The manufacturer Buderus, part of the Bosch group of companies, produces heating equipment of various models, which are characterized by traditional German quality and reliability.

Buderus boiler errors are various problems in operation: from minor failures in which the equipment continues to function, to malfunctions that cause it to shut down. Failures invariably occur during the operation of the heating system, and in order for the boiler to last a long time, but without having to call a technician at every display signal, the user needs to learn how to decipher the most common Buderus error codes and correct minor problems with their own hands.

Malfunctions of Buderus boilers

If you are not 100% sure what exactly the problem is and that you can solve it, immediately contact the service center to diagnose and fix the problem.

The burner does not turn on

The emergency switch for the heating system is in the off position - on.

Control system start switch in off position - turn on.

The circuit breakers are faulty - check their functionality and, if necessary, replace the defective circuit breaker.

The boiler water temperature regulator is damaged - check and, if necessary, replace defective parts.

The safety temperature limiter is damaged - check and, if necessary, replace defective parts.

Error message from external safety devices (for example, from a water level safety device) - the consumer must check the Buderus boiler, eliminate the fault and, if necessary, replace the element.

The flue gas monitoring system has activated:

- AW 10 - unlock the flue gas control system;

- AW 50 - Wait a maximum of 15 minutes.

The boiler will turn on automatically if there is a request for heat. If it is triggered multiple times, check the flue gas path and check the functionality of the flue gas control system. If there is a defect, replace it.

The burner starts and switches to fault. No spark when igniting

Is there a sound when an ignition spark forms when the ignition cable is removed?

- If not, then replace the ignition transformer;

- If yes, then replace the ignition electrode or ignition burner.

Burner starts and switches to fault

All gas shut-off valves are closed - open the gas shut-off valves.

Natural gas supply pressure is more than 8 mbar - if not, determine the cause and correct the problem.

Has air been removed from the gas pipeline? Remove air until gas can be ignited.

The Buderus boiler burner starts and switches to fault. No ionization current

If connections N and L are mixed up, eliminate the error.

Is there voltage between L and PE? If not, ground the PE, in this case install an isolation transformer.

Poor contact of the ionization wire - eliminate the error, in this case, replace the defective part.

Short to ground on the ionization electrode - correct the damage.

Burner control defective - replace element.

The burner starts and switches to fault. Ionization current less than 1.5 mA

The core or ceramics of the ionization electrode is dirty - clean the ionization electrode and, if necessary, replace the ignition burner.

Boiling sounds

Lime deposits or scale formation in the boiler - clean the water circuit of the heating boiler in accordance with the manufacturer's recommendations.

If there is constant water loss, determine and eliminate the cause. If necessary, carry out water treatment and install a dirt trap.

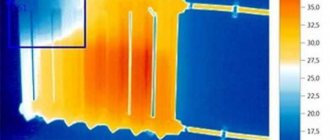

Measuring instruments for setting up heating systems

Due to rising energy prices, proper adjustment of heating equipment is becoming an important component for optimizing utility costs. Testo portable flue gas analyzers will help you complete any task of setting up, commissioning and servicing heating equipment

Professional gas analysis with testo 330-1 LL h4>

The testo 330-1 LL gas analyzer with extended sensor life is a reliable device for diagnosing faults in heating equipment and for monitoring the level of emissions of harmful substances into the atmosphere or for the daily work of heating system specialists. It is able to meet the highest demands placed on a gas analyzer: the highest sensor accuracy and sensor service life.

Professional gas analysis with testo 330-2 LL h4>

In addition to all the advantages of the Testo 330-1 LL gas analyzer, you can use the testo 330-2 gas analyzer with higher CO concentrations in the flue gases. This is achieved through the built-in function of automatically diluting the flue gas sample with a factor of 5. You will receive additional convenience by using the pressure/draft sensor zeroing function with the probe remaining in the chimney.

Highly efficient gas analysis with testo 320

h4>

Gas analyzer Testo 320 is a multifunctional flue gas analyzer for heating system specialists. The intuitive menu structure and ease of operation of the testo 320 gas analyzer, combined with a high-resolution color display, allow you to carry out all the necessary measurements during installation, commissioning, service and maintenance of heating boilers and burners.

Basic level gas analysis testo 310 h4>

The testo 310 gas analyzer combines ease of use with high measurement accuracy and is ideal for all basic measurements on gas boilers and burners. The long battery life guarantees the possibility of long-term use of the device, including for a series of measurements of flue gas concentrations

Soot number analyzer Testo 308 h4>

The Testo 308 soot number analyzer helps you measure the soot number. The built-in pump and the automatic display of the measured value on the backlit display allow you to obtain data on the soot content in the chimney using a modern measurement method. This measurement method is comparable to traditional soot number measurement methods using a hand pump.

Easy management of measurement data with easyHeat software h4>

With Testo's dedicated software, you can easily transfer data from your gas analyzer to a PC for further processing. A wide range of functions, such as customer data and measurement management, allows you to optimize the work of planning service activities at your customers' sites.

Error 6A

Error 6A, displayed on the display of wall-mounted gas boilers Buderus Logamax U 072 on absolutely all models with a power of 12, 18, 24, 28 and 35 kW, signals the absence of a flame on the burner. To control the flame in the combustion chamber, an ionization electrode is installed on the burner, through which a small current flows during gas combustion, that is, a certain amount of free electrons and negative ions, which are transmitted to the control board via wire. If for some reason the ionization intensity drops below a certain level, the control board, after three attempts to ignite the burner, displays an error code on the display and the boiler goes into trouble!

This malfunction is extensive and a large number of elements will have to be checked.

You need to start with the most basic thing, this is to make sure that the gas valve is open, what if someone turned it off, and that’s why there is no gas!

Secondly, you need to make sure there is sufficient gas inlet pressure. To do this, connect a pressure gauge to the gas valve fitting and make sure that the pressure is between 17 and 25 mbar.

Third, while the pressure gauge is connected to the gas valve, check that the gas operating pressure adjustment in the minimum and maximum modes is consistent. But this is only in the case when the boiler can work for a short time after resetting the error. If the boiler does not start, then you will not be able to do this.

Fourthly, you need to check the gas fittings themselves for the presence of power and the serviceability of the coil and solenoid valve.

If anything is faulty, the gas fittings must be replaced.

Then we move on to inspecting the electrode and wires. Here you need to check the wire for breaks and its reliable connection to the electrode and the control board. There should be no cracks or chips on the ceramic part of the electrode, and the metal rod itself should be clean and located at a distance of about 8 mm from the burner.

Next, fifthly, be sure to check the flue gas system for correct assembly and, as trivial as it may sound, for the absence of foreign objects and debris in it. And if the malfunction appears in winter, then there is a possibility of ice forming on the chimney head.

Sixthly, the heat exchanger and burner in the combustion chamber must be clean and free of dust and soot. Otherwise, the lack of proper combustion due to lack of oxygen and carbon deposits can lead to incorrect readings from the ignition electrode, and to be honest, you don’t want to suffocate from carbon monoxide! I recommend maintenance at least once a year!

And lastly, seventh, this is a malfunction of the board, which can be checked with a multimeter by measuring the voltage on the coil and electromagnet. If there is no voltage, then you need to replace the board with a new one!

This error 6A is critical and after eliminating the fault the boiler will not start on its own, so you need to manually press the RESET button and reset the error.

Using the sequence when troubleshooting, you can eliminate any non-functioning component and start the boiler so as not to freeze in winter. If I helped you solve the problem, then I did everything right! Support me with your thumbs up and subscribe to the channel! Until next time, see you!

Device

Buderus gas boilers are designed using advanced engineering developments based on many years of production and technical experience. The main design element is a gas burner combined with a combustion chamber and a copper primary heat exchanger.

In this unit, the coolant is heated to the maximum possible value specified by the operating mode. After this, the OM goes into a secondary plate-type heat exchanger made of stainless steel.

That OV gives up part of its thermal energy to prepare hot water. The coolant then flows into a three-way valve (or mixing unit), where it is partially combined with the cooler return flow to obtain the desired temperature.

The fully prepared coolant enters the heating circuit. The movement of liquid is provided by a circulation pump. A turbocharger fan is used to organize combustion and remove smoke.

The entire operation of the boiler is constantly monitored by a system of sensors connected to the control board.

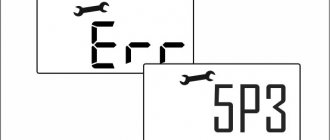

NOTE! Any malfunctions are immediately displayed on the display using a particular error code. Next to the display there are control and setting buttons that allow the user to change the operating modes of the boiler at will.

Buderus boiler malfunction

Like any other wall-mounted boiler, Buderus is equipped with a protection system and if an emergency occurs, the operation will be stopped and the user will receive an error message indicating in which system of the unit the malfunction occurred.

Some devices are equipped with an LCD display, and the user will see an error code. If the boiler is not equipped with a display, the fault will be indicated by flashing temperature indicators. For example, if the temperature indicator flashes 80, this means a 3C error, which would appear on a similar boiler with a display.

A complete list of error codes reflected by blinking indicators can be seen in the figure. Next, we will consider the most popular errors and recommendations for eliminating them.

What series and models are wall mounted?

Buderus wall-mounted boilers are represented by one large Logamax line, which consists of 4 series:

- Buderus Logamax U042 / U044. Double-circuit installations with a power of 24 kW. Equipped with a bithermic heat exchanger, which allows you to simultaneously heat both the coolant and hot water. There are models with a closed (042) and open combustion chamber (044).

- U052 / U054 K. Single- and double-circuit boilers with an open (054) and closed (052) combustion chamber. For dual-circuit models, the designation contains the letter “K” (combined). Two models are available with a power of 24 and 28 kW.

- U052 T / U054 T. 24 kW model with open or closed combustion chamber. A special feature is the presence of a 48-liter hot water storage tank, which allows you to meet high demands for hot water.

- U072. The most popular series of turbocharged boilers with a capacity of 12, , and kW. Single and double circuit models are available. High demand is due to the relatively low cost of boilers. Equipped with two heat exchangers - primary (for coolant) and secondary (for hot water supply). The most popular boilers are 24 and 35 kW, producing up to 12 and 16 liters of hot water per minute, respectively. Capable of heating 240 and 350 m2 of residential, public or commercial areas.

When choosing a boiler, you should compare its characteristics with the size of the room and the family’s need for hot water. The manufacturer provides a choice for any conditions, which allows you to get the best option.

Date: September 25, 2020

Buderus error 3c (fourth indicator 80 flashes)

If such an error occurs, the boiler control board does not receive a signal from the differential pressure switch, that is, its contacts do not close after the fan starts. The pressure switch is used to determine the necessary conditions for removing combustion products.

The procedure for putting the boiler into operation is as follows:

- The control unit gives a signal to start the fan

- The fan creates the necessary vacuum in the exhaust pipe

- The differential relay registers the vacuum and the microswitch contacts close

- The board sends a signal to open the gas valve and ignite

Therefore, to understand the problem, you need to determine at what specific moment the boiler goes into error. If the fan starts, but the relay does not click, it is tedious to inspect the supply pipes; perhaps there is a blockage or condensation, or there is actually a blockage in the chimney itself.

If the fan does not start, you need to check whether voltage is supplied to it. A faulty electronic board may be the reason why the fan does not start.

If the fan is working, there are no problems with the chimney and the pneumatic relay tubes, you need to check the pneumatic relay itself, creating a vacuum yourself and checking for a characteristic click.

Constantly closed relay contacts or their opening during burner operation will also be regarded by the security system as a malfunction.

Buderus boilers can be equipped with a fan with adjustable rotation speed, which is controlled electronically and equipped with a sensor.

Start-up and operating instructions

Before turning on the boiler for the first time, it is necessary to install it on a wall or ramp (supporting structure), connect all communications and power supplies. These actions are performed only by gas service specialists or authorized technicians from the service center.

Be sure to check gas pipe connections using soapy water. The system is then filled with water, guided by the pressure readings on the display. It should not be brought to the limit; it is enough to provide 0.8 Bar.

When heated, the coolant will expand, causing the pressure to rise and reach its optimal operating value.

The Buderus Logamax u072 24k boiler is started using the “Stand-by” button.

At the same time, the display will show the current temperature of the coolant. When you first start it is set to minimum, so to start working you should set the desired heating mode. The burner and circulation pump will start, and the boiler operation will begin.

Operation of the unit does not require any special actions from the user.

The temperature is adjusted periodically according to weather or climatic conditions.

Once a year you need to call a technician to carry out maintenance; if breakdowns occur, a specialist from the service center is also immediately invited.

Useful tips

Checking all electrical circuits

Errors that appear on the Buderus display are generated in the electronic board of the boiler based on signals received from the corresponding sensors. The first step in solving any problem should be to check all electrical circuits. Loose contacts, oxidized lamellas - this can be eliminated in a few minutes. It will not take much more time to replace the wire in case of insulation melting or breakage.

Instability in the power supply often triggers Buderus errors. This often manifests itself at sites in intensively built-up areas. Periodic switching on of welding machines and powerful heaters leads to voltage surges and phase imbalance. The conclusion is simple: before searching for the cause of the boiler error display, you need to check the parameters of the supply network.

Uninterrupted operation of Buderus is ensured by its connection via a UPS. The stabilizer will not give the desired effect, especially since it is provided for in the electronic circuit of the boiler. The power supply supplies voltage even if there are problems with power lines due to the built-in batteries; depending on their total capacity from 2 to 14 hours. For suburban properties this is a more than rational solution.

Not everyone carefully reads the manufacturer's obligations. One of the guarantee conditions for Buderus is professional installation. The absence of a service organization mark in the boiler passport is the reason for refusal in case of user complaints. In order not to pay for warranty service or repair of heating equipment out of your own pocket, it is better not to do independent installation and piping (in order to save money) with Buderus.

Advantages of wood-plastic - natural wood rests!

We hope that from our short review you understood how liquid wood is produced and figured out what it is. The described wood-polymer products are characterized by a number of operational advantages. We present the main ones below:

- increased resistance to mechanical damage;

- resistance to temperature changes (WPC products can be used at both +150 °C and -50 °C);

- high moisture resistance;

- ease of self-processing and installation (for these purposes, use a tool that works with natural wood);

- long service life (minimum 25–30 years);

- large selection of colors;

- resistance to fungus;

- ease of maintenance (the composite is easy to clean, it can be scraped, varnished, painted in any color).

An important advantage of wood-plastic is that it has a very affordable price. This is achieved through the use of recycled products (crushed plywood, sawdust, shavings) in the production of WPC. It is difficult to find shortcomings in the material we are considering, but they exist. What would we do without it? Wood-plastic has only two disadvantages. Firstly, when using it in living rooms, it is necessary to provide high-quality ventilation. Secondly, WPC is not recommended for use in cases where high humidity and elevated air temperature are simultaneously and constantly present in the room.

The special characteristics of a composite of wood and plastic make it possible to manufacture various construction products from it. This material is used for the production of exterior siding, garden parquet, smooth, hollow, corrugated and solid decking (in other words, decking boards). WPC is used to make chic balustrades, elaborate railings, secure fences, luxurious gazebos and many other structures. Wooden plastic will allow you to luxuriously arrange the interiors of your living space and make your suburban area truly beautiful.

Problems not shown on the display

When they occur, the Buderus error is not displayed, but a number of signs indicate incorrect operation of the boiler or the entire heating system.

Adjusting the circulation pump

1. Slow heating of batteries; noise of fluid circulating along the circuit. The main reason is the incorrectly set pump speed. The switch is located on its body.

2. “Difficult” ignition, boiler efficiency is lower than declared. There are several options: from poor burner performance to the use of gas with characteristics that do not meet the manufacturer’s requirements.

Recommendation: carry out Buderus service, check the set parameters.

The article provides explanations for all problems that can be resolved independently. It’s better not to go deeper - the boiler is expensive, and unprofessional intervention in its operation will not lead to anything good.

Kinds

Buderus double-circuit boilers are predominantly wall-mounted.

All floor-standing installations are single-circuit, but have the ability to connect an external indirect heating boiler, which allows you to obtain a full-fledged hot water circuit. There are different design options for dual-circuit installations.

According to the type of thermal energy transfer, they are:

- Convection. Heating is carried out in the usual way, in the flame of a gas burner.

- Condensation. A new technology that makes it possible to use thermal energy obtained by condensing water vapor contained in flue gases. The coolant is preheated in the condensation chamber, due to which it enters the primary heat exchanger already prepared. As a result, it becomes possible to reduce the intensity of the main heating, reduce gas consumption and achieve an efficiency of 108%.

NOTE! From a theoretical point of view, such efficiency is impossible. This is a common marketing ploy designed to increase demand. However, condensing boilers can only operate effectively under appropriate conditions - if the indoor temperature is +20°, then the temperature outside should not be below 0°, otherwise the boiler will work like a regular convection unit

However, condensing boilers can only operate effectively under appropriate conditions - if the indoor temperature is +20°, then the temperature outside should not be below 0°, otherwise the boiler will work like a regular convection unit.

According to the type of combustion chamber there are:

- Open (atmospheric). Air enters the boiler directly from the room, and smoke is removed using natural draft.

- Closed (turbocharged), the air supply and smoke exhaust are produced by a turbocharging fan.

For use in private houses or apartments, turbocharged boilers are more convenient, which are capable of providing stable draft that is independent of external conditions.

Buderus boiler error 6a how to fix

First of all, you need to exclude the accidental occurrence of an error and simply reset it. If the error occurs again and the boiler does not start, then the problem requires a solution. In most cases, ignition problems can only be corrected by a qualified specialist. The simplest thing that can be done is to inspect the combustion chamber and electrodes for contamination and clean if necessary.

If the boiler makes unsuccessful attempts to ignite, visually check that the spark is striking the burner and not somewhere else. If you hear a crackling sound, but there is no spark between the electrode and the burner, the insulation of the electrode is probably damaged somewhere and needs to be replaced.

The gas valve can only be adjusted by a specialist. Checking the presence of proper network gas pressure can be done through a gas stove. If you light all the burners on the stove at the same time, they should work without interruption. If this is not the case, we can assume that the incoming pressure is not enough and you need to call the gas service.

In our practice, there was a case when a crack in the combustion chamber inspection window was the cause of a malfunction.

If the boiler lights up, but goes out after a while, this may be due to a faulty electronic board. You can check by replacing the board with a known good one.

Connection instructions

The Buderus boiler is connected after installation on a solid wall or a special ramp.

All communications are connected:

- Forward and return lines of the heating circuit.

- Water supply.

- Gas pipeline.

- Power supply.

Particular attention is paid to the condition of gas pipeline connections. They should be checked with a soap solution to detect leaks

Then the power supply is connected through a special socket with a grounding electrode.

The boiler starts after the system is filled with water. It is poured using a refill tap, bringing the pressure to approximately 0.8 bar.

This is necessary in order not to exceed the pressure when heating, so the water will expand. After filling the system, the boiler is turned on and the required coolant temperature is set. The burner will start and the boiler will start working.

When starting for the first time after a long period of inactivity, you often have to make several startup attempts due to air locks in the system. When they are all removed, the operation of the unit will be stable and smooth.

Fault codes for gas boilers and methods for eliminating them

The most popular among consumers is the Logamax model, which produces not only heating, but also hot water. It is equipped with an automatic system that diagnoses components and, if there are problems, displays error data.

If the error appears on the screen for the first time, you need to try rebooting the device. Sometimes it happens that after such manipulation it does not happen again. If the fault code for the Buderus mounted gas boiler is displayed again, then you need to find the cause of the problem.

| Error code | Causes | Elimination method |

| A- | The Chimney Sweep mode is enabled. The error disappears after 15 minutes | |

| -N | Heating mode activated | |

| =N | Hot water mode active | |

| OA | The boiler is in the mode between turning the burner on and off | |

| OS | Starting the burner | |

| OE | Thermal energy production is less than the minimum output of the device | |

| HE | Indicates the equipment is ready for work | |

| 0L | Opening gas valves | |

| 0U | Starting the unit | |

| 0Y | System shutdown because the water temperature in the supply pipe exceeded the set one | |

| 2E | The boiler is in venting mode. ... The supply temperature rises rapidly | Measure the water pressure or add coolant to the system |

| 2H | Protection of the pump and 3-way valve from jamming | |

| 2P | The hot water temperature rises quickly. | It is necessary that the pressure corresponds to the norm. Checking the pump, repairing or replacing it |

| 5H | Automatic testing | |

| H11 (CL) | Malfunctions in the DHW temperature sensor | The temperature sensor and its connection are checked. |

| H13 | The inspection time has passed | Perform inspection and reset errors |

| H31 | The system does not see the pump | Check the pump wiring and functionality |

| 0Y | The inlet coolant temperature is higher than the maximum permissible (more than 95ºC) | Diagnose the temperature sensor. Inspect the pump, connect it to the regulator. Adjust pump power |

| 3A (A3) | Fan doesn't work | Tighten the fan wires, replace the broken element |

| 3F | Continuous operation of the fan and burner lasts more than 24 hours. Turning on the "rest" mode | |

| 3U | The fan is spinning too fast | Check the chimney for serviceability:

|

| 4C (1C) | Heat exchanger overheat protection activated | |

| 4U | The supply temperature sensor may have short-circuited | Checking contacts, replacing parts |

| 4Y | Temperature sensor break | |

| 6A | No flame | Open the gas valve fully. ... There may be no draft - you should check the permeability of the chimney. Check the flow switch, replace it if necessary. Clean the sensor contacts and reconnect the wiring. Clean the burner jets. Replace faulty items |

| 6C | False signal about the presence of flame in the burner | Check the following components:

|

| 6L (def) | The burner works, but there is no signal from the ionizer | Change settings and restart burner |

| 7L | Timing control error on first delay or second start | Check the wiring that leads to the control module. Replace BC20 regulator |

| 9L (d7) | There were problems with gas fittings | Check the gas fittings and their wiring |

| 9P | There is no communication with the unit identification module | Install the module in the correct position |

| 9C | DIP control is not set correctly | Reconfigure |

| EL | Control modules are broken | Replace damaged items |

| 8Y | The temperature relay has tripped or is broken. There is no jumper between the relay terminals | Adjust the relay. Install the jumper. Check capacitor wiring and functionality |

| fd | Activation of the button for more than 30 seconds. | Press this button again and hold for less than half a minute |

Popularity of the German manufacturer

There are hundreds of companies that produce gas boilers, but German products are an order of magnitude superior to them in reliability and quality. What is the reason? The basis of the highest quality, the famous German quality, is pedantic and careful design, scrupulous selection of materials and components. After the prototype has been manufactured, tests are carried out and the design is adjusted based on the test results, and only then the production of the product begins.

Therefore, boilers from German companies are popular all over the world. They have proven themselves to be reliable, durable and economical devices with high efficiency. For example, Buderus convection gas boilers have an efficiency of up to 97%.

Elimination of defects in work

Usually, the appearance of an error does not mean that the boiler is broken. It is possible that the sensor may trigger falsely in response to a power surge or for other reasons.

Therefore, the first reaction to an error is to reset it and restart the boiler. If the error appears again and again, more effective measures must be taken.

Let's look at ways to eliminate the most common errors:

- F03. Boiler overheating. The temperature of the heating agent rose to the maximum 95°. After the temperature drops, the boiler will start automatically. If the error persists, the thermal fuse must be reset.

- F04. Failure of the DHW sensor. Check the contacts and clean them from oxides. As a last resort, replace the sensor.

- F10-11. Failure of the supply or return temperature sensors causes the boiler to shut down due to the inability to control the degree of heating of the system. Check the condition of the sensors, clean the contacts, and if the problem recurs, replace the faulty element.

- F20. Overheating of the boiler can happen for various reasons. Most often, the culprit is poor circulation due to a broken pump impeller. It is also often difficult to heat water due to layers on the walls of pipelines. The sensors do not confirm that the set temperature has been reached, and the heat exchanger outside is already too hot. The solution to the problem will be flushing the heat exchanger.

- F28. Check the presence of gas in the line. Clean the ionization electrode using fine sandpaper. Check the condition of the boiler grounding circuit. If all these measures do not give a positive result, look for the reason in the boiler’s electronic board. Most often you have to change it.

- F62. Gas valve malfunction. The device requires maintenance, cleaning and lubrication. There may also be problems with the electronic control board.

- F75. Problems with the pressure sensor. Check the total pressure in the system. Inspect the condition of the pump. Bleed the air in the radiators using a Mayevsky tap.

It is inappropriate to provide a complete list of problems and ways to eliminate them, since the very name of the error most often contains a hint on how to fix it. The predominant type of solution to the problem is to replace the unreliable element.

What is an electric boiler

An electric boiler is a special high-tech equipment designed for heating various types of premises. A distinctive feature of such a unit is the use of a special type of fuel - electrical energy. In many respects, the boiler is superior to equipment operating on other types of fuel: liquid, solid, gas.

Electrical equipment is considered the safest to use. But in order for it to function well, it is necessary to strictly follow the rules of its operation and perform timely technological maintenance.

Watch the video about the operating principle and design of the Protherm Skat electric boiler.

Device

Despite the wide variety of boilers with different operating principles, the design of all models is approximately the same. The main place in the structure is given to the heating element. Depending on the type of heater used and the principle of its operation, there are several types of boiler units.

All heating elements are located in heat exchangers, which are considered the main structural elements of the boiler unit. If they malfunction, heating of the coolant is impossible.

Depending on the design and manufacturer, the equipment may have different configurations.

- Electronic control unit. Regulates the temperature by turning the equipment on and off at the right time.

- Circulation pump (heat pump). It is a mandatory component of the system and maintains a stable speed of coolant movement in the circuit. It produces forced circulation of liquid and creates the necessary pressure in the system, while ensuring the most effective heat exchange and heating of the room.

- Expansion tank. Not all types of electric boilers with a pump are equipped with an expansion tank. Therefore, if you purchase equipment without a tank, you will need to purchase this part separately and install it by cutting it into the pipe heating circuit.

- Filters. They purify and remove various impurities from water.

- Safety valves. Protect the system from unwanted deviations in operation.

- Safety valve. Connected to the return pipe. Performs emergency water release when the pressure rises above the established norm.

- Pressure gauge. This device determines the pressure of liquids and gases inside the boiler and pipes of heating systems; it is necessary for monitoring.

- Thermal switch. Shuts down equipment when it overheats. Connected to a temperature sensor located at the top of the electric boiler.

- Automatic air valve. It is located above the heating tank and produces an emergency release of air from the tank in case of excess pressure.

Electric heating elements

The principle of operation is based on simple electrical heating of elements that give off their heat to the liquid. Heating element – heating element. Water or other approved liquids are used as a coolant, in accordance with the operating instructions.

Induction

Their action is based on the principle of electromagnetic induction. The heating element is a coil, inside of which there is a pipeline filled with water. When an electric current passes through the coil under the influence of an electromagnetic field, the coolant heats up.

Ionic

The working element in such structures are electrodes placed in a special aqueous medium, where the process of heating the coolant occurs when alternating current passes through it.

A feature of the use of this type of boiler is the mandatory monitoring of the electrical conductivity of the liquid and the adoption of measures to regulate it. The phenomenon of electrolysis and breakdown should not be allowed. Failure to comply with these requirements may result in equipment failure.

The liquid used cannot be used for domestic purposes. The heat carrier, which circulates through the pipes and enters the working tank of the boiler, comes into direct contact with the electric current. It is not recommended to carry out repair and commissioning work without the involvement of an experienced technician.