How the Oasis boiler works

The devices of this manufacturer are dual-circuit. This means that the water heater can provide not only hot water at the tap, but also heating in the room. The heating temperature is from 35 to 60 degrees, the average productivity is 10 liters per minute.

Oasis equipment runs on natural gas, so it can be installed in houses connected to the mains.

The boiler is equipped with two heat exchangers. One of them is responsible for providing water for heating batteries, the other for hot water supply (DHW). Accordingly, fuel consumption and heating waiting time in the summer are reduced.

Combustion products are removed forcibly. The closed chamber and coaxial chimney ensure automatic and safe operation. Flame, gas supply, and flow sensors are installed for monitoring. There is also a safety valve that is activated when the pressure rises.

It can't do without troubleshooting. The equipment is equipped with a self-diagnosis system. In the event of a malfunction, an error is displayed on the display, the meaning of which is indicated in the instructions.

What do error codes mean in Oasis boilers?

Error E1 – No gas – Open the gas valve. Gas valve defective – Replace gas valve. Electrodes do not see flame – Clean or replace ionization electrodes. If you receive a message with this code, the control board is disconnected or faulty - Check the quality of connections of all wires. Replace the board if necessary. If replacement does not help, then the diagnosis was performed incorrectly.

Error E2 – No draft in the chimney (clogging) – Check the chimney. Venturi tube is defective or clogged – Clean or replace Venturi tube. Draft condensate has accumulated in the silicone tubes - Check the tubes and the quality of their connections. The draft sensor (air pressure switch) is faulty – Check the functionality of the sensor and replace it if necessary. The turbine does not work - Check the operation of the turbine and replace it if necessary.

Error E3 – Heat exchanger overheating – Check that the valves at the inlet and outlet of the heating circuit are open. Also, if this code is present, the overheating sensor may be faulty - Replace the sensor. In working condition, the sensor is closed. Opening at 92C.

Error E4 - The coolant overheating sensor has tripped (94C) - Check the cause of the high temperature. The coolant overheating sensor is faulty - If the Oasis boiler does not resume operation when it cools down, replace the sensor.

Error E5 (for RT model) – Incorrect settings in the center of the CL parameter of the service menu.

Error E5 (for BM model) – DHW incoming temperature sensor – Poor contact. If defective, replace it.

Error E6 – DHW outlet temperature sensor – Poor contact. If defective, replace it.

Error E7 – Heating outlet temperature sensor – Poor contact. If defective, replace it.

Error E8 – Ionization (flame) sensor – Dirty – clean. Doesn't work - replace.

Error E9 - The water pressure sensor has tripped. The pressure in the heating system is below 0.5 bar or above 3 bar. Check the pressure gauge. Open the feed tap and restore pressure. Relief of excess pressure by automatic valve. In this case, water will come out of the silicone tube. The water pressure sensor is faulty – If the pressure gauge shows that there is pressure, then the water pressure sensor needs to be replaced.

Error E0 – A temperature of less than 1C is recorded in the DHW or heating circuit – Carry out work on errors E5, 6 and 7. Monitor the temperature entering the boiler.

How to neutralize possible problems

Gas boiler Oasis. Twice already there was something incomprehensible. It is turned on for heating with a temperature of 55 degrees, everything seems to work. But suddenly I looked at the display, the number 07 appeared, and the unit was working non-stop and the batteries could no longer be touched - they were hot. I tried to turn it off with the buttons and it didn’t respond. Just unplug it. What problems did he have? Maybe it's completely broken? I plugged it in and it works fine again. I'm afraid to leave him unattended. Suddenly there will be failures again. What about him?

Most likely there is a problem with the control board and it needs to be replaced.

Tell me what to do, I welded an automatic air vent into the heating system, after which I began to start the boiler. It turns on, ignites, then the pump starts humming, error E9 appears on the display and stops working. I can't find the reason.

Error E9 indicates insufficient pressure in the heating system. On the pressure gauge when the boiler is turned off, the pressure should be at least 0.8 bar. If it is lower, then add water to the system using the make-up tap. It is also possible that there is air in the circulation pump - release the air by loosening the plug in the center of the front of the pump.

Wall-mounted gas boiler Oasis 24 kW with connected external thermostat. The problem is this: when the temperature is set on the thermostat, say 30 degrees, the unit starts to work, while the pump runs almost continuously and the pressure constantly increases, to 3 and above, when the temperature in the room reaches the set value, the pressure in it drops to 0 and jumps out error E9. I raise the pressure (I add water to the system), it starts to drip somewhere from below, I set the thermostat to a higher temperature - then the problem repeats itself. Tell me, what could be the cause of the malfunction?

In the expansion tank. It either deflated or burst. The problem may occur due to a faulty membrane in the expansion tank. Check its condition, making sure that when you press the tank nipple, no water comes out of it. The pressure in the expansion tank should be 1 bar.

Basic faults

What to do if an error appears on the display? How to fix the situation? First you need to decipher the meaning of the symbols on the screen, and only after that start looking for a breakdown.

Error codes and solutions

Let's look at what the symbols that the boiler shows mean.

E1 - problems with ignition, no ignition. What could be the reason:

E2 - the fan has been running for 8 seconds, but the pressure switch does not close. What does it mean:

In this case, you need to clean the chimney on your own side, and call utility workers from the street to clean it. Open the combustion chamber. You will see that there are two tubes connected to the manostat (pressure regulator), which also need to be cleaned;

E3 - the input DHW temperature sensor has failed. Diagnose the sensor and wiring. Replace faulty parts.

E4 - DHW output sensor is broken. Proceed in the same way as in case of E3.

E5 - the heating sensor does not work. Similar actions.

E6 - no flame. What to do:

E7 - low pressure in the line. What could have caused the problem:

E8 - the water is overheating. What is the reason:

E9 - the pressure in the system is not normal. The pump is broken, so the burner may not light.

We have examined all the errors characteristic of Oasis gas boilers. In addition, users are faced with a malfunction such as lack of heating: when opening the mixer, there is no hot flow. This indicates a turbine failure. It cannot be repaired; it is better to install a new one.

Before starting work on equipment, turn off the gas and water supplies. If the error code does not disappear from the screen after all the efforts, contact a specialist. You should not carry out independent work on the gas line - this is dangerous and can lead to an accident.

Probable errors and causes of occurrence

This article contains all possible malfunctions and options for eliminating them, as well as error codes for Oasis boilers.

All information is read in the following order: code - name - possible malfunction. If you have any additional questions, please leave them in the comments to this article. If you are not 100% sure what exactly the problem is and that you can solve it, immediately contact the service center to diagnose and fix the problem.

Error code E1 - No gas

Error code E2 - No draft in the chimney (clogged)

Error code E3 - Heat exchanger overheating

Check that the valves at the inlet and outlet of the heating circuit are open.

Error code E4 - The coolant overheating sensor has tripped (94C)

Check the cause of the high temperature.

The coolant overheating sensor is faulty - If the boiler does not resume operation when it cools down, replace the sensor.

Error code E5 (for RT model) - Error in setting the center of the CL parameter of the service menu

Incorrect settings in the center of the CL parameter in the service menu.

Error code E5 (for BM model) - DHW incoming temperature sensor, poor contact

If defective, replace it.

Error code E6 - DHW outlet temperature sensor, poor contact

If defective, replace it.

Error code E7 - Heating outlet temperature sensor, poor contact

If defective, replace it.

Error code E8 - Ionization sensor error (flame)

Error code E9 - Water pressure sensor has tripped

Error code E0 - A temperature of less than 1C is recorded in the DHW or heating circuit

Carry out work on errors E5, 6 and 7. Monitor the temperature entering the boiler.

Source

Do-it-yourself repair of the Oasis geyser

Before you start troubleshooting the Oasis geyser and choosing a way to eliminate them, you must clearly understand what type of device it is, know the device, and the principle of its operation.

The layout of the Oasis gas water column components is typical for most models of Chinese-made flow columns

The diagram above shows the design of a typical gas water heater, which is also typical for Oasis columns. Let's look further at how the most common type of brand's flow-through chimney model with automatic ignition works.

When the tap is opened, water is supplied through the inlet pipe into the water-gas unit, which turns on the ignition and gas supply. As soon as it ignites, a signal is sent from the flame sensor to the electronic unit to stop sparking.

Next, the water passes through a coil rigidly fixed to a heat exchanger, which is heated by burning gas. The coil transfers heat to the flowing water coming out.

When the tap closes, the water-gas unit turns off the gas supply. The combustion stops and the column goes into standby mode for the water tap to open.

An important condition for the normal and safe operation of the column is the removal of combustion products through the ventilation chimney. If the hood is missing or insufficient, the draft sensor is triggered and the column is turned off.

An overheating sensor is responsible for timely shutdown of the column when the maximum temperature is reached. It is an important element of the column, providing protection against overheating

Maintaining the required temperature regime is an equally important condition for fire safety and long service life of the column. Overheating negatively affects the condition of all elements, primarily the heat exchanger, which leads to their premature failure.

What do error codes mean in Oasis boilers?

Error E1 – No gas – Open the gas valve. Gas valve defective – Replace gas valve. Electrodes do not see flame – Clean or replace ionization electrodes. If you receive a message with this code, the control board is disconnected or faulty - Check the quality of connections of all wires. Replace the board if necessary. If replacement does not help, then the diagnosis was performed incorrectly.

Error E2 – No draft in the chimney (clogging) – Check the chimney. Venturi tube is defective or clogged – Clean or replace Venturi tube. Draft condensate has accumulated in the silicone tubes - Check the tubes and the quality of their connections. The draft sensor (air pressure switch) is faulty – Check the functionality of the sensor and replace it if necessary. The turbine does not work - Check the operation of the turbine and replace it if necessary.

Error E3 – Heat exchanger overheating – Check that the valves at the inlet and outlet of the heating circuit are open. Also, if this code is present, the overheating sensor may be faulty - Replace the sensor. In working condition, the sensor is closed. Opening at 92C.

Error E4 - The coolant overheating sensor has tripped (94C) - Check the cause of the high temperature. The coolant overheating sensor is faulty - If the Oasis boiler does not resume operation when it cools down, replace the sensor.

Error E5 (for RT model) – Incorrect settings in the center of the CL parameter of the service menu.

Error E5 (for BM model) – DHW incoming temperature sensor – Poor contact. If defective, replace it.

Error E6 – DHW outlet temperature sensor – Poor contact. If defective, replace it.

Error E7 – Heating outlet temperature sensor – Poor contact. If defective, replace it.

Error E8 – Ionization (flame) sensor – Dirty – clean. Doesn't work - replace.

Error E9 - The water pressure sensor has tripped. The pressure in the heating system is below 0.5 bar or above 3 bar. Check the pressure gauge. Open the feed tap and restore pressure. Relief of excess pressure by automatic valve. In this case, water will come out of the silicone tube. The water pressure sensor is faulty – If the pressure gauge shows that there is pressure, then the water pressure sensor needs to be replaced.

Error E0 – A temperature of less than 1C is recorded in the DHW or heating circuit – Carry out work on errors E5, 6 and 7. Monitor the temperature entering the boiler.

How to neutralize possible problems

Gas boiler Oasis. Twice already there was something incomprehensible. It is turned on for heating with a temperature of 55 degrees, everything seems to work. But suddenly I looked at the display, the number 07 appeared, and the unit was working non-stop and the batteries could no longer be touched - they were hot. I tried to turn it off with the buttons and it didn’t respond. Just unplug it. What problems did he have? Maybe it's completely broken? I plugged it in and it works fine again. I'm afraid to leave him unattended. Suddenly there will be failures again. What about him?

Most likely there is a problem with the control board and it needs to be replaced.

Tell me what to do, I welded an automatic air vent into the heating system, after which I began to start the boiler. It turns on, ignites, then the pump starts humming, error E9 appears on the display and stops working. I can't find the reason.

Error E9 indicates insufficient pressure in the heating system. On the pressure gauge when the boiler is turned off, the pressure should be at least 0.8 bar. If it is lower, then add water to the system using the make-up tap. It is also possible that there is air in the circulation pump - release the air by loosening the plug in the center of the front of the pump.

Wall-mounted gas boiler Oasis 24 kW with connected external thermostat. The problem is this: when the temperature is set on the thermostat, say 30 degrees, the unit starts to work, while the pump runs almost continuously and the pressure constantly increases, to 3 and above, when the temperature in the room reaches the set value, the pressure in it drops to 0 and jumps out error E9. I raise the pressure (I add water to the system), it starts to drip somewhere from below, I set the thermostat to a higher temperature - then the problem repeats itself. Tell me, what could be the cause of the malfunction?

In the expansion tank. It either deflated or burst. The problem may occur due to a faulty membrane in the expansion tank. Check its condition, making sure that when you press the tank nipple, no water comes out of it. The pressure in the expansion tank should be 1 bar.

Main causes of malfunction and their elimination

The designs of all geysers are similar to each other. Why not summarize all the problems and describe options for solving them? Because each brand has its own weaknesses. This is when malfunctions specific to specific brands appear. We analyzed user reviews to collect reliable information for you.

Factory defects in Oasis water heaters are extremely rare.

The cause of failure can be external and internal factors:

We have described ways to resolve these problems below.

Column does not light up

There can be many reasons, we will help you figure it out. The main thing is to correctly determine the location of the breakdown.

If the device does not ignite at all, no spark is produced, then:

How do you know if you have cravings? Light the match and bring it to the viewing window of the column. The flame deviates - there is draft; it burns evenly - no. You can also lean a sheet of paper against the ventilation. If there is traction, the sheet will press against the output, otherwise it will fall.

The flame comes on and goes out

This happens when the electronic unit does not receive the ignition signal, stops ignition and shuts off the gas. The cause may be a malfunction of the flame sensor or the formation of carbon deposits on the sensor.

Remedy: lightly clean the sensor with fine sandpaper (zero sandpaper). In this case, you should not be too zealous so as not to damage the metal coating. If this procedure does not produce results, the flame sensor must be replaced.

Column leaked

A leak is a serious problem, but you can deal with it yourself.

The seal is leaking through the rod. To verify this, remove the cover and check where the water is coming from.

How to carry out DIY repairs:

A more serious problem is a leak in the radiator. The new heat exchanger costs almost the same as the new Oasis Turbo model. How to save money? Close the fistulas using the soldering method. Read more in the article “How to solder a gas water heater.”

The easiest way to fix a leak is if the hole is on the outside of the tube. Then you can use cold welding. Internal corrosion requires the use of a soldering iron or torch with a temperature of 170 degrees. Rosin or an aspirin tablet can be used as a flux.

Before you begin, prepare the radiator:

You can start repairing. To prevent the fistula from appearing again, the thickness of the solder should be 2-3 mm. Inspect the node for the presence of green spots - these are future fistulas. It's better to take care of them right away.

The speaker goes out after a few minutes

This malfunction is often associated with poor traction or overheating.

Remedy: clean the chimney, reduce the water temperature by adjusting the flame and pressure, do not dilute the hot water with the mixer.

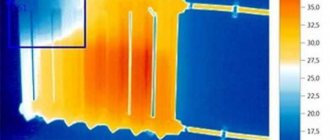

Heat exchanger clogged

How to understand that the radiator is clogged:

These are indirect signs, so it is better to inspect the device. Scale on the heat exchanger plates and coil appears from poor quality water and high heating temperatures. It is recommended to set the temperature to 55°C and not mix the flows on the mixer.

There are two ways to get rid of a blockage.

Reduced pressure and low water heating

Signs of scale formation in the heat exchanger are a decrease in the water flow at the outlet of the column and its low heating. In this case, the column may not ignite well, and the radiator overheats due to poor heat exchange with water. This triggers the thermal protection sensor and turns off the column.

Clogged radiator fins also lead to overheating. When they become clogged with debris and scale, it becomes difficult for combustion products to exit into the chimney, which can lead to burnout of the heat exchanger skirt.

Water hardness is the main reason for the deterioration of pipeline capacity. The presence of calcium, magnesium salts and other impurities promotes scale formation and reduces heat transfer. Heating significantly enhances this process.

Scale reduces efficiency and increases gas costs to achieve the desired temperature. If measures are not taken to remove it, deposits will grow even faster, until the water flow is completely blocked.

You cannot use a column with heat exchanger tubes clogged with scale. This will lead to local overheating, cracks in the coil and the need to replace it.

Remedy: wash the heat exchanger with a special solution. There is a wide selection of reagents for professional use. They do the best job of removing scale without damaging the pipeline.

Most chemicals contain solutions of various acids. Their concentration and composition are selected in such a way as to effectively dissolve salt deposits, but act as gently as possible on the inner surface of the pipeline. The selection of a suitable reagent should take into account the heat exchanger material.

For example, reagents intended for copper radiators cannot be used for pipelines made of galvanized and stainless steel and vice versa.

The highest quality washing is done using special equipment (boosters). The effect is achieved through repeated circulation of the reagent, its heating, reverse, and the use of special compounds. The cost of such equipment, as well as services, is quite high. Purchasing boosters is more justified for professional use.

Good results can be achieved in less expensive ways using available devices and reagents.

The most popular and proven means of washing heat exchangers are solutions of citric acid, vinegar, anti-scale and other acidic cleaners. It is important to observe the dosage - exceeding the concentration of the active substance can damage the pipeline

To remove scale, 10–20% solutions are usually used. For 1 liter of water take 100 g - 200 g of anti-scale or citric acid or 9% vinegar. The greatest effect is achieved when the solution is heated to 80 - 100 degrees.

Washing can be done in two ways:

To flush the radiator without removing it, you need to perform a number of steps. First, turn off the water by placing a container to drain. Disconnect the outlet pipe and open the tap. Next, unscrew the nut connecting the coil to the water block. Connect a funnel from a cut plastic bottle with a flexible hose to the inlet of the coil.

Then secure the funnel above the heat exchanger. Pour the working solution into the funnel in small portions until foam appears at the other end of the coil. The procedure must be carried out for 4-6 hours until the chemical reaction stops, guided by the foam released, or using acidity indicators.

After dismantling the heat exchanger, washing is performed as follows: first disassemble the column, remove the radiator and burner. Then the plate is cleaned of soot and soot. After this, place the radiator in a large metal container with water, pour the reagent inside the pipeline and heat the container. At the end, the heat exchanger should be rinsed with cold water and a 10% soda solution.

Gas smell when turned on

This is a serious and dangerous problem. Shut off the gas supply immediately! Contact your gas company.

The seal is probably worn out. Replacement in the event of a gas leak must be carried out by a specialist. We described above how to disassemble the gas-water unit and get to the oil seal.

Before using the equipment, read the instructions. It is recommended to carry out a preventive inspection of all components of the water heater once a year. Now you know what to do. And if you are confused, turn off the fuel supply and contact the service center.

Errors in gas boilers Arderia (Arderia) and methods for eliminating them

Any gas boiler needs regular maintenance and preventive measures. It happens that the causes of problems are external factors: low pressure in the line, voltage drops, etc.

We recommend: Is it possible to paint hot radiators and how to do it correctly?

Malfunctions of Arderia gas double-circuit wall-mounted boilers are detected in the form of codes on the screen. Their decoding is available in the operating instructions.

- pump failure;

- 3-way valve failure;

- failure of the DHW flow sensor.

All heating system shut-off valves may be closed

Open shut-off valves.

Check the functionality of the three-way valve and the DHW flow sensor.

Replace broken items

- lack of fluid in the heating system;

- air jams;

- malfunction of the circulation pump or flow sensor

The speed of the circulation pump impeller should be adjusted.

Replace faulty elements

- low gas pressure;

- malfunctions of the gas valve or transformer;

- blocking of the gas duct

- shut-off valves are closed;

- filters are clogged;

- There is a problem with the circulation pump or three-way valve.

Check the functionality of the pump and three-way valve

Replacing a faulty element

Models of gas boilers Arderia B10, B14, B16 have different error codes. Let's look at what they mean and how to troubleshoot.

E0 – antifreeze mode. This code is displayed on the screen if the coolant temperature drops below +1°C. It is necessary to check the integrity of the system in which the liquid circulates. The error disappears if the coolant is heated. If it still hasn't disappeared, call a professional.

Code E1 indicates an ionization sensor error. This occurs when there is no expected flame. Appears as a result of unsuccessful ignition of the unit or after the flame fails during operation.

E2 – pressure sensor error. Appears as a result of weak draft, which is caused by malfunctions of the sensor or fan. The unit will attempt to return to normal operation for 15 minutes. Check the chimney and the presence of draft in it. If the error does not disappear after 15 minutes, contact the service center technician.

E3 – overheating thermostat error. Occurs when there is no coolant or its movement in the heating system. The circulation pump may be faulty. You should also check all valves and lines of the system. You can remove the lock using the MODE button. If this does not help, contact customer service.

E4 – overheating of temperature sensors. Appears on the screen due to the lack of fluid in the system or its circulation. Check the valves and heating pipe. The lock is released using the MODE button.

E5 – temperature sensor error. Appears when the cold water sensor is faulty. Turn off the hot water and wait. The lock can be released by pressing the MODE button. Code E6 – DHW sensor error. Appears when the DHW sensor is faulty. Close the hot water taps to normalize the heating system. The lock is released using the MODE button.

E7 – problem with the temperature sensor. Displayed when the heating circuit temperature sensor fails. Typically, this code appears when communication with the sensor is lost. When it gets better, the problem disappears.

E8 – indicates the presence of residual fire (ionization sensor error). Occurs if there is still fire in the combustion chamber or as a result of a sensor error. Unlock using the MODE button. If the error occurs again, contact customer service. E9 means pressure sensor error. Appears when fluid pressure is low or absent. You should check the system for leaks or adjust the speed at which the pump pumps coolant. It is necessary to eliminate any identified leaks or adjust the pump operation.

The fan starts working, but the flame does not appear

The air pressure switch does not work. Blocking the chimney. Leak in the combustion products exhaust system. The combustion chamber is not sealed. Power supply voltage is below 170 V. Install a voltage stabilizer

Incorrect combustion: flame color yellow or red

The burner is dirty. Incorrect functioning of the chimney. Incorrect gas valve setting.

Long waiting time for hot water

Since in the absence of water supply the water in the DHW pipe cools down, some time must pass before hot water appears from the tap.

The Arderia boiler often turns off: due to excessive temperature (error A4) or low pressure in the heating system (error A5).

Insufficient pressure, leaks or circulation problems in the heating system. It is necessary to check that the pressure in the heating system is within 1-1.2 bar, and that there are no leaks in the system. Checking the circulation in the heating system must be carried out by authorized personnel.

Presence of air in the heating system. Remove air.

Insufficient air pressure in the boiler expansion tank. Raise the air pressure in the tank to 1.0 bar - at zero pressure in the heating system.

The boiler pump shaft is blocked. The boiler pump is faulty. You need to call an authorized specialist.

Frequent spontaneous shutdowns of the boiler in DHW mode

Insufficient cold water pressure at the boiler inlet.

Ensure that the cold sanitary water inlet pressure is at least 1.5 bar. When using an individual water supply system with a hydraulic accumulator and uneven pressure, it is recommended that the pump turn on pressure be at least 2.0 bar.

Hot water flow too low. Do not set the water flow below 2 l/min, as this will trigger the DHW flow sensor and subsequently turn off the water heating. Random opening and closing of water taps respectively starts and stops the water heating process, which can lead to an increase in waiting time for hot water.

Fluctuations in hot water temperature

The simultaneous use of several hot water consumption points makes water consumption unstable. To reduce temperature fluctuations, do not use more than one hot water tap at a time.

The boiler burner does not turn on (error A6)

The power cord is not connected - connect the power cord. No gas supply - open the gas supply valve. The water temperature is set too low - set the temperature to a higher temperature using the regulator.

The appearance of strange sounds during boiler operation

There is air left in the pipes - bleed the air. Repeat filling the boiler with water. All shut-off valves are closed - open the shut-off valves. The Arderia boiler is not attached to the wall correctly - secure the boiler correctly. If the noise does not disappear, call a specialist from the service center.

The room does not warm up to a comfortable temperature

The boiler is operating in DHW mode - turn on the heating mode. The coolant temperature is set too low - set a higher temperature using the regulator. The shut-off valve in the heating circuit is closed - locate and open the valve. One or more taps in the heating circuit are not fully open - check all taps. Open partially closed ones. The boiler filter is clogged - clean the filter. There is air left in the pipes - bleed the air. Repeat filling the boiler with water.

No DHW

Clean the filter. The DHW stop tap is closed - open the DHW tap. The filter is clogged - clean the filter.

The boiler is overheating

Shut-off valves in the heating system are closed - check all valves. Open if they are closed.

How to prevent breakdown of the Oasis geyser

In order to prevent a situation where repair of the Oasis geyser is required, it is necessary to properly care for gas equipment and operate it correctly. These are the recommendations that can be read in the instructions for geysers. Here are some operating tips:

Features of using batteries

Of all the parts, batteries require the most frequent replacement. For geysers, you should choose only alkaline batteries made using Alkalin power technology, size “D” and the first letter “L” in the designation is LR20. Their capacity and service life are five times greater than those of salt ones: from 1 to 1.5 years.

It is better not to buy elements that are too cheap, as they may turn out to be fake. It is possible to install NiMH or Li-Ion batteries, but their price with a charger is higher

To do this, you can buy a special 3 V power supply, or use a 5 V mobile phone charger with an additional stabilizer. The main requirement is that its power is sufficient for ignition, which occurs at a supply voltage of 3 V and a current of 350 mA.

In case of a power outage, you can always keep batteries in reserve; fortunately, alkaline batteries have a shelf life of 5 years or more.

Column heat exchanger quality

When choosing a column, special attention should be paid to the quality of the heat exchanger. The type of metal and its quality have a great influence on the lifespan of the radiator. They are made of galvanized steel, stainless steel, copper.

The most durable of stainless steel, but inferior in thermal conductivity to copper. Accordingly, they are less economical and have lower efficiency. Copper is the most efficient in heat transfer, but also the most expensive.

When replacing the heat exchanger with a new one, pay attention to the thickness of the metal and the weight of the radiator. Quality should not be too light

The high cost of copper leads to the fact that manufacturers save as much as possible on the thickness of the heat exchanger wall, bringing it down to 0.5 mm, which significantly reduces the service life. For the same reason, other metals are added to copper. The alloy obtained in this way may have unpredictable properties. As a result, such a heat exchanger cannot even be soldered.

System water quality

If the water in the system is subjected to frequent chlorination, this will negatively affect the condition of the copper heat exchanger. In combination with the thinned walls of the pipeline, this can quickly lead to corrosion and the appearance of fistulas.

Increased water hardness in combination with heating causes no less problems. Scale deposits require periodic washing.

You can improve water quality using aquafilters and magnetic softeners.

Overheating of the geyser

The most important factor leading to malfunctions and reduced service life of the column is its overheating. It is important not to raise the temperature to 65 degrees or higher.

To reduce the risk of the water becoming too hot, do not use the faucet to cool the water. Only change the temperature using the flame and water flow control knobs intended for this purpose.

A situation may arise when the boiler stops heating water, that is, cold water flows from the tap when turned on. Most likely, the problem lies in a malfunction of the turbine, which does not transmit a signal to the sensor, then the flame does not ignite and, as a result, the liquid does not heat up.

The turbine cannot be repaired and needs to be replaced. To prevent a similar situation from happening again with a newly installed turbine, we recommend purchasing and installing a high-quality fluid filter.

In this article we will look at the Oasis gas boiler of the NZR series (available in 4 modifications). The number after the abbreviation “NZR” indicates the power of this boiler. For example, the Oasis NZR 13 model has a thermal power of 13 kW.

Since all modifications have similar characteristics, we will denote their numerical expression in a range.

We have a certain residential or administrative area, which has its own dimensions. Managers of household appliance showrooms guide buyers towards them when choosing a boiler. But at the same time, the features of the building or apartment are absolutely not taken into account:

The approximate power that the boiler should have is determined at the rate of 10 kW per 100 m 2 of room (ceilings of standard height). But if any mechanism is “driven” to the limit, then it will not work for long. That is why the power calculated in this way is increased by a third (the required reserve).

Other faults

A situation may arise when the boiler stops heating water, that is, cold water flows from the tap when turned on. Most likely, the problem lies in a malfunction of the turbine, which does not transmit a signal to the sensor, then the flame does not ignite and, as a result, the liquid does not heat up.

The turbine cannot be repaired and needs to be replaced. To prevent a similar situation from happening again with a newly installed turbine, we recommend purchasing and installing a high-quality fluid filter.

Source

How the Oasis boiler works

The devices of this manufacturer are dual-circuit. This means that the water heater can provide not only hot water at the tap, but also heating in the room. The heating temperature is from 35 to 60 degrees, the average productivity is 10 liters per minute.

The boiler is equipped with two heat exchangers. One of them is responsible for providing water for heating batteries, the other for hot water supply (DHW). Accordingly, fuel consumption and heating waiting time in the summer are reduced.

Combustion products are removed forcibly. Closed chamber and ensure automatic and safe operation. Flame, gas supply, and flow sensors are installed for monitoring. There is also a safety valve that is activated when the pressure rises.

It can't do without troubleshooting. The equipment is equipped with a self-diagnosis system. In the event of a malfunction, an error is displayed on the display, the meaning of which is indicated in the instructions.

Installation and connection

The Oasis boiler is a wall-mounted model. Unlike floor-standing devices, it does not require boiler room equipment; it can be installed even in small rooms.

Fastening is done either with anchors or large screws, since the weight of the boilers is comparable to the weight of a regular gas water heater, and the dimensions are approximately the same.

The described gas boilers are produced with a closed combustion chamber. What does this mean? To ensure the combustion process, an air flow is required. A device with a closed chamber in this regard is isolated from the room in which it is mounted. Air is supplied from outside using a fan equipped with the boiler.

Therefore, before purchasing the Oasis product, you need to think about installing a special coaxial chimney. For private houses this is not a problem, but installation in an apartment will require specialist advice. Although such models are considered safer and more environmentally friendly.

A few words about the manufacturer

The Oasis company is a well-known manufacturer of equipment designed for autonomous home heating. The product range includes:

The Oasis boiler manufacturer is of Chinese origin, but most sellers position it as a Russian product. The company itself is quite well known in Asian countries, but in the Russian Federation, water heating heating equipment of the Oasis brand appeared relatively recently. Chinese heating household gas boilers Oasis are distinguished by the thoughtfulness of their operation and the technical part of the device, as evidenced by consumer reviews.

Internal structure of Oasis boilers

One of the characteristic features of the modifications is the presence of a closed combustion chamber. Air intake is carried out from the street, using a coaxial chimney. Combustion products are also removed through the pipe. This makes the operation of boilers as safe as possible. In addition, due to the closed firebox, gas consumption is significantly reduced.

Separately, we can note the presence of two heat exchangers. This solution increases the speed of heating water for domestic hot water, and also allows the device to be started in summer mode, which increases its efficiency.

All Oasis wall-mounted double-circuit gas heating boilers have a high degree of autonomy, achieved thanks to an internal structure that includes:

Oasis boilers have been certified and received permission to operate by Rostechnadzor. This made it possible to operate equipment from a Chinese manufacturer throughout the Russian Federation.

What to focus on in operation

Boiler piping - the internal structure of the boiler contains a circulation pump and an expansion tank. During installation, you will need to additionally install a filtration system. The automation is sensitive to voltage drops, which is one of the main disadvantages of the Oasis boiler. To eliminate possible failure of the control board, you need to connect a UPS. Lots of noise – the forced-air burner is noisy. The noise level requires installation of the boiler in a separate room. The technical characteristics declared by the manufacturer in this regard are somewhat different from what actually happens

It is especially noisy when the DHW is turned on.

Coaxial chimney - it is extremely important to comply with the installation requirements, strictly adhere to the maximum height, angle of inclination and other parameters. Productivity and efficiency ultimately depend on a quality installation.

Chinese doesn't mean bad

All components from the closed combustion chamber to the temperature sensor are checked for quality and compliance with standards. The only condition for trouble-free operation is the installation and operation of the boiler in accordance with all the rules and in accordance with the manufacturer’s recommendations.

The Oasis gas boiler can only operate on natural gas; conversion to liquefied gas is excluded; accordingly, it can be installed in rooms connected to the central gas main.

These devices are double-circuit, designed to heat a room and supply it with hot water for domestic needs. The heating temperature of the liquid ranges from 35-60 degrees, the hot water supply capacity is 10 liters per minute.

Equipped with a closed combustion chamber, which significantly reduces gas consumption. The operation of the burner is controlled automatically; there are photo sensors on it that monitor the presence of gas. A coaxial chimney is used for smoke removal; the air required for the combustion process comes from the street.

The design provides two heat exchangers, one for the heating circuit, the second for heating the DHW liquid. Thanks to this, the heating time of the liquid is reduced, and it is also possible to use the boiler in the summer.

It is possible to connect to a room thermostat, which is not included in the package; it must be purchased separately. For safe operation, there are relief valves that are activated if the coolant temperature exceeds the permissible limits. Also, for safe operation, there are flow sensors that monitor the pressure in the heating circuit; in case of non-compliance with the standards, the operation of the system is blocked.

Diagnosis of errors and malfunctions of the Oasis boiler

Error E1

Error code E2

Error code E3

Error E4

Problems with determining the temperature by the DHW sensor. This situation means that the DHW temperature sensor is damaged or the operating temperature is exceeded. Possible reasons that influence the formation of this problem: the temperature sensor for the hot water supply is defective. Poor contact between the electronic board and the DHW temperature sensor. Failure of the electronic board. When the hot water temperature sensor is in good condition and firmly connected to the electronic board, although the device shows an error, then most likely the electronic board is damaged.

Error code E5

Error E6

Problems related to ignition. This code is displayed if the ignition does not work or the burner flame fails. It is recommended to check the contacts between the ignition device and the flame sensor, and also between the electronic board and the gas valve. One of the factors causing the burner flame to break off may be insufficient draft.

Code E7

The circulation pump is malfunctioning or an air lock has formed in the heating system.

Error code E9

It signals low pressure in the system. Probable causes of this malfunction: a decrease in coolant pressure in the heating circuit. Lack of contact between the electronic board and the pressure switch. Pressostat malfunction. First you need to know the pressure gauge readings. In many cases, the problem can be corrected by using a make-up valve that is designed to add water to the system. If the problem recurs, it appears that there is a coolant leak. The circulation pump, main heat exchanger, excess pressure relief valve, damaged gaskets, make-up valve and other components may leak. Leaks are determined visually by inspecting hydraulic components.

The Oasis gas boiler was put into operation. This week the E1 ignition error is starting to appear almost around the clock. After resetting with the reset key, the device occasionally starts normally, but this happens sporadically. I removed the air plug the other day and it runs better. What's wrong?

When an error related to smoke exhaust is displayed, the protective covers must be opened. This will facilitate the flow of air from the living space. Next, inspect the smoke exhaust pipe for ice and, if there is any, clean it. In the event of a flame failure, it is necessary to find out whether gas is flowing into the room.

Error code E5 is on the boiler all the time. Please tell me what the problem is?

This code may indicate problems with the heating temperature sensor. Most likely, it needs to be replaced.

Why didn't the Oasis boiler turn on? And error E3 also comes on regularly. How to fix?

This malfunction can occur due to various problems in the thermostat, temperature sensor, or if there is a problem with the main circulation circuit. It looks like the heat exchanger has overheated. If the thermostat and temperature sensor are working, then the problem is in the electronic board. It should be changed.

What is the problem if the boiler does not start and displays error code E9? The pressure in the system is normal, no leaks are visible. I tried turning it off from the mains, but the fault was not cleared. Tell me, what is the reason?

A fault code is usually issued when the fluid pressure in the heating circuit is low. If this problem occurs, you need to check the water level sensor. Most likely, the problem is there.

The malfunction of the device looks like this: the hot water supply is set to forty degrees. When the hot water is turned on, the burner burns for a short time and then goes out. This cycle occurs regularly. Warm water flows from the mixer, but not hot, then cold. Periodically displays error E3. What is causing this malfunction?

This circumstance indicates overheating of the coolant in the DHW circuit. Most likely, there is severe contamination of the heat exchanger, or the thermostat has incorrect settings.

There was such a problem. During ignition, the unit displays error E6 (the flame breaks). If you restart it, it turns on normally, but as soon as the burner ignites, strange clicks are heard, and the error is displayed again. I changed the ignition electrode, washed the flow sensor and removed the ground from the plug, but there was no improvement. What could it be?

This malfunction occurs in three cases. Damage to the flame control electrode. Difficulties with gas supply. The control board is damaged.

The unit turned off spontaneously and displays code E9. What's happened?

Low water level in the device or a broken pressure sensor. First, fill the system with coolant.

The gas boiler interrupts operation with error E2 displayed. Blowing and cleaning helped in the short term. What's happened?

This code indicates insufficient draft, and it is recommended to check the exhaust system. Presumably the membrane is stuck. In another case, you need to contact the service department for a thorough check of the gas boiler and then further check it.

Our house has an Oasis gas boiler. An error with code E4 began to appear. The unit itself does the work; the temperature level of the liquid is regulated by a manual switch. When we installed it, it seemed to overheat because the automatic temperature control mode was turned on. We do not have an external air temperature sensor. For what reason did this happen?

We assume that there is damage to the DHW temperature sensor. Sometimes the electronics board is damaged.

The device performs work for approximately 2-3 minutes, after which the gas burner turns off and an error code E2 is displayed. It burns for no more than a minute, the burner starts working again, and the device functions uninterruptedly for another three to four minutes, and so on many times. This code, judging by the instructions, indicates that the draft sensor is triggered, but the chimney duct is clean and exhaust gases are discharged well. Can anyone explain what is causing the problem?

In this case, the main factors for the lack of traction are: breakdown of the pneumatic relay-traction sensor. Poor contact between the control board and the traction sensor. The presence of condensation, as well as poor connection of the tubes to the pressure switch. There is a problem with the fan operation. Perhaps he is unable to develop the necessary speed.

Source

Basic faults

What to do if an error appears on the display? How to fix the situation? First you need to decipher the meaning of the symbols on the screen, and only after that start looking for a breakdown.

Error codes and solutions

Let's look at what the symbols that the boiler shows mean.

E1

— problems with ignition, no ignition. What could be the reason:

The ignition electrode does not work. This happens if the part has moved and is located far from the burner. Remove the casing, inspect the elements and return the electrode to its place. Additionally, clean it with a wire brush. If the burner does not light after this, install a new electrode.

E2

— the fan has been running for 8 seconds, but the pressure switch does not close. What does it mean:

No traction. The pipe or chimney is clogged. To check, light a match and hold it to the inspection window. The flame deviates to the side - there is draft, it burns evenly - no. You can hold a sheet of paper to the ventilation hole. With normal traction, it will tighten, and if the passage is clogged, the leaf will fall.

In this case, you need to clean the chimney on your own side, and call utility workers from the street to clean it. Open the combustion chamber. You will see that there are two tubes connected to the manostat (pressure regulator), which also need to be cleaned;

The fan does not work

. The part is inspected for damage. There are tubes connected to it that may have melted and need to be replaced. Then start the boiler and close the manostat contacts. If the burner lights up, the manostat is broken; if not, the main unit is broken.

E3 -

The DHW input temperature sensor has failed. Diagnose the sensor and wiring. Replace faulty parts.

E4 -

The DHW output sensor is broken. Proceed in the same way as in case of E3.

E5 -

The heating sensor does not work. Similar actions.

E6

- there is no flame. What to do:

E7

- low pressure in the line. What could be causing the problem:

E8 -

the water overheats. What is the reason:

E9 -

The pressure in the system is not normal. The pump is broken, so the burner may not light.

Thermal sensor is faulty. Diagnostics and replacement are carried out.

We have examined all the errors characteristic of Oasis gas boilers. In addition, users are faced with a malfunction such as lack of heating: when opening the mixer, there is no hot flow. This indicates a turbine failure. It cannot be repaired; it is better to install a new one.

Before starting work on equipment, turn off the gas and water supplies. If the error code does not disappear from the screen after all the efforts, contact a specialist. You should not carry out independent work on the gas line - this is dangerous and can lead to an accident.

Basic error codes

Let's try to look in more detail at the error codes of Oasis boilers and the possible reasons for their appearance.

e1

Error e1. Indicates an ignition malfunction, possible causes:

- There is no gas supply to the device. Check if the gas valve is open, if not, open it. There may also be insufficient or, on the contrary, excessive gas pressure; to eliminate this, you must contact the gas service.

- The contact connection is broken or missing. Check for opens and shorts using a multimeter. They may have oxidized, in this case, strip and insulate the wires...

- The board has failed. It is necessary to test it and, in case of malfunction, replace it with a new one; this type of repair requires the necessary qualifications.

Boiler control board - The control ignition electrode is broken. First, clean it using a wire brush and visually check for damage to its body. If you find a defect in it or its wire, replace it.

- The plug is not inserted correctly into the socket, replace it with the other side

e2

Error e2. Lights up if the air pressure switch does not close 8 seconds after turning on the fan.

The reasons may be:

- Clogged pipe or chimney. Check for draft and clean the chimney. It would also be a good idea to open the combustion chamber, there are two pipes connected to the monostat, remove them and blow them out.

- The relay that controls the air pressure has failed. Test it for serviceability and replace if necessary.

- The fan has failed. Check its serviceability, examine it carefully, there are tubes in it, check their integrity, whether they are melted. Next, you need to turn on the boiler and after the fan starts working, short-circuit the two wires going to the monostat.

Oasis boiler fan

If the boiler lights up, it means the monostat is broken and needs to be replaced, and if not, then the problem is in the control board. - The electronic part of the device is faulty, or a wire is coming off somewhere. Perform a visual inspection of all connections of the device and the integrity of the wires. If the board is faulty, then it is better to contact specialists to repair and diagnose it.

e6

Error e6. Indicates that there is no flame. What to do if a similar problem arises?

The following must be excluded:

- Presence of stray flame. There may be an accumulation of air in the system. Try restarting again.

- The connection in the wires is broken. Check for correctness and integrity.

Wire connection methods - One of the board elements that is responsible for starting the device is broken. The board needs to be tested.

e7

Error e7. Low pressure or insufficient amount of liquid in the hot water supply system.

Probable reasons:

- There is not enough water in the system; the cause may be a leak in any of the system elements; this can be done with a dry cloth. Check everything carefully and if a leak is found, fix it. This can be done using special sealants, tightening the joints, use high-quality seals.

- The pressure level in the expansion tank is not adjusted. Since the liquid expands when heated, the pressure in it increases and the liquid is discharged using the valve. It is necessary to strictly follow the characteristics of a particular model and adjust the required level of pressure in the system.

Expansion tank in the heating system - And, of course, the problem may lie in the electronic board of the device itself. It is necessary to inspect the board for disconnected contacts and other damage.

e9

Error e9. Indicates that the pump has failed, or that the pressure in the system is unacceptable.

Check the following:

- The level of optimal fluid pressure in the system varies from 0.1 to 0.15 atm.

- Check the serviceability of the water pump by first removing it. If necessary, clean the pump, rinse, check the integrity of the blades.

- The control board is broken. Needs replacement.

- You also need to pay attention to whether the temperature sensor is working properly.

conclusions

Let's summarize all of the above:

It should be added that the manufacturer provides a 2-year warranty on its products.

Boilers have relatively recently appeared on the heating equipment market. Positioning itself as a large international corporation created by German investors, Forte occupied a niche in the production and sale of bimetallic radiators. In order to expand the sales market, a step was taken to produce.

Currently, the model range is represented by one type of gas equipment - the Oasis NZR boiler. In order to increase the number of potential buyers, 4 main modifications of this boiler were made.

The Oasis NZR double-circuit gas boiler is designed to heat the coolant in the heating system and provide hot running water. Its general characteristics allow it to be used as the main heating device both in private homes and in small office buildings.

4 boiler models have been developed, which differ in rated power - from 13 to 24 kW. The company's marketing strategy allowed boilers with low power to confidently occupy their market segment. The relative shortage of inexpensive and low-power boilers has become a niche that allows Forte to continue its successful advancement in the market.

A few words about the manufacturer

The Oasis company is a well-known manufacturer of equipment designed for autonomous home heating. The product range includes:

The Oasis boiler manufacturer is of Chinese origin, but most sellers position it as a Russian product. The company itself is quite well known in Asian countries, but in the Russian Federation, water heating heating equipment of the Oasis brand appeared relatively recently. Chinese heating household gas boilers Oasis are distinguished by the thoughtfulness of their operation and the technical part of the device, as evidenced by consumer reviews.