Solid fuel in the form of firewood, coal and briquettes remains relevant, despite the emergence of other sources of heat generation. Electricity and gas are not available everywhere, and they are more expensive. But inefficient wood-burning stoves and potbelly stoves, which emit a lot of heat into the atmosphere, are becoming a thing of the past. Today, the pyrolysis boiler is more popular, differing from them in its combustion duration and higher efficiency. For comfortable living in a country house, this is the most economical unit in terms of fuel consumption and the most convenient to operate.

Pyrolysis boilers are suitable for all types of solid fuel Source eurosantehnik.ru

The principle of pyrolysis combustion

To burn wood or coal in a conventional stove, a constant supply of air is required, or rather, the oxygen contained in it, without which the oxidation processes that accompany combustion are impossible. Moreover, the influx must be constant and sufficient, otherwise the fuel will smolder and not burn, emitting a huge amount of flammable gases into the chimney along with the smoke.

A long-burning solid fuel boiler with a water circuit works differently; it retains these gases, mixes them with air and forces them to burn in a special chamber, completely transferring the heat to heat the house. It is the gas formed during the slow combustion of wood that is the main generator of thermal energy. Its combustion temperature is much higher than that of solid fuel.

Fundamentally, a pyrolysis oven differs from a conventional oven in the number of chambers and the ability to regulate the volume of air entering them using dampers. Its influx is specially limited so that the main fuel smolders and releases flammable gases.

The simplest diagram of a pyrolysis furnace Source sdelaikamin.ru

How to assemble a structure with a water jacket

The manufacture of the chimney is carried out in the following sequence of operations:

- Carefully cut the balloon at the top. The resulting cap is subsequently used to make a lid for the boiler.

- The bottom of the cylinder is equipped with homemade legs. Each of them must be exactly level before fixing.

The piston is constructed in three stages:

- A steel circle is cut out: in cross section it should be approximately 35-45 mm smaller than the internal diameter of the cylinder. Thanks to the side gaps, pyrolysis gases will leak into the secondary chamber without interference. A hole is made in the center of the circle for the air duct: this pipe should be inserted into it quite tightly.

- Next, the metal circle and pipe are welded to each other.

- A piece of channel is welded on top of the piston base.

To make a furnace lid, you can use the upper cut part of the cylinder. On its surface, markings are applied for the air duct pipe with a fixed supply piston. In this case, it is necessary to provide a certain margin for the free movement of the pipe. Cutting is done along the drawn lines. On the side, the homemade lid is decorated with handles, for which fittings bent in a vice are used. Now you can begin installing the chimney at the top of the improvised pyrolysis oven. Using a grinder, a cutout is made for the pipe blank: welding is also used to fasten the parts.

At this point, the main part of the work on the construction of Bubafoni is considered completed: it can be put into operation. It is advisable to install the stove on a pre-arranged foundation.

Comparison with conventional boilers: pros and cons

First, we list the obvious criteria by which a long-burning pyrolysis boiler outperforms classic wood-burning and gas stoves.

- High efficiency: in it the fuel burns almost completely, giving all the heat to the heating system, while the efficiency of a conventional wood stove is at best 75%.

- Fuel savings due to higher heat transfer.

- Long-term burning of one bookmark: depending on the boiler model and chamber volume, it can operate from 5-6 hours to a day, without requiring the addition of fuel and maintaining a comfortable temperature in the premises.

- No need for frequent cleaning: since the wood burns completely, forming a tiny amount of fine ash, you have to clean the stove much less often.

On a note! Ash from pyrolysis furnaces can be used as a ready-made fertilizer for indoor, garden and vegetable plants.

- Reliability: due to the simple design, breakdowns are rare.

One of the disadvantages is the need to use only dry firewood so that part of the heat does not go to drying it and evaporating moisture.

A supply of firewood for several days is kept in a drying room Source dumazahrada.cz

Like a regular wood-burning boiler, the pyrolysis unit can only be installed on the floor. It is quite heavy and large, and together with the fuel supply, it requires a lot of space, so it is recommended to allocate a separate technical room for it - a boiler room.

Another drawback is the energy dependence of most of these units - for correct operation they are equipped with fans and smoke exhausters.

Finally, a long-burning boiler will cost more when purchased and put into operation. Particularly versatile, capable of burning different types of solid fuels. Running only on wood – cheaper.

conclusions

Having considered how to make different types of pyrolysis furnaces, we can summarize that it is realistic to make only a structure from a gas cylinder. You won’t be able to build a brick oven yourself; it’s too difficult. A camping option made from cans also has a right to exist, but it can only be made at home; this cannot be done in the field. And finally, the exhaust furnace is simple but dangerous and requires very careful and careful operation. The risk is quite high, so we do not recommend it for heating a garage.

With the onset of winter cold, the owners of private households, who bear full responsibility for heating their homes, add more worries. In those rooms where the main heating power is weak or absent altogether (sheds, garages), you have to look for inexpensive alternative methods.

Types and features of work

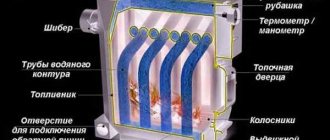

Unlike classic boilers, pyrolysis boilers have not one, but two combustion chambers. They are divided into two types: with bottom and top combustion.

Boiler

Fuel is placed in the upper chamber, ignited and a fan is turned on, which mixes flammable gases with air and distills them into the second chamber. It is located under the top and separated from it by grates - a lattice bottom. The main combustion occurs in it, the temperature of which exceeds 1000 degrees, while in the loading chamber it is much lower - 500-600 degrees.

Design differences between conventional and pyrolysis boilers Source ksao.ru

See also: Catalog of companies that specialize in the design and installation of fireplaces and stoves

To prevent firewood from burning quickly, air access to it is limited using a mechanical damper. The firebox is fully loaded, since at low load the long-burning pyrolysis furnace does not work efficiently, and when burning fuel, a lot of soot and ash are formed.

For reference! If the firewood is damp, then when the moisture evaporates, the internal walls of the unit become covered with soot and tar, which reduce heat transfer and cause the fire to die out. You can determine the quality of the fuel by the color of the flame - it should be light, yellow-white, not red-orange.

The coolant in such boilers is located in the space between the double walls of the housing - the so-called external heat exchanger. The high combustion temperature and large area of the heated surface of the heat exchanger leads to rapid heating of water and good circulation in the system.

Bottom combustion boiler in section Source prom.st

There is no ash pan in such stoves, since the main part of the combustion products is thrown out through the chimney, leaving only a small amount of fine ash in the lower chamber.

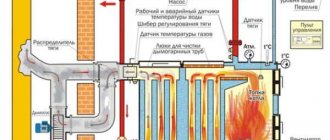

Top combustion boiler

A wood-burning boiler for water heating with an upper gas combustion chamber is designed differently. It usually has a cylindrical shape; the chambers in it are separated not by a grate, but by a movable pipe for supplying air with a disk.

- Before loading fuel, the moving element is raised upward using a cable located outside.

- Firewood is loaded through the door and ignited.

- The disk is lowered directly onto the firewood and air is forced into the combustion chamber.

- When fuel burns slowly, its level in the chamber decreases, changing the position of the air distributor.

- Combustible gases rush upward and, bending around the disk, enter the upper chamber, in which they mix with air and burn.

- The intensity of gas flow into the upper chamber is controlled by an automatic draft regulator, which determines the temperature of the water in the heat exchanger.

Diagram of a boiler with an upper afterburning chamber Source stropuva-nn.ru

Such long-burning pyrolysis boilers with a water circuit are less popular than those with a gas combustion chamber located at the bottom. Because they periodically have to change the movable air distribution element with the disk. It is constantly exposed to hot gases and flames, so it burns out.

But you can put fuel in it or burn household waste without waiting for the main filling to burn out. To do this, simply raise the disk above the door level.

Is it worth doing it yourself?

If you have the necessary knowledge, capabilities and drawings, then you can make a pyrolysis boiler yourself. The Belyaev pyrolysis boiler scheme is popular among the population. This technology cannot be called simple, however, it is one of the most accessible and implementable.

Boiler diagram. Photo source: balserv.ru

To make a pyrolysis boiler with your own hands according to the drawings, you need:

- metal pipe (D32,57,159 mm);

- profile pipe (20x20, 80x40, 60x30 mm);

- metal sheet;

- fireclay brick;

- air supply pump;

- temperature sensor.

In addition, you will need a tool and a welding machine. An assistant will be needed. First, the sheet parts of the installation are made, cut off with a precision tool, and then, following step-by-step instructions, the rest of the work on assembling a homemade boiler is completed.

Features of kindling

Having understood what a pyrolysis boiler is and how it works, you should learn how to melt it correctly. Especially for the first time or after a long period of inactivity. A cold firebox must be preheated; for this purpose, small kindling is first lit at the bottom and allowed to burn well with the draft open. Wood chips and thin logs are added until the chamber warms up and smoldering coals form in it that can ignite the main fire.

The firebox is loaded to the top and the wood is allowed to burn well, after which the damper is closed and the draft is reduced.

Basic criteria for choosing a unit

Buying a heating device is a responsible matter; not only the creation of a comfortable microclimate in the house, but also the ease of maintaining it, fuel costs, and safety depends on the right choice. Knowing what characteristics you need to pay attention to will make it easier to make the right choice. These include power, workmanship, duration of continuous operation, and type of fuel used.

- Power.

Selected according to the heated area. The simplest power calculation is based on the following relationship: 1 kW is required per 10 m2, provided that the ceiling height is no more than 3 meters. If it is larger, add another 3-5%. There are other calculation methods, for example, based on heat loss.

Formula for calculating the power of heating equipment Source avenue116.rf

Advice! It is better to choose long-burning solid fuel boilers for heating a private home with a power reserve of at least 10%. For example, with a house area of 180 m2, the unit must have a power of at least 20 kW.

- Workmanship.

Boilers with cast iron bodies are considered the best - this alloy is less susceptible to corrosion. But most modern models are made from sheet steel, the thickness of which must correspond to the power of the equipment. For household units with a power not exceeding 65 kW, it is enough that the thickness of the internal walls is 5 mm and the external ones 4 mm. With increasing power, these parameters should also change upward.

- Number of circuits.

A long-burning wood-burning boiler with a water circuit can provide not only heating, but also hot water supply to the house. To do this, it is equipped with an additional heat exchanger, which is connected to the DHW system.

- Loading chamber dimensions.

They are selected depending on the type of fuel and the required combustion duration.

The depth of the firebox of a wood-burning boiler should be no less than the length of standard logs and be 50-65 cm Source oboiman.ru

- Price.

You should not persist in choosing only imported equipment. Products from manufacturers from our country and neighboring countries are in no way inferior to it, but cost much less.

Reviews

The overwhelming majority of reviews from owners of this type of heating are positive. In most cases, they note the following positive aspects:

- excellent savings on raw materials and preservation of the family budget;

- the ability to use slightly damper firewood than those recommended by manufacturers (up to 20% humidity compared to the stated 12%);

- ease of operation;

- Reduced download frequency.

What deters people from buying is mainly the price of the issue and the insufficient distribution of this type in mass use. With a long period of use and permanent residence in the house, the price will pay off. If you pay special attention to the quality of the device and compliance with the installation process, there will be no problems during operation.

Types of solid fuel

Different types of fuel have different costs, amount of heat generated, burning time, and availability for a particular area. Before choosing a heating device, you need to decide what you will burn in it. You can buy a universal unit, but its price is usually high.

- Firewood.

A wood heating boiler allows the use of only dry fuel with a humidity of up to 20%. Depending on the technical characteristics, it can even allow loading uncut firewood. This is the most environmentally friendly solid fuel, but its disadvantage is its unevenness and relatively high combustion rate, which depends on the type of wood being burned and its density. The average operating time of a wood stove is 5-6 hours.

- Coal.

A firebox for burning coal must have vertical walls and a height of at least half a meter. All doors close hermetically. The disadvantage of this fuel is the need to maintain its uniform layer, and since it is difficult to ignite, a new portion should be added on time, preventing complete combustion to the grate. Plus – a very long burning of one bookmark, the duration of which can reach a day.

Coal-wood boiler ATMOS Source atmos.by

For reference! Most coal boilers can also burn wood.

- Peat briquettes.

Currently, wood heating is increasingly competing with peat heating. This type of fuel is produced in the form of pressed briquettes. It costs significantly less than coal, and is much more convenient to load.

- Pellets.

Pellets are fuel briquettes made from waste wood of various shapes and sizes. Their advantages: uniform combustion, high calorific value, minimal smoke formation, combustion without residue. Even if the briquette does not burn out, it can be reused. A big plus is the convenient packaging, as well as the zero humidity of the pellets.

On a note! When using firewood or briquettes as the main fuel, sawdust can be added to them, but not more than 25-30%.

Briefly about the main thing

Having found out what a pyrolysis boiler is and what its advantage is over classic types of solid fuel stoves, you can seriously think about using it for heating a house, workshop or garage. With an equal volume of fuel, it produces much more heat, since the gases produced by burning coal or wood are not released into the atmosphere, but are burned in a separate chamber. For most homeowners, their most important advantage is their long burning time without the need to add a new portion of fuel.

What is pyrolysis

This is the process of formation of flammable gas and its combustion in solid fuel boilers and stoves, where hot carbon monoxide is released when burning wood. When it is combined with oxygen, it burns with heat release and the formation of carbon dioxide.

Photo source: rpgrant.com.ua

In modern technology, this physical phenomenon is widespread. For example, the oven cleaning function works on this principle. Bubbling works in much the same way. Using this property of fuel combustion, manufacturers began to experiment with designs where the fuel did not burn immediately, but smoldered in the absence of oxygen, releasing CO (carbon monoxide).

The resulting gas was supposed to be burned in another chamber. As fuel, you can use ordinary chopped firewood or special charcoal briquettes (Tyumen Pyrolysis Plant).

In addition to pyrolysis boilers that run on wood, there are models that run on coal. Some work on natural draft.