. They are due to increased tolerances. Manufacturers use molds of different sizes. Due to the different sizes of products, the consumption of plaster mixture increases;

The material, thanks to the harmonious combination of the best properties of stone and wood, will serve faithfully for many years

- disruption of structure at elevated temperatures. If a fire hazard occurs, wood concrete does not ignite for a limited time, but when heated, the wood chips smolder and the material gradually loses its integrity;

- increased hygroscopicity. Unplastered wood concrete walls quickly become saturated with moisture. To use blocks, you must carefully waterproof the base of the building, as well as perform external finishing.

Violation of the composition and manufacturing technology of wood concrete affects the quality of the product. With a reduced lime content, microorganisms develop, and a decrease in cement concentration affects strength. Builders also note the breathability of the building material, which requires additional thermal insulation. The disadvantages include the possibility of the appearance of a peculiar odor caused by mineralizers and chemical reagents included in the composition of the wood concrete mass.

Compound

Like any concrete, the material contains a binder and filler - exclusively organic matter, as well as all kinds of additives. The origin and characteristics of the components have a great influence on the quality of the finished product. Organic additives give wood concrete very significant sound and heat insulation characteristics.

In terms of strength, the building material is practically no worse than concrete with similar density parameters. Such a combination of advantages is obtained only with the proper selection of raw materials.

Chemical additives

Cement has extremely little adhesion to wood due to the presence of various polysaccharides and sugars in it. Polysaccharides, once in an alkaline environment, such as a cement mixture, due to the decomposition process become easily soluble sugars in water, which are considered a “concrete killer”. All soluble sugars, once in an aqueous solution of cement, destroy the chemical processes of hardening, the effect of which should be a complete cement stone.

The more polysaccharides in the water, the less the binder transforms into stone in the required period of time. The fruit of these actions will not be a monolithic stone, but a loose cement stone. It does not have high strength and is not able to bind the wood additive into a coherent material.

There is only one method to counter this - washing sugars from wood pulp; for this, compositions of various reactants are used in heated water. Such reactants include:

- aluminum sulfate;

- potassium and (or) sodium silicate (liquid glass);

- calcium chloride;

- slaked lime.

Organic Ingredients

Several types of raw materials are used as wood additives. Not every wood chip is suitable as a raw material; wood concrete should not be combined with sawdust concrete. The latest GOST clearly establishes the dimensions and shape of inclusions mixed into wood concrete.

- Crushed wood is made by grinding illiquid wood - knots, slabs, tops, etc. To create wood concrete, crushed wood is used: length - 15-20 millimeters - no more than 40 millimeters, width - 10 millimeters and thickness 2-3 millimeters. On an industrial scale, grinding is carried out by specialized units. Practice shows that in order to obtain optimal quality during production, crushed crushed wood concrete must have a needle configuration and be smaller in its parameters: length no more than 25 millimeters, width – 5-10 millimeters, thickness – 3-5 millimeters.

The bottom line is that wood absorbs moisture differently across and along the grain, and the above parameters balance this difference.

- Not every tree is suitable for crushing: you can use pine, spruce, aspen, beech, birch, but larch wood is not suitable. Before use, wood must be disinfected with antiseptics to prevent the formation of fungus or mold.

- Crushed bark and Christmas tree needles can also be used. Only their percentage is lower: bark can be no more than 10% of the weight of the product, and Christmas tree needles - no more than 5%.

- The raw materials also include rice straw, woody parts of the stem of cannabis and flax, as well as woody stems of cotton. They are crushed: length no more than 40 millimeters, width – 2-5 millimeters. Tow (waste from cleaning fibrous material) and hemp, if they are included in the mixture, should not exceed 5% by weight. GOST 19222-84 regulates the parameters of fractions obtained in the process of crushing various types of raw materials. And even if deviations are possible in the ratio of components, it is prohibited to deviate from the standards of raw materials.

Flax contains a significant accumulation of sugars, which, entering into a chemical interaction with cement, destroy it. To avoid this, the woody parts of the flax stem are initially soaked in slaked lime for 1-2 days or kept outside for 3-4 months.

Inorganic substances

The cementing ingredients in wood concrete are:

- Portland cement is a classic material, it is especially popular;

- Portland cement with mineral auxiliary elements - as a rule, a similar method increases the frost resistance of blocks;

- sulfate-resistant cement, in addition to pozzolanic cement, guarantees resistance to aggressive chemicals;

- in accordance with the conditions of GOST, only material of a grade that meets the following conditions can be used: no less than 300 (this applies to heat-insulating wood concrete) or no less than 400 (for structural concrete).

Water

GOST regulates the purity of water, but in reality they use different types - from the central water supply, wells, wells. For proper quality of wood concrete, water temperature is considered decisive. It is mixed into the mixture together with auxiliary components.

In order for the hardening rate of the solution to be optimal, heated water is required at least +15 C. Already around +7 +8 C, the hardening rate of cement is significantly reduced.

Wood

Being a natural material, wood contains a small amount of water in its pores. It is also enriched with organic sugars, which must be removed before using the raw materials. This will make it possible to create high-quality material with increased strength and performance properties.

The technological process involves cutting chips of raw wood, after which it is placed in an environment with chemical reagents to remove sugars. The material must be exclusively raw, since such chips have the correct shape for chaotic distribution throughout the block.

Initially, this stage looks simple and understandable, but it obliges the master to adhere to the exact recipe and rules. If any requirement is missed, the final design will begin to crumble.

Wood, like cement, has low adhesive properties. Therefore, in order for it to acquire the required properties, you need to carefully understand the mechanism of interaction between wood chips, chemical reagents and cement.

Depending on the size of the chips, the amount of cement that will be used in the production of 1 m³ of block is determined. Dry raw materials have a fine fraction and a needle-like structure, which will require the use of more cement mixture.

For 1 cu. m. block you need:

- 8-10 kg of chemical reagents.

- 250 kg of cement.

- The same amount of wood chips.

When making batches, it is important to properly moisten the wood chips (to avoid excessive release of liquid) and immerse the raw materials in the cement layer. After compaction, all pores and blown holes will be tightly closed.

Recipe

When creating wood concrete with your own hands at home, you can choose the proportions according to different recipes. However, regardless of the chosen recipe, there are a number of universal requirements that must be met without deviation. First of all, it is necessary to remove all moisture and sugar, and also isolate the wood chips from the penetration of water from the outside.

A properly created structure has no dew point, which allows it to be used as an independent building material or insulation. When choosing the appropriate recipe, it is important to consider the operating conditions of the sides. So, in one region there may be high humidity, so the raw materials will need extensive drying, and in another - an excessively low level.

During the production of wood concrete blocks, it is necessary to isolate the wood chips from moisture and swelling during mixing. A similar problem occurs quite often and is called bloating.

Next, you should decide on the type of chemical additives that will be included in the wood concrete. There are 4 types of reagents that ensure the correct performance properties of the material. They are selected taking into account the location of the future building.

Aluminum sulfate

This chemical reagent is widely used in wood concrete production because it is capable of breaking down sugars. The additive also shortens the term for gaining brand strength.

Calcium chloride

Another popular additive is potassium chloride. Together with aluminum sulfate, it removes all microorganisms from the wood and provides wood chips with anti-rot properties. The tandem of 2 reagents increases the resistance of blocks to various negative influences. If it is not possible to purchase calcium chloride, it can be replaced with aluminum chloride.

Liquid glass, or sodium silicate

Knowing what the composition of wood concrete consists of and the proportions, you need to take care of a reagent such as liquid glass (sodium silicate). The component is intended to close all pores in the wood and protect the wood chips from moisture penetration. The additive is added after the decomposition of sugars. It also helps improve the setting of the solution.

Slaked lime

The additive is an alternative solution to the first 2 reagents and is used in case of their absence. The substance breaks down sugars and microorganisms in the wood chips and provides a faster set of desired performance qualities.

Design

In the process of creating a project, the composition and characteristics of the soil are determined in order to calculate the characteristics of the foundation in accordance with this information. Then the shape of the house, the thickness of the walls, the presence or absence of thermal insulation, the placement of windows and doors, as well as other necessary characteristics are established. In addition, during the process of creating a project, the quantity and type of building materials are determined.

For example, on the outskirts of the city of Sochi, a wall thickness of 20 centimeters makes it possible to do without thermal insulation, while in the Omsk area the smallest wall thickness, which allows one to do without the use of thermal insulation, is 50 centimeters.

A competently created project will save you from unnecessary consumption of materials and the possibility of rebuilding some areas or details during the construction of the house.

Projects of houses made of wood concrete with an area of 100 to 150 square meters. m can be one-story or two-story and have in its structure an attic, a garage and even a basement or ground floor.

Preparation of the solution

If it is not possible to keep the wood chips in the air to destroy the sugars, they are subjected to chemical treatment: left in lime milk for 3 days. The wood waste is mixed from time to time. There is no need to dry the wood chips after this. It is only necessary to remove excess solution. In the process of laying such blocks, a solution of different composition is used.

Sand with cement

Recommended proportions of components: 1 share of M400 cement and 2 shares of sand. If you plan to use M500 cement, then prepare 3 parts of sand for 1 part of this material. The components are mixed dry using a construction mixer.

Perlite

Kneading begins by combining water (10 l) and a dry mixture of perlite (2 buckets). When the components are thoroughly mixed, cement is added to them (no more than 0.5 buckets). When working with perlite, it is necessary to wear a respirator, safety glasses and closed clothing.

Glue mixture

Standard scheme: 5 kg of adhesive (dry) and 5 liters of liquid. The mixture is left at rest for 5 minutes. Then the mixing process is repeated. The finished material must be used within 2 hours, then it will lose its properties.

The procedure and features of mixing the solution

First, sufficient sawdust is poured into a container or concrete mixer. After this, water is poured in. Special additives and liquid are mixed separately. At the next stage, the solution is added to a concrete mixer, where the sawdust is soaked. After these manipulations, cement is poured in small portions.

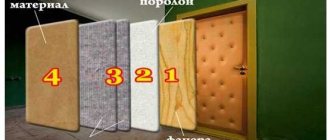

Block molding

Forms for the finished mixture are made or purchased. They should have handles, but without a bottom. Such structures are installed on a wooden base. The solution is poured into them. If the work is done with your own hands, the mixture is laid out in molds in layers, each time tamping the material using a manual vibrating platform. Air is periodically removed from the thickness of the mixture. To do this, the material is pierced with a rod. At the last stage, the surface of the workpieces is leveled, for which a metal strip is used - it helps to remove unevenness.

Reviews from thematic forums

Next, we suggest that you read the reviews of developers who used wood concrete in various forms of release:

Andrey, Krasnogorsk, Russian Federation.

I built my one-story house 11 x 15.6 m from monolithic wood concrete, which was prepared from wood chips right on the site, the solution was immediately poured into the formwork. Upon completion, I submitted several samples to the laboratory, taken from walls in different places, and was pleased with the results. Judge for yourself: density from 370 to 455 kg/m³, strength - 1.1-1.7 MPa. From chemistry, alumina sulfate was used.

Valery, town. Balakleya, Ukraine.

I bought a special machine with vibration and made the first batch of blocks from wood chips. To begin with, I took the recipe from the Internet and used M400 cement. When I removed the formwork to transfer the products to drying, I deliberately dropped one arboblock, and it easily crumbled into pieces. I tried it with my hand and it crumbled. I'm afraid I messed something up with the solution, I'll experiment further.

Anastasia, Izhevsk, Russian Federation.

Three years ago, my husband decided to build a one-story house from wood concrete blocks, wood concrete, that is. That’s what was done: the load-bearing walls were made of this material, and on the outside there was a beautiful “Bassoon” brick, the foundation was a ribbon. Last year we moved in and immediately noticed that there was no humidity anywhere, it was dry, and it was easy to breathe. I recommend.

Vladimir, Vitebsk, Republic of Belarus.

Together with my brother-in-law, we made 3 blocks from wood chips and shavings for testing without any vibrators. True, they added sand to the solution, although it is not listed in the recipes on the Internet. After hardening, they subjected them to field tests and decided to build a house from them, since the products turned out to be amazingly strong. True, making wood concrete yourself is too expensive due to the loss of time. I will look for high-quality factory material.

How to make it yourself

It is extremely important to consider for what purpose the material is used - private or commercial.

In the first situation, there is no need to purchase expensive devices and equipment. It is necessary to correctly follow the technology and carry out the work.

Where to get wood chips

To produce wood concrete blocks you will need high-quality wood chips:

- The best wood chips come from pine trees. It is possible to use larch, but during mixing it is necessary to double the number of chemical additives. Among deciduous trees, the use of aspen, birch, and poplar is acceptable.

- There are certain requirements for wood chips: the largest dimensions are 40 by 10 by 5 mm. Based on practice, the optimal characteristics of wood chips have been identified - length approximately 2.5 cm, width - 1 cm, thickness 0.4 cm. The most reliable wood concrete blocks are made from such raw materials with your own hands.

- The volume of the cortex does not exceed 10%.

- There should be no dust, sand, soil, or foreign inclusions. Minor fractions and sand are removed from the chips using a sieve, and large impurities are removed independently (often these are soil fragments or stones).

- There should be no visible mold or rot.

Material proportions

It is important to correctly calculate the proportions of wood concrete with your own hands at home. The density of the structure can vary between 600-850 kg per cubic meter. m. Low-grade thermal insulation material is perfect for insulating horizontal coverings. A more reliable brand can be used when laying in a vertical cavity or for fastening to walls. For correct calculation, the classic rule will help:

- there are chemicals whose effects are aimed directly at wood chips;

- There are chemicals that react with cement.

Important! For 1 cu. m of wood chips, take 6-10 kg of aluminum sulfate along with calcium chloride, in a ratio of 1 to 1, not taking into account slaked lime and liquid glass, which is used to process the wood chips. It is possible to divide such a mixture into two parts with a ratio of 2 to 3.

Is certification required?

The quality and environmental safety of wood concrete blocks must be confirmed by certificates: fire and voluntary GOST R.

- Fire safety certificates. Arbolite blocks can be used for thermal insulation and structural purposes. Each of them has its own fire safety requirements.

A mandatory fire safety certificate is issued for blocks intended for the thermal insulation layer. This material is tested for flammability, combustibility, smoke generation and toxicity.For structural blocks, a voluntary fire safety certificate is sufficient, which indicates the fire resistance limit. A fire certificate is issued for a period of up to 5 years.

- Certificate of quality . In another way, the quality certificate is called GOST R. This document confirms that the product complies with GOST. A quality certificate for wood concrete blocks is issued for a maximum of 3 years.

The presence of certificates increases customer confidence in the manufacturer.

Making wood concrete yourself: instructions for beginners

Before moving directly to the step-by-step production of arboblocks, it is worth mentioning several nuances:

- CANNOT for wood concrete . Just wood chips.

- Almost any woodworking waste is suitable for obtaining filler - slabs, branches, timber trimmings, tree tops.

- If you plan to use large-sized wood concrete blocks (for example, long transverse beams) in the building structure, then you should take care of their additional reinforcement. We are talking not only about the strength frame, but also about the rigging loops for easy transportation.

Please note: the best wood for wood concrete blocks is considered to be coniferous species: pine, spruce. Deciduous trees include birch, poplar, and aspen. It is strictly not recommended to use waste from larch, beech, and elm to make wood concrete.

Compound

For wood concrete, high grade cement is used - M-400 and M-500 . Be sure to keep the cement fresh and dry.

Wood chips, as already mentioned, must be crushed to certain sizes - 25x8x5 mm (optimum) or 40x10x5 (maximum) mm. Try to avoid high concentrations of misgrade - because of it, the final strength of the arboblock will decrease.

The following chemical additives are used:

- Food additive E509 – calcium chloride and nitrate.

- Aluminum sulfate.

- Liquid glass.

- The water used is potable (from the tap). You should not make an arbolite mixture using water from reservoirs - dirt and other impurities will destabilize the connecting connections between the components of the block, which will cause its premature destruction.

IMPORTANT: Follow the procedure when mixing ingredients. Remember firmly: first we mix water and chemical impurities, then add wood chips there and only after it is evenly wet, add cement.

Dimensions of arbolite blocks

Arboblocks are classified by density into:

- Structural - from 500 to 850 kg/m3.

- Thermal insulation – up to 500 kg/m3.

Which blocks you will use directly depends on the building being constructed. For a two-story building or a one-story house with a basement or attic, structural blocks with a density of 600 kg/m2 should be used. For an ordinary one-story building without additional levels, the lightest structural blocks are suitable - 500 kg/m3. Thermal insulating blocks are usually not used to build walls. They are used as additional protection from the cold when lining walls made of other materials.

The standard size of an arbolite block is 50x20 cm. But the thickness varies from 10 to 50 cm. But you yourself can provide other dimensions that are suitable specifically for you.

You can see the typical dimensional parameters of wood concrete blocks from the table below:

It is also worth considering the strength of wood concrete blocks made on your own. It is divided into classes. If you plan to build a residential building from wood concrete with your own hands, then you need a maximum strength class of B2.5:

Video making wood concrete blocks

Step-by-step instruction

So, let's start producing wood concrete blocks with our own hands.

We take the proportions for mixing the components from this table:

Please note: wood shavings (chips) must be free of sugar, otherwise it will ferment and cause the block to collapse. It can, of course, be removed chemically. But usually the wood chips are simply allowed to sit in the air for three months. Remember this when preparing raw materials for the wood concrete mixture.

- You will need a forced-type concrete mixer. You can use a regular “pear”, but the quality of mixing will be lower.

- Add chemical additives to water in the required proportion. Mix thoroughly.

- Pour out the sawdust. Stir a little. Wait until they are completely wet and there are no dry “islands” left.

- Start adding cement in batches. Under no circumstances fill the entire volume at once - it will be very difficult to cope with clumping.

- By alternating mixing and adding cement, we achieve uniform envelopment of the sawdust with the resulting mixture. This is only possible if the sawdust is sufficiently wet.

- When you have a homogeneous mixture, you can start pouring it into molds.

- If you have a molding machine with a vibration motor, the process is greatly simplified. All you have to do is load the raw materials, wait and remove the finished block.

- But in artisanal conditions, they most often use homemade molds and manual pressing (in the best case, a vibrating table).

- The form is a metal box without a bottom. They place it on a flat surface (a board, for example) and begin to pour in the mixture. If you use hand pressing, you should do it in layers. The number of layers depends on the height of the form. Usually they make at least four to five layers.

- Each layer is compacted with a metal platform with a handle (it is desirable that it coincides in area with the cross-section of the mold). In order for air to escape from the mixture better, it is pierced in several places with reinforcement, and then compacted again.

- We recommend that you make (or purchase) a pressing lever mechanism. Then you can better regulate the density of the output block. In addition, in this case, you can pour the entire volume of the mixture into the mold at once. This will significantly speed up the manufacturing process.

- If you need high-density blocks, alternate between light and strong pressure during the compaction process. With this technique, depressing (change in shape due to the elasticity of the solution) is less pronounced, and the blocks are more durable.

- After compacting is completed, remove excess mortar with a metal scraper.

- Vibration further contributes to the strength of the finished building material. If you have a vibrating table, then the lever mechanism is not needed. Simply place the form on the table surface, load the wood concrete mixture, place a weight on top and turn on the vibration.

- After the block is formed, it is transferred to the drying site. When you have a thick enough mixture, you can remove the mold from the wet block. But when making low-density blocks from wood concrete, the solution is too liquid and loses its geometry. In this case, take care to create a sufficient number of forms so as not to waste time.

- In summer, you can dry arboblocks outside for 15-20 days. But according to technology, they are required to be kept for two days in a room with a temperature of 60 °C.

After all this, the blocks are, in principle, ready for use in construction work. If necessary, they can be machined to give the desired shape.

Instead of an afterword

In conclusion, we have prepared for you a small digest of nuances that will help you make wood concrete blocks with your own hands:

- Chips for wood concrete blocks can be produced independently if you have the necessary machines - a chipper and a crusher. But you can purchase it at nearby woodworking enterprises or in workshops for the production of wood blocks.

- To make it easier to remove the blocks, line the inner walls of the mold with linoleum or other smooth and thin material.

- When it is necessary to produce structural wood concrete of maximum strength, hydration should be carried out. To do this, place the finished block under film for 10 days at 15 C.

- If you use wood concrete not for constructing walls, but for insulating an already constructed building, some precision in the technology for producing the mixture and blocks can be neglected. But don't overdo it.

- If you are removing the sugar from the chips by letting them sit in the air, be sure to stir them.

- There is a way to immediately prepare wood concrete blocks for exterior finishing. To do this, after compacting, apply a layer of plaster to the top of the block and level it with a spatula.

- If you do not have a special drying room with the required temperature conditions, then drying the blocks in the open air will take at least two weeks.

Criteria for quality products

Choosing wood concrete is a responsible process, since the service life of the future structure, as well as the microclimate inside it, will largely depend on it

Experienced builders, when purchasing material, advise, first of all, to pay attention to its cost. It is unlikely that the manufacturer will work to his detriment and sell high-quality wood concrete blocks below their market price

When choosing wood concrete, it is important to make a visual assessment of it. Below are the quality indicators of such material

- Uniformity of composition. If the wood concrete mixture was heterogeneous, the finished blocks will delaminate over time. According to the regulations, the delamination rate must be less than 10%.

- Correct geometric shape. Its violations are observed when the storage conditions of finished products or production technology are not observed.

- Uniform gray color. Uneven color of blocks or foreign inclusions indicate low quality of the products. For example, the presence of green or brown shades is a sign of under-drying of the products. It is worth considering that materials may have various inclusions (straw, sawdust, pine needles, tree bark), but not more than 5%.

- Chips of the same size (the presence of particles with sizes exceeding the established standards is unacceptable). Wood fractions that are too large are unable to be completely saturated with chemicals. Because of this, they do not mix well with concrete and reduce the strength of the finished building material.

To be sure of the quality of wood concrete, you should agree with the manufacturer on the possibility of laboratory testing of random samples of material from the released batch.

More about production tools

It is impossible to produce high-quality material without:

- Wood chip cutter. Also called a hammer crusher. The estimated price of a new machine is 45-50 thousand rubles. The wood chip cutter produces wood chips that are easy to produce (length no more than 25 mm). It is for production in a subsidiary farm that it is enough to install a rotary-hammer type machine. Blueprints:

- Machine for arbolite blocks. Again, the work will require a device not of an industrial scale, but a mini version of it. Since small-scale production of wood concrete is gaining momentum, the price of equipment for garages, sheds and small industrial areas is correspondingly increasing. The equipment will cost the private owner the same 50-60 thousand. One block can be produced in one minute, which gives up to 6.5 cubic meters of material per working day (approximately up to 450 blocks)

- Concrete mixers. Gravity-type devices common in construction will not work. Their cycle is not enough for a high-quality mixture. Because even your own small-scale production requires a forced-type apparatus (mortar mixer). Usually they are also made with their own hands.

- Press. For small volumes, it is possible to compact the mixture manually, but a private flow line requires a vibrating press. Has proven itself to be excellent.

Rifey devices.

But the most common device for a production line is “Condor 1”, costing from 265 thousand rubles.

However, private subsidiary farming accepts any auxiliary means, so it is also customary to use “Builder-1” or “Hephaestus-1” mini-machines.

- Special forms. There is nothing complicated here; you can stamp ordinary boxes for convenience. But there are some tricks. For example, it is customary to cover internal areas with oilcloth. This is simply ideal for drying mortar. Sometimes oil waste is simply poured into the bottom of the mold. There are many innovations, but the most important thing is the process of compacting into the mold itself. It is impossible to arrange the composition evenly right away, so make 3 or 4 bookmarks with periodic tamping.

Solving possible problems

The production of wood concrete can be complicated by two main problems:

Mandatory use of a mineralizer entails the formation of “cement poisons.”

Do not be alarmed, such substances are safe for humans, but have a negative effect on the mixture. They increase the setting time of the mixture. These substances are formed by the reaction of wood sugars with cement.

A lot of sugars are contained in deciduous wood. It is better to use coniferous wood chips, since they least contribute to the formation of “cement poisons.” The rather low strength grade does not make it possible to erect high-rise buildings, but it is enough for the construction of a two-story cottage. For taller buildings, it is worth using wood concrete as an insulating material or using the monolithic frame method.