Heating systems with water coolant very often become airy. Air penetrates massively into the liquid medium when heating networks are fed, and in addition is released from the water in different temperature conditions. In high areas of the network sections, air also collects, forming air plugs, which, depending on their size, can either completely block the circulation of water movement, or significantly limit it, thereby reducing the level of heat transfer, and therefore the efficiency of the system as a whole.

Air pockets can also be located in the heating source, which is especially dangerous and leads to serious accidents on boiler units. In this connection, there is a need for timely discharge of air from the internal circuit of the network using air vents. This is one of the main tasks of safe operation of heat supply systems.

Reasons for heating heating

There are several reasons for the appearance of air in the heating system:

- the content of dissolved oxygen in water heating pipes, which, when heated, is released in the form of microbubbles, which subsequently form an air plug;

- supply of media too quickly when filling the system, as a result, the air does not have time to bleed;

- air entering the pipes as a result of media leakage (for example, loose connections);

- use of pipes with oxygen-permeable walls in heating;

- the appearance of air jams as a result of improper installation of the heating system and after repairs.

What to do if the heating system is affected by one of the listed troubles? Of course, bleed the air. To do this, an air vent is cut into the system. Let us further understand what an automatic type device is.

Air! Air!

Risers, or even the entire hot water supply circuit, have to be reset from time to time.

There are several reasons for this:

- Seasonal repair work (inspection of shut-off valves, scheduled testing of heating mains, etc.);

Scheduled inspection of shut-off valves

- Emergency work (elimination of gusts, leaks of risers and spills);

- Work in apartments with faulty valves (in particular, replacement of these valves).

Now let's imagine what will happen when a pair of risers connected by a jumper is reset and then launched:

- As soon as you turn off the valves on the risers, unscrew the plugs and open any tap on any plumbing fixture, the water will completely drain from the paired risers and they will fill with air;

Each shutdown of the hot water supply leads to airing of the risers

- When starting paired risers, air will be forced out by water pressure into the upper part of the closed circuit - into the jumper;

- Since the pressure difference driving the water is minimal, the air in the water supply system will completely stop the circulation in this section. The obvious consequences are the same long heating of water during tapping and cold heated towel rails.

The video in this article will help you learn more about how to remove air from a water supply system.

Device

The design of the automatic air vent is enclosed in a metal case (bronze, brass, stainless steel), at the bottom of which there is a connecting pipe. The body is sealed and can be cylindrical or cone-shaped. In our country, we have established the production of air vents with external connecting threads 1/2” (DN15) and ¾” (DN 20), in rare cases you can find 3/8”. Inside the barrel there is a float made of polymer material or stainless steel. Through the rocker arm (lever), the float is combined with a spool (spring-loaded drain valve), on the fitting of which a locking cap is placed. In general, the part looks like this:

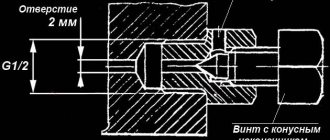

Mechanical

The body of a manual release is usually made of brass, has a simple design and small size. The main part of the entire Mayevsky faucet is a needle-type shut-off valve. To engage it and expel air, you need to turn the screw counterclockwise one turn with a special key, screwdriver or hand, depending on the model of the device. The needle opens a hole and gases escape through it. At this point, a faint hissing sound will be heard. As soon as all the air has escaped, coolant begins to flow out through the hole. After this, you need to tighten the screw all the way.

The only drawback of mechanical devices is that all operations with them have to be carried out manually.

Principle of operation

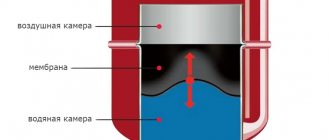

The automatic air vent is designed to operate without intervention from the user of the heating system. The operating algorithm of the device is simple:

- In normal condition, the air vent housing is filled with a carrier that pushes the float upward. Thus, the air vent remains closed.

- When air enters, the coolant level drops, and with it the float.

- Having reached a critical point, the float uses a lever to open the drain valve.

- Under the pressure of the water, the air comes out, and water takes its place again, again raising the float up.

- The valve closes.

The work flow looks like this:

Important! An automatic air vent will serve for the benefit of the normal functioning of the heating system at temperatures from -10C to +120C. You should not think that once you install the device, you can forever forget about it and the problems it solves. Like any other device, the air vent requires care, preventive inspection and cleaning. When circulating low-quality coolant in pipes, these actions must be performed regularly. For reliable uninterrupted operation of the device, it needs to be under hydrostatic pressure, and this is only possible if the requirements for operating pressure in the entire heating system are met.

Operating instructions

- Modern models of devices are equipped with elastic gaskets so that the connection to the radiator and pipeline is elastic and reliable.

- If the presence of a gasket is not enough, plumbing thread is wound at the joint or linen tow and putty are used.

- Installation is available without inviting a plumber. To connect to the system, just use an adjustable wrench.

- Experienced plumbers recommend installing an automatic air vent, the operating principle of which involves effective bleeding of air, not from the blind radiator plug, but on the inlet pipe - between the radiator and the tap.

Set it and forget it: is that true?

The Smart Home system implies the presence of various devices that create comfortable living in the house. The monitoring device periodically requires attention, despite its autonomous operation. Over time, the air vent begins to bleed not only air, but also water. The needle valve stops opening and closing independently due to the jamming of the polymer resin float. The light weight and soft texture of the core make it vulnerable to the slightest ingress of debris and hard abrasive particles.

Device options

There are three types of automatic air vents: corner type, straight type and radiator type. External differences and scope of application do not in any way affect the operating principle of the devices. Let's look at the features of each modification.

Direct air vent

Direct air vent

The most common type is with a straight connection pipe. Installed at the highest points of the heating system, where air pockets most often form.

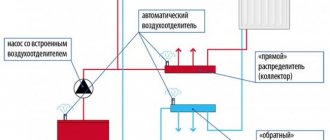

The direct automated air vent is part of the safety group of the heat generator, which is located on the pipe extending from it. An air vent is necessary here to remove air when filling the boiler tank with water. In case of carrying out maintenance work, the boiler tank can be disconnected from the heating system and emptied using an air vent.

Some types of circulation pumps also require the installation of an air vent in order to ensure uninterrupted operation. Pumping equipment transports only an incompressible medium, and if an air lock appears in the impeller, it may stop. This threat is controlled and prevented by the diverter.

Radiator air vent

Radiator air vent

An automatic radiator air vent is mounted on radiators instead of Mayevsky taps. It is slightly different from the traditional model in size and more expensive. Insertion of the element is necessary in aluminum and bimetallic batteries, where air pockets are constantly formed during the chemical reaction of the metal alloy with the carrier.

Installation of Mayevsky crane

For the Mayevsky crane to operate efficiently, it is necessary to ensure its correct installation. The air vent is installed on a bimetallic or aluminum Ogint radiator without any problems, since its thread size corresponds to standard hole sizes. The main thing is to choose the right installation location. The Mayevsky tap must be installed in the upper radiator foot on the side opposite the coolant inlet.

The Mayevsky tap has a high-quality o-ring that seals the installation site. Also, for additional reliability, it is recommended to use FUM tape during installation.

In addition to radiators, air vents can be installed on heated towel rails.

Automatic air vent installation areas

Where in a heating circuit with forced circulation should an air vent be present to most effectively fulfill its intended purpose? How to prevent the formation of air locks in the system? There are several specific requirements:

- The pipeline must be laid in such a way that the coolant and the released air move in the same direction. The idea is that the hot carrier rises from the main riser to the distant ones;

- The air vent is installed in the highest areas. There is a reason for this that is completely explainable by the laws of physics: the release of air begins when the speed of flow of the coolant decreases, and this process occurs precisely at the highest points;

- The likelihood of the risk of air jams forming is present to a large extent at pipeline turns, in areas of transition from larger to smaller diameter pipes, and directly on heating devices (radiators). Therefore, it is quite logical to install air collectors in such places.

Purpose and types of air vents

Autonomous heat supply systems, as well as heating devices connected to the main network, are equipped with specialized air vent valves. The most common among them are the Mayevsky manual valve and the automatic air valve.

There are 3 types of air valves sold in the retail chain:

- Traditional straight type, with vertical installation.

- Angular 90 degrees. They are used on heating appliances as an alternative to the Mayevsky tap, when the design of the heating pipework does not allow direct modification.

- Specialized air vents for heating devices.

Corner and radiator air vents

In various heating systems, sometimes a situation arises when it is necessary to vent air in inaccessible or remote areas. Where it is not possible to install a traditional type of air valve for heating, therefore a corner structure is installed. The angle valve has a special lower pipe with a rotation angle of 90 C and is capable of connecting to a horizontal section.

It should be noted that the corner design with an external threaded connection is practically no different from a conventional vent and can be used instead, if necessary.

Where to install air vents correctly

In various heat supply schemes there are areas where the installation of air vents is mandatory. In a professionally executed version of the heating network, installation locations are indicated according to the heating network design. There are general approaches to the placement of such protective devices. For example, Mayevsky taps are attached to all heating devices to release accumulated air. Insertion point - in the upper corner plug, remote from the point of connection of the supply pipe to the heating device, air collects in this area. When the boiler unit is equipped with a built-in air vent, it is not installed on the supply pipe.

An automatic air vent for heating must be installed vertically in the following places in the heating network:

- Safety unit for a boiler operating in a closed heating network.

- On the supply and return manifolds of the “warm floor” system.

- If in the intra-house wiring of the heating network, the highest point is a pipeline, and not a battery, then a float vent is mounted in it.

- Installation of an expander and an indirect heating boiler into the tank is carried out when this is provided for in the design scheme.

- On a hydraulic arrow, to separate the heating circuits in the house.

In addition to the noted zones, air vents are installed in problematic areas of the heating network, where, due to the difficult circumstances of installing pipes of different diameters, P-compensators of the upper direction are formed. In particular, when pipes go around doors or a flight of stairs, and then go down again. In such devices, air accumulates in 100% of cases, for this reason, in such places an air vent is needed, preferably an automatic one.

In intra-house heating circuits of multi-storey buildings, air vents are installed:

- At all collector sites

- On vertical P-compensators.

- At the highest point of the network of each riser of a multi-story building.

Consequences of the absence of an air vent in heating

The functioning of the heating complex is based on the circulation of the medium in the pipeline and the transfer of part of the heat to heating devices. The latter, in turn, share this heat with the room in which they are located. An air plug formed in a pipeline or in a radiator (airing) leads to a disruption of the entire process: the circulation of the coolant becomes difficult or stops completely. What else is fraught with the absence of automatic air vents in the heating circuit?

- noisy movement of the carrier in pipes, vibration, increased likelihood of destruction at soldering points;

- airing in remote sections of the pipeline, in areas where the temperature regime is not constantly monitored, can cause a stop in circulation through some radiators. In some cases, this can lead to defrosting of the entire heating complex;

- reduction in the efficiency of heat supply and excessive consumption of heating raw materials;

- failure of radiators caused by corrosion. Corrosion occurs as a result of air entering the internal walls of the batteries.

Automatic air vents are the same necessary components of the heating system as heating devices, pipes and a heat generator. Automated devices enable the heating complex to function fully and maintain all other elements of the circuit in operating condition.

Choosing an air vent: expert advice

Such an important mandatory safety device for any heating network as an automatic air vent for heating must be chosen correctly.

It is usually supplied complete with other boiler equipment. If the home owner still has to choose an automatic air vent on his own, it is recommended to pay attention to the quality of the material from which the valve is made. It is necessary to protect yourself from all kinds of silumin fakes that imitate copper modifications. Professionals recommend choosing automatic devices with exhaust pipes directed upwards. According to reviews from numerous customers, on models with side outlets, leaks occur much earlier.

In addition, during installation it is necessary to ensure the vertical position of the device. Main recommendations for selecting air vents:

- It is more reliable to purchase a motorized air vent with a plastic or iron handle; this eliminates the need to carry various keys or screwdrivers with you. This faucet is convenient to use even in hard-to-reach places.

- In the case where young children live in the apartment, it is recommended to install an ordinary manual air vent, made for screwdriver control. Otherwise, children will be able to unscrew the air vent with a handle and scald themselves with boiling water.

- It is advisable to purchase devices with a self-acting cut-off device.

- If the estimate allows, it is possible to order a mechanism with additional options that can make servicing the heating network more comfortable.

- The high-quality anodized coating of the air vent essentially plays absolutely no role, but only reduces the level of rust formation on metals.

- Today in the retail chain it is possible to find combined modifications of heating network devices, which are also equipped with air vents. This list includes balancing valve devices, a variety of shut-off and safety valves and electric coolant circulation pumps.