Craftsmen consider long-burning sawdust stoves, made with their own hands, to be the most economical heating method for a summer house or garage.

The savings come from the fact that you don’t have to spend money on purchasing an expensive heating stove.

Along with this, sawdust also minimizes costs, because they are considered the cheapest fuel in our country.

Craftsmen post original drawings and diagrams of such devices online. The design of the stove is quite simple, it does not require many items to manufacture, it can be made from scrap material.

By all indicators, making a long-burning sawdust stove is extremely beneficial for the population, especially for heating a country house, greenhouse or garage.

Technology for making a homemade sawdust stove

A homemade version of a heating stove can be made from a voluminous metal or cast iron barrel without mechanical damage or traces of corrosion. If desired, it can be replaced:

- Gas cylinder.

- Sheet steel.

- A pipe cut.

- Volumetric fire extinguisher.

Additionally, the following materials will be required for assembly:

- Pipe cuttings, reinforcing bars or channels for legs.

- Metal circles around the diameter of the container up to 6 mm thick.

- Metal door (homemade or ready-made).

- A pipe with a diameter of 10 cm, a length 20 cm greater than the height of the barrel.

- Pipe for chimney – diameter 10 cm, length 5.5 m.

Required set of tools:

- Grinder, cutter.

- Welding equipment.

- Hammer.

- Measuring devices - tape measure and building level.

Self-assembly of the device is carried out in accordance with the prepared drawing and involves the following steps:

- Preparing the fuel tank. The top of the container is cut off according to the previously applied markings. The bottom is removed in the same way, from which you can make a protective cover for the heating device.

- Construction of the furnace bottom. A blank according to the diameter of the fuel chamber is made from sheet steel. A hole is cut in the center of the workpiece for a pipe with a diameter of 10 cm to supply the air mixture.

- Making a pipe for supplying oxygen to the fuel chamber. For this, an elongated pipe is used, in which longitudinal grooves or perforations are made with a grinder.

- A perforated pipe is installed in the center of the bottom and fixed by welding. Next, a cover is made with a central hole with a diameter equal to the diameter of the pipe (the cover is installed on the pipe). Additionally, an edge hole is cut to enhance traction, onto which the damper is installed. The pipe cover is equipped with handles for ease of use.

- Chimney installation. A hole is made in the upper part of the container for the diameter of the pipe. A pipe is welded to it, which will connect the chimney pipe to the stove using a clamp.

- Supports made of selected materials are welded to the bottom of the furnace.

The process of self-assembling a sawdust pyrolysis furnace, subject to all conditions, is quite easy to master even for a novice master. A technically competently manufactured device can provide fast and economical heating of small rooms with economical fuel consumption.

Types of heating and types of stoves

Greenhouses are heated using several methods:

- biological;

- electrical;

- air;

- gas;

- stove.

Stove heating is the most economical heating option, which allows the use of most types of fuel. They can work on wood, coal, gas and even pellets.

Stove heating has one significant drawback - drying out the air due to the rapid heating of the equipment.

Stove heating using sawdust, which is waste from wood processing enterprises. Therefore, the purchase of this fuel does not require large expenses. To build a sawdust stove, you need to purchase a tin barrel, preferably a couple of barrels, a gas cylinder and a piece of pipe.

- A waste oil stove is an economical heating option with a long burning time. Used oils are disposed of from any vehicle fleet, so fleet workers will be happy to share the oil.

- To heat the greenhouse in the cold season, potbelly stoves are used, which provide good heating.

- Kuznetsov's brick heating stove is of particular interest to gardeners due to its high efficiency (80%). However, the brick stove body must be insulated with basalt material.

- A miracle diesel stove is an excellent solution for a greenhouse where there is no connection to the central heating system. The stove is used both as an additional and as the main source of heat.

There are many types of stoves for heating greenhouses, which differ from each other:

- principle of heat transfer;

- convection;

- radiation;

- main and additional parts;

- fuel combustion chamber;

- pipes for air supply.

Schemes of country stoves, drawings

The device for heating a summer house is made in several versions depending on the preferences of the owner:

- The heating circuit is one of the simplest and most popular. All structural elements are aimed at heating the room. This variety is well suited for a country house in which electricity is installed and a stove is used for cooking. The structure includes a firebox, an ash pit and a chimney.

Photo 1. Drawing of a brick stove for a summer house, used for heating the premises. The order of the device is also presented.

The cooking circuit is more suitable for dachas where people live during the warm season. The components of this oven maximize the cooking function

Heating does not play an important role. The structure consists of a brick body, firebox, ash pan and chimney

It is possible to equip the stove with an oven and a tank for heating water. This helps create comfortable conditions.

Photo 2. Drawing and arrangement of a brick structure for a summer house with a hob for cooking.

- A universal stove is built according to the heating and cooking scheme. Its design includes a firebox, chimney, ash pan, hob, and oven. Such a stove is quite massive and is rarely installed in dachas where an alternative heating system is provided. It is most popular in Russia, as it combines the functions of the two previously described schemes. With its help, they organize efficient heating of the room and prepare delicious food for the whole family.

Reference. The described options for stoves for a summer residence include additional elements according to the individual preferences of the owner.

A comfortable bed, a wood-burning oven, an oven or a water-heating tank can play a complementary role. Stoves have positive and negative sides, which the owner of the dacha takes into account before starting to purchase materials, select a location and lay out the future device for heating and cooking.

Positive characteristics of sawdust stoves

Heating units have a number of positive characteristics:

- The duration of the combustion process with one addition of sawdust is from 8 to 18 hours.

- Autonomous operation without the need for human supervision.

- Ergonomic body and light weight.

- High heat transfer in a short period of time.

- Does not require arrangement of an additional foundation.

- Possibility of laying various types of fuel material - sawdust, firewood, wood chips and pellets.

- Durability, safety and operational reliability.

- Complete combustion of fuel and minimal amount of ash.

- Reduced smoke emission.

- Easy to assemble at home from scrap materials.

- Affordable manufacturing cost.

- Possibility of use for organizing hot water supply and cooking.

Such homemade stoves have practically no significant disadvantages. The only negative point is that they are completely ineffective for heating large areas.

What have we learned?

From an article on biology (6th grade) we learned that in many plants, the roots perform, in addition to the main ones, some additional functions, which are associated with corresponding modifications of the roots. Although these functions are considered additional and specific, they still relate to the support and nutrition of the plant. The types of modified roots are very diverse.

Fuel requirements

The productivity of the heating process depends on the quality of raw materials loaded into the boiler. The main requirements for wood fuel are:

- Density. The efficiency of the heating device is significantly affected by the size of the raw material. The lower the density of the material, the greater the heat transfer during its combustion. The best option is sawdust from a milling machine. The density of such wood waste is on average 120 kg/m³. From 250 grams of such material you can get 1 kW of thermal energy.

- Humidity. Dried sawdust significantly increases the efficiency of the combustion process. The moisture content of wood waste for the boiler should not exceed 20%.

Some models of factory heating units are able to function normally on sawdust with a moisture content of up to 40%. Such designs have a built-in element that rotates the wood fuel. When exposed to high temperatures, sawdust dries quickly.

The humidity of sawdust should not exceed 20%

For ease of storage and loading, compressed sawdust is often used. The amount of thermal energy from such a material corresponds to the volume of heat that is released during the combustion of the same portion of natural wood.

Advantages and disadvantages of long-burning stoves

The main and main advantage of this type of furnace is its low cost. Depending on the region, it can start from an amount of eight thousand rubles. The ranking of the 10 best-selling boilers is given below.

- Klondike

- Buderus

- Sogra

- Siberia

- Thermal

- Bubafonya

- Germa

- Alaska

- Slobozhanka

- Teplodar

You can make such a stove at home, then its price can be reduced almost to the cost of the material

When making your own, special attention should be paid to the quality of the metal used. It must be heat resistant

The absence of open fire is a big plus for the fire safety of your dacha. A long burning time allows you to maintain the microclimate in the room for a long time. It should be noted that the stove is simple in design and easy to operate. All control consists of adjusting the air using the lower damper, as well as adjusting the damper of the upper pipe. Moreover, the boiler firebox is designed in such a way that even with the pipe damper completely closed, it is almost impossible to get carbon monoxide poisoning.

If used correctly, a long-burning boiler will be your faithful assistant for a long time. At your dacha, thanks to the influx of fresh air and the exhaust of hot air, natural ventilation will constantly occur, which will also have a beneficial effect on the room climate. Scientists have proven that a smooth transition from heat to cold and vice versa is optimal for human health. This is precisely the transition that these furnaces provide.

The following disadvantages should be noted:

- the need to prepare firewood

- small size of the heated room

- periodic cleaning of the ash pan

- availability of storage space for firewood

It should be noted that you don’t need so much firewood for your dacha, cleaning the ash pit is not difficult, and making a shed for firewood is very simple. So with creativity and a positive attitude, all these disadvantages can easily be turned into advantages.

Review of brick kilns

There are many models of furnace devices, which are different both in their form and in their functions. The most popular are Russian, Dutch and Swedish stove units. They are slightly inferior to the Finnish, Kuznetsov stove and housekeeper.

Russian stove

This multifunctional design with large dimensions is one of the oldest models. In past times, it was very common: in every home, the presence of a beautiful Russian stove was mandatory.

Russian stove

The main advantages are:

- possibility of heating the room, beds;

- cooking food;

- use as a drying device for clothes and shoes;

- With regular heating, it provides an even, long-lasting temperature;

- creates a special Russian flavor and will become the main decoration of any room.

Despite their advantages, such brick stoves for wood-burning homes have several disadvantages:

- massiveness requires the installation of a solid foundation;

- occupies a significant area in the room;

- the need for regular cleaning;

- difficulty in installation;

- The efficiency is only 60 percent.

Dutch

Another very popular model is the Dutch oven. This design, which looks like a column, really appealed to the owners of country houses and small-sized premises. Its height is significantly greater than its width, so the Dutch model takes up little space.

Dutch oven

Advantages of a brick stove for a Dutch-type wood-burning cottage:

- compactness;

- low cost of masonry material;

- possibility of rapid heating due to thin walls;

- long breaks between fireboxes do not affect the quality of heating;

- You can heat a medium sized room.

Disadvantages of this model:

- relatively low efficiency, which is equal to 40 percent;

- requires regular cleaning of the ash pan. Without proper care, cravings can get worse;

- requires constant attention during combustion and some skills in maintaining the fire.

Swede

This model is designed taking into account the cold climate of northern countries, so it is ideal for our region.

Stove "Swedish"

Advantages of this model:

- compactness;

- high performance;

- fast heating;

- possibility of heating adjacent rooms.

Flaws:

- the cost of construction increases due to the use of fireclay bricks;

- the need for good thermal insulation to avoid heat loss through the floor;

- not suitable for houses and areas that are rarely heated. If it cools completely and is not heated frequently, the furnace masonry may be damaged.

Housekeeper

This small Russian brick stove for a summer house or home can be installed even in a small room. Its design is very simple, but the oven can also be used for cooking. This model is becoming increasingly popular, because its dimensions contribute to the rational use of space.

Housekeeper

Advantages of the economy stove:

- does not take up much space;

- heats the room well;

- you can cook food.

Flaws:

- You cannot fire two fireboxes at the same time;

- requires constant ash removal;

- takes time to heat up;

- For better combustion, you need to use firewood of noticeably the same thickness.

Finca stove

This heating device differs from other types in its special design: one firebox body is located inside the other.

"Finka"

Advantages of the furnace unit:

- high heat transfer efficiency;

- ease of manufacture;

- low cost;

- fast heating;

- safety and environmental friendliness.

Disadvantages of this type of furnace device:

- relatively large dimensions;

- It is necessary to carefully monitor the amount of fuel in the firebox.

Kuznetsov furnace

The heating device received its name thanks to the name of the developer Kuznetsov. The operating principle of such a unit is based on the movement of free gases.

Kuznetsov furnace

Advantages:

- excellent thermal efficiency;

- complete combustion of fuel;

- no soot;

- a small amount of masonry material.

Flaws:

- difficulty in installation due to the design;

- high requirements for material;

- Some skills are required to fire such a device.

Other stove models

In addition to the above models, there are other, less common:

- V. Bykov's stove, which is only suitable for heating a small room;

- Podgorodnikov’s two-bell stove, which can be heated with either coal or wood.

Bubafonya - the most popular long-burning potbelly stove design

The practicality of the Bubafonya stove is proven by its popularity. The fact that this is one of the most popular long-burning stoves is evidenced by the fact that it is used in almost all small greenhouse farms.

The great advantage of this stove is its practicality and ease of use - it is practically omnivorous; dry firewood, sawdust, pellets and briquettes made from straw or sunflower can be burned in the firebox. This stove also shows one of the highest results in terms of fuel combustion duration.

The basic concept of this heating device is that the fuel combustion process combines the process of burning conventional fuel with a controlled supply of oxygen and the process of pyrolysis. The design of the furnace is a metal body with an open top. For the body, a 200 liter thick-walled metal barrel is most often used. It contains a central rod, made of a thick-walled pipe, with a rigidly welded metal disk slightly smaller than the internal diameter of the barrel. The height of the pipe is 10-15 cm higher than the barrel. Ribs are welded on the bottom side of the disk so that there is a small space between the disk and the bottom of the barrel - this is necessary for oxygen access to the firebox. The third element of the design is a structure similar to a guide with a disk. The difference is that the diameter of the pipe is larger than the guide, and the disk itself has holes throughout its entire area. It is put on the internal guide and gradually moves down as the fuel burns. The lid is made of thick metal so that the hole allows the press to lower evenly as the fuel burns. The chimney is sealed in the upper part of the body at a distance of 5-7 cm from the top.

How bubafoni works

Before use, the central guide is inserted into the housing. The entire volume of the body is filled with fuel - firewood, briquettes, flights. The firewood is stacked vertically very tightly. The height of the bookmark should be 5-7 cm below the top cut of the barrel. After this, the upper press is installed on the guide and the cover is put on. Ignition is carried out from above. After the fuel combustion process begins, a process of gradual temperature rise occurs - oxygen enters through the pipes into the combustion chamber. When the temperature rises to 300 degrees, the process of gas formation begins. The gases rise upward and the flame moves into the space between the lid and the upper press. Thus, the process of combustion of gases begins. To regulate the burning speed, an adjustable damper is installed on the pipe of the upper press. When using such a stove, one load of firewood is enough for 48-72 hours of burning.

Greenhouse heating options

Familiarize yourself with the main features of the systems most commonly used to heat greenhouses.

Steam heating

Steam heating

This option should be considered if it is possible to connect the heating of the greenhouse to the heating system of the house.

Pipes laid from the house to the greenhouse require high-quality insulation. The boiler power reserve must be sufficient to provide the required level of heating for both the house and the greenhouse.

There is also a way to organize autonomous steam heating. In this case, the boiler is installed in the greenhouse. Pipes and batteries are connected to the heating unit, and the coolant supply is ensured. Water is traditionally used as a coolant.

To ensure forced circulation of water, the system is usually equipped with appropriate pumping equipment.

Air heating

Air heating

To organize air heating, air heated in the firebox of a special boiler is used. Such heating is characterized by minimal monetary costs for fuel and high thermal efficiency.

Air heating

About half an hour after starting the equipment, the air temperature in the greenhouse can rise by 20 degrees. An additional advantage of the system is that there is no need to use any intermediate coolants.

Gas heating

Gas heating

In such a system, heat is generated as a result of gas combustion. The system can be configured either by connecting to a permanently supplied gas or by using fuel in cylinders.

Gas heater

During operation of the system, there is an intensive intake of air from the heated room, accompanied by the release of water, carbon dioxide and other waste that pose a danger to humans and, of course, plants. In view of this, the installation of gas heating will entail additional costs for organizing the ventilation system.

This type of heating is well suited for small greenhouses. When used over large areas, the costs and complexity of maintenance may be prohibitively high.

Electric heating

Electric heating

Modern electric heating units allow you to efficiently heat a greenhouse without much effort.

Among the main advantages of such devices, it should be noted that during their operation, only the heating of plants and soil occurs. The air does not warm up. It gradually receives heat from the heated earth. This allows you to equip the most efficient and economical heating system.

IR heaters

Modern systems are equipped with sensors and temperature controllers, which provide ample opportunities for dividing the greenhouse into different thermal zones and providing the most comfortable conditions for each group of plants.

Prices for popular models of infrared heaters

IR heaters

Stove heating

Greenhouse stove

The main unit in such a heating system is a solid fuel boiler, usually burning wood or coal.

The simplest stove heating system includes a solid fuel boiler and a smoke exhaust pipe leading from the greenhouse to the street. Additionally, you can equip the system with pipes and radiators, which will allow you to organize the most efficient and high-quality heating.

Both conventional wood-burning stoves and modern long-burning boilers are available on the market. Such devices do not require frequent fuel supply and use it as efficiently as possible.

Installing a solid fuel boiler directly in the greenhouse will lead to drying out of the air and soil, as a result of which the cultivated plants may simply die. To prevent this from happening, when installing a solid fuel boiler in a greenhouse, it is necessary to equip an air humidification system. Usually it is enough to install a large container of water.

Stove heating

Stove heating of a greenhouse is the most popular heating option. In addition, there is nothing complicated in setting up such a system - even a novice master can handle the job. Also, solid fuel heating unconditionally outperforms electric heating in terms of cost. That is why the procedure for organizing heating of a greenhouse will be considered using the example of stove heating.

A simple sawdust stove from a barrel

If you have a metal barrel at your disposal, then first of all you need to cut off the top from it. This should be done carefully, since in the future the part will be used for its intended purpose, but as a removable cover.

Next, a circle with a diameter slightly smaller than the parameters of the barrel is cut out of a metal sheet with a thickness of at least 3 mm. In the center of the circle, make a hole for a pipe with a diameter of 10 cm and carefully weld the resulting workpiece to the inner walls, departing 15-20 cm from the bottom.

Just below the welded sheet, a small window is cut out - a blower, to allow the oxygen necessary for combustion to enter the firebox. A hole for the chimney is cut out in the upper part of the cylinder; a pipe is welded to it to remove carbon monoxide from the firebox.

The chimney requires special attention - too powerful a draft will contribute to the rapid release of gases and reduce the thermal efficiency of the device. If the draft is weak, another problem may arise - life-threatening combustion products will begin to enter the room.

Experienced craftsmen recommend artificially lengthening the chimney pipe by running it around the perimeter of the room, or adapting the chimney for preparing hot water by including a boiler in the design. All this will help keep the house warm and get the most out of it.

The lid is made from a cut off top, welding the sides to it, or from a metal sheet

It is important to ensure the tightness of the structure, otherwise combustion will occur instead of smoldering. For the tightest possible connection, special heat-resistant seals for furnaces are used.

For convenience, be sure to weld the handle.

Positive characteristics of a sawdust stove

The stove option under consideration has its advantages, namely:

- Such a creation will begin to produce heat immediately after the sawdust smoldering. Within half an hour, the cold air in the house will turn into warm air and the room will be comfortable.

- This oven is quite convenient to use. When assembled according to the rules, it will be safe to use. The efficiency of such a furnace is significantly higher compared to any standard design that runs on solid fuel.

- Sawdust is still the cheapest fuel in Russia, thanks to this the population has another way to save.

Boiler installation on a permanent basis

“Underground” installation of a boiler with thermal insulation

If there are no problems with sawdust in your region, and this heating method is the most profitable, you can install this boiler more efficiently and conveniently.

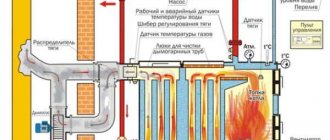

The figure shows the boiler installation diagram:

- A pit of the appropriate size was dug for its installation.

- A foundation is laid at the bottom of the pit.

- The walls of the pit must be strengthened against crumbling.

- The boiler is installed in a pit.

- Thermal insulation is installed around the boiler, inside the pit.

- The boiler cover is thermally insulated separately so that it can be removed.

- Coolant pipelines are connected.

- The register is also insulated.

- The chimney is connected.

- The boiler is ready for operation.

Device and manufacturing methods

A boiler operating on sawdust includes the following parts in its design:

- fuel supply device;

- firebox;

- grates;

- a device that distributes hot air masses in the firebox;

- heat exchanger;

- box for waste raw materials.

There are holes in the firebox of such a boiler to control air. They are placed in a special order and contribute to the duration and uniformity of combustion of raw materials.

Sawdust boilers are made in two ways. The first is that air is supplied from above through a special channel, and the second from the bottom of the device, passing through a passage made in the wood fuel. Units with a top air duct are the most efficient.

DIY making

The general scheme for manufacturing a rocket stove is elementary; numerous metal containers can be used for its manufacture. Heat transfer will directly depend on their useful volume, and the thickness of the walls will affect its service life. You can make a very economical and mobile version to use for heating a winter tent, or a more solid one with a longer shock-absorbing life for a garage box or an industrial workshop with an area of 50 m² - it all depends on the goals.

The basis of the stove can be a 200 liter metal barrel, propane or oxygen cylinders, fire extinguishers, sections of main water pipes, and if all this is not available, you can make the container yourself. Of course, it is better to use cylindrical shapes, since the fuel burns in them without leaving a residue, but for lack of a better one, you can use cubic containers, which are easy to cook yourself.

Main material

It should be remembered that the thicker the walls of the pyrolysis equipment, the longer it will last.

In addition to the main capacitive component, other materials will be required:

- profile pipe and corners, for arranging supports, locking devices, etc.;

- metal circles along the diameter of the main container - the thicker the better (ideally corrugated iron);

- combustion door or homemade equivalent;

- chimney pipe of adequate length - on average at least 3 meters;

- in the case of more complex structures: a second circuit, an additional tank for installing a second heating chamber (hood), etc.

Drawing

After the necessary material and tools have been collected, mental work begins.

Although the design of the furnace is simple, it is impossible to do without a drawing. In it you need to determine the dimensions of all structural elements and use it to find out the order of work. A well-designed circuit will significantly reduce equipment assembly time.

Gas cylinder construction

The simplest and most common scheme for homemade stoves.

simple circuit

Main assembly steps

- The cylinder is equipped with a grate - this can be a metal circle welded at some distance from the bottom, with a drilled hole in the center with a diameter of about 5 cm (other structures, including removable ones, can be used).

- A door (adjustable valve) is formed between the grate and the bottom in the wall of the cylinder.

- At the top of the cylinder, a pipe for the chimney is welded to the side.

- The upper edges of the cylinder are equipped with a sand lock to eliminate smoke leakage from the fuel compartment.

- A locking lid with an air valve for primary ignition is manufactured.

- The cylinder is equipped with support elements for stability, and the chimney pipe is connected to the welded pipe.

Video about the budget option:

The oven is ready for the first start.

Furnace design with external contour

The differences from the first design are minor, and consist in the fact that the combustion chamber is placed inside a larger container so that there is a distance of about 5 cm between the outer and inner contours; hot gases will circulate in this space.

The chimney pipe is welded to the outer contour at the bottom to remove smoke.

External contour

Two-barrel stove design

The first two options can be equipped with an additional cylinder to increase efficiency. Hot gases leaving the fuel compartment or external circuit do not enter the chimney, but into the next cylinder and only after that leave the heating equipment. Maximum efficiency.

Ignition rules

Ignition is easy to do using paper. A small amount of it is placed in the blower, and some is placed on top of the compacted sawdust. Adding paper on top is optional, but it avoids any popping noises that may occur during startup.

You need to set fire through the ash pit. The top cover is locked, but the air valve is left open. After the sawdust has set by pyrolysis, the valve is closed and draft begins through the chimney.

Stove for a greenhouse: making a homemade long-burning stove

Today there are different types of long-burning stoves. Let's look at them in more detail.

Important! It is better to carry out the first heating of a new oven outdoors to allow polymerization of the coating to occur. If this is not done, the greenhouse will smell of burnt paint and factory grease.

Simple potbelly stove

The design of any potbelly stove consists of a metal body with a smoke exhaust pipe and several openings with doors. Fuel is placed in the upper opening, and the lower one is used to regulate combustion by air supply.

You can throw a variety of fuels into a potbelly stove. If you close the ash flap, the fire burns quietly, but if you open it slightly, the combustion processes intensify.

Slobozhanka

This type of potbelly stove is named after the area where it was first used. Its design includes an upper ignition chamber, a combustion chamber, a convection jacket and two structures for air supply and distribution.

Air masses come from the side of the furnace and gradually rise upward. The oxygen necessary for combustion enters all layers, and the fuel consumes the required amount, and the excess goes further. This ensures more active combustion processes.

Did you know? The Japanese call a potbelly stove a daruma stove. A daruma doll is a traditional Japanese tumbler doll.

With water circuit

Long-burning stoves can be equipped with a water circuit to ensure more uniform heating of the greenhouse. In this case, fuel is loaded in the lower part, and a distributor for air masses is installed inside, pressing down the burning wood.

It looks like a disk with a hollow pipe and welded ribs, through which air enters the fuel and is distributed over its surface. As the wood burns, it lowers.

The loading opening, equipped with a door, is located in the center of the body, and at the bottom there is a cleaning hole and an ash pan. The smoke exhaust pipe is at the top.

Firewood in such a stove burns in 8 hours, and coal and pellets in 12 hours . Piping is installed along the perimeter of the greenhouse, which is connected to the stove pipes.

Wood burning

The simplest stove option for a wood-burning greenhouse is bubafonya. This design consists of a metal body, a press with a hollow pipe and stiffening ribs that supplies air to the firewood, an ash pan at the bottom and a chimney.

Firewood is loaded from above and closed with a press. As the wood burns, it goes down.

On sawdust

The option that runs on sawdust produces little smoke. In general, the design of such a furnace is typical. Sawdust in a long-burning stove should smolder slowly and not burn quickly. To do this, use a sealed structure with a poor air supply to prevent strong combustion.

On coal

A coal stove has greater heat output because it runs on high-calorie fuel that burns at higher temperatures. This stove is made of refractory brick or cast iron.

It is better to make a brick stove for coal, since a metal stove gets very hot and requires the installation of a protective screen. Due to the fact that with coal heating the amount of waste increases, the ash pan is made larger.

Its hole acts as a blower, since the air in such devices must come from below. The ash pan is located under the grate, which allows air to pass through to the fuel.

The boiler is made of cast iron or the combustion chamber is reinforced with sheets of refractory steel. The walls of the fuel compartment are often made with a slope so that the burnt coal falls down more easily. The structure must stand on a foundation.

Important! In a coal stove, you should not make a multi-channel chimney or heating shield, as this poses a risk of burning. In the version running on coal, there must be good traction.

Features of using the oven

The operation of sawdust stoves has significant differences from traditional wood or coal devices. Fuel is loaded into a special fuel chamber, which is completely filled up to the chimney pipe. Thin branches, paper or rags soaked in a flammable mixture are laid on top of the sawdust mass. Next, the press is installed, and the chamber is closed with a lid.

After the combustion process begins, the damper remains motionless, and the device is warmed up until the next fuel supply.

The combustion process itself begins in the center of the embedded fuel mass, then moves to the circumference of the walls. As it smolders, the compressed sawdust significantly decreases in volume, which ensures a burning duration of up to 10 hours.

The heat transfer coefficient of a sawdust stove directly depends on the diameter and volume of the fuel chamber. Long and tapered designs provide accelerated heating, while large-diameter devices provide slow heating and high heat transfer.

How does the combustion process occur in a sawdust stove?

If we compare this device with a standard design, then in no case should fuel be added to this stove during combustion. It would be correct if you put pressed sawdust in the oven and until it burns completely, you should not open the oven.

For prolonged combustion of fuel, in order to preserve heat in the room, you can reduce the combustion intensity. With a slow burning, the beginning of which will be in the center at the bottom, will gradually spread upward and to the sides, which will allow the sawdust to fall during the combustion process. Some stoves are quite capable of providing combustion for 8-10 hours.

Installation of a finished stove at the dacha

The location for the stove is determined during the construction of the house. The best place for placement is the outer wall. By placing the heating system in this way, the owner will create comfort and have the opportunity to use the stove for cooking. But if you need to heat a large room, then it is better to mount the stove in the center.

If we are talking about a two-level house, then they think about heating the second floor. A special place is allocated in the foundation to accommodate a massive structure weighing about 200 kg. During installation, adhere to the following requirements:

- A metal sheet with fireproof properties is placed on the floor in front of the firebox door.

- During installation, maintain a distance from the walls and ceiling, which reaches 125 cm.

When installing, the first step is to equip the base

Particular attention is paid to smoke exhaust. Today, it is widespread to assemble a chimney from ready-made parts and then install it

It is also built from brick. This design has a longer service life. When installing a chimney you must:

- Attach the first chimney element without insulation to the pipe.

- Make a hole for the pipe. It is done in a certain place and, if necessary, treated with a layer of thermal insulation.

- Raise the pipe 4-5 meters and strengthen it with special brackets.

- Install a spark arrestor and mesh at the end of the chimney. It will not allow moisture or precipitation to get inside.

If you follow all the described stages of choosing a location for the furnace and follow the technology during installation, the design will work as efficiently as possible.

What is the difference from conventional ovens?

First, you can consider what disadvantages the owner of a conventional stove faces:

- very low efficiency, the level of which can be increased to 80 percent, no more;

- You constantly need to ensure that you add a new portion of fuel on time (usually this needs to be done every 2-3 hours);

- there is no way to automate the combustion process and thus reduce labor costs.

There are none of the listed disadvantages in top combustion furnaces. We can say that they have become an improved version of the traditional stove, which has not lost its position for many centuries. In addition, it has a lot of advantages, including the almost complete absence of soot, small dimensions of the boiler, and the ability to regulate the combustion process. There are many designs that you can make with your own hands.

A long-burning furnace is designed so that oxygen supplies the fuel in limited quantities. Firewood (coal, pellets) does not burn, but smolders. At this moment they release so-called pyrolysis gas. It goes into a separate chamber and burns out completely. As a result, efficiency increases by another 10-15 percent, and the fuel loading period extends from 8 to 12 hours.

For such stoves, sawdust, firewood, coal and pellets can be used as fuel. That is, it is not difficult to choose it depending on the region and the availability of any type of fuel. When such advanced stoves use pellets, the fuel loading process is easily automated. You just need to monitor the filling of the bunker.

An automated long-burning stove using pellets can operate without human intervention for several days.

Principle of operation

The following can be used as fuel:

- coal and carbon braces;

- pellets from sawdust, seed husks;

- peat;

- household waste;

- firewood.

As practice shows, in the vast majority of cases wood is used.

The essence of the operation of such a boiler is that its special design ensures long-term burning of wood - sometimes up to 16-24 hours. The logs burn out almost completely, leaving virtually no ash behind. Therefore, you need to clean the oven no more than once every two weeks, which is also very convenient.

Among other positive characteristics:

- the possibility of not only air heating, but also connecting a water circuit;

- independence from electricity and gas supply;

- efficiency – more than 85%;

- ease of operation;

- efficiency.

Long-term combustion in this case is ensured by the pyrolysis process. The fuel does not burn in the chamber, but smolders slowly with minimal air access, releasing a large amount of pyrolysis gases. The latter, in turn, also burn in a separate chamber, releasing additional heat. This duplicated combustion process of one bookmark provides, on the one hand, a longer time (up to 8-10 hours) and, on the other hand, a significant effect compared to traditional furnaces.

What do manufacturers offer?

Stove for greenhouse "Vologda"

This model:

- has high heat transfer;

- economically beneficial;

- You only need to add firewood a couple of times a day;

- has high efficiency - about 80%.

The owner does not need to constantly monitor the operation of the equipment. To supply coolant, special flexible hoses are used, which are connected to the back of the boiler and led to a tank filled with coolant. To ensure water heating to 60 degrees, 30 to 40 minutes are enough.

Price – 4200-5800 rubles.

"Buleryan"

This brand is extremely rarely used for installation in greenhouses, but at the same time it ensures long-term combustion of fuel, thereby maintaining the required temperature.

It looks like a large barrel laid on its side with release tubes attached to it. There are several options, depending on the size. The smallest one passes about five cubic meters of air through the tubes every minute. To ensure that the body does not become hot and is safe, it is treated with special paint.

Among the negative properties:

- lack of a regulator to adjust the temperature;

- not easy to install;

- requires constant monitoring.

Price 8500 – 25500 rub.

Butakov stove

Named after the engineer, professor, who developed it. The operating principle of Butakov’s model is similar to the “Buleryan” described above.

Today, several factories are engaged in the production of such a heating device:

- "Thermofor" - a large one - copied the boiler, but did it very professionally and efficiently;

- "Convection" and others.

In general, all developments are very similar to each other, but there are advantages and disadvantages specific to a particular brand. Consultants in stores will tell you more about them - there you can make your final choice by comparing the products in reality.

Price 9000 – 36000 rubles.

Greenhouse stove “Slobozhanka”

Another high-quality and efficient stove - it has vertical loading of logs. Additionally, a special cylinder is used, which exerts pressure on combustible materials, gradually lowering as they burn out.

You can also connect a water circuit to Slobozhanka, so you can easily create a full-fledged heating system with radiators. “Slobozhanka” can be easily copied by creating a similar oven yourself, as described below!

Making a boiler yourself

The advantages of the devices described above are not only that they will provide the required temperature in the greenhouse for a long time, but also that they can be made independently using ordinary metal.

In this section, we will talk in detail about how to make a stove for a long-burning greenhouse with your own hands, and the video will help you better understand the principles of creating the unit. To do this, you don’t need much - desire, dexterity, ability to use ordinary tools and consumables.

Pre-production

It is best to use metal as it heats up quickly, distributes heat evenly and is ideal for creating forced-air heating.

The basis is, of course, the body - it can be made of:

- sheet steel formed into a cylinder;

- old gas cylinder;

- large steel pipe;

- old metal barrel.

The easiest way is to make a unit from an old barrel. Yes, and it’s not difficult to get it. Therefore, in our instructions we take it as a basis. For the barrel you will need:

- metal pipe for smoke removal;

- metal corner.

Tools you will need:

- welding machine;

- grinder with a disc for working on metal;

- any device for identifying and applying markings.

Sequencing

All work is carried out according to a pre-prepared scheme or drawing

Diagram of the simplest long-burning furnace

First of all, you should prepare the body, that is, the barrel:

- the top cover (if it is not removable) is cut off;

- a hole is cut in the side of the upper part of the barrel, the diameter corresponding to the size of the chimney pipe;

- A square or rectangular hole is cut out at the bottom, through which the logs will subsequently be placed - naturally, you will also need a metal door that fits tightly and ensures tightness.

The body is ready, and therefore it’s time to create other structural elements. In particular, the cut top lid should be slightly reduced in size so that it fits freely into the barrel.

Make a small hole in the middle of your “pancake”. Connect a small diameter pipe to it - oxygen will flow through the hole. A hole that is too large will cause the wood to burn out quickly - it is enough if its diameter is about two centimeters.

Weld steel strips to the bottom of the “pancake”, which will help strengthen the lid and make the pressure on the wood more effective.

As a result, the firewood will gradually smolder, and the lid will put pressure on it and gradually lower. By the way, by the level of its lowering you can determine when to reload fuel again.

To make the stove safe, it should be installed on legs - also use a metal corner for this. Make four corner pieces of equal length and weld them to the barrel. Weld small metal plates at the bottom of the corners, which will provide additional stability to the solid fuel boiler you created.

Important points

When working on creating a long-burning stove with your own hands, you need to know about some of the nuances of this process.

Furnace assembly algorithm

Professionals with experience in this matter are well aware of them:

- When assembling the chimney, it is necessary to act in the direction opposite to the movement of combustion products.

- A structure should be arranged that can be easily disassembled for cleaning of deposits.

- Before starting operation, the sawdust stove must be tested in various modes. You should find out the most suitable temperature conditions for use, as well as the optimal amount of fuel that can be loaded into the ignition chamber.

- The procedure for manufacturing such equipment is not very difficult if the necessary materials are available and there is also some experience in such work.

In order to obtain an installation that will last for a long time, during its manufacture it is necessary to maintain dimensional accuracy and use high-quality materials. When using the device, you need to remember that it is a fire hazard, so you should not conduct various experiments with it.

A long-burning sawdust stove with your own hands is perfect as a heating device in a garage or workshop. When making the installation yourself, the costs are minimal. Even with the help of scrap materials, you can create effective heating equipment. You just need to follow the order of the work, and carry out the event itself, focusing on a pre-developed drawing. In this case, you can get a potbelly stove that will provide a warm microclimate in the room with minimal fuel consumption.

Long-burning stove using wood waste (sawdust, wood chips, branches)

You can heat a utility room, greenhouse, workshop, or garage with a stove into which sawdust and other waste from the wood industry are compacted. In some regions they can be found for free, or extremely cheaply, which is why such stoves are popular. The advantages include the fact that after lighting it, you don’t have to approach this stove during the entire period of fuel combustion, which can be extended for 12 hours or more.

Sawdust stove design

Fuel combustion occurs in a round or square container with a volume of approximately 100 liters, which is considered optimal in terms of the duration of work on one load, and the possibility of burning the entire stored volume. A round hole approximately 110 mm in diameter is made in the bottom of the container in the center for air supply.

This container is placed in another with larger dimensions, such that there is a gap of at least 50 mm between their sides. For example, you can take two barrels - one for a hundred liters, and the other for 180 liters.

In a large container on the bottom in the center there is an ashpit-ashpit - an oblong box, and the hole in the first container is directly above this ashpit. Thus, air enters the small container from below.

At the top of the large container, along the edge of the sides, there is a sand castle on which the lid is installed. To do this, a corner is welded around the perimeter, and the resulting gutter is filled with sand. The sides of the lid rest on it, thus ensuring tightness.

For a square shape, the optimal dimensions are 40x40 cm for an internal container, and 50x50 cm for an external one, with a height of 1 meter or a little more.

How does a long-burning sawdust stove work?

A long pipe with a diameter of 100 mm or more is installed in the hole in the center of the small container (the combustion power depends on the diameter), then the container is filled with sawdust, into which larger wood elements can be mixed, the sawdust is compacted, after which the pipe is carefully removed. The stove contains a fuel container with a through hole in the center.

All that remains is to set fire to the filling from below; for this, wood chips are placed in the ash box and set on fire. The fuel burns out from the center to the edges, air is supplied from below, passes through the fuel and the already hot gases fall down between the sides of the large and small tanks, and go to the chimney connected at the bottom of the large body.

Thus, the stove initially has a large body area, which only increases the percentage of heat delivered.

How the sawdust stove works - watch the video.

Is it possible to warm up from a potbelly stove - the real power of a sawdust stove

How much energy is contained in the buried sawdust?

- Let us take the average calorific value of large pine sawdust as 2.5 kW/kg.

- The mass of sawdust in the barrel is about 20 kg, with a bulk density of about 200 kg/m3, and a filling volume of approximately 100 liters.

- The energy from combustion of the entire volume is 50 kW.

- If the combustion is extended over 12 hours, then on average we get 4 kW/hour.

Taking into account the efficiency of no more than 50%, we get the real heat output of our stove to be no more than that of an electric heater of 2.0 kW. Which, in principle, is enough to warm up a medium-sized garage or workshop, while being significantly cheaper than electric heating.

But, of course, it will not be possible to obtain greater energy output and quickly warm up a cold room using sawdust...

Ways to increase energy efficiency

Sometimes you need to get more power, for example, 5 kW instead of 2 - this is not difficult to achieve.

- Use dry sawdust, dried for a long time in a warm place; their real calorific value can be up to 1.5 times greater than that of wet sawdust.

- Transfer sawdust with small dry firewood, their calorific value is even higher - up to 4.0 kW per kg.

- Burn faster - make the hole in the filling larger in diameter - the initial volume of fuel combustion increases, giving the maximum amount of air...

In addition to increasing the quantity and quality of fuel, the energy efficiency of the structure itself can also be increased, i.e. Efficiency

- Make vertical fins on the body.

- Leave a large length of the chimney inside the room - make an inclined chimney to the far wall with hatches for cleaning soot.

To quickly warm up the room and increase energy efficiency, you can put a small stack of firewood in the stove, which will burn happily...

Another video about the design of a sawdust stove and its operating features