It seems to many that corrugated pipes are a relatively recent product on the plumbing market. In fact, corrugated pipes have long been firmly established in every home as a shower hose. Corrugated stainless steel pipes for heating came into use a decade ago, successfully replacing smooth-walled counterparts in modern engineering systems. Let's figure out what benefits the use of corrugation brings, what it comes in, and why its installation is considered simple.

Connecting a radiator through a corrugated pipe Source metallobaza-sm.ru

Varieties

The industry produces two types of corrugated stainless steel pipes, differing in the method of technological processing:

- Annealed. After additional heat treatment, the metal becomes softer and more ductile (however, such products are one and a half times more expensive than conventional analogues). If the system is designed with turns, the pipe will successfully withstand the kinks and remain intact.

- Unannealed. Externally, they cannot be distinguished from products that have undergone additional heat treatment. They hold their shape well and practically do not sag between the support points, maintaining a horizontal state (if the areas are not too long). It is better to avoid them if the system is complex and has many turns, since deformations will form at the bends.

The main characteristic of flexible heating pipes, rigidity, depends not only on the heat treatment, but also on the wall thickness (more precisely, on the thickness of the sheet from which the corrugation is made). The thickness varies between 0.13-0.5 mm. The higher the parameter, the worse the corrugated spiral bends. There is an advantage to this: the stiffer the product, the better it retains its shape.

Fragment of corrugation with fitting Source laminatepol.ru

How are corrugated pipes made from stainless steel?

The technical conditions for the manufacture of corrugated pipes regulate the use of AISI 304 stainless steel.

It is produced using the following technology:

- the stainless steel sheet enters the forming machine, where it takes on a cylindrical shape;

- the edges of the cylinder are welded together by laser, plasma or induction current;

- the strength of the weld is checked by eddy currents;

- then the workpiece undergoes calibration, during which the product acquires a characteristic wavy structure;

- When leaving the calibrating machine, cutting to the required length is carried out.

Such a pipe can already be used for installation, but it is less durable and ductile. To increase these indicators, products are subjected to heat treatment (firing) at a temperature of +600ºС, followed by a period of forced cooling (tempering).

Visually, the products are no different, but after firing they become stronger and more flexible, which means that when bent, creases will not form on them, as on unmolded corrugation.

Performance characteristics

Stainless steel corrugation is considered a convenient and inexpensive substitute for classic heating pipelines (especially when compared with copper ones). The practicality is obvious: in terms of performance characteristics, stainless steel is not inferior to copper, but in terms of finance it is many times more attractive. The use of high-quality metal corrugations allows you to obtain a reliable system while maintaining its reasonable cost.

Standard corrugation in the mid-price segment (for household systems) has the following characteristics:

- Diameter: 15, 20, 25, 32 mm. Large diameters (up to 100 mm and above) are rarely used. There is a concept of external and internal diameter. For example, a product stated to have a diameter of 12 mm has an outer diameter of 16.2 mm and an inner diameter of 11.8 mm.

- Wall thickness: 0.25-0.3 mm.

- Working pressure – 15 bar (atmospheres). An excess of up to 50 bar is permissible. Some products (Korean, Japanese) are able to withstand a short-term increase of up to 200 bar, but then they collapse.

Corrugated stainless steel pipe for heating Source twimg.com

- Coolant temperature: +110 °C.

- The operating temperature for corrugated material ranges from -50 to +110 °C.

- It is also important to consider the purpose, corrugation pitch, coil length and bending radius.

Application and labeling

Stainless steel corrugation is used in the following cases:

- When installing heating systems of private houses, bathhouses, greenhouses (usually a product with a diameter of 20 mm is used). They help connect heating appliances to the heating riser.

- When installing standard water supply pipelines and connecting plumbing fixtures.

- When installing heated floors and varieties (warm walls, baseboards); in heating radiators.

- As cable ducts for protecting electrical cables.

- In fire extinguishing systems as a fire-fighting pipeline.

- When laying communication networks.

- In gas supply systems.

- In internal combustion engines: transports fuel and removes exhaust gases.

Product markings indicate how they can be used:

- With the letter "A". The corrugation is made of unannealed steel.

- With the letter "M". Annealing technology was used.

Connecting a corrugated pipe to a fitting Source prodomostroy.ru

- With the letter "P". The pipe is protected by an additional plastic sheath.

- With the letter combination “El”. For electricians.

See also: Catalog of companies that specialize in engineering systems (heating, water supply, sewerage and others) and related work

Features of corrugated stainless steel unannealed pipe

We will continue the topic of what are the differences between stainless steel corrugated annealed and unannealed pipes by considering the second type of these products. Structurally, unannealed pipes differ only in the shell material. Steel that has not undergone heat treatment is more rigid. Pipes of this type require a larger bending radius, which creates inconvenience when working with them in cramped conditions. They cannot be used for rolling joints because the unannealed corrugated casing has insufficient ductility.

If you make a mistake when bending unannealed pipes, then after alignment, visible traces of previous bends will remain on the corrugation. Therefore, such work requires special care.

As for marking, unannealed pipes are indicated by the following symbols:

- GF at Lavita;

- A at Kofulso;

- TN at Hydrosta.

Let us remind you that there are no external differences between the two types of pipes, but they exist for products designed for different installation conditions and main intended purposes. We must also remember that, other things being equal, the cost of a meter of unannealed corrugated pipes is approximately 10% lower than that of annealed products.

pros

Stainless corrugated piping technology is attractive for the following reasons:

- The product is not subject to corrosion due to the metal - ordinary, stainless or galvanized steel. Stainless steel corrugation has the highest corrosion resistance.

- An important property of pipes is durability. The service life of the system is virtually unlimited, and is determined by the service life of the couplings used for crimping. Some parts (O-rings) are designed to last 50 years.

- Economical technology. Construction budgets are saved due to overall low metal consumption and reduced assembly time. According to experts, costs are reduced by 20-25%.

- The products are ideal for organizing heating and plumbing systems. A stainless steel corrugated pipe for water supply has characteristics that allow it to cope with temperature fluctuations (up to freezing of the coolant) and water hammer.

Flexibility is one of the main advantages of corrugation Source amazon.com

- Practicality during use. The pipes are flexible and resist static and dynamic loads well. Bends do not affect the permeability, therefore, when using corrugated products, you can avoid fittings (connecting parts).

- The weight of corrugated pipes is insignificant, comparable to some types of polymer analogues.

- Due to the high heat transfer coefficient of metal, corrugated pipes are effective in heating systems.

- The smooth inner surface prevents the section from overgrowing; hydraulic resistance remains minimal. Pipes do not require additional flushing.

- Installation is as easy as possible; Standard fittings are used for connections. Thanks to its flexibility, utility lines can be laid in hard-to-reach places. The number of connections has also been reduced.

Material with a polymer shell of different colors Source atmosfera.ua

Alternatives

In addition to stainless steel, plastic or cast iron (products with a ribbed surface) are used to make corrugated pipes. Plastic products are not the best option for heating, where the operating temperature of the coolant can reach +110ºС, since they can function normally only at temperatures up to +85ºС and a pressure in the system of no more than 20 atmospheres.

Cast iron finned pipes are characterized by high resistance to thermal loads, but they are gradually falling out of mass use due to their high weight, low impact resistance and complex installation process.

Minuses

The disadvantages include the following features:

- Stainless steel is not a cheap raw material, and a corrugated stainless pipe for heating from the best manufacturers costs a decent amount.

- If you plan to design a heated floor, experts recommend using corrugation in a polyethylene braid that protects against contact with chemically active substances. In addition, the concrete screed should be replaced with a “dry” installation method.

- Corrugated pipes have an “industrial” look that will not fit into every design. On sale you can find corrugated polymer shells in different colors, which leaves some room for maneuver.

- The recesses between the corrugation rings sooner or later fill with dust, which is not so easy to clean out.

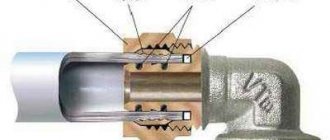

Connection methods

To connect stainless steel corrugated pipes, a brass compression fitting with a silicone or rubber O-ring is used. The end of the pipe is inserted into it until it stops and tightened with a ring.

When switching from a smooth steel pipe to a corrugated one, the fitting is first attached to the smooth pipe, and then a stainless corrugated pipe is inserted into it.

Flexible radiator connection

A manual rolling machine is used to make flexible hoses for radiators and heaters.

First, a piece of pipe of the required length is cut with a pipe cutter or grinder, and the cut line is carefully cleaned. The pipe is then inserted into the protruding flaring machine onto two corrugated rings to allow the protruding edge to be flared using a hammer. Next, a union nut with a rubber gasket is put on this end of the pipe. Attaching the union nut to the other end is done in the same way.

Warm floor

For laying corrugated pipes in a “warm floor” system, it is recommended to use plastic clips as fastening elements.

Holes for dowels for attaching clamps must be drilled through the insulation layer into the concrete screed.

Installation should begin from the distribution cabinet, connecting one end to the manifold outlet. Next, the pipe is rolled out of the coil and placed between the clips in coils, the distance between which should be 30 cm and at least 20 cm from the walls. After the pipe is evenly distributed throughout the room, its second end is connected to the outlet of the return collector.

Installation subtleties

Sometimes the flexibility of corrugated pipes for heating or water supply turns from an advantage into a disadvantage, which must be remembered in the following situations:

- In difficult places in the system, do not repeatedly bend the corrugated part. During operation, this place will be a weak link, since bending loads will exceed permissible values.

Heat exchangers for heating a private house (in a brick oven) Source ytimg.com

- If there are children in the house, it is worth considering how to secure the system. Children's imagination can easily turn a flexible part into a convenient support or crossbar. Sooner or later, fatigue will accumulate in the material with all the ensuing (in every sense) consequences.

Installation of corrugated stainless steel pipes for heating includes the following operations:

- A piece of the required size is cut from the bay, for which a grinder or pipe cutter is used. If necessary, the cut site is cleared of burrs.

- The pipes are connected using fittings. In this case, you must ensure that the diameters match and the union nut is tightly tightened.

- If necessary, the pipeline is fixed to the wall using brackets.

- Lastly, water is supplied to make sure the joint is tight.

A pipe cutter allows you to obtain a cut without deforming the pipe Source rothenberger-russia.ru

Purchasing: what to look for

When purchasing any components, make sure that they have a certificate of conformity. It is convenient to evaluate the quality of corrugated pipes according to the following criteria:

- No obvious defects (deformations, chips) upon visual inspection.

- Seam quality: choose products with smooth and unbroken seams.

- A high-quality coil has ease of bending: if you bend and release the fragment, it will return to its original position.

- Pitch uniformity: correct when the spacing between the rings remains the same anywhere in the bay.

Check not only the characteristics, but also the integrity of the packaging Source vseinstrumenti.ru

Pay attention to the labeling. Since it cannot be applied to a corrugated surface, all relevant information is printed on the coil wrapper. It is not advisable to purchase a corrugated pipe for heating if the container is damaged. This may indicate substitution, a desire to pass off a cheap product as a high-quality one.

Open-end wrenches are used in installation work; you will also need a cutting tool; It is best to stock up on a pipe cutter - it can make a cut at a right angle. The stability of the system is determined by the fittings, and there are also certain requirements for them.

The surface of the fitting must be smooth; any damage to the gaskets is unacceptable. Experts recommend giving preference to brass fittings, as they provide better tightness: in the future you will not have to periodically check and tighten the joints.

Connecting (clamping) fitting helps to assemble complex routes Source proteplo33.ru

Briefly about the main thing

Corrugated steel pipe is an advanced engineering communication that combines usually incompatible properties: strength and flexibility. The material is convenient to install and operate in different types of systems; it lasts for decades and remains resistant to chemical corrosion all this time. The property is especially valuable for the use of water supply and sewer systems.

Corrugated material has gained popularity due to its ability to withstand heavy loads, as well as quick installation and a reduction in the number of connection points. Such capabilities simplify the creation of complex configuration systems, which is especially important for plumbing or heating in a private home.