Autonomous heating systems are becoming the most preferred not only among owners of private houses, but also among apartment residents or owners of non-residential premises.

The ability to control the heating mode yourself and determine the start and end time of the heating season attracts many people, and constantly rising housing and communal services tariffs only strengthen this preference.

Gas boilers are considered the best option for creating your own heating.

They are economical, capable of operating automatically and require almost no human intervention.

Let's consider the most successful models of mounted gas units.

Features of double-circuit wall-mounted gas boilers

Double-circuit boilers are capable of simultaneously performing two functions:

- Heating of coolant for supply to the heating circuit.

- Preparation of hot water for domestic needs.

Wall mounting places special demands on the design of the units. The weight of the boiler should not be too large so as not to create excessive load on the load-bearing planes.

Therefore, the power of the units is limited and rarely exceeds 45-50 kW. Wall-mounted boilers are allowed to be installed in a kitchen or other room, but the general requirements for gas installations also apply to them.

For example, you cannot install such a unit in a living room or other unfenced area . In addition, for installation you should choose only strong solid walls, ideally load-bearing ones.

These requirements put the owner within a certain framework, but no significant problems arise, since the vast majority of users prefer to install double-circuit wall-mounted boilers in the kitchen.

NOTE!

If installing the boiler on a temporary partition or insufficiently strong wall is impossible, a ramp - a special supporting structure that allows installation anywhere in the room - can be a way out.

Distinctive features of heat exchangers

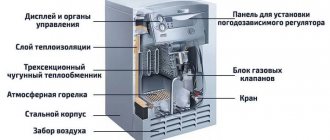

The heat exchange unit of the heating device can be cast iron, steel or copper. The cast iron version retains heat for a long time, is almost not subject to corrosion due to the high wall thickness and is resistant to aggressive coolants. It is heavy and therefore mainly integrated into floor-standing boilers.

Requires great care during installation, since any impacts violate the structural integrity of the material and lead to the formation of microcracks.

The steel structure weighs little, is not afraid of mechanical stress, can easily withstand temperature changes in the coolant, and is easily transported and installed. Has some tendency to corrosion. The boiler control system helps to avoid it, which prevents the coolant temperature from falling below the critical point.

Copper elements are an order of magnitude more expensive than their cast iron and steel counterparts, but they compensate for the substantial cost with a large number of advantages. Inside the copper heat exchanger, sediment and scale are formed to a minimum and do not interfere with the normal circulation of the working fluid. The walls of the device are heated evenly and do not cause local overheating of the coolant.

What parameters should you pay attention to when purchasing?

When choosing the most suitable gas boiler, you should be guided not so much by the name of the manufacturer, but by the technical characteristics of the unit.

All manufacturers have a wide range of equipment with different parameters, so you need to have an accurate understanding of the properties and features of boilers.

Let's look at them in order:

Unit type

There are two types of boilers:

- Convection . This is a common, common design, where the coolant is heated by burning gas in a burner.

- Condensation . This is a relatively new, two-stage coolant heating technology. First, it is slightly heated using the thermal energy released when water vapor condenses from the exhaust smoke. The coolant then enters the primary heat exchanger and receives final heating. This results in noticeable savings on fuel consumption and increases the durability of the most heavily loaded boiler components . At the same time, the condensation model can only work in low-temperature systems. It is calculated that the process can only occur when the difference between internal and external temperatures is no more than 20°. For Russia, such a ratio is impossible, only in the southernmost regions.

When choosing a boiler, you should understand its specifics and purpose. Condensing boilers cost almost twice as much .

Spending money on a feature you can't get is unacceptable.

Power

The boiler power level is directly related to the area served. For most models, the rule is that 1 kW of power is required to heat 10 m2 of area .

Guided by this rule, it is easy to choose a suitable boiler for your home. At the same time, the power level does not affect DHW performance so directly, although there is a certain dependence.

When choosing, you need to clarify the parameters of this unit, checking the technical characteristics from the device passport.

IMPORTANT!

It is not recommended to choose a unit “for growth”, with a large power reserve. The boiler will operate in abnormal mode, heating will constantly start and stop immediately, which will lead to rapid wear of the burner and heat exchanger.

Combustion chamber type

There are two types of combustion chambers:

- Open (atmospheric) . A design in which air is taken directly from the room, and smoke is removed under the influence of natural draft. It requires connection to a common house chimney, which limits installation possibilities (it becomes tied to the location). In addition, natural cravings are extremely unstable and susceptible to external factors.

- Closed (turbocharged) . The air is supplied using a fan, which at the same time performs the function of smoke removal. Such boilers do not need to be connected to a common chimney, using horizontal chimneys of the coaxial type (pipe-in-pipe design). The operation of such a boiler does not depend on external factors, and is more stable and adjustable.

Atmospheric boilers are capable of operating in energy-independent mode, although in practice this has not been the case for a long time. Wall-mounted models are all volatile and do not work without power supply .

This makes turbocharged units the most convenient and preferable, as they are more stable and reliable in operation.

Heat exchanger material

The heat exchanger of gas boilers can be made of different materials:

- Stainless steel . This is the most common option, relatively inexpensive and quite effective.

- Copper . It features high heat transfer, durability and practicality. Boilers with a copper heat exchanger are expensive. As a rule, these are models from top companies from Europe (German or Italian).

- Cast iron . There are no models with a cast iron heat exchanger among wall-mounted gas boilers. This is due to the large weight of the units, which allows only floor installation. Such boilers have high power and efficiency, they are efficient and durable.

There are also secondary heat exchangers responsible for preparing hot water. Most of them have a plate design and are made of stainless steel .

There are combined (bithermal) heat exchangers that combine the functions of heating coolant and hot water in one unit.

They are effective, but quickly become covered from the inside with lime deposits, which disrupts the heating mode and leads to rapid failure of the boiler.

Model differences in power

Double-circuit boilers are divided by power into single-stage and two-stage. Single-stage devices always operate at a constant power level and use the same amount of fuel resource year-round.

This is not effective and entails excessive gas consumption, because a house or apartment requires high-quality heating for no more than 5 months a year. At all other times, running the equipment at full power is neither reasonable nor economically profitable.

When installing equipment with a base power of 30 kW, you should know that these types of devices should not be located in residential premises, but in separate rooms equipped with a high-quality ventilation system, individual access to the street and a full-fledged chimney

The functionality of two-stage devices is wider.

With it you can:

- regulate the gas flow regime and rationally consume fuel;

- reduce the number of on/off switches, thus reducing equipment wear and extending its service life;

- reduce the volume of harmful emissions into the air to a minimum.

Additionally, the device is equipped with a smooth switching module, which reduces energy consumption and allows you to simultaneously operate a boiler and a boiler of any capacity, installed separately.

TOP 10 rating

Let's look at the most popular models of gas boilers from different manufacturers:

Buderus Logamax U072-24K

A compact, reliable boiler from a subsidiary of Bosh, which in itself sufficiently characterizes the unit. The design is of a traditional type for European heating engineering - a separate heat exchanger, the primary one is made of copper, the secondary one is a stainless steel plate.

DHW heating occurs in flow mode. The power of the unit allows you to heat an area of up to 240 m2.

The service life declared by the manufacturer is 15 years.

Federica Bugatti 24 Turbo

Italian gas boiler of convection type with a closed burner.

Manufactured in accordance with European requirements for reliability, full protection from external factors, and has a relatively low price . It demonstrates fairly high DHW performance, which is positively perceived by users.

The high quality of assembly of the unit is also noted. A separate heat exchanger was used (primary copper, secondary stainless steel plate) .

Has a built-in water filter.

Oasis BM-16

Gas boiler with bithermal heat exchanger. Designed to heat an area of up to 160 m2.

The combustion chamber is closed type. All modern protection systems are present - self-diagnosis, control of gas supply and flow, safety valve, etc.

The manufacturer's warranty is 2 years, and the total service life is 12 years.

Bosch Gaz 6000 W WBN 6000-24 C

A German gas convection boiler that provides heating for a house up to 240 m2 and supply of hot water in flow mode. Optimal for wall mounting - it is light, compact, and has an attractive appearance.

The built-in thermal disinfection system increases the capabilities of the boiler and makes it more preferable for domestic use than alternative options.

The copper primary heat exchanger ensures the unit's service life of up to 15 years or more.

Leberg Flamme 24 ASD

Convection wall-mounted double-circuit boiler, belonging to the economy class. Has a separate heat exchanger made of stainless steel . The power of the unit is 20 kW, which is optimal for rooms up to 200 m2.

The manufacturer's warranty is 2 years, there are all the necessary protection and controls.

Lemax PRIME-V32

A representative of domestic heating engineering, successfully competing with European models of gas boilers. Produced in Taganrog, Russia.

This model has a power of 32 kW, which allows servicing rooms of 290-320 m2.

Equipped with a closed combustion chamber, modulated burner, and electronically controlled. Warranty period - 2 years.

Navien DELUXE 24K

Korean double-circuit wall-mounted boiler with a closed combustion chamber and a separate heat exchanger. The power of the unit is 24 kW, which makes it possible to provide thermal energy to 240 m2 of residential or public space.

It has a very successful set of functions and a relatively low price. The main feature of the boiler is its high DHW productivity - at 25° it produces 13.8 l/min.

Can be controlled from the remote control or remotely.

MORA-TOP Meteor PK24KT

A Czech company that produces a wide range of heating boilers for various purposes and designs. The Meteor Plus series consists of dual-circuit models with a closed combustion chamber .

The units have a good price-quality ratio and demonstrate quite satisfactory performance. There are all ways to protect against external or internal influences. The PK24KT model is capable of developing a power of 24 kW, which is optimal for rooms of 220 -240 m2.

There are auto-diagnostics and other means of protection against external or internal problems.

Lemax PRIME-V20

Another model from a domestic manufacturer. The boiler power is 20 kW, suitable for heating a house of 200 m2 . This is a common size of a private house or cottage.

The manufacturer takes into account the climate and technological operating conditions of the equipment, which makes Lemax PRIME-V20 boilers preferred and in demand among users.

Navien ATMO 24AN

Wall-mounted double-circuit gas boiler from the Korean company Navien. Belongs to the ATMO line, consisting of units with an open combustion chamber .

Equipped with copper primary and stainless steel plate secondary heat exchangers. There is electronic control and several degrees of protection.

The power of the unit is 24 kW, designed to heat 240 m2.

NOTE!

Most models of gas boilers have almost the same performance, which is explained by the high degree of design elaboration and the presence of high-quality parts and components.

What is important to do before installation work begins?

Before purchasing a gas boiler for an apartment, there are requirements that must be met:

- obtain permission from the gas service to install heating equipment;

- select the room and location where the unit will be located;

- take care of the availability of high-quality ventilation;

- choose a coaxial chimney and think about how it will be laid.

You cannot install gas equipment in apartments:

- multi-storey buildings not connected to the main gas pipeline;

- where there are false ceilings and capital mezzanines.

To carry out installation, it is better to call specialists who have the right to perform such work.