Expanded polystyrene is a heat-insulating building material that is popular for insulating the facades of private houses and apartments located in multi-storey buildings. Insulating the facade with polystyrene foam is a quick and simple solution to the problem of heat loss in the room. The article describes in detail all the features and nuances of the insulation process.

Before you start purchasing building materials, you need to determine the quantity. This is not difficult to do; just measure the area of the walls and, based on these values, calculate the required number of sheets of expanded polystyrene.

Criteria for choosing expanded polystyrene

The main characteristic when choosing insulating building materials for the facade of a house and roof is the density of polystyrene foam, its numerical expression is indicated in the brand. PSB-15 has the minimum indicator, and PSB-S-15, PSB-S-25, PSB-S-35 are recommended for outdoor work.

Figure 1. Facade insulation with polystyrene foam

The choice of thickness of expanded polystyrene slabs is focused on the climatic features of the region where the building is located. It should be noted that a 3 cm sheet of PSB-15 in terms of thermal conductivity is similar to 40 cm of brickwork, 25 cm of gas or foam concrete or 10 cm of wood. In addition, the foam plastic is necessarily covered with a layer of plaster, which also acts as insulation for the facade walls.

Application benefits

This material has a high degree of heat retention, since its structure is porous and consists almost entirely of air. Also among the advantages of polystyrene foam are the following:

- high level of compressive strength;

- moisture resistance, which prevents decomposition and deformation;

- low level of vapor permeability, which allows the material to be attached to the internal walls of buildings;

- resistance to external sources of influence, such as precipitation, temperature changes, atmospheric phenomena and ultraviolet rays;

- duration of use of the material. If all rules for installing insulation are followed, it can be used for 50 years or more;

- the material is unattractive to rodents, insects and birds;

- fire resistance of insulation;

- environmental friendliness of the material. As mentioned earlier, polystyrene foam is extruded without the use of harmful freons.

Preparatory work

Before insulation of the external walls of the house begins, it is necessary to prepare the working surface.

Preparation of external walls

The surface to which the insulation will be attached must be smooth and clean. All differences when preparing the walls of the house must be removed, because this can cause fractures of the polystyrene foam during its installation. Fluctuations in uniformity should not exceed 1-2 cm, and large tubercles can be knocked down with a hammer, after which all peelings can be carefully removed. Also, if paint or whitewash was previously applied, it must be removed and dust and dirt removed.

Figure 2. Wall preparation process

To prime or not

After leveling, the surface of the wall should be treated with a soil mixture, because in this way small particles are removed and maximum adhesion and protection against the spread of microorganisms and fungi is ensured.

You can avoid priming the walls; running your palm over them does not leave any dirt behind. The choice is yours, but this inexpensive process improves the quality of facade insulation with polystyrene foam.

Any priming mixture can be used for exterior use according to the instructions on the package. Apply by brush, roller or spray.

Preparation of EPPS

In fact, foam boards are already ready to go, but if you have chosen extruded polystyrene foam, then you should pay special attention to it. A very smooth surface does not adhere well to glue, so it is necessary to make it looser before installing the slabs. This procedure is carried out with a needle roller for working with drywall; if such a tool is not in your arsenal, then it can be done using a mounting knife, which you need to make grooves. If you plan to apply the insulation in two layers, then treat both sides.

Finishing window sills and slopes

The structures of window sills, slopes and “drip” should be installed before the walls are insulated. Particular attention should be paid to the following points:

- The window sill should have a protrusion of 30-40 mm from the finish, so 10-11 cm must be added to the width, because the width of the polystyrene foam, as well as the finish, is taken into account.

- When finishing slopes, insulation with a smaller thickness is used - 2-3 cm is enough to prevent the wall from moving onto the glass. When performing installation, the foam board should protrude 10 mm beyond the facade wall for easy joining.

- Between the base and the insulation, it is necessary to install a so-called “drip line” made of galvanized steel, so that natural precipitation does not accumulate on the walls, but flows off.

Figure 3. Finishing near the windows

Thus, you see that the preparatory work stage requires special attention and a lot of time and effort, however, the service life and effectiveness of polystyrene insulation will depend on the quality of their implementation, so you should not neglect this.

Installation of the starting profile

After all the preparatory work regarding the surface of the walls, so that the first row when insulating the facade with extruded polystyrene foam is installed correctly, it is necessary to install the starting profile. For this design, you can use a metal profile for working with plasterboard or a special plinth. The width of the load-bearing support must be selected according to the thickness of the slab of insulating material.

The starting metal profile is attached along the entire perimeter of the facade using a dowel fastening (the dowel is driven in at a distance of 30 cm), and the horizontal plane is controlled by the building level.

Figure 4. Beginning of installation

And so as not to doubt the correct vertical arrangement of the sheets? It is advisable to install plumb lines every 50-60 cm; a nylon thread with a weight attached to one end is ideal for this.

Mounting methods

In order for the insulation to fulfill its intended purpose, it must be properly secured to the base. Professional craftsmen use several methods to attach foam:

For the adhesive composition.

This option is suitable if the insulation will not be used as a basis for heavy finishing material. Using fasteners. A more reliable method, but also suitable for spruce on foam plastic, it is planned to install heavy decorative trim. A combination of the first and second options. The use of glue and dowels allows for the most reliable fixation.

But before you start installing polystyrene foam, you must prepare the base and all the necessary materials.

Installation of polystyrene foam boards

According to the technology for insulating a façade with extruded polystyrene foam, the slabs are first glued, and the second step involves fixing them using special dowels.

Figure 5. Facade insulation with polystyrene foam

Choosing an adhesive composition

To choose the right adhesive mixture for installation work, you should not “go into the weeds”; builders claim that there are no special requirements, so any type of adhesive with a universal composition for working with tiles will do. Such mixtures from well-known companies are characterized by moisture resistance, resistance to temperature changes, are quite elastic and durable, and are absolutely safe for humans. However, when visiting a building materials store, purchase glue for exterior finishing; both dry mixtures and glue in bottles will do.

Expanded polystyrene installation technology

All work with polystyrene insulation materials is carried out in the following sequence:

- On prepared slabs of polystyrene foam or EPS 35 kg m3 100 mm or higher density, as well as on smooth facade walls, glue should be applied with a notched spatula. The mixture can be applied in a continuous layer or spotwise (in the center and in the corners) with a thickness of 3-5 mm.

- The first row is glued to the starting strip, which prevents the slabs from moving.

- Subsequent rows are glued in a checkerboard pattern.

- If gaps are formed when joining the sheets, it is necessary to prevent glue from getting into them; in the future, by applying plaster, everything can be corrected.

- Throughout all work, check the levelness using plumb lines and a mounting level.

- After pasting all the sheets, you must wait for the glue to dry and proceed to the next step of insulating the facade of the house with polystyrene foam.

- After the adhesive mixture has dried, usually for 24 hours, they proceed to driving in the dowels, while the fungi should be driven into the drilled holes in the center and in the corners, and the “cap” should be located flush with the surface of the slab.

Figure 6. Installation of polystyrene foam boards

There are situations when, to improve the quality of thermal insulation, the technology of laying polystyrene foam in two layers is used, which has distinctive features:

- The first layer of slabs cannot be putty; all finishing work is carried out after installing the second layer of slabs.

- To fix the second layer, you don’t even need to use glue; you can only hammer in disc-shaped dowels, taking into account the thickness of both layers.

It is important to take into account the places where the previous layer was fixed in order to prevent repeated driving in.

Before moving on to further work, you need to rub and putty the seams and caps to level the surface.

On fasteners

To attach foam plastic in this way, you need to purchase special dowels with a wide head.

They are called "fungi" or "umbrellas". To calculate the required number of fasteners, you should multiply the number of whole sheets of insulation by 5. Since the slabs are fastened with 5 dowels each.

The first step is to install the starting profile in the same way as in the previous version. Next, you need to secure the first sheet of foam. It is placed in the starting profile and using a hammer drill or electric drill, make holes with a depth corresponding to the length of the dowel plus 1–3 mm.

In order not to overdo it on the drill, you can install a limiter or make a mark with a marker. First, the dowel is installed, and then the core is driven into it. The head of the fastener should “sink” into the insulation by 1–2 mm. The fasteners are installed in the corners of the insulation sheet and one in the center. If the head is very wide, then one dowel can hold 2-3 slabs. A gap is left between the elements, which is then sealed with sealant. The place where the dowel is located must be covered with plaster.

The renovation of the façade is completed by installing decorative finishing.

Reinforcement and plastering of foam plastic

Occasionally, experts recommend insulating with polystyrene foam for two seasons, that is, allowing it to overwinter at a certain stage, preferably after applying a leveling layer of plaster. Sheets should not be left unfinished; even packaged slabs must be stored indoors and not outdoors.

Sticker of reinforcing mesh on corners

To give additional density and strength, a reinforcing mesh is attached to the corners and other sheets.

First of all, the mesh is pasted on the corners: external, internal, as well as on slopes. A universal composition is used as an adhesive base, which should be prepared according to the instructions, but more liquid so that it can be pressed well through the mesh with a spatula.

Figure 7. Sticker of reinforcing mesh on the corners

It is more convenient to mount ready-made corners, but they are more expensive. If you are interested in an economical option, then you can cut strips 30 cm wide and 100 cm long and fold them in half by pressing them with a spatula.

The fastening technology is almost the same: glue is applied to the working tool and it must be applied in a strip 6-7 cm wide, in a layer of 2-3 mm, retreating 5-7 cm in height for further joining of the cuts. Movements with a spatula are made in a “herringbone” pattern from top to bottom and to the sides; for convenience, you can purchase an angle tool, which will greatly facilitate this work.

Foam reinforcement on walls

Expanded polystyrene on the walls should also be reinforced using a special mesh, glued with adhesive with a universal composition.

The algorithm is as follows:

- The adhesive base is applied to the slabs using a spatula.

- The mesh is unwound from top to bottom so that 5-7 cm of glue does not overlap on one side.

- It is pressed with a spatula to sink the mesh into the glue, while it is desirable to make the surface as smooth as possible.

- The next strip is rolled out from the free edge, thus duplication is formed at the joints, but due to the fact that there is less glue, the overall level of the facade remains the same.

Upon completion of the reinforcement, you should expect complete drying: 12-24 hours, after which grouting is carried out using fine-grained sandpaper to smooth out the slightest imperfections.

Foam plastic plaster: applying a leveling layer

To perform final leveling, mixtures with polymer compounds are used that are more resistant to negative environmental influences: moisture, frost, and do not change their structure and color when exposed to ultraviolet radiation.

The prepared mixture should have the consistency of liquid sour cream, and the thickness of the layer depends on the evenness of the previous level, so the leveling layer can be applied only a few millimeters.

Just like the previous layers, they must be completely dried and sanded before painting or applying decorative plaster.

What you need

In order to properly insulate your home and then live peacefully in warmth and comfort, you will need the following materials:

- Expanded polystyrene sheets. Their number is equal to the wall area, not taking into account the windows. If the thickness turns out to be very non-standard, then two layers will be required. And the second of them should be attached only after this glue has dried.

- Mineral slabs. They are laid for safe purposes, to avoid fires. Place around doors and windows. The slabs must be high-strength and dense, the same in thickness as the foam sheets. There are as many windows as there are slabs.

- Reinforcing mesh.

- Primer. If the surface is porous, two coats will be required.

- Glue presented as a dry mixture.

Tools and materials for insulation - Metal corner with perforation.

- Hammer drill with 10mm drill bit.

- Mixer for construction.

- Level.

- Stationery knife.

Advantages and disadvantages of the material

Any insulation is characterized by a number of signs, both positive and negative. Expanded polystyrene for facade insulation is no exception.

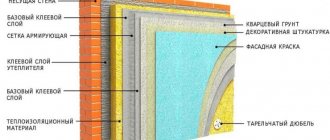

Figure 8. Facade insulation scheme

The benefits include the following:

- affordable price;

- ease of handling;

- minimizing the spread of bacteria;

- high moisture resistant qualities;

- light weight;

- hygienic properties: resistance to mold growth, as well as other forms of bacteria;

- good thermal conductivity;

- durability;

Negative aspects:

- flammability;

- toxicity;

- prone to damage by small rodents.

As you can see, there are more positive aspects than negative ones. This material does not lose its properties over time, like mineral wool, and does not change its size under the influence of negative environmental factors. As a result of completing all the stages of insulating the facade with polystyrene foam, the entire structure resembles a “sandwich” as in the photo.

How to insulate a ventilated facade with your own hands

A ventilated façade is a suspended structure that looks like a layer cake. The principle itself is that a gap of 30 to 50 mm is left between the wall to which the insulation is attached and the decorative protective panel. Thanks to this gap, the facade got its name, and through this air gap, excess moisture evaporates. Thermal insulating material has an important function here, and its high-quality choice will further ensure the correct functioning of the entire system.

Material selection

Mineral wool has tangible advantages. This insulation is vapor permeable and has excellent, although slightly more modest, thermal performance. Basalt wool is a fairly hard material and tends to cake over the years, becoming even more durable. In addition, mineral wool is a fairly inexpensive material. Another plus is the wide variety of insulation shapes and thicknesses, which allows you to adapt to any technological requirements.

Installation of mineral wool on a ventilated facade

Thermal insulation from mineral wool is inserted into the sheathing, which is made of an L-shaped profile or wooden blocks. To do this, vertical profiles are mounted to the wall, and the distance between them should be slightly less than the width of the heat-insulating slab. It is best to pre-glue the insulation to the wall, but it can only be mounted on disc-shaped dowels, as shown in the photo.

A wind barrier is attached to the insulation. It protects it from destruction from atmospheric influences. After this, a decorative protective panel is installed.

Cost of façade insulation with polystyrene foam (expanded polystyrene)

The cost estimate for façade insulation with polystyrene foam includes all necessary materials and work. If you want to save money, you can study the technologies and recommendations for insulating facades with expanded polystyrene and polystyrene foam and carry out the installation yourself. However, if your house has several floors, then it is better to trust the professionals.

To calculate the cost of work, you can take into account the following prices:

- installation and dismantling of scaffolding per m2 - 100-140 rubles;

- insulation per m2 - 300-360 rubles;

- reinforcement per m2 - 300-350 rubles;

- decoration per m2 - 300-350 rubles.

Thus, the final estimate will depend on the cost of materials and services, as well as the complexity of the object and deadlines.

Installing expanded polystyrene on the facade of a house is not a difficult task; the main thing is to know the basic rules of this process and choose the right consumables and tools.