Just a decade ago, only smooth-walled pipes were considered in heating systems. Now the market of materials for installation of heating systems has been replenished with an interesting new product, which are corrugated pipes for heating. The combination of the flexibility of corrugation and the strength of stainless steel has proven to be very successful, and many modern heating systems are installed using these particular products.

Corrugated pipes are one of the newest materials for heating systems.

Application nuances

The scope of use of stainless steel in the heating sector is extensive, which makes it possible to use corrugation when arranging complex pipelines at industrial facilities and simple heating systems in different facilities. Unique flexibility, resistance to moisture and pressure make corrugated pipe an excellent solution for creating heated floors. It guarantees a high thermal conductivity parameter and heats concrete up to 100 mm thick.

Corrugated heating pipes, due to their characteristics, require special attention already at the purchase stage. Pay attention to the appearance of the product. Signs of damage, rust or fractures can lead to problems during operation. During installation, check the quality of the joints, because corrugated pipe is very flexible and if laid incorrectly, there is a high risk of leakage. If there are no errors, the service life is 20 years or more.

Pay attention to the certificates of conformity confirming the quality and possibility of using corrugations in the heating system. Check the quality of the cut, any damage to the edges and the sufficiency of the contents. As a rule, the kit includes fittings for combining sections. We will dwell on the issue of choice in more detail.

Varieties

To begin with, it should be said that there are many varieties of such products that have their own characteristics and properties. At the same time, they have their own areas of operation, which is why they were built. However, it should be noted that the standard instructions for the installation process do not require the use of a specific type, but it is developed specifically for it.

When developing heating structures, it is often necessary to create bends, and the use of similar pipes helps to avoid the use of adapters or elements for profiles that weaken the product

- Very often, metal products that are not flexible were used to install heating radiators . However, with the advent of new technologies, flexible copper pipes or metal-plastic products are used for these purposes. They make it possible to carry out the installation process in virtually different places and with different connections.

Some craftsmen use this material even when developing the batteries themselves, which makes it possible to save a lot of money, but only specialized corrugated pipes are suitable for this work

- It should be noted that in this area flexible pipes are not used for water supply, since they cannot always withstand high temperatures in the system . Due to this, special materials designed for heating are used for these cases.

- If all work on a similar installation process will be done with your own hands, then it is fundamentally important to pay your own attention to the connection elements and the fact that bends are not allowed in this area . Approximately about 20 centimeters until the joint is formed, the installation line should be straight.

Advice! When choosing similar materials, you need to pay attention to products from popular manufacturers who have already proven themselves as responsible and high-quality suppliers of pipes.

The creative process of heated floors using elastic components

Heated floors

There are flexible plumbing pipes designed to create heated floors. They stand out for their in-house made material and are designed with proper heat transfer in mind.

Underfloor heating systems require the use of elastic materials as there are too many turns and bends.

A similar heat-resistant flexible pipe can perfectly take virtually different shapes, even organizing a ring. Such characteristics are designed specifically to simplify installation and uniform filling of the entire premises.

Distortions must not be allowed during installation of points of use and even during pipe connections between each other

It is important to remember that this material is used as a solid product. As a rule, it is not allowed to create connections, since they will act as weak points in the system, and since it is located under a concrete layer, it is not permissible to leave such areas.

Advice! Such products are sold in roll form, cutting off the piece the buyer needs. Because of this, experts recommend that you first make all the calculations that are necessary for this, and then buy the product with a smaller margin.

Copper materials are not used so often due to their price, but they can also be classified as this type

Water metering station and sewerage

In most cases, a flexible pipe for a water metering unit has a structure of several layers and is very often presented in the form of metal-plastic products. It should be noted that polyethylene systems do not belong to these types. They are not flexible enough and cannot create straight angles.

Metal-plastic pipes have good ductility and are very easy to install

It should be noted that the price of such products can be even less than that of ordinary plastic pipes. At the same time, the price of connectors and other elements of pipe connections is an order of magnitude higher, since they have a complex design and consist of a wide variety of parts.

Sewer corrugated coupling, for connecting the system to the toilet or to create smooth transitions

There is also a flexible pipe for sewerage. It contains a corrugated structure and is used to connect the key system to the points of use. Such products are available in a variety of shapes and diameters, depending on the area of use.

Advice! When developing sewerage systems, they try not to use wavy products. They serve as a source of waste collection and often cause congestion in them. However, there are cases when you cannot do without them.

A sewer pipe with these characteristics, which is designed to create transitions between sources of use and the key system

By studying the video in this article, you can obtain additional information about similar types of pipes and their areas of use. Also, based on the publications above, it is necessary to conclude that this type of material is widely used to create quite a variety of pipeline options, although in most cases its use is undesirable.

Corrugated pipe for heating: Pros and cons

The material used for production can be different - cast iron, plastic or stainless steel. Plastic corrugation has low thermal conductivity, so it is usually used as additional protection. Cast iron construction has excellent heat transfer characteristics, but is rarely used due to its heavy weight and fragility. The most in demand is stainless steel corrugated pipe.

Pros:

- Flexibility and reduction in the number of connections when creating a heating system. As a result, reliability increases and the risk of leakage during operation is reduced.

- Resistant to rust. Stainless steel is resistant to moisture and is not afraid of temperature surges and sudden changes in pressure.

- Sale in bays. The length of finished products is not limited to two or three meters, as is the case with conventional pipes. Corrugated pipes up to 50 m or more in length are available to customers.

- Ease of installation. Reducing the number of joints makes the job accessible even to beginners. Fittings equipped with O-rings are used to connect sections. When performing all activities, welding is not required and you can get by with a regular wrench.

- Surface smoothness. The absence of roughness guarantees fewer deposits, even during prolonged use.

- Resistance to low and high temperature. The properties of corrugation are not lost even when frozen and defrosted in difficult climatic conditions.

- Light weight. The corrugated pipe is very light, which simplifies transportation and installation.

Other advantages stand out - noiselessness during water circulation, affordable price, large selection of options. Compared to copper pipes, this is a convenient and cost-effective solution.

Minuses

Despite a number of advantages, one cannot ignore the disadvantages:

- Fear of mechanical influences. During operation, it is better to avoid impacts or falling of heavy objects.

- Accumulation of dust in recesses. If necessary, it is extremely difficult to wash numerous “pits”.

- The need for maintenance of fittings. The flexible design does not involve the use of welding, so fittings are suitable for joining.

- High heat losses. When making stainless steel piping, be prepared to insulate the conductor. The exception is when corrugation is used as a heating radiator.

- When connecting different elements, twisting is prohibited.

- There is a risk of rust due to electromechanical processes. To protect against such consequences, grounding is necessary.

The disadvantages discussed do not at all discourage you from purchasing. The main thing is to approach the selection and installation correctly, and then take into account the manufacturer’s advice on operation.

Connection methods

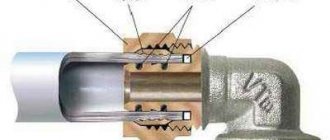

To obtain an even cut at the joined end, it is better to use a pipe cutter for corrugated products. You should not use a grinder, since there is a high probability of wall deformation. When joining a corrugated and a regular pipe, fixing the fitting begins from the side of the smooth element.

Flexible radiator connection

The batteries are connected to the heating system using a manual roller. After cutting a piece of corrugated pipe to the required length, its ends are cleaned of burrs. Then one of them is inserted into the opening of the rolling machine so that two turns of corrugation protrude. They are flared with a hammer.

Then put on the union nut, not forgetting to insert the rubber gasket into it. The second end is prepared in the same way. After fixing the fittings on the riser and radiator pipes, tighten the nuts on the corrugation. In this case, you need to ensure that the flexible pipe does not twist. If leaks are detected during hydraulic testing, the nuts on the fittings must be tightened. To prevent the corrugation from dangling, you should fix it on the wall.

Warm floor

In this case, it is recommended to install the pipe using plastic clips. They are attached with dowels to the concrete screed through holes drilled in the insulation. The clips are placed in accordance with the selected floor heating scheme. The optimal distance between pipeline branches is 30 cm, and from the walls - no less than 20 cm.

Installation begins by connecting one end to the supply pipe of the distribution cabinet. Then the coil is rolled out and the corrugation is secured in clips. If the length is not enough, the joints need to be brought out near the walls to ensure easy access to them. Excess residues are cut off, the second end is connected to the return pipe of the manifold. To protect against stray currents that can cause electrochemical corrosion, a stainless steel circuit is grounded or pipes in a polymer sheath are used.

Properties and characteristics of stainless steel for heating: corrugated pipes, corrugated pipes, corrugated pipes

The wide scope of application is explained by the unique properties of corrugation. It copes with the task even at temperatures as low as -50 degrees Celsius while maintaining flexibility. The maximum parameter is limited to +800 degrees. When using plastic fittings, it is worth considering temperature restrictions (up to +110 degrees Celsius).

Corrugated heating pipes have a number of other positive characteristics:

- Resistance to bending. According to the manufacturers, a bend of three times the diameter is allowed.

- Resistant to high water pressure. The corrugation can withstand changes of up to 50 atmospheres.

- The roughness coefficient is only 0.008.

- The resource is on average 20 years.

Properties may vary depending on the purpose, material, and area of use. Annealed corrugation has the greatest flexibility. The unannealed version has greater elasticity and weight. The presence of a polyethylene protective coating guarantees better tightness and is suitable for transporting water, gas, and constructing underground communications. A corrugated pipe covered with film can even be concreted.

Installation subtleties

To achieve the best effect, it is recommended to follow a number of rules during the installation process. Basic recommendations:

- The optimal distance between turns is 200 mm.

- It is not advisable to use casings made of polymer materials. Strength remains the same, but heat transfer deteriorates.

- When creating a heating system, twisting is prohibited due to the risk of damage.

- A grinder is used for cutting. Before starting work, the structure must be secured with ticks to create an accurate cut.

The connection of different sections is ensured using fittings. They have special tabs that allow you to connect pipes with uneven structures.

Nuances of corrugation production

On the modern market, corrugated pipes for heating are presented in many companies from South Korea, Russia and other countries. For example, the South Korean company Lavita produces products for heating, cold and hot water supply, and gas supply. There are two types of pipes on sale - HF and HFP. In the second case, a PE shell is used, which protects against negative influences and allows the use of corrugated pipes when laying underground communications. Products from Kofulso, Hydrosta, Meibes, Neptun and others are no less in demand.

The manufacturing process of corrugated pipes takes place in several stages:

- Creating a stainless steel strip and sending it for molding.

- Giving it a cylindrical shape.

- Connecting the turns by welding and then checking for leaks. A special laser installation is used for control.

- Warming up to 1000 degrees Celsius followed by cooling to 200 degrees.

- Cutting the finished product into pieces of 20-50 m, followed by rolling into a coil, marking and packaging.

The process takes place automatically, which eliminates errors due to the human factor. The manufacturer guarantees the quality of the product and determines the approximate service life if the operating conditions meet the requirements.

Production of corrugated stainless steel pipes for heating

The production of corrugated pipes made of metal is a serious process, thanks to which each stage is fully automated. The stainless steel sheet is shaped into a cylinder as it passes through the forming conveyor, after which a seam is welded onto the workpiece.

The ribbed structure of the pipe is ensured by rolling with specialized rollers

The ribbed texture is imparted during the rolling procedure with rollers of different sizes. The plasticity of the corrugation is imparted by processing at high temperatures. The bulk of the corrugations is manufactured in South Korea. Very often you can find products from the following brands on sale:

- Lavita. Lavita is a manufacturer of corrugated stainless steel pipes for heating, selling its own products at very good prices. There are complaints about the strength of the pipe walls: when tightening the ring to seal the fitting, sometimes the stainless steel is cut, causing leaks. True, this drawback can most likely be attributed to the consequences of illiterate installation.

- Kofulso. Corrugated stainless steel tube for heating produced by Cofulso is in most cases considered the standard among other substitutes. True, its cost will be several times higher than the prices for pipes of the previous brand. Fittings for connections of these pipe models have specially thickened O-rings, which helps ensure good installation quality.

- Hydrosta. Hydrosta's pricing policy is close to the price of products from Lavita, in other words, it belongs to the budget segment. However, there is evidence that these pipes often have manufacturing defects. Leakage of connectors occurs on average in 7 cases out of 100, regardless of the degree of professional installation skills.

- Meibes. The quality of products from Meibas is at a good level. However, the price of their corrugations is considered unreasonably high.

High temperatures and pressures in the heating system require the use of high-quality pipes, so it is necessary to select products from trusted companies

How to choose and install corrugated pipes

When choosing corrugation, consider the purposes for which you plan to use it. Look at the diameter and cross-section, which should be suitable for the power of the equipment used. The grade of steel and type of corrugated pipes are also important. A quality product must have a maximum pressure of up to 50 bar, operate at temperatures from -50 to +110 degrees Celsius, and also include the necessary elements for connection.

During the inspection, pay attention to the integrity of the structure, the identical distances between elements, and the quick return in case of bending. Inspect the O-rings of the fittings. There should be no damage to them. An equally important criterion is the smoothness of the surface. Before placing an order or purchasing in a store, accurately measure the length and volume of the heating system.

An important point is the integrity of the packaging. If it is torn, there may have been mechanical stress during transportation. Look at the label, manufacturer and compliance of the product with GOST requirements.

Before performing installation work, you must prepare:

- pipe cutter (scissors for cutting corrugations);

- device for pressing fittings;

- crimp key;

- end flaring equipment.

Laying a corrugated pipe for heating begins with preparing sections of the required length for installation on site. At the next stage, the pipe sections are connected using fittings and laid along a pre-designed route. At the final stage, the tightness of the system is checked.

Recommendations for selection

The first confusion that awaits you when choosing is that the stainless heating pipe is not marked. All information about the manufacturer and technical parameters of the product is printed on the packaging of the coil. That is, with a certain dexterity, it costs nothing for an unscrupulous seller to pack a not very high-quality product from the Middle Kingdom into the packaging of the famous South Korean brand KOFULSO or LAVITA. There are two options here: trust the sales representative or purchase the material from places recommended by friends who have already purchased and installed the system some time ago.

As for the recommended brands, at the moment the most popular are the mentioned “Koreans” KOFULSO and LAVITA, which have been tested in operation and have proven themselves to be good. Moreover, LAVITA products are somewhat cheaper, but the quality is slightly worse. There are also a number of German brands, but their stainless steel corrugation is unreasonably expensive. Well, you shouldn’t pay attention to unknown companies whose products are surprisingly cheap. Surely such pipes do not have the required wall thickness.

Practice of use

Corrugated pipes are widely used. Due to ease of installation, accessibility and unique properties, they are relevant in a variety of areas. Based on practice, corrugation is useful in the following cases:

- Arrangement of heating units using solar collectors.

- Warm floor.

- Connection to batteries

- Hot or cold water supply.

- Connecting dishwashers and geysers.

- Installation of taps and mixers.

- Laying cable products, etc.

The choice of corrugated pipe is due to its ability to withstand high heat and pressure up to six atmospheres. I am attracted by the ease of installation and flexibility of the material.

Reviews and operating experience

The appearance of corrugated stainless steel on sale is estimated at several years, so there is not much operating experience with it. Reviews on forums are only positive from those who have installed such systems at home, and some negative from specialists who claim that such products have higher resistance to coolant flow. However, none of those who installed a heating system using such pipes required the installation of a more powerful circulation pump. Basically, such a system is connected in houses to a wall-mounted gas boiler and includes the usual wiring from heating devices and “warm floors”.

Regarding quality, Kofulso products deserve more positive reviews than products from other brands.

Technical characteristics of the corrugation

The modern market offers products with a diameter of 15 to 32 mm in increments of 5-7 mm. Other sizes are made to order, taking into account the characteristics of the object and personal agreement with the customer.

For example, consider the parameters of corrugated pipes with a parameter of 15 mm:

- External and internal diameters - 18.1 and 14.1 mm.

- Wall thickness - 2.5 mm.

- The weight of the coil is 7.5 kg with a length of 50 m.

- Temperature at 10 bars - 0-100 degrees Celsius.

The exact parameters are indicated in the accompanying documentation or on the label. Specifications may differ for each manufacturer.

Dimensions

The production of corrugated products is regulated by GOST 3262-75. They are produced in coils with a length of 10-50 m, but upon individual orders it is possible to increase it. Depending on the internal cross-section for corrugated flexible pipes, the dimensions indicated in the table are established.

| Nominal diameter | 8A | 12A | 15A | 18A | 20A | 25A | 32A | 40A | 50A |

| External diameter | 12.8 | 16.2 | 18.1 | 20.3 | 25.6 | 32 | 37.6 | 48 | 59.8 |

| Inner diameter | 9.7 | 12.7 | 14.1 | 16.5 | 21.1 | 27 | 32.1 | 42 | 53.5 |

| Wall thickness | 0.3 (0.25) | 0.3 (0.25) | 0.3 (0.25) | 0.3 (0.25) | 0.3 (0.25) | 0.3 (0.25) | 0.3 (0.25) | 0.4 (0.3) | 0.4 (0.3) |

| Number of corrugation turns per 10 cm, not less | 25 | 24 | 23 | 21 | 19 | 18 | 18 | 14 | 13 |

| Minimum bend radius, mm | Up to 20 | Up to 30 | Up to 30 | Up to 40 | Up to 40 | Up to 50 | Up to 80 | Up to 120 | Up to 150 |

| Standard length, m | 60 | 60 | 50 | 40 | 30 | 30 | 20 | 10 | 10 |

Fittings for corrugated pipes made of stainless steel

Installation of corrugation is impossible without fittings - products that provide a tight connection of several sections into a single structure. With their help, you can implement a transition between different pipeline branches, assemble a strong connection, increase the length of the circuit and adjust the laying route. Additionally, the fitting device is responsible for the number of branches.

Fittings are:

- Seamless. They are made in one piece and are highly reliable, but require the use of special tools during installation.

- Electric welded. Formed from several elements, precisely fitted to each other and ensuring minimal clearance.

The most popular are metal fittings, which are not susceptible to moisture, are shock-resistant and are easy to install. Plastic structures are sometimes used, but they are less reliable and require careful tightening due to the risk of damage.

Review of prices and manufacturers

The most popular are products from Korean and Russian manufacturers.

The following brands have proven themselves well:

- KOFULSO. The main difference is fittings with thicker seals. Cost 3-22 $ (195-1500 rubles).

- Levita. The pipes are of good quality, but the fittings will have to be changed due to the excessive pressure of the metal ring on the pipe wall, which leads to leaks. The price starts from $2 (170 rubles), and finished pieces can cost from $15 (980 rubles).

- Handrosta. The price starts from $2 (170 rubles), but there are complaints about the low resistance of the products to mechanical stress and the appearance of leaks. To minimize the risk, you will have to regularly inspect the line and carefully select fittings.

- Meibes. Price from $4.5 (295 rubles) per 1 linear meter. Durable and reliable pipes that meet all declared characteristics.

Advice! For autonomous heating systems, the optimal choice would be KOFULSO - the pipes last for more than 30 years, while they are characterized by normal rigidity, withstand large pressure drops, temperature fluctuations, and many freezing/thawing cycles.