Installation of a heating system with metal-plastic pipes

Metal-plastic pipes easily change shape and are quite convenient to install.

An additional advantage is that there is no need for expensive tools; they have an attractive appearance, so painting the system is not required. You can even do without special scissors (replace with a hacksaw) and a pipe bender (a spring is enough). In order to bend metal-plastic heating pipes, various pipe benders and external or internal springs (mandrels) are used. The bending radius depends on the outer diameter of the product, but cannot exceed four diameters.

Follow installation with detachable fittings

Detachable (threaded and compression) fittings are quite expensive, but without them it is impossible to create connections between pipes and devices. If necessary, these elements can be dismantled and installed again (in compression ones, the crimp ring must be replaced).

Regardless of the fitting used, you first need to cut a piece of pipe to the desired length, calibrate the end and remove the chamfer. When cutting, maintain perpendicularity to the axis. Both the presence of a chamfer and unevenness during cutting can lead to a violation of the tightness of the connection.

If the fitting is threaded (coupling, tee, cross), then it is enough to screw the pipes to its ends. If it is compression, then it is equipped with a special nut, which should be tightened with a wrench immediately after the pipe is inserted into the fitting. Both threaded and compression ones do not require the use of special tools during installation, but they must be monitored during operation, since such connections tend to relax. They are used for open installation, as well as for connecting to manifolds, installing radiators and connecting to valves.

Sequence with press fittings

If it is necessary to monolith metal-plastic pipes for heating, installation is carried out using press fittings that cannot be disassembled and do not require maintenance during operation. In this case, you cannot do without a press tool that compresses the sleeve around the fitting.

When installing a heating system, you can use fittings made of plastic, bronze and brass.

Metal-plastic heating pipes have not only advantages, but also disadvantages:

- the “layer cake” design is weakened by repeated deformations caused by temperature fluctuations;

- the cross-section of the fitting is narrower than the cross-section of the pipes;

- high-quality fittings are very expensive;

- counterfeit materials create problems during operation of the heating system;

- metal-plastic is unstable in relation to ultraviolet rays, mechanical and thermal influences.

The cost of high-quality metal-plastic cannot be less than 90 rubles per meter. This should be taken into account when purchasing. For example, metal-plastic pipes for heating rehau with a diameter of 16 mm cost 119 rubles per meter, with a diameter of 40 mm - 959 rubles per meter.

Installation of heating and water supply systems has become significantly easier with the advent of a new building material on the market - metal-plastic pipes. They have a number of advantages: they bend easily and reliably retain their given shape, are resistant to corrosion, do not require painting, have a lower noise level of liquid flow, are light in weight, and the flow area does not narrow during the entire period of operation.

Polyethylene is inert towards aggressive environments, and metal-plastic pipes are not subject to corrosion.

Regardless of what diameters of metal-plastic pipes are used in installation, the expansion coefficient of the material is always the same.

This ensures the reliability and durability of the pipeline

It is important that these products can come into contact with any materials, including concrete. They have proven themselves well in the Russian climate and can work without insulation at a temperature of -25°C

They are sold in coils and measured in linear meters. Flexible, allowing installation without the use of special tools.

Options for piping heating radiators

Radiator piping occurs in several ways, all of which depend on the connection of the radiator itself.

Let's look at each method in more detail:

- Radiator piping for one-way connection. Most often, this type of connection requires tying with metal pipes at the outlet of the system. The configuration requires two ball valves, two tees and two bends, that is, parts that have external threads at each end. In this case, it is necessary to have bypasses that will allow you to turn off the radiator in emergency situations. It is also worth sealing each threaded connection using FUM tapes or linen windings, and applying a layer of packaging paste on top.

- Radiator piping for diagonal connection. This method is the most optimal, since the heat transfer of such connections is most effective. With all this, tying such systems requires a large amount of materials and time.

- Radiator piping for saddle connection. This connection is the most convenient and invisible in terms of installation. The fact is that the pipes are connected in the lower parts of the radiator, which also allows you to install a bypass, which, although not necessary in this case, will still reduce the risk of heating malfunctions.

It is worth noting that the prices for piping heating radiators depend on the method of their connection, as well as their location.

Diameters of metal-plastic pipes

These are the most popular metal-plastic products for wiring heating and water supply systems in city apartments. Lime and rust do not accumulate in them and do not block the passage of the working environment. The fittings for them are the most inexpensive, which is the determining factor in the choice. 16 mm products are often used as outlets for faucets in the bathroom and kitchen, when installing meters, while the main pipelines can be made with larger diameter products.

20*2, where 20 is the outer diameter, 2 is the wall thickness, and the internal section is 16 mm;

A variety of fittings allow for competent and technologically correct wiring of systems.

These metal-plastic products are traditionally used in the installation of “warm floor” systems. The fittings on them are more expensive, but the throughput is higher than the previous ones. Therefore, if the water pressure is unstable, it is better to use them for installing hot and cold water supply systems than 16 mm metal-plastic pipes. Especially if you need to run a long route. Withstand pressure up to 10 bar, which corresponds to the characteristics of steel products.

20*26, where 20 is the internal section, and 26 is the external. Wall thickness - 0.3 cm;

Often used for installation of risers and underfloor heating systems. They are the preferred choice when installing engineering systems in a private home, since for autonomous heating and water supply it is necessary to provide a higher throughput due to possible surges in internal pressure.

26*32, where 26 is the inner diameter and 32 is the outer diameter. Wall thickness - 0.3 cm;

Large diameter products are the basis of any heating and water supply systems. They are used as risers and the main pipeline in low-pressure conditions, since, thanks to their high throughput, they ensure the uninterrupted supply of a large amount of liquid.

32*40, where 32 mm is the internal section, and 40 mm is the external. Wall thickness - 0.39 cm;

They are used to create networks of central and individual heating and water supply, central air conditioning, and in water treatment systems. They are used to assemble long routes for engineering systems in industrial and civil construction.

40*50, where the internal section is 40 mm and the external section is 48 mm. Wall thickness - 0.4 mm.

One of the common materials for manufacturing is metal-plastic. This is a modern material that has excellent qualities for use in heating systems.

This gives them incomparable advantages over pipes made from other materials:

- they do not require painting;

- ease of installation - no welding machine is required for operation;

- they can be walled into the wall and poured into the floor;

- they are lightweight, there is little waste during installation;

- their throughput is almost 1.5 times higher than that of metal pipes;

- stray currents will not be able to pass through them;

- have an aesthetic appearance;

- they are easy to replace, repair, or install an additional element into the heating system (for example, an additional radiator).

Metal-plastic pipes also have minor disadvantages:

- high price for pipes and fittings for them;

- they are sensitive to defrosting;

- service life is reduced by 2 times when used in systems with high operating temperatures (about 95° C);

- the presence of many threaded connections requires careful insulation, otherwise the pipes will leak.

A metal-plastic pipe is a pipe made of modern composite material. An aluminum pipe runs inside, surrounded on both sides by plastic.

Conclusion

For the most efficient heating operation, it is important to choose the right method and type of connection of devices to the coolant supply and outlet pipes. For self-installation, you will need instructions, which we presented in the video in this article.

Is it possible to connect bimetallic central heating radiators with metal-plastic.

8th floor of a 15-story building in a new building, supply from above. direct connection is planned.

I wouldn’t have asked this question if it weren’t for this (at the same time, maybe you can answer on the topic there?): ">

Thank you in advance for your answers on the topic.

Krick wrote: is it possible to connect bimetallic central heating radiators with metal-plastic.

A single-pipe, as I understand it, cannot be connected with metal: copper, stainless steel, even black metal.

Krick wrote: is it possible to connect bimetallic central heating radiators with metal-plastic. 8th floor of a 15-story building in a new building, supply from above.

. you can, but you don't need to! Listen to DOCA

DOKA wrote: One-pipe, as I understand it, it’s impossible

Why can’t we just ask him what pipe is currently in the house (riser and its diameter) that can increase the diameter of the metal-plastic?

Uncle wrote: why not right away?

Because the operating parameters of such a system may go beyond the acceptable limits for MP. It's strange that you have to explain this.

Heating risers and connections to the radiator are the responsibility of the service organization. The responsibility of the resident is from the inlet taps and therefore only replace them with the same one of the same diameter. 8th floor of a 15-story building in a new building, supply from above Operating pressure - somewhere around 8-10 bar - pressure testing can be pressed to 15 bar after maintenance work at the end of summer or early autumn and where can M.Plast go? pipe - designed for 10 bar Vandalism of new residents is not in vain.

We come only when people need us.

- And when you are not needed?

- Then we are gone. We don't exist. We don't exist for you

the riser is 1″, the foreman said that we will install it with three-quarter metal-plastic.

understood thanks. did not know. I looked at the specification - really 10 bar maximum :=/

Three-quarter MP, is this not 20mm? If so, spit in his face, and then measure with frost the narrowest place in the 20mm MP system - the fitting, and then compare its clearance with the clearance of a 3/4″ steel pipe. Plus, MP has all the corners with a small radius and a narrowed section, while steel has all the corners on the contrary, with a larger radius and widening. Even 25mm MP can't compare to 1/2″.

ASM wrote: Three-quarter MP, is this not 20mm?

ASM wrote: If yes, spit in his face

But in this case, what to do (wrong answer)? » >

thanks for the answer.

Just in case, I will openly state that it is possible or not to connect an MP 25mm battery in your situation, I don’t know. I just ran into the fact that the dimensions of the MP are equated to the dimensions of steel pipes several times, and I personally verified the fallacy of this superstition with a ruler. Regarding “don’t care”, my neighbors below had their 3/4″ risers replaced with 25mm MP. Therefore, I don’t care, every time I hear such “identity”, I really want it. As for the connection to the battery, if the riser is not replaced with an “alternative” MP, then it’s really up to you to choose. The main thing is not to harm other users of the riser.

Application area

Due to the technical characteristics of metal-plastic, the material has found application in pipelines for cold and hot water supply, as well as sewage.

It is used for various heating systems:

- Underfloor heating device "warm floor".

- Connection to wall-mounted radiator radiators.

- Heating of soil in closed greenhouse complexes and greenhouses.

- Water heating device for swimming pools.

- Laying protective screens for power cables.

- Compressed air supply.

Metal-plastic products can be found in air conditioning systems and in transport routes for the movement of gaseous and liquid substances.

Installation and wiring of the system - installation

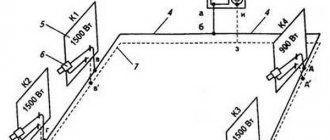

To construct a heating circuit in a private house, you need to take into account some details. There are different system wiring diagrams

It is important to choose and design the most optimal option. Media circulation can be natural or forced

In some cases, the first option is convenient, in others, the second.

Natural circulation occurs due to changes in liquid density. A hot medium is characterized by a lower density. The water going the other way is denser. Thus, the heated liquid rises along the riser and moves along horizontal lines. They are mounted at a slight angle of no more than five degrees. The slope allows the carrier to move by gravity.

A heating scheme based on natural circulation is considered the simplest. To perform its installation you do not need to have high qualifications. But it is only suitable for small buildings. The length of the highway in this case should not exceed thirty meters. The disadvantages of this scheme include low pressure inside the system and the need to use channels of large cross-section.

Forced circulation implies the presence of a special circulation pump. Its function is to ensure the movement of media along the highway. When implementing a scheme with forced fluid movement, there is no need to create an inclination of the contour. One of its disadvantages is the energy dependence of the system. If there is a power outage, the movement of media in the system will be difficult. Therefore, it is advisable that the house have its own generator.

The wiring happens:

- Single-pipe.

- Two-pipe.

The first option is implemented through sequential flow of the medium through all radiators. This scheme is economical. To implement it, a minimum number of pipes and fittings for them will be required.

To do this, you need to use the so-called “Leningrad” wiring diagram.

It involves installing bypass pipes and shut-off valves on each radiator. This principle allows for uninterrupted circulation of the carrier when any battery is cut off.

Installing a two-pipe heating circuit in a private house involves connecting reverse and forward current to each radiator. This approximately doubles the channel consumption. But the implementation of this option allows you to regulate the heat transfer in each battery. Thus, it will be possible to adjust the temperature in each individual room.

There are several types of two-pipe wiring:

- lower vertical;

- top vertical;

- horizontal.

Lower vertical wiring involves running a supply circuit along the floor of the lower floor of a building or its basement. Then, from the main line through the risers, the carrier goes up and enters the radiators. From each device there is a “return”, delivering the cooled liquid to the boiler. When implementing this scheme, you need to install an expansion tank. There is also a need to install Mayevsky taps on all heating devices located on the upper floors.

The upper vertical wiring is arranged differently. Fluid from the heating unit goes into the attic. The carrier then moves down through several risers. It goes through all the radiators and returns to the unit along the main circuit. To remove air from this system, an expansion tank is needed. This scheme is more effective than the previous one. Because there is a higher pressure inside the system.

The horizontal two-pipe type wiring diagram with forced circulation is the most popular. It comes in three varieties:

- with radial distribution (1);

- with associated movement of liquid (2);

- dead-end (3).

The radial distribution option consists of connecting each battery to a boiler. This operating principle is the most convenient. Heat is distributed evenly in all rooms.

The option with a parallel movement of liquid is quite convenient. All lines going to the radiators are of equal length. Adjustment of such a system is quite simple and convenient. To install this wiring you need to purchase a significant number of channels.

The last option is implemented by using a small number of channels. The downside is the significant length of the circuit from the distant battery, which complicates the adjustment of the functioning of the system.

Armature

Let's find out what shut-off and throttling valves will be needed in each of the described cases.

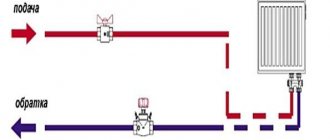

For single-pipe wiring

A typical solution for the most popular, simple and trouble-free single-pipe Leningrad system is the bottom connection of heating devices; diagonal is used a little less often.

The minimum price for the following set of fittings for each radiator:

- ball valve - 2 pieces (supply and return);

- Mayevsky tap - 1 piece.

Hint: the Mayevsky tap is installed in the upper passage plug.

Ball valves provide the ability to turn off the radiator; The air vent allows air to be released above the level of the connections. However, such piping requires a noticeable amount of time during startup and does not allow flexible adjustment of the heat transfer of the radiator.

Here is an advanced set of equipment that solves both problems:

- ball valve for return line;

- throttle or thermal head (thermostatic valve) for supply line;

- automatic air vent.

This is exactly the set of fittings used here.

The throttle allows you to regulate the heat transfer of the battery with your own hands. A slightly more expensive thermal head independently regulates the permeability of the liner, reducing or increasing heat transfer depending on the air temperature in the room.

With a diagonal connection, the radiator can be equipped with a flush tap. The best flushers are made from ordinary ball valves with male-female threads screwed into the radiator plugs.

For two-pipe wiring

The instructions for selecting fittings for a two-pipe circuit differ only in that the presence of at least one choke in the kit is mandatory. Heating balancing, remember? But you can do without vents if one of the bottlings passes above the heating devices: the only Mayevsky valve or automatic air vent is installed at the top point of the circuit.

Please note: often the automatic vent is part of the safety group of the heating boiler and is located in its body.

The most practical set of fittings includes:

- throttle on the return pipeline;

- thermal head on feed;

Heating systems: their types and installation rules

Before installing a heating system in a house, you should first decide how the coolant (in most cases it is water or non-freezing antifreeze liquid) will circulate through it. Because both the choice of heating boiler and the choice of pipes directly depend on this step.

At the moment, there are the following types of boilers used for heating private houses:

- gas - one of the most popular, powered by natural gas;

- solid fuel - also very popular, can run on various types of solid fuel (coal, firewood, peat);

- liquid fuel (diesel) – less popular compared to others and run on liquid fuel (usually diesel fuel);

- electric - optimal in conditions of lack of gas, because they run on electricity;

- combined ones are universal and can operate on different types of fuel.

As a rule, the following option for dividing heating systems is generally accepted:

- with natural circulation, in which the coolant moves due to the temperature difference: hot water rises and, gradually cooling, naturally falls down;

- with forced circulation, in which the movement of the coolant occurs due to the connected circulation pump.

The first option allows the heating system to operate only using a gas boiler, without additional installations. But, at the same time, its installation will require complex calculations, calculation and compliance with the required slopes and a strictly defined distance between the pipes.

In this regard, a forced circulation heating system has a number of advantages and is considered more efficient. A pump installed separately or built into the boiler provides the necessary pressure in the system, regardless of the presence or absence of a slope or the length of communications. Even in this case, you can install heating pipes of small diameter, which provides additional opportunities for interior design.

The pressure created in a heating system with natural circulation is usually 1.5 - 2 bar, and in a system with forced circulation - 2 - 4 bar.

Its main advantages include the absence of high temperatures and pressure, as well as the possibility of using thin metal or flexible corrugated foil pipes. But despite this, this system also has disadvantages. So, due to the strong noise and overall dimensions of such pipes, installation and installation in the wall may not always be possible.

After you have been able to decide on the type of heating system to be installed and choose the most suitable option, you should familiarize yourself with some points that are important to consider when installing it.

So, the rules for installing heating systems are as follows:

It is necessary to maintain the recommended distance between communications and not install additional objects (shut-off valves, strainer) between the boiler and the safety group (pressure gauge, relief valve, automatic air vent). In a network with a forced heating system, a strainer can be installed in front of the pump. Pipes should be selected based on the type of boiler. Different types of pipes can be combined, but you must carefully study their markings and manufacturer’s recommendations. When connecting a large number of radiators, double-circuit wiring should be done and large-diameter pipes should be installed. It is important to provide for the installation and removal of combustion products to the outside if required by the boiler design.

Now we will tell you in detail about what types of heating pipes there are, what main characteristics and properties they have.

System recharge

Closed-type heating systems are equipped with outlets for recharging the circuit with coolant. If water is used as the coolant, the return heating circuit can be connected directly to the water supply. The replenishment will be done through shut-off valves and a mud filter (a softener filter will also be useful here).

A pressure gauge will help track the pressure difference in the forward and return lines.

If antifreeze is used as a coolant, then a special branch is made in the circuit for pumping antifreeze. Also, do not forget about the coolant drain taps, which cut into the lowest point of the system.

Installation of heating from metal-plastic pipes

There are 3 known ways to connect metal-plastic pipes to each other:

- threaded or collet connection. It is detachable and used as a dynamic option. If necessary, you can disconnect/connect one or another branch of the network;

- compression or conditionally detachable connection. It can also be disconnected or reconnected, but this is associated with certain difficulties;

— press fitting, a fixed connection technology that does not imply the possibility of disassembling and reassembling the unit.

Installing heating using metal-plastic pipes is easy to do yourself, since it does not require special knowledge or complex equipment. The heating system is designed in accordance with the location of the rooms, the boiler, the location of the radiators and some other factors. You can choose a collector, one- or two-pipe scheme, with top or bottom hot water supply.

The most economical is the single-pipe scheme, but the temperature of the radiators will decrease as they move away from the boiler. To distribute heat evenly between the radiators, a collector circuit should be installed. But its installation will require more material. Two-pipe is a compromise solution: heat distribution is more uniform than in the case of single-pipe distribution, and fewer pipes are required than in a manifold circuit.

Installation of a heating system based on metal-plastic pipes is carried out taking into account the following rules:

— work should be carried out at an ambient temperature of at least +10 °C;

- if the pipes were stored at lower temperatures before installation, they must be allowed to warm up to the specified temperature;

— installation of pipes should be carried out only after the final finishing of the wall surface;

— pipes should be cut only with special scissors;

— do not allow pipes to break when bending;

— attach the pipes to the hay using clamps or clips.

Features of radiator piping

It is worth noting that this procedure will allow you to operate your heating system more efficiently, as well as set the optimal amount of heat transfer from the radiator to the room.

An important part of the installation work is determining the type of radiator and connection diagrams (diagonal, side or bottom).

In general, installation of heating radiator piping includes several primary actions, including:

- Dismantling of an outdated system.

- Correct selection of location for installing systems, installation of fasteners.

- Installation work of a shut-off device, thermostat, tap and air mass vent.

- Work on sealing each connection.

- Pressure testing of the system.

- Works on supplying coolants.

It should be understood that such work is quite complex and requires the help of qualified specialists who have everything necessary for tying.

What is taken into account when choosing pipe diameter

Heat generator power. It is taken as a basis and determined individually for each building. What does the owner focus on when purchasing a boiler?

For the total area of all heated premises. This is exactly what the manager at the point of sale will definitely clarify if the buyer has questions about this item.

Coolant speed. If it is less than 0.25 m/sec, then there is a risk of airing the system and causing traffic jams on the highway. Exceeding the value of 1.5 is fraught with “noise” in the highway.

This is especially noticeable when the pipes are metal, and even laid in an open way. But in any case, the movement of the coolant along the route will be clearly audible.

Practice has proven that for a private building (with an autonomous heating circuit) you should focus on an indicator in the range from 0.3 to 0.7. This is the optimal value for any system.

Circuit configuration. In private houses, when installing it, as a rule (regardless of the circuit), all the “threads” are connected to the collector. Each of them is “loaded” with a certain number of radiators.

There is no point in purchasing pipes of the same diameter for all lines, given that the larger the cross-section of the workpiece, the higher the price of 1 running meter.

Pipe diameter. The outer one does not play a special role, since products made from different materials have differences in wall thickness. This parameter only indicates the ease of fastening the product. The internal diameter is about the throughput of the route. It is he who is decisive.

Pipe diameters are usually indicated in inches. For us, this is an unusual (non-metric) system, so you should know the rules for converting quantities. The ratio of inches to centimeters is ½.54 (or 25.4 mm). Pipe material – metal-plastic, steel, PP, PE.

Specifics of the structure. First of all, this relates to the effectiveness of its thermal insulation - what materials it is assembled from, what method is used, and so on.

How to connect pipes

Before installing the flange, you need to check it for the presence of various sharp parts, burrs, corners - all of them can damage the plastic pipe. When purchasing, check the flange for defects; they should not have cracks or unevenness at the joints.

High-quality pipeline connection

Let's look at how to properly connect metal-plastic pipes without threads:

- Before starting work, you need to make an even cut on plastic pipes using special scissors;

- After this, a selected flange of suitable diameter is put on the cut;

- Next, a durable rubber gasket is threaded under the flange to ensure a strong and tight connection;

- A flange is also placed on the metal pipe and is bolted to the flange connection of the plastic pipe.

To prevent sewerage connected in this way from leaking, the connection points must be treated with sealants

Also pay attention to the tightening force of the flanges. They need to be tightened firmly enough with the bolts, but do not pinch the plastic so that it does not crack under pressure.

Pipe flange

Gears are very convenient for making rotary transitions in the pipeline system. They are most often used in private construction work; they are used to connect plastic pipes with common metal pipes.

To make a threaded connection, you will need a fitting.

- At the designated junction of pipes made of different materials, the coupling is removed from the metal transition. It happens to many owners that there is no coupling in these places, in which case the main pipe is simply cut;

- To carry out the work, you will need a thread cutter - this is a special device similar to a hand cutter; it will make a thread on the cut section of the pipe;

- When working on a riser, you need to make no more than 5 turns of thread, and only 3 of them are treated with sealants and sealing tapes;

- Before covering the threads with sealants, you need to clear them of chips;

- On any hand-threaded pipes, the fitting must be screwed on only by hand. If you use special clamps, you can damage the non-standard thread and you will have to cut the pipe even further, which will shorten it;

- The fitting is simply pushed onto a PVC, PP or PE pipe;

- All that remains is to carry out welding work at the places where the fitting and plastic are attached using a special inverter.

Work is carried out similarly when heating, if you need to connect plastic pipes with metal taps. You will also need to cut a thread on one end (metal) and weld an adapter on the other. In this case, you will need an American faucet.

Fitting for copper and plastic pipe

Naturally, a flange connection is much more difficult to implement than a fitting connection, but it is considered more reliable. Do not forget to seal threaded connections with special devices: self-adhesive tapes, jute, resins.

Tips on how to make connecting plastic pipes to metal ones as simple as possible:

- Work according to the project;

- Consult with specialists; your pipeline may require a special approach and selection of adapters;

- Before starting work, be sure to turn off the water in the riser;

- Periodically check connections for leaks or physical damage;

- Metal fasteners must be treated with protective mastics, which will help prevent the appearance of rust at the attachment points of flanges and fittings.

Useful connection tips

There are some recommendations on how to connect a battery to a plastic pipe efficiently. Before attaching the fitting, the pipe must be freed from the outer chamfer. This will free the pipe from burrs that could cause the connection to become loose.

When installing brackets for mounting the radiator, you should equip every three sections with separate fasteners. To ensure that the threaded connections of the system are as tight as possible, it is practiced to use flax with paint or a polymer sealing thread. Without paint, flax will quickly fade, and FUM tape usually begins to leak in the case of minimal thread reverse.

DIY installation features

Self-installation of an individual heating system has its own characteristics and nuances. Most questions arise regarding the issues of giving the desired shape to the pipe line and the choice of connection methods.

How to bend a pipe

The most optimal way to bend a pipe is to use a special device - a pipe bender. If this is not available, an alternative method of bending is used by heating with a construction hairdryer. It should be remembered that, unlike steel, metal-plastic is a more fragile material and therefore the bending radius is equal to seven times the diameter of the pipes being connected. If the bending angle is smaller, it is best to install an elbow fitting.

Connection methods

With an open installation method, experienced plumbers recommend connecting individual sections of the thermal distribution with compression fittings. If pipes are laid in a hidden way, for example, in a floor structure, press fittings or crimp couplings are used.

Detachable connections are installed only with open heating pipelines.

The need for piping heating pipes

Parts for adjusting the operation of heating devices

The piping of heating radiators ensures the correct operation of all elements of the heating main and the timeliness of their adjustment. The works also solve the following problems:

- choosing a method of control over the system - manual or automatic;

- normalization of the functions of heating communications - the flow of coolant in a separate area is limited;

- reducing utility bills;

- the safety of the finished system, which is not clogged with deposits and debris;

- ensuring normal temperature and protection from pressure fluctuations;

- removing air jams from communications;

- adjusting the heating speed of heating devices;

- the ability to connect different circuits and configure them;

- quality of distribution of thermal resources among batteries.

Strapping elements must be selected with the condition of their maximum heating.

Overview of fittings for metal-plastic systems

To prepare for work, it is important to cut the pipes into sections of the required length, and all cuts must be made strictly at right angles. If the pipe is deformed during the cutting process, it must be leveled with a gauge (it will also help remove the internal chamfer)

To connect metal-plastic pipes of different categories into a single structure, connecting elements are used - fittings that differ in design, size and fastening methods

To install the structure, various types of fasteners are used - fittings; we will dwell on them separately.

Option #1: collet

Push-in fittings, consisting of a body, a ferrule, and a rubber gasket, have a detachable design, so they can be used several times. The thread of the parts allows them to be combined with household appliances.

To connect the connecting elements to the pipe, you need to put a nut and a ring in series. Insert the resulting structure into the fitting and tighten the nut. To make it easier for the pipe to pass into the connecting element, it is advisable to wet it.

Option #2: compression

Parts widely used for connecting pipes, which can be called conditionally detachable

Before installation, it is important to ensure the presence of o-rings and dielectric gaskets, which should be located on the shank of the part

Compression fittings are widely used in the construction of metal-plastic structures. They allow you to easily create connections without the use of special tools

To connect, a nut and a ferrule are put on the end of the pipe (if it has the shape of a cone, then the process is carried out on the narrower side of the part). After this, the shank is inserted into the pipe (this requires some effort), and in order to seal, the part is covered with tow, flax, and sealant.

The next step is to put the union nut on the fitting body and tighten it. It is convenient to do this with the help of two keys: one of them fixes the part, the other tightens the nut.

This method is quite easy and does not require the use of special equipment, however, it is not advisable to use it for hidden wiring, since it requires checking the connection.

Option #3: push fittings

Convenient connecting elements that do not require special tools for fastening. For installation, it is enough to insert the product into the connecting part, and the end of the pipe should be visible in the inspection window.

Immediately upon completion of installation, thanks to the included water jet, the fitting wedge is pushed forward, forming a clamp that prevents leakage.

This method allows you to quickly and easily create the required structure, ensuring high-quality, durable connections. Almost the only drawback of push fittings is their high cost.

Option #4: press fittings

These elements are used to create permanent connections using press jaws or similar devices.

Press fittings create tight, long-lasting connections, but can only be used once. In addition, to work with such elements you will need press pliers.

To connect using press fittings, you need to calibrate the part by removing the fez from it, after which the sleeve is put on it and the fitting is inserted. The sleeve is grabbed by press jaws, after which the part is firmly clamped by bringing the handle together.

This element can only be used once, but the fasteners mounted with it are quite tight and reliable, making them suitable for hidden wiring.

Installation of press fittings is carried out in the following order:

Installation of pipes from different types of materials

To connect elements, one of which is made of metal and the other of metal-plastic, special fittings are designed, one end of which is equipped with a thread, and the other with a socket.

For installation, a metal pipe needs to be threaded, wrapped in tow, lubricated with soap or silicone, and then the fitting is put on by hand. After its second end is connected to the plastic element, the thread is completely tightened using a wrench.

Assortment of fittings of different shapes

For ease of installation, the connecting elements can have different shapes. The most common are:

- adapters for connecting pipes with different diameters;

- tees providing branches from the central pipe;

- corners for changing the direction of flow;

- water sockets (installation elbows);

- crosspieces that allow you to organize different flow directions for 4 pipes.

Press fittings can have a special configuration (couplings, triangles, tees).

Fittings for polypropylene pipes

The following fittings are used to connect a heating radiator to a polypropylene pipe:

- Coupling tee with diameter transition. Used when inserting into horizontal filling. As a rule, forced circulation circuits are equipped with spills with a diameter of 25-32 mm. If you need to connect a separate radiator, then it is better to take a 20 mm fitting.

- Adapters from welded socket to 1/2 inch thread. Used to connect valves, throttles, thermostatic valves.

- American. This is the name for a quick-release fitting that has union nuts and rubber gaskets. Installation of such a device takes 30-40 seconds.

Installation process

As we said above, most negative reviews about metal-plastic pipelines are associated with errors made during installation of the system. Therefore, before starting the actual installation, you need to study the manufacturers’ recommendations and read the instructions for installing the heating circuit from the products in question.

Before installation begins, a diagram of the future highway is drawn up. The location of the threads and other necessary components is placed on the house plan. After this, they calculate the volumes of materials that will be required to solve the problem.

The step-by-step installation looks like this:

- A piece of pipe is cut off with scissors.

- The calibrator is used to align the inlet pipe for connection to the fitting.

- The press fitting is mounted and clamped using crimping pliers.

If you have purchased high-quality metal-plastic pipes, it is permissible to use a spring pipe bender. In this case, the minimum bending radius must be carefully observed. It directly depends on the cross-sectional index of the product.

What materials is the harness made of?

At the moment, there are several popular materials that are used for strapping.

This list includes:

- Polypropylene pipes.

- Reinforced polypropylene pipes.

- Steel pipes.

- Other materials.

It should be understood that in addition to the basic materials, additional ones are also used, which include:

- Ball valves.

- Tees.

- Sgony.

- FUM tape.

- Linen windings.

- Packaging pastes.

Basic rules for installing metal-plastic pipes

Metal-plastic pipes are highly sensitive to mechanical damage, temperature influences, and do not tolerate direct exposure to ultraviolet rays. Therefore, open laying of metal-polymer pipes is possible only in those places where the presence of these factors is excluded.

In order to easily repair concealed metal-plastic pipes with screw fittings, it is necessary to provide inspection hatches at the joints. These elements should not have sharp edges.

Metal-plastic pipes are laid through building structures using sleeves. There should be a gap of 3-5 mm between the inner surface of the sleeve and the outer side of the pipe, which is created using a soft, non-flammable material that allows longitudinal movement of the pipe.

Therefore, sharp objects should not be used when unpacking pipes. Marks can only be drawn with a marker or pencil.

For the installation of press fittings, reliable equipment is used, which eliminates the creation of poor-quality connections.

Installation of metal-plastic pipes - video materials will help you cope with this process - should be carried out using hangers and supports offered by pipe manufacturers. When using metal fasteners, the pipe is protected with gaskets made of soft materials.

To solve the question of how to repair a metal-plastic pipe, you can choose one of the options:

- to eliminate a leak, it is necessary to cut out a piece of pipe and install a new one using a connecting fitting;

- if the leakage area is small, you can install only a connecting fitting without buying a new pipe;

- The leak can be sealed by installing a flange with a gasket or sealed with epoxy glue or sealant.

Metal-plastic pipes are the most versatile among polymer pipes; they are reliable in operation, easy to install and have an aesthetically attractive appearance. It is these properties that explain the growth of their popularity.

Definition of the term “battery strapping”

A set of fittings for connecting a radiator to the main line - there is a piping of batteries. The

piping of heating radiators is understood as a set of pipeline elements and fittings for connecting radiators to the main line. The piping is the most vulnerable area of communications due to detachable connections, the likelihood of using low-quality fittings and the lack of protection from mechanical stress in the circuit.

The principle of connecting the battery to the pipeline is unimportant; efficiency and reliability depend on the chosen circuit. The simplest horizontal technology is stable; when using the lateral method, you need to calculate the financial costs.

To lift the system from the floor, special metal tubes are used - they increase the reliability of the harness.

Tools and materials for laying pipes

Laying metal-polymer systems requires a minimum of devices and materials, but it is better to choose high-quality devices and pipes.

Pipeline installation accessories

To create a structure made of metal-plastic, a very modest set of tools is enough: a pipe cutter, a simple pipe bender, press pliers, a sliding and spanner wrench.

To install a metal-plastic system with your own hands, you need a minimum of tools, which can be purchased in a set or separately from a construction supermarket.

To separate measured sections of pipe from the coil, it is advisable to stock up on a pipe cutter designed for cutting metal-plastic pipes. Since metal-plastic is a fairly malleable material, it can be cut with a hacksaw or even a sharp knife.

However, ideal perpendicularity of the lines, without which it is difficult to obtain a tight connection, can only be achieved by using a special cutter.

Different types of wrenches are important for installing and assembling threaded connections on pipeline fittings. If absolutely necessary, you can get by with one spanner, but for comfortable work it is better to use two spanners and one adjustable wrench.

A gauge is an important tool for creating an accurate and tight connection between a pipe and a fitting: it allows you to center the cut plane and chamfer the inside of the product.

The pipe bender allows you to change the configuration of the element, so you can save on corner fittings

It is especially important to have this tool if the design involves a large number of angular mates

Before starting work, we advise you to familiarize yourself with the rules and specifics of crimping metal-plastic pipes.

What materials will be needed?

To lay the pipeline, it is important to stock up on the following components:

- pipes (coils, measured sections);

- various fitting options (bends, tees, corners), with the help of which individual sections of pipes are transformed into a single system;

- fastening elements - dismountable clamps and clips, with the help of which metal-plastic structures are fixed to supporting surfaces, most often on the wall.

It is important to select all the necessary materials and tools in advance so that you can carry out all the work smoothly. This article will introduce you to the range of metal-plastic products for pipeline assembly.

This article will introduce you to the range of metal-plastic products for pipeline assembly.

Date: September 25, 2022