The development of technology, automation, as well as rising prices for traditional gas and electric energy sources pushed engineers to search for alternatives. Intensive destruction of forests has led to the formation of mountains of wood waste. The desire to use sawdust and wood chips as a heat source has only intensified with the advent of the ability of modern equipment to do this effectively.

However, the use of such fuel is most often justified only on an industrial scale, and there are not many household boilers designed to burn sawdust. Therefore, the article is primarily intended for the industrial sector, but almost all the information is relevant for domestic conditions, and the models discussed in the article are intended primarily for private homes.

Sawdust and wood chips: their effectiveness as solid fuel

Shredded wood obtained from processing logs or specially prepared from industrial waste is called sawdust and can be used as fuel. The raw materials for boilers are wood waste such as:

- slabs of various species, ash boards, wood chips of various shapes and sizes;

- fresh sawdust or outdoor storage, different humidity and age;

- shavings are dry, small and long, stale, in varying degrees of preservation;

- furniture that has fallen into disrepair, remains of building structures, doors, pallets.

Raw materials that are preparing to become fuel must comply with the requirements of GOST 33103.1 - 2014:

- do not have toxic chemical compounds released during combustion and metal inclusions (nails, hinges in the remains of fiberboard, chipboard);

- contain no more than 0.5% mineral impurities, 5% rot and 8% tree bark.

The resulting biomass is sifted to obtain sawdust fractions up to 30 mm in size . This parameter is critical for the operation of the feed mechanisms of automatic boilers and affects the combustion process. Smaller sawdust requires more air injection for complete combustion than those specified by GOST requirements.

This is what bulk fuel looks like in the photo. On the left is sawdust, on the right is wood chips.

Ash content is a parameter that determines the amount of resulting fuel combustion waste. The higher the ash content, the more often the boiler is cleaned, the lower the calorific value of the fuel. The presence of formaldehyde and other toxic chemicals in sawdust used as fuel in household boilers is unacceptable and requires other disposal. The most important parameter that determines the amount of heat produced from sawdust is humidity. It can significantly change the ability of an automatic boiler to perform its functions. It is advisable to control this parameter before loading and be able to bring sawdust in accordance with the requirements of the boiler manufacturer.

When concluding contracts for the supply of sawdust to fuel an automatic boiler, not only the price, but also the quality of the supplied products is important. Based on the requirements of GOST 33103.1 - 2014, we recommend that the sawdust parameters be clearly stated in the contract. Compliance with these points will allow you to operate the unit for a long time and with full heat transfer. Having a supplier nearby with a good price and decent quality of fuel is the main point when choosing a solid fuel boiler for heating your home.

Sawdust as a fuel for automatic boilers has the following advantages:

- The efficiency of even budget automatic boilers using sawdust is up to 90%;

- availability of high-quality raw materials for fuel;

- low cost of raw material from wood processing industries;

- a correctly selected and configured boiler burns environmentally friendly fuel with a minimum of smoke, soot and ash;

- interruptions in quality sawdust are easily covered by any solid fuel (chips, firewood, coal, raw sawdust) with loss of efficiency, but without catastrophe.

But the disadvantages of sawdust are also significant:

- transportation from wood processing industries requires appropriate packaging since this wood waste material is free-flowing and bulky, especially in dry form;

- equipment for a seasonal sawdust warehouse requires a separate building with good ventilation and compliance with fire safety standards SNIP and PPB;

- periodic maintenance of the sawdust conveyor to the boiler, cleaning the chimney, monitoring the humidity of raw materials.

To determine how effective sawdust and wood chips are as fuel for heating boilers, we compared the characteristics of the most common types of fuel in one table:

| Type of fuel (W – humidity) | Calorific value kW/kg | Efficiency,% | Fuel price, rub./ton (m3) | Cost of kW of energy, rub. |

| Brown coal (w up to 40%) | 3,6 | 70 | 3 200 | 1,27 |

| Hard coal (w from 7 to 15%) | 7,5 | 70 | 7 000 | 1,34 |

| Anthracite (w from 1% to 3%) | 8,7 | 70 | 8 500 | 1,40 |

| Natural gas | 10,3 | 90 | 5 700 | 0,65 |

| Firewood (w 60-50%) | 2,2 | 60 | 1 500 | 1,05 |

| Firewood (w 30-20%) | 3,1 | 60 | 1 800 | 0,83 |

| Granules (pellets) | 4,7 | 85 | 9000 | 2,25 |

| Crushed chips (w up to 20%) | 2,0 | 95 | 200 | 1,33 |

| Sawdust (w up to 20%) | 0,81 | 95 | 120 | 1,33 |

| Briquettes (eurowood) | 4,3 | 85% | 8500 | 1,65 – 2,32 |

Two in one - smokehouse with stove

An interesting option for making a smokehouse with your own hands is when a stove is built directly in the body of the washing machine, which heats the sawdust. That is, not only the tank is involved here, but also the metal body itself.

The sequence of actions is as follows:

We remove the engine from the car, take out the tank, and cut a rectangular hole in the body.

Cutting a hole for the firebox

We seal the tank: to seal the holes without welding, you can use self-tapping screws with metal plates on them, they will close all the holes.

A grill from a refrigerator, oven, or some other mesh is suitable as a shelf for food. We weld it inside the tank.

We seal the lid - also using a plate and self-tapping screws. We install the tank in its original place. We put about 100 grams of sawdust on the bottom and place food on the grate.

If you don't have a washing machine, you can replace it with a barrel!

We make a fire through a sawn hole under the tank. If it is undesirable to do this on the surface where the smokehouse stands, then it is good to weld a metal sheet inside and place firewood on it. When the smoke starts, you need to note the time required to smoke a particular product. During the process, it is advisable to check the condition of the meat or fish and ensure that the wood chips do not overheat.

To prevent sawdust from burning, it is recommended to slightly moisten it. Another option is to use fresh, not dried wood chips. Under no circumstances should you use coniferous wood for smoking; alder and fruit trees and shrubs are ideal.

The design and principle of operation of boilers capable of burning sawdust

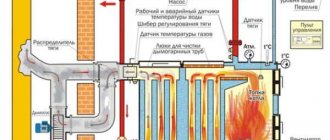

A device based on the example of “Pyrolysis Master” BIO, specialized for burning sawdust and wood chips.

The small sizes of sawdust fractions fit tightly to each other, not allowing air to circulate in the mass even without compaction. Due to the difficulty of oxygen access, the temperature of burning sawdust and wood chips is lower than that of other solid fuels and only its outer layer burns (up to 15 mm). The small amount of pyrolysis gases during such combustion significantly reduces the power of a universal solid fuel boiler when switching to sawdust.

A specialized gas-generating boiler, where sawdust and wood chips are the main solid fuel, is equipped with a vertical heat exchanger around the chimney of at least three bends. A burner bowl is located in the center of the vertical firebox with holes for air oxygen to enter. Sawdust can be ignited automatically. The process of burning wood chips and sawdust occurs under air pressure forced into the bowl by special fans to ensure an even column of flame.

The computer that controls the boiler usually provides three operating modes for an automatic wood chip boiler:

- Maximum combustion to ensure that the home heating and hot water heating system reaches the specified parameters when put into operation. Requires increased fuel consumption.

- Medium - the main operating mode for maintaining the coolant temperature within the limits defined by the user or the manufacturer of the unit. Sawdust consumption is moderate.

- Pause. Climatic conditions do not require heating and the combustion process is stopped.

Boilers with a burning duration of one load of fuel up to 7 days

A self-cleaning mechanism for soot removal and moving grate bars can be placed inside the boiler. As soot and ash accumulate, the unit automatically dumps them and sends them to the storage tank with augers. This design ensures a high combustion temperature of sawdust and wood chips, ensuring their complete combustion with virtually no “under-burning”. A high level of boiler automation using a lambda probe allows you to smoothly control the output power from 30% to 100% of the nominal value and achieve an efficiency of 92%.

In industrial heating systems, pyrolysis boilers (shaft furnaces) are used; their operation for the same purposes has different implementations. A household automatic boiler using wood chips and sawdust should provide the user with maximum comfort and safety with reliable operation. Comfort lies in the minimum amount of time the owner spends on servicing the heating and hot water system.

One of the conditions for continuous operation of the boiler is to ensure that the unit's hopper is loaded with sawdust from the storage facility and to create breaks in the fuel flow from the storage facility to the burner, so as not to turn the fuel supply into a fuse cord. This gap is created by a combination of auger and drum. Their alternate operation creates the necessary gap, and the processor controls the filling of the boiler hopper and the activation of the augers, drum and sawdust agitator.

Arranging a seasonal sawdust storage and boiler room for a private home requires careful compliance with fire safety standards, building codes and electrical safety for such premises. It would be a good idea to install an automatic fire alarm and fire extinguishing system.

How to choose a waste oil boiler for heating a private home

Design features

The specificity of fuel such as sawdust is that its particles are tightly pressed against each other and prevent the penetration of oxygen necessary to maintain the combustion process (those who have had to deal with coal know that for the same reason large stones burn much better than coal crushed into dust).

They are tightly packed into a cylindrical combustion chamber, and a conical rod is inserted in the central part.

During combustion, the rod is removed and a vertical channel is formed - an adit, through which air moves. Sawdust burns layer by layer from the middle.

And this combustion occurs very slowly, in smoldering mode.

There are several modifications of such heating devices:

- One or two holes for the chimney.

- One or two walls.

- Remote or built-in ash drawer.

Note. The stove is made from a two-hundred-liter barrel and can be heated with one load of sawdust for 10 hours.

Reviews of household boilers using sawdust and wood chips: advantages and disadvantages

Owners of various household boilers using sawdust and wood chips emphasize in their reviews that most models of automatic modern units fulfill the promises of the manufacturers, subject to their conditions.

In practice, heating boilers using dry wood chips and sawdust provide the declared power and efficiency. However, it is often necessary to burn wet fuel. The boiler unit can lose up to 30% of its rated power for drying wet raw materials. We suggest following the following recommendations:

- It is advisable to add raw fuel after the heating system reaches the specified mode;

- the content of wet sawdust in the total supply volume should not exceed one third;

- It is better to purchase raw materials from special factories with an optimal humidity of 20%.

Below is a summary table of the advantages and disadvantages of boilers using sawdust and wood chips according to our practice and feedback from owners:

| Advantages | Flaws |

| The design of modern units, equipped with automation, selects the most economical combustion process, taking into account the user’s instructions, weather and raw materials within the range of 30% - 100% of rated power | The boiler room consists of two rooms, equipped in accordance with SP and PPB, and occupies a large area of housing. It is safer to place equipment in a separate building |

| The manufacturability of modern models makes it possible to achieve indicators close to those when burning much more calorific solid fuels. As a result, the cost of 1 kW of thermal energy is less than that of pellets, briquettes and some types of coal | The cost of even budget boilers with minimal automation is 3-5 times more expensive than solid fuel automatic units of comparable power. However, it is worth noting that there are also cheaper universal boilers for domestic needs. |

| Low cost, availability and environmental friendliness of raw materials. Its price is especially low in places with developed woodworking industries, and for its own needs it is practically free (often enterprises are only happy to organize the sale of woodworking waste). | Organizing a warehouse for a seasonal supply of fuel requires serious investments in order to maintain normal humidity, not violate fire safety standards, and automate the supply of fuel to the boiler room. |

| Despite all the complexities of the technologies and mechanisms used to achieve high results, operating the unit does not cause any inconvenience. | Despite the increased level of equipment reliability, monitoring must be carried out regularly and, if necessary, the chimney and firebox must be cleaned of soot and ash, since the raw materials may not always be suitable. |

| Most maintenance work is accessible and simple. Installation of such equipment in a private home does not require permission from regulatory authorities. |

Automation tools

Automation requires a special control unit - the automation of a solid fuel boiler does not have the appropriate capabilities. The auger and blower motors, as well as temperature sensors, are connected to the controller. Receiving a signal from the sensors, the controller will control the operation of the engines, regulating the fuel supply and traction.

The homemade product can also be equipped with a device for automatic ignition and flame control with a photosensor, which are also controlled by the controller. The filling sensor in the fuel pipe will allow you to control the supply of bulk energy.

The use of automation equipment significantly increases the cost of the unit, but makes it as convenient to use as possible.

Automation of boiler operation using a pellet burner

Calculation of the minimum required power

Determining the minimum heating power required to ensure a comfortable stay begins with the user making decisions about:

- number of circuits (housing heating, hot water supply, underfloor heating).

- region of residence (local climate, wind rose, etc.).

- number of floors, wall material, ceiling height, area and number of windows of the building.

Using the standards and coefficients of SNiP 2.04.01-85, using our and other examples, a fairly accurate calculation can be made.

In practice, in the initial calculations, the total area of the heated building is determined and, based on the norm of 1 kW of heat per 10 m2, the required power spent on heating is obtained, then 20% is added for the DHW circuit and another 20% for possible inaccuracies and the creation of a safety margin .

For example, for two heat consumption circuits in a building with a total area of 200 m2, (200x1)/10 = 20 kW is enough for heating, DHW and safety margin will add another 20 * 0.4 = 8 kW, for a total of 28 kW. When choosing a specific boiler, the nearest standard power of the unit greater than the minimum required is accepted.

For industrial buildings, it is necessary to make an individual calculation taking into account all correction factors.

Possible heating systems

The following sawdust heating systems are used for homes and large premises:

- Bake. Used to heat the adjacent space. As you move away from the oven, the temperature drops rapidly.

- A stove with a water register or heater. The operation of the heating system combines local heating of the room directly from the stove, as well as heating and delivery of the required coolant to remote areas of the building through an air duct (for air) and a pipe (for water, antifreeze).

- Water heating through installed radiators, which release thermal energy to the air in the room due to the constant circulation of the heated liquid.

- Air heating differs from water heating in a different coolant and is considered an expensive heating option. To implement such a heating system, it is necessary to lay a network of air ducts and install automatic devices for humidifying very dry air.

Air and water heating can provide for forced (using a pump) and natural (taking into account the physical properties of the movement of the heated substance) circulation of the coolant.

- Warm floor. The system can operate with different coolants. With this heating, a comfortable microclimate is created at all levels from floor to ceiling. The downside is the high cost of the required materials, the complexity of the work, the need for thermal insulation of the floor from the foundation, basement or ground.

The best known manufacturers and models: characteristics and prices

When choosing a boiler for sawdust and wood chips, in addition to technical characteristics, you should pay attention to the country and brand of the manufacturer. Northern European countries have learned to squeeze the highest economic performance out of fuel. To this end, they have been working for a long time on improving automation specifically for private homes, and given their desire for comfort and environmental requirements, you should pay attention to the products of the companies Hargassner, Froling, ETA. Of course, if the budget allows.

Russian-made boilers, especially if the developer is a well-known European brand on the market, may well be competitive. At a significantly lower price, they are quite capable of providing both the reliability and comfort of a private home. In addition, they are unpretentious in raw materials and maintenance, and the automation even in European solid fuel boilers is often from China.

Specialized

These are boilers designed primarily for the use of bulk solid fuels.

Pyrolysis Master BIO-15

One of the best sawdust boilers for heating a private home. It also works on wood chips, peat, and sunflower husks. With the use of replaceable burners it can burn straw. Thanks to a five-pass heat exchanger, it has a high efficiency of 91% and has a hopper capacity of 200 liters. The only drawback is its considerable dimensions.

Cost: 185,000-240,000 rubles.

FACI FSS 115

It is produced in Russia, but the developer is Italy. This is an automatic industrial boiler for burning wood waste. Power adjustable within 25-115 kW, efficiency 92%. As additional options, it is equipped with auto-ignition, burner self-cleaning, and remote control. Hopper capacity is 810 liters, fuel is supplied by two augers. Can burn any biomass with a fraction not exceeding 40 mm. The 115 kW model has a huge weight of 1150 kg, which increases the flooring and transport requirements.

Cost: 450,000-477,000 rubles.

Universal models

Boilers using any solid fuel: all types of coal, peat, firewood, wood waste, seed husks, briquettes with varying efficiency, but structurally designed for long-term combustion. They are much cheaper than specialized ones, but also much less effective and practical when working with sawdust.

Tis Pro DR

Excellent inexpensive universal boiler. Furnace steel 5 mm thick is used as a heat exchanger, which is a very good indicator in terms of reliability and durability. It also features a huge firebox; depending on the power, the volume of the combustion chamber can be 80-116 liters. Does not use fan pressure and is non-volatile. Available in 17, 22 and 27 kW versions, efficiency reaches 82%.

Owners often note that the design of the grate is extremely practical: they are separate, cast iron (reliable and easily replaceable). No deficiencies were found due to operating practices.

Cost: 58,500-72,000 rubles.

PEREKO KSP Duo

High-tech Polish universal TT boiler of the highest price category. The innovative burner allows high-quality combustion of fine-grained fuel from eco-peas to oats as efficiently as possible. A water-filled grate in the combustion chamber makes it possible to burn wood and its waste.

Equipped with automation controlled by the ST-480 controller, which, in addition to controlling the central heating and hot water pumps, the boost fan, can also control the operation of the mixing valve and take into account signals from room and street temperature sensors. Available in power variations: 12, 18, 26, 36, 52 kW. In addition to the price, the disadvantages are large dimensions, weight and low permissible operating pressure - only 1.5 bar.

Cost: 283,000-498,000 rubles.

LIEPSNELĖ L20U

Universal Lithuanian long-burning shaft-type boiler with a power of 20 kW. The fuel is coal, pressed briquettes from coal, peat, wood waste, sawdust and other raw materials. The efficiency reaches 91%, but this is only when heating with low-ash coal; when using sawdust and wood chips, the efficiency will be lower. The heat exchanger is cast iron, in a steel casing. The boiler is known for its reliability, quality of alloys used and assembly. Even when using sawdust and wood chips, the burning time of one load can be achieved in 2-3 days.

The only drawbacks, as in the previous case, are the low operating pressure of 1.5 bar and heavy weight.

Cost: 110,000-125,000 rubles.

Requirements for heating devices

For heating with sawdust, it is necessary to use long-burning boilers and stoves that meet the following conditions :

- fuel combustion from top to bottom ;

- large outer surface area (important for stoves);

- large area of the heat exchanger or water jacket;

- large volume of firebox ;

- possibility of supplying air to the combustion zone.

Due to the small size of sawdust, they can be fed into the stove or boiler automatically, which further increases the battery life of the heating device. Most often, an auger feed is used for this - a rotating auger lifts or lowers sawdust from the hopper and scatters it in the combustion zone.

When there is too much ash, the heater is stopped and cooled to clear the ash and reload it with fuel.

Boilers and long-burning stoves of the Stropuva type (Russian analogue of Bubafonya) are well suited for heating with sawdust. These devices implement the principle of top combustion of wood , and air enters directly into the combustion zone.

Long-burning stoves and boilers running on sawdust can not only be bought, but also made with your own hands. Homemade devices also implement the requirements for heating devices described above.

Prices: summary comparison table

| Model | Specialization | Cost, rub. |

| Pyrolysis Master BIO-15, Russia | special | 185 000-240 000 |

| FACI FSS 115, Italy-Russia | special | 450 000-477 000 |

| Tis Pro DR, Belarus | universal | 58 500-72 000 |

| PEREKO KSP Duo, Poland | universal | 283 000-498 000 |

| LIEPSNEL L20U, Lithuania | universal | 110 000-125 000 |

Further development of automation of boilers using sawdust and wood chips will provide real competition to gas and electric boilers in terms of comfort and efficiency.

BoilersSolid fuel boilers

Equipment advantages

The popularity of heating appliances that run on wood chips is largely due to the numerous advantages of this technology. self-made sawdust boiler that burns for a long time has the following advantages:

- Safety of use.

- Ability to control raw material consumption and temperature conditions.

- Environmental friendliness of the equipment.

- Minimum fuel costs.

- Fast heating of the room.

- High efficiency.

Self-made sawdust boilers are characterized by versatility and efficiency. With the help of such heating equipment, you can easily heat a room of any size. Thanks to the simple design of the device, you can make it yourself, and subsequently you can buy fuel for free at sawmills or buy ready-made dried pressed sawdust briquettes.

One of the disadvantages of sawdust boilers is their increased requirements for fuel quality and its moisture content. You will also need to periodically clean the chimney from ash and soot. The efficiency of the equipment and its operational safety will directly depend on the correctness of such maintenance.

Installing a coolant register

Now you can think about connecting the boiler to the heating system. To do this, you will need to install a register at the chimney outlet of the boiler.

The figure clearly shows the installed register with the connected supply and return connected to the central heating system. This is one option, you can use a completely different one. The main thing is that it corresponds to the thermal parameters of the boiler you have manufactured and fully satisfies the volume of the installed radiator heating system.

We will not dwell in detail on the structure of the register. Let's say one thing: the closer to the boiler it is installed, the more efficiently it works.

Pipelines connected to the register

DIY making

On sale today you can find various modifications of autonomous heating boilers that burn wood chips and sawdust. Despite all their advantages, they have one significant drawback - the high cost of equipment. Therefore, many summer residents and owners of private houses make universal boilers on their own, since the simple design of such equipment allows you to construct it even in the absence of relevant knowledge and experience.

To make a wood chip boiler with your own hands, you will need the following tools and materials:

A round pipe with a diameter of 5 centimeters.

- Rectangular profile 40 by 60 millimeters.

- Grinder or metal cutter.

- Electric drill.

- Welding machine.

- Roulette and hammer.

On the Internet you can find various drawings of the design of boilers operating on sawdust and wood chips. The easiest way to make such heaters is on the basis of a pipe or gas cylinder. You just need to use durable, thick-walled steel, which will ensure the durability of your homemade boiler .

The valve is removed from the gas cylinder and all the gas is released. The top is cut off along the line of the weld, after which the edges are cleaned using a grinder or manually, and all burrs are removed. Subsequently, the blank from the gas cylinder will be used as a firebox body.

- 2. The cut off upper part of the cylinder is also cleaned, and then adjusted to the base of the firebox body. Along the edges of the workpiece, a edging is welded on top, which is made from strips of thick-walled steel.

- 3. A hole is drilled in the lid into which a pipe for air supply is welded.

- 4. In the upper part of the firebox body, a hole is made with a drill, which is necessary for attaching the chimney pipe. An iron pipe is inserted into the resulting hole and welded.

- 5. The design of the sawdust firebox implies the presence of a load that presses the fuel from above, thereby regulating its combustion rate. The weight is made of thick-walled sheet metal, which is cut to fit the internal diameter of the cylinder. A hole is made in the center of the disk, which is identical in diameter to the pipe cut into the boiler lid.

- 6. It is recommended to weld iron ribs to the inner surface of the round weight, which allows air masses to disperse, increasing the efficiency of the heating installation.

- 7. A water jacket is made from a metal sheet, through which the coolant will circulate. The water jacket is located outside the firebox and has the shape and dimensions of the body.

- 8. Stiffening ribs are welded in a circle to the furnace body, which protect the water jacket from its temperature deformation.

- 9. The water jacket is attached to metal stiffeners.

We recommend: Design of a circulation pump for heating: how it works, how it works in the system, principle of operation, where it should work, design

At this point, the work on manufacturing the heating boiler is completed. It is necessary to carry out a test run, check the quality of welding, and also make sure that there are no leaks in the water jacket, along the contour of which the coolant circulates. In the future, it is possible to modernize the heating boiler, to which a hopper with sawdust and a screw mechanism for automatically loading chips into the combustion chamber are additionally mounted.

By making a homemade pyrolysis boiler using sawdust and wood chips, you can not only solve problems with heating a small private house or country house, but also reduce the cost of living outside the city in the winter season. In specialized stores you can purchase ready-made industrial boilers that have one or two circuits, are completely safe to operate and are equipped with automatic control.

If necessary, it is possible to produce universal versions of autonomous heaters, which will differ in their power ratings, duration of operation from one fuel fill, as well as a number of other characteristics.

How to make a long burning stove

To make a sawdust stove with your own hands, you can use a ready-made metal container: a barrel, a can, an empty gas cylinder or a pipe of a suitable diameter. To work you will need a welding machine, an angle grinder and skills to work with them.

A simple sawdust stove from a barrel

If you have a metal barrel at your disposal, then first of all you need to cut off the top from it. This should be done carefully, since in the future the part will be used for its intended purpose, but as a removable cover.

Diagram of a homemade sawdust stove from a barrel

Self-installation

Instead of buying such a necessary and efficient heating device, you can make it yourself. To create a sawdust boiler you will need the following tools and materials:

- several pipes: with a rectangular profile 60-40 mm and round ones with a diameter of 4 and 5 cm;

- welding machine and electrodes for it;

- angle grinder (“grinder”).

The pipe sections should be selected so that they fit inside the boiler with dimensions of 36x40x80 cm. In this case, structures of rectangular cross-section will be used as vertical posts in which round holes are cut for the remaining parts. It is worth considering that on the side where the door will be located, the diameters of the pipelines will be 50 mm. In the back of the cauldron, the dimensions of the first 4 cut rectangles should be 5x6 cm, and the next four - 4x4 cm.

The supply of pipes for cold and heated water is ensured by cutting round holes with a diameter of 5 cm.

Welding the front and rear parts of the device is carried out as follows:

- rectangular posts are welded;

- round pipes are connected to them so that they are located perpendicular to the floor of the room;

- coolant supply and discharge pipelines are connected to the boiler;

- the ends of all open pipes are welded using pieces of metal.

Now you can check the sawdust boiler for leaks - pour liquid into the pipes and check for leaks.

After this, the equipment is mounted in a brick firebox. You can also make it yourself using refractory bricks as the material.