Supply and return in the heating system are separate systems designed to supply heated water to heating radiators and remove cooled liquid to the boiler or other heating equipment in order to further increase the temperature of the coolant. In what ways can you organize supply and return in modern conditions, read on.

Location of supply and return in the heating system

What is needed for this

To calculate the diameter of the pipe, as a rule, the following factors are taken into account:

- Total heat loss of the home.

- What power do heating radiators have separately in each room.

- The total length of the circuit pipes.

- How is the system wired?

To be able to calculate the diameter of the pipes, it is necessary to determine in advance the total heat loss, the power of the boiler equipment and batteries for each room. It is also important which method will be chosen for pipe routing. Having all these parameters in hand, a future calculation scheme is drawn up.

It is also important to remember some of the specific markings of different pipes. Thus, on polypropylene pipes for heating a private house, the outer diameter is indicated (the same applies to copper products). To calculate the internal parameter, the wall thickness is subtracted from this indicator. Steel and metal-plastic pipes are marked by their internal cross-section.

Selecting the appropriate pipe diameter for heating

It is almost impossible to accurately calculate the pipeline cross-section. For these purposes, several methods are used, with approximately the same final result. As you know, the main task of the system is to deliver the required amount of heat to the batteries in order to achieve maximum uniform heating of the heating device.

In forced circuits, a pipeline, coolant and circulation pump are used for these purposes. Using this set of devices, it is necessary to supply the required portion of the coolant in a fixed time. There are two ways to achieve this task - using smaller diameter pipes in combination with a higher speed of water movement, or using a system with a larger cross-section in which the traffic intensity will be lower.

Reasons for the popularity of the first option:

- Lower price for thinner pipes.

- Great ease of installation.

- In open areas such systems are less noticeable. If they are placed on the floor or walls, smaller installation spaces are required.

- Narrow pipes contain less liquid. This leads to a decrease in system inertia and fuel savings.

Thanks to a set of standard diameters and a fixed amount of heat transported through them, there is no need to carry out the same type of calculations. For these purposes, special tables have been compiled: they allow, having on hand data on the required amount of heat, water supply speed and operating temperature of the heating circuit, to calculate the required dimensions. To determine what pipe diameters there are for heating, you need to find the necessary table.

To calculate the diameter of heating pipes, the following formula is used: D = √354x(0.86x Q/∆t)/V, where D is the desired pipeline diameter (mm), ∆t° is the temperature delta (the difference between supply and return), Q is load for a given section of the system, kW – a certain amount of heat required to heat the room, V – coolant velocity (m/s).

Autonomous systems usually have a coolant movement speed of 0.2 - 1.5 m/s. As practical experience shows, the most optimal speed in such cases is 0.3 m/s - 0.7 m/s. When this indicator decreases, there is a real threat of air jams; when it increases, the coolant begins to make a lot of noise when moving.

There are tables to select the optimal value. They contain data for pipes made of different materials - metal, polypropylene, metal-plastic, copper. When determining the diameter of heating pipes, as a rule, the emphasis was placed on standard operating conditions with high and medium temperatures. Some examples will help you understand the essence of the procedure.

Types of heating schemes

For multi-storey buildings, a single-pipe direct distribution system is often used. It does not have a clear division of pipes into the liquid supply to the radiators and the return, so the complete circuit is conventionally divided into two equal parts. The riser coming out of the boiler is called the supply, and the pipes coming out of the last radiator are called the return. Advantages of this scheme:

- saving time and material costs;

- convenience and simplicity of installation work;

- aesthetic appearance;

- the absence of a return riser and a sequential arrangement of radiators (coolant is supplied to the 1st, then the 2nd, 3rd and so on ).

For a single-pipe system, vertical wiring with a vertical circuit and heat supply from above is common.

With a two-pipe wiring system, it is meant to install two closed, parallel-connected circuits, one of them provides the function of supplying coolant to the heating device (radiator), the second - the function of its outlet (return).

Radiators are connected in several ways:

- Lower (or saddle, crescent-shaped). Provides for connection of supply and return to the lower connecting holes of the radiator. A Mayevsky tap and a plug are installed on the upper holes. Used for systems in which pipes are hidden under the floor or baseboard. Suitable for multi-section radiators; with a small number of sections, heat loss reaches up to 15%.

- The lateral method is popular. The pipes are connected to the radiator on one side: coolant supply through the top, return through the bottom. Not suitable for devices with a large number of sections.

Photo 2. Two-pipe heating circuit with a side connection type. The supply and return temperatures are indicated.

- The diagonal (or lateral cross ) method involves supplying hot water from above, connecting the return line from below and on the other side. Suitable for radiators with at least 14 sections.

- The third option for organizing a heating scheme is a hybrid method, based on the simultaneous use of one-pipe and two-pipe systems. For example, a collector circuit involves supplying coolant through a single riser; further on-site wiring is carried out according to an individual plan.

How it works and how to improve productivity

A single circuit does not ensure uniform heating of heating devices; heat transfer decreases with distance from the boiler (the last radiators receive coolant cooler than the first ones). The disadvantage of such a system is the high coolant pressure.

Reference. The performance of a single-pipe system is increased by the presence of a circular pump or bypasses formed on each floor.

Advantages of a two-pipe heating option:

- heating a sufficient number of devices equally, regardless of their distance to the heat source;

- adjusting the temperature regime or carrying out repairs on a separate device does not affect the operation of others.

Flaws:

- complexity of the wiring diagram;

- complexity of installation and connection.

The optimal choice for private construction is the most productive two-pipe system, which is also often chosen for heating luxury housing.

It is advisable to install a two-pipe system with the installation of a circulation pump, which allows the use of pipes of smaller diameter.

After it, in order to protect the recirculation circuit from squeezing, a check valve is installed.

When installing a system without a circular pump, the rule is observed : supply is possible if there is a slope from or to the boiler. A coolant with a higher temperature enters the radiator through the inlet (slope from the boiler to the heating device) and warms it up, and then exits through the return (slope from the radiator to the boiler), but at a lower temperature. Experienced craftsmen often resort to replacing the recirculation pump ring with a system of 3 or 4-way mixers.

Important! With natural circulation, the entire pipeline from the riser to the radiators should not be long.

Peculiarities

Long-term operation of boiler equipment is possible with a properly designed pipe distribution system, which ensures a certain temperature difference between the pipes that discharge and supply the coolant.

Attention! The presence of a significant difference in temperature values causes the formation of abundant condensate on the combustion chamber.

Drops of water, especially in combination with carbon monoxide formed during combustion (in the case of solid fuel equipment), quickly corrode the walls of the chamber, the seal of an important element is broken, and the boiler fails.

An acceptable solution in this situation is to connect an additional water heating device - a boiler. It is installed next to the boiler in a special way so that the coolant, having passed through all the devices of the system, enters it and then into the boiler.

Photo 3. Heating system with a boiler for heating water. The device is installed next to a gas boiler.

Calculation of two-pipe systems

We are talking about a two-story house with a two-pipe heating system, two wings on each floor. Polypropylene pipes are used to construct the system. Operating mode – 80/60, temperature delta – 20 degrees. Heat loss level - 38 kW of thermal energy (first floor - 20 kW, second - 18 kW).

- First you need to decide which pipe to decorate the area between the boiler and the first branch. The entire volume of coolant is transported here, transferring heat to 38 kW. The reference data indicates two suitable parameters - 40 and 50 mm. It is more profitable to stay at a smaller diameter of 40 mm.

- At the point of flow separation, 20 kW is sent to the first floor, and 18 kW to the second. According to the reference book, the section is determined. In this case, for each direction the optimal diameter is 32 mm.

- In turn, each circuit includes two lines with an equal load. On the first floor, 10 kW is distributed in both directions (20 kW/2 = 10 kW), on the second floor - 9 kW (18 kW/2) = 9 kW). A suitable value for these branches would be 25mm. It is more reasonable to use this parameter until the load is reduced to 5 kW. After this, they switch to a diameter of 20 mm. The first floor is translated by 20 mm immediately behind the second radiator. The second floor usually passes after the third device. As practice shows, this transition is best carried out at a load of 3 kW.

In this way, the diameter of polypropylene pipes for a two-pipe system is calculated. There is no point in determining the dimensions of the return pipe: they are taken the same as for the supply. This procedure is simple: the main thing is to have everyone’s initial data. If you plan to use a different type of pipe to organize the system, you need to use data for a specific material of manufacture. Calculating the diameter of heating pipes with natural circulation is somewhat different.

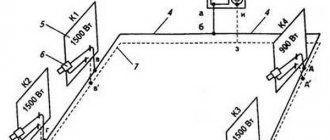

Two-pipe heating system diagram

In two-pipe schemes, the supply of hot coolant to the radiator and the removal of cooled coolant from the radiator are carried out through two different pipelines of the heating systems.

There are several options for two-pipe schemes: classic or standard, associated, fan or beam.

Two-pipe classic wiring

Classic two-pipe heating system wiring diagram.

In the classical scheme, the direction of movement of the coolant in the supply pipeline is opposite to the movement in the return pipeline. This scheme is most common in modern heating systems, both in multi-storey buildings and in private individual ones. The two-pipe circuit allows you to evenly distribute the coolant between radiators without loss of temperature and effectively regulate heat transfer in each room, including automatically through the use of thermostatic valves with installed thermal heads.

Such a device has a two-pipe heating system in a multi-story building.

Associated scheme or “Tichelman loop”

Associated heating wiring diagram.

The associated scheme is a variation of the classical scheme with the difference that the direction of movement of the coolant in the supply and return is the same. This scheme is used in heating systems with long and remote branches. Using a passing circuit allows you to reduce the hydraulic resistance of the branch and distribute the coolant evenly across all radiators.

Fan (radial)

A fan or radial scheme is used in multi-storey construction for apartment heating with the possibility of installing a heat meter (heat meter) in each apartment and in private housing construction in systems with floor-to-floor piping. With a fan-shaped scheme in a multi-storey building, a collector is installed on each floor with exits to all apartments of a separate pipeline and an installed heat meter. This allows each apartment owner to account for and pay only for the heat they consume.

Fan or radiant heating system.

In a private house, a fan diagram is used for floor-to-floor distribution of pipelines and for radial connection of each radiator to a common collector, i.e., each radiator has a separate supply and return pipe from the collector. This connection method allows you to distribute the coolant as evenly as possible across the radiators and reduce hydraulic losses of all elements of the heating system.

Note! When distributing pipelines in a fan pattern within one floor, installation is carried out in solid (without breaks or branches) sections of pipes. When using polymer multilayer or copper pipes, all pipelines can be cast into a concrete screed, thereby reducing the likelihood of rupture or leakage at the junction of network elements.

Calculation of a single-pipe forced-type system

The principle applied is the same as in the previous case, but the algorithm of actions changes. For example, you can take the calculation of the internal diameter of a simple single-pipe heating system in a one-story house. The circuit has six radiators connected in series.

The procedure for calculating the diameter of the heating pipeline based on thermal power:

- The boiler transfers 15 kW of heat to the beginning of the system. According to the reference data, this section can be equipped with 25 mm and 20 mm pipes. As in the first example, it is better to choose 20 mm.

- Inside the first battery, the thermal load is reduced to 12 kW. This does not affect the cross-section of the outgoing pipe in any way: it remains the same value of 20 mm.

- The third radiator reduces the load to 10.5 kW. In this case, the cross-section remains the same - the same 20 mm.

- The transition to a smaller diameter of 15 mm occurs after the fourth battery, as the load is reduced to 8.5 kW.

- The coolant is transported to the fifth device through a 15 mm pipe, and after it there is a transition to 12 mm.

At first glance, it may seem that calculating pipe diameters for a heating system is easy and simple. Indeed, when polypropylene or metal-plastic products are used to organize the circuit, difficulties usually do not arise. This is explained by their low thermal conductivity and small heat leaks through the walls (they can be ignored). The situation is completely different with metal products. If the steel, copper or stainless steel pipeline is of considerable length, quite a lot of thermal energy will flow through its surface.

How to cut heating

How to refuse heating in an apartment building?

Documentation

We will only partially touch on the documentary part. The problem is quite painful; permission to disconnect from the central heating center is given by organizations extremely reluctantly, and often it has to be obtained through the courts. It is quite possible that in your case it would be much more useful not to read a technical article, but to consult a lawyer knowledgeable in the Housing Code.

The main steps are:

- Let's find out if it is technically possible to turn it off. It is at this stage that most of the friction will occur: neither housing and communal services nor heat suppliers like to lose payers.

- Technical specifications for an autonomous heating system are being prepared. You need to calculate the approximate gas consumption (if you use it for heating) and show that you are able to provide a temperature regime in the apartment that is safe for the building’s structures.

- The fire inspection act is signed.

- If you plan to install a boiler with a closed burner and exhaust of combustion products to the facade of the building, you will need a permit signed by the Sanitary and Epidemiological Supervision Authority.

- A licensed installation organization is hired to draw up the project. You will need a full package of documents - from instructions for the boiler to a copy of the installers’ license.

- After installation is completed, a gas service representative is invited to connect the boiler and start it up for the first time.

- The last stage: you put the boiler on permanent maintenance and notify the gas supplier about the transition to individual heating.

Technical side

Refusal of heating in an apartment building is due to the fact that you need to dismantle all heating devices without disrupting the operation of the heating system. How it's done?

In houses with bottom filling, it is worth considering two cases separately:

- If you live on the top floor, you obtain the consent of the lower neighbors and move the jumper between the paired risers to their apartment. Thus, you completely isolate yourself from the CO. Of course, you will have to pay for welding work, installation of an air vent, and cosmetic repairs to the neighbors’ ceiling.

- On the middle floor, only heating appliances are dismantled, with welding and cutting off the hoses. A jumper of the same diameter as the rest of the pipe cuts into the riser. Then the riser along its entire length is carefully insulated.

How to calculate metal pipes

Large heating systems equipped with metal pipes require taking into account heat loss through the walls. Although on average these figures are quite low, on very long branches the total value of lost energy is quite high. Often because of this, the last batteries in the heating circuit do not heat up well enough. There is only one reason - the diameter of the pipes was chosen incorrectly.

An example would be the determination of losses of a 40 mm steel pipe with a wall thickness of 1.4 mm. For the calculation, the formula is used q = kх3.14х(tв-tп), where q is the heat loss of a meter of pipe, k is the linear heat transfer coefficient (in this case it corresponds to 0.272 W*m/s), tв is the temperature of the water inside (+80 degrees), tп – air temperature in the room (+22 degrees).

To get the result, you need to substitute the required values into the formula:

q = 0.272x3.15x(80-22) = 49 W/s

The picture that emerges is that every meter of pipe loses heat in an amount of almost 50 W. On very long pipelines, the total losses can be simply catastrophic. In this case, the volume of leaks directly depends on the cross-section of the circuit. To take into account such losses, a similar indicator on the pipeline must be added to the indicator for reducing the thermal load on the battery. Determination of the optimal pipeline diameter is carried out taking into account the total value of leaks.

Typically, in autonomous heating systems, these indicators are not critical. In addition, during the procedure for determining heat loss and boiler power, the data obtained is usually rounded up. Thanks to this, a safety stock is created, freeing from complex calculations.

Finding relevant data

As for finding the optimal reference data, almost all websites of manufacturers of heating system components provide this information. In cases where suitable values have not been found, there is a special system for selecting diameters. This technique is based on calculations, and not on average patterns based on processing data on a huge number of heating systems. Calculation of the coolant by pipe cross-section was developed by plumbers with practical experience in installation work, and is used for arranging small circuits inside homes.

In the vast majority of cases, heating boilers are equipped with two sizes of supply and return pipes: ¾ and ½ inches. This size is taken as the basis for wiring up to the first branch. In the future, each new branch serves as a reason to reduce the diameter by one position. This method allows you to calculate the cross-section of pipes in an apartment. We are talking about small systems with 3-8 radiators. Typically such circuits consist of two or three lines with 1-2 batteries. Small private cottages can be calculated in a similar way. If there are two or more floors, you have to use reference data.

Options for organizing the supply and removal of coolant to radiators

When installing heating systems, two main wirings are used: with one or two pipes; a combined supply of free-standing heat exchangers is often practiced. In many cases, the connection points for radiators are their two pipes located on the sides; modifications with two lower outlets are similarly connected when installed using special N-shaped bottom connection units (binoculars).

Fig. 5 Top supply in an apartment building - traffic diagram

Single pipe system

This wiring has become widespread in public utilities and everyday life due to its following advantages and features:

- The option with one pipe is the most profitable from a financial point of view, allowing you to save materials twice as much as compared to a two-pipe one.

- In addition to saving materials, the complexity of installation is reduced and, accordingly, the cost of arranging a single-pipe distribution is reduced - fewer grooves are made in the walls, a relatively small number of different types of fittings are purchased: bends, tees, shut-off and control valves, couplings, the work on assembling the pipeline is accelerated by soldering, press or compression fittings.

- In a line with one pipe, the coolant moves sequentially along the entire chain of radiators, with the first one, closest to the heating boiler or heating network, having the highest heat transfer, and the last one being the coldest.

Equation method

Although pipes made of different materials are marked with different values (internal or external), in some cases they can be equated. This applies to situations where it is not possible to find data on a specific pipe: in such a situation, you can use information on a similar cross-section of a product made of a different material.

Let's say you need to calculate what diameter of a metal-plastic pipe is needed for heating, but the necessary information on this material has not been found. As an alternative, a table of coolant speed in the heating system for polypropylene products is used. Using the appropriate dimensions, the appropriate parameters for the metal-plastic pipe are selected. In this case, it is impossible to avoid inaccuracies, but in forced-type circuits they are not critical.

Conclusion

Using a not very complex and branched scheme to organize the heating of your home, you can calculate the optimal pipeline diameter on your own. To do this, you need to arm yourself with information about the heat loss of your home and the power of each battery. Next, using special tables and reference books, the optimal value of the pipe cross-section is selected, which can ensure the transportation of the required volume of thermal energy to each of the rooms.

If complex schemes with many elements are used, then it is advisable to invite a professional plumber to calculate them. If you have confidence in your own abilities, it is still recommended to consult with a specialist. There are cases when, due to mistakes made, it is necessary to undertake an expensive reconstruction of the entire circuit.

The diameter of the heating pipes depends on the volume of coolant that will pass through them. Obviously, on the main supply pipeline coming from the heating boiler, the diameter will be larger, on the branch with three radiators it will be even smaller, and on the final radiator it will be the smallest. Accordingly, the diameter of the pipe will depend on the total thermal power of the radiators that feed the pipeline.

In addition, the diameter of the pipeline depends on the speed of movement of the coolant in the system and on the supply/return temperature difference. The higher this difference, the smaller the pipeline diameter required. The standard temperature difference is 20°C. In more comfortable systems, this difference is less – 10°C.

A heating system with a circulation pump is characterized by a high coolant speed, while a system with natural circulation has a low speed, so this must be taken into account when selecting heating pipes. You should not factor in too high a speed of water movement in the pipes when calculating pipelines, because... this will create various unpleasant noises and babbling in the pipes. If the speed is too low, there is a risk of air locks forming in the system. The speed of movement in the pipes should be in the range of 0.4 - 0.6 m/s. A gravity-flow system is characterized by a significantly lower coolant velocity, so the diameter of the pipes must be chosen larger.

Therefore, below we provide tables for selecting pipe diameters for various systems with the specified parameters. The table uses the selection of pipe diameters from various materials. VGP steel pipes are designated by the internal diameter, while polypropylene, metal-plastic and cross-linked polyethylene pipes are designated by the outer diameter. This is taken into account in the table for selecting pipeline diameters.

The battery does not heat up

If one or more radiators do not heat or heat poorly, then the first thing you need to do is check if there is air in them using air vents. If water flows from the drains, but the radiator still does not heat, then you need to make sure that both taps of this radiator are open (such inattention can often occur). The next step is to check if the radiator is clogged. To do this, other heating radiators that heat and are on the same branch as the non-working one must be shut off so that all the water flows through this radiator. If it starts to warm up, it means it is not clogged. In this case, it is necessary to hydraulically level the branch. In simple terms, it is necessary to cover the remaining radiators on the branch so that the one who is not working gets more. You need to be prepared that leveling will take more than one day, because the heating system may be slow to respond to changes in settings. If the taps in front of the radiator are completely open, and it is cold, then it is clogged (extremely low probability). Basically, the last radiators on the branch may not heat . But this can always be eliminated by hydraulic leveling. If someone tells you that “it’s not pumping there” or “the pump’s power is insufficient,” don’t rush to believe and touch the pump or pipes. In order to prevent the pump from pumping too much, you need to try very hard when installing the heating system. If one or more of the last radiators does not heat up even after working with the taps, then there may be an air lock in the pipes (see circulation disturbance in the heating system).

Application example: two-pipe system with circulation pump, total power 18 kW.

The wiring is made with a polypropylene pipe, symbol - PP.

As we can see from the diagram, first a polypropylene pipe with a diameter of 40 mm comes out of the boiler, its internal clearance is 25 mm, which corresponds to a metal VGP pipe of 1 inch (25 mm). Next comes the outlet for the boiler (4 kW) and heated floors (2 kW) of two PP pipes with a diameter of 16 mm. After this, part of the coolant separated, so there is no need for such a thick pipe. A thinner pipe will be used for heating the 1st and 2nd floors - 32mm, it will go to the first tee. At the tee, a branch is separated to the 1st floor, with a diameter of 25 mm, and to the 2nd floor, also with a diameter of 25 mm. A polypropylene pipe with a diameter of 16 mm is already suitable for the final radiators. And on the last 3 radiators the supply pipe is also narrowed to 16mm.

In a one-pipe system, unlike a two-pipe system, the entire coolant of the system is supplied through one pipeline. Therefore, in such a system, the entire pipeline (after branching the pipe to the boiler and heated floor) will have a diameter of 32 mm, and 16 mm pipes will be suitable for individual radiators from the main pipeline.

In the article we will consider systems with forced circulation. In them, the movement of the coolant is ensured by a constantly running circulation pump. When choosing the diameter of heating pipes, it is assumed that their main task is to ensure the delivery of the required amount of heat to heating devices - radiators or registers. For the calculation you will need the following data:

- General heat loss of a house or apartment.

- The power of heating devices (radiators) in each room.

- Pipeline length.

- Method of wiring the system (one-pipe, two-pipe, with forced or natural circulation).

That is, before you start calculating the diameters of the pipes, you first calculate the total heat loss, determine the power of the boiler and calculate the power of the radiators for each room. You will also need to decide on the wiring method. Using these data, you draw up a diagram and then just start calculating.

To determine the diameter of the heating pipes, you will need a diagram with the thermal load values assigned to each element.

What else do you need to pay attention to? The fact is that the outer diameter of polypropylene and copper pipes is marked, and the inner diameter is calculated (subtract the wall thickness). For steel and metal-plastic ones, the internal size is indicated when marking. So don't forget this little thing.

Connection diagrams for boilers, radiators, piping in home heating

You can make a heating system for your home yourself if you have the skills to do plumbing and construction work. In other words, you need to be able to solder pipes, cut them, connect them, and also tighten nuts, know the purpose and technical characteristics of the equipment used, have an understanding of hydraulics and heating engineering, and much more...

Then, using standard proven schemes and solutions, you can create a heating system for a small house only with your own hands.

But if you don’t have the skills to do the work, you will have to watch how specialists make the heating system. At the same time, it is also highly advisable to familiarize yourself with the basic rules for creating a system, equipment layout diagrams, etc., in order to monitor the progress of work and eliminate errors in a timely manner, if any are made.

Below are some nuances of creating a heating system in a private home, which you should always pay attention to first. Let's start with connecting the boiler, since many mistakes are often made in the boiler room.

Connecting a wall-mounted boiler

Wall-mounted boilers are usually automated; they contain two important elements of the heating system:

- safety group, which usually consists of an air valve, pressure gauge, emergency overpressure valve;

- circulation pump, which ensures the movement of fluid in the heating system;

Therefore, connecting a wall-mounted boiler is the simplest; it should be done according to the following scheme (we consider the direction “from the boiler”):

Supply: – tap with American connection for connecting the boiler; - transition fitting for pipes - American.

The tap is required and is placed immediately in front of the boiler so that the boiler can be serviced without draining the system.

Return: - tap with American connection for connecting the boiler; — dirt filter; - tap; — a tee with an expansion tank, a shut-off valve, a drain and fill valve for the system. - transition fitting for pipes - American.

A dirt filter is a mandatory element of any heating system. It is installed with the sump facing down, or, in extreme cases, horizontally. Dirt from the system will accumulate in the filter and is periodically removed from the sump. When installing, you must observe the direction relative to the stream.

The taps near the filter are required; only by closing both taps can you service and clean the filter.

Next, let's look at the piping of a floor-standing boiler. It is more complicated, since a floor-standing boiler does not have a safety group and a pump. Therefore, they are installed independently, like elements of a boiler room.

Safety group, circulation pump, expansion tank

For the safety group, it is better to purchase a special tee and mount the devices listed above on it. It is important to select devices in accordance with the parameters of the heating system, usually the maximum pressure is 4 MPa, the operating pressure is 1.5 - 2.0 Atm.

The pump is purchased according to the characteristics of the system. For an ordinary small house (up to 150 sq. m.), a circulation pump with a pressure of up to 4 m (0.4 atm) will always be sufficient for the heating system (often for radiators up to 250 sq. m.)

Accordingly, the pump is marked 25 - 40, where the first number indicates the thread diameter of the connection pipes, in this case 25 mm - 1 inch, but it can be 32 mm or more. The second number 40 is a designation of the pressure created - up to 0.4 atm, and therefore, indirectly, the power of the pump.

Each circulation pump has a rotation speed adjustment in at least 3 positions, which will determine the volume of liquid pumped and the actual power consumption.

In the first adjustment position, the circulation pump 25-40 will consume no more than 30 W of electricity. More often, for a properly designed heating system in an insulated house up to 150 sq. m. There will be enough thermal energy that can be supplied by this pump at first speed.

An often repeated mistake when creating a heating system is installing overly powerful pumps, despite the fact that they cost many times more and consume more electricity. Where a pump of 25 - 40 m is optimal (in most small houses), pumps of 25 - 60, and even 25 - 80 and more powerful are installed.

The volume of the expansion tank can be selected using a simplified formula - 1/10 of the volume of coolant in the system. A little more is better, but not less. For example, if the system has 200 liters, then it is better to install a 35 liter expansion tank but not less than 20 liters.

Connecting a floor-standing non-automated boiler

Let's look at a diagram of how a floor-standing boiler that is not equipped with automation should be connected. (In the direction from the boiler.)

How to choose the diameter of a heating pipe

It will not be possible to calculate exactly what cross-section of pipes you need. You will have to choose from several options. And all because the same effect can be achieved in different ways.

Let me explain. It is important for us to deliver the right amount of heat to the radiators and at the same time achieve uniform heating of the radiators. In systems with forced circulation, we do this using pipes, coolant and a pump. In principle, all we need is to “drive” a certain amount of coolant over a certain period of time. There are two options: install pipes of a smaller diameter and supply coolant at a higher speed, or make a system of a larger cross-section, but with less traffic. Usually the first option is chosen. And that's why:

- the cost of products with a smaller diameter is lower;

- they are easier to work with;

- when laid open, they do not attract so much attention, and when laid in the floor or walls, smaller grooves are required;

- with a small diameter, there is less coolant in the system, which reduces its inertia and leads to fuel savings.

Calculation of the diameter of copper heating pipes depending on the power of the radiators

Since there is a certain set of diameters and a certain amount of heat that needs to be delivered through them, it is unreasonable to calculate the same thing every time. Therefore, special tables have been developed, according to which, depending on the required amount of heat, the speed of movement of the coolant and the temperature indicators of the system, the possible size is determined. That is, to determine the cross-section of pipes in the heating system, find the required table and select the appropriate cross-section from it.

The diameter of the heating pipes was calculated using the following formula (you can calculate it if you wish). Then the calculated values were recorded in a table.

Formula for calculating the diameter of a heating pipe

D - required pipeline diameter, mm ∆t° - temperature delta (difference between supply and return), °C Q - load on a given section of the system, kW - determined amount of heat required to heat the room V - coolant velocity, m/s - selected from a certain range.

In individual heating systems, the coolant movement speed can be from 0.2 m/s to 1.5 m/s. Based on operating experience, it is known that the optimal speed is in the range of 0.3 m/s - 0.7 m/s. If the coolant moves more slowly, air jams occur; if it moves faster, the noise level increases significantly. The optimal speed range is selected in the table. The tables are designed for different types of pipes: metal, polypropylene, metal-plastic, copper. The values are calculated for standard operating modes: high and medium temperatures. To make the selection process more clear, let’s look at specific examples.

The role of return and its difference from supply

Sometimes, when carrying out plumbing work on their own, the user does not know how to identify the supply and return pipes when the battery is connected. If you are completely unfamiliar with the design, you can use a thermometer, identifying the supply and return pipelines by the temperature difference, if you know the circuits for discharging coolant to the heating radiators, consider the following options:

- With diagonal and side switching, the supply is always at the top and the outlet at the bottom.

- In the lower connection, the direction of movement of the input and output flows is sometimes indicated by arrows on the supply unit (binoculars).

- In Leningradka, the return pipe is considered to be the one coming from the last radiator in the row.

- In the manifold distribution, the supply combs are equipped with adjustable supply sensors in the form of fittings with transparent caps and indicators placed inside; the shut-off valves of the return comb are closed with threaded plugs. Also, the color marking of the forward feed is red, and the return feed is blue.

Rice. 3 Organization of heating systems using an open expansion tank

The return line plays no less important role than the direct line for supplying media to heat exchange devices or heated floors, its purpose and installation methods:

In gravity flow structures with an open storage tank. The movement of water in open circuits occurs due to the difference in hydrostatic pressures of the cooled and hot water columns due to the fact that the hot liquid has a lower density.

It follows from this that the greater the temperature difference between the cold and hot water column, the more significant the difference between the supply and return in pressure and, accordingly, the force that pushes the heated flow upward.

Therefore, the return line is designed and installed taking into account the following rules:

- Heat loss in the return must be quite significant to minimize the cooling of the water, that is, the batteries must have significant heat transfer.

- As the distance from the bottom point of the radiators to the boiler inlet pipes increases, the length of the low-temperature column increases and, accordingly, it more effectively displaces the heated coolant. The high location of the boiler from the battery lengthens the section with a cooled return, while simultaneously shortening the section of the high-temperature column - as a result, a large temperature difference shifts the working fluid much further up the circuit and heating occurs more efficiently.

- The upper installation of the boiler is contradicted by the condition under which it must be at a height below the level of the last batteries in the chain for the gravity flow of the carrier into it at an angle. If the boiler is installed low in the basement, to ensure normal circulation during installation, slopes towards the heating unit should be observed (2 - 3 mm per linear meter).

It should be noted that both of the above schemes are working (the latter is used more often) and their choice is related to the convenience of installing boiler equipment in the house.

Rice. 4 Closed heating system - diagram

Perhaps by reading. what is the return of a heating system, it will be interesting to read about Connecting the boiler to the heating system

In closed circuits with an electric pump. In multi-circuit heating with heated floors, circular pumps are installed that create the required pressure in the main; in many cases, two circular pumps are used - one pumps water throughout the system, and the second supplies coolant to the floors or radiator heaters.

With collector wiring, the return temperature relative to the supply plays an important role; the difference should not exceed 10º C, standard differences are 55 - 45, 50 - 40, 45 - 35, 40 - 30 degrees. To achieve these parameters, the cooled coolant from the return manifold is partially mixed with the hot coolant coming from the boiler, and then supplied to the heated floors.

In boiler piping. When the boilers are put into operation, the initial difference between the supply and return temperatures is quite significant - this leads to the formation of condensation on the walls of the heating chamber and chimney pipes, which, entering into a chemical reaction with carbon dioxide and other combustion products, causes accelerated corrosion of their surface.

To prevent these negative consequences, a small circuit is created with an adjustable check valve, in which the temperatures of the coolant entering the boiler and the heated fluid are quickly equalized. After reaching the specified temperature threshold, the thermal valve automatically opens and the entire system line is connected to the small heating circuit.

Sometimes, to equalize the temperature parameters of the supply and return, a bypass jumper of small diameter is installed between them; the width of its passage channel can be adjusted with screw valves (ball valves are used only for completely closing and opening passages).

Calculation for a two-pipe system

There is a two-story house with a two-pipe heating system, two wings on each floor. Polypropylene products will be used, operating mode 80/60 with a temperature delta of 20 °C. The heat loss of the house is 38 kW of thermal energy. The first floor has 20 kW, the second 18 kW. The diagram is shown below.

Two-pipe heating scheme for a two-story house. Right wing (click to enlarge)

Two-pipe heating scheme for a two-story house. Left wing (click to enlarge)

On the right is a table from which we will determine the diameter. The pinkish area is the zone of optimal coolant movement speed.

Table for calculating the diameter of polypropylene heating pipes. Operating mode 80/60 with a temperature delta of 20°C (click to enlarge)

- We determine which pipe needs to be used in the area from the boiler to the first branch. The entire coolant passes through this section, therefore the entire heat volume of 38 kW passes through. In the table we find the corresponding line, follow it to the pink-tinted area and go up. We see that two diameters are suitable: 40 mm, 50 mm. For obvious reasons, we choose the smaller one - 40 mm.

- Let's look at the diagram again. Where the flow is divided, 20 kW goes to the 1st floor, 18 kW goes to the 2nd floor. In the table we find the corresponding lines and determine the cross-section of the pipes. It turns out that we are dividing both branches with a diameter of 32 mm.

- Each of the circuits is divided into two branches with equal load. On the first floor there is 10 kW each to the right and left (20 kW/2=10 kW), on the second floor 9 kW each (18 kW/2)=9 kW). Using the table, we find the corresponding values for these areas: 25 mm. This size is continued to be used until the heat load drops to 5 kW (as seen in the table). Next comes a section of 20 mm. On the first floor we go 20 mm after the second radiator (look at the load), on the second - after the third. At this point there is one amendment made by accumulated experience - it is better to switch to 20 mm at a load of 3 kW.

What is heating system return?

Knowing the basic principles of a heating device, it is quite simple to answer the question of what a return is - it is a pipeline through which the medium leaving the heat transfer devices is directed to the boiler equipment for subsequent heating.

Almost any heating device has at least two built-in connection pipes, and with a two-pipe system, the return and supply circuits have a clear distinction (separate collectors). With a single-pipe connection method, the devices are connected in series to each other, so the supply pipe is connected to the first battery in the circuit from the boiler, and the return pipe is the pipe coming out of the last one. When using the popular “Leningrad”, the return should be considered the pipeline section after all the heaters in the circuit.

Rice. 2 Multi-circuit heating scheme for a cottage - example (the return of the heating system is marked in blue)

Determination of pipe diameter for a single-pipe system with forced circulation

The principle remains the same, the methodology changes. Let's use another table to determine the diameter of pipes with a different principle for entering data. In it, the optimal zone of coolant movement speeds is colored blue, the power values are not in the side column, but are entered in the field. That's why the process itself is a little different.

Table for calculating the diameter of heating pipes

Using this table, we calculate the internal diameter of the pipes for a simple one-pipe heating circuit for one floor and six radiators connected in series. Let's start the calculation:

- 15 kW is supplied to the system input from the boiler. We find values close to 15 kW in the optimal speed zone (blue). There are two of them: in a line measuring 25 mm and 20 mm. For obvious reasons, we choose 20 mm.

- On the first radiator, the thermal load is reduced to 12 kW. We find this value in the table. It turns out that it goes further from it of the same size - 20 mm.

- On the third radiator the load is already 10.5 kW. We determine the cross section - still the same 20 mm.

- Judging by the table, the fourth radiator is already 15 mm: 10.5 kW-2 kW = 8.5 kW.

- On the fifth there is another 15mm, and after that you can already put 12mm.

Scheme of a one-pipe system with six radiators

Please note again that the table above defines internal diameters. Using them you can then find the markings of pipes made of the desired material.

It seems that there should be no problems with how to calculate the diameter of the heating pipe. Everything is quite clear. But this is true for polypropylene and metal-plastic products - their thermal conductivity is low and losses through the walls are insignificant, therefore they are not taken into account when calculating. Another thing is metals - steel, stainless steel and aluminum. If the length of the pipeline is significant, then the losses through their surface will be significant.

What is needed for installation

Installation of heating radiators of any type requires devices and consumables. The set of necessary materials is almost the same, but for cast iron batteries, for example, the plugs are large, and they do not install a Mayevsky valve, but instead, somewhere at the highest point of the system, they install an automatic air vent. But the installation of aluminum and bimetallic heating radiators is absolutely the same.

Steel panel ones also have some differences, but only in terms of hanging - they come with brackets, and on the back panel there are special arms cast from metal, with which the heater clings to the hooks of the brackets.

These are the arms that hook the hooks

Mayevsky crane or automatic air vent

This is a small device for releasing air that may accumulate in the radiator. Placed on the free upper outlet (collector). It must be on every heating device when installing aluminum and bimetallic radiators. The size of this device is significantly smaller than the diameter of the manifold, so you will also need an adapter, but Mayevsky taps usually come complete with adapters, you just need to know the diameter of the manifold (connection dimensions).

Mayevsky crane and method of its installation

In addition to the Mayevsky crane, there are also automatic air vents. They can also be installed on radiators, but they are slightly larger in size and for some reason are only available in a brass or nickel-plated case. Not in white enamel. In general, the picture is unattractive and, although they deflate automatically, they are rarely installed.

This is what a compact automatic air vent looks like (there are more bulky models)

The side-connected radiator has four outputs. Two of them are occupied by the supply and return pipelines, on the third they install a Mayevsky valve. The fourth entrance is closed with a plug. It, like most modern batteries, is most often painted with white enamel and does not spoil the appearance at all.

Where to install the Mayevsky plug and tap for different connection methods

Shut-off valves

You will need two more ball valves or shut-off valves that can be adjusted. They are placed on each battery at the input and output. If these are ordinary ball valves, they are needed so that, if necessary, you can turn off the radiator and remove it (emergency repairs, replacement during the heating season). In this case, even if something happens to the radiator, you will cut it off, and the rest of the system will work. The advantage of this solution is the low price of ball valves, the disadvantage is the impossibility of adjusting heat transfer.

Radiator taps

Almost the same tasks, but with the ability to change the intensity of the coolant flow, are performed by shut-off control valves. They are more expensive, but they also allow you to adjust the heat transfer (make it less), and they look better externally; they are available in straight and angular versions, so the piping itself is more accurate.

If desired, you can install a thermostat on the coolant supply after the ball valve. This is a relatively small device that allows you to change the heat output of a heating device. If the radiator does not heat well, you cannot install them - it will be even worse, since they can only reduce the flow. There are different thermostats for batteries - automatic electronic ones, but more often they use the simplest one - mechanical.

Related materials and tools

You will also need hooks or brackets for hanging on walls. Their number depends on the size of the batteries:

- if there are no more than 8 sections or the length of the radiator is no more than 1.2 m, two mounting points on top and one on the bottom are sufficient;

- For every next 50 cm or 5-6 sections, add one fastener at the top and bottom.

You also need fum tape or linen winding and plumbing paste to seal the joints. You will also need a drill with drills, a level (preferably a level, but a regular bubble one will do), and a number of dowels. You will also need equipment for connecting pipes and fittings, but it depends on the type of pipes. That's all.

Features of calculating the cross-section of metal pipes

For large heating systems with metal pipes, heat loss through the walls must be taken into account. The losses are not that great, but over a long distance they can lead to the fact that the temperature on the last radiators will be very low due to the wrong choice of diameter.

Let's calculate the losses for a 40 mm steel pipe with a wall thickness of 1.4 mm. Losses are calculated using the formula:

q = k*3.14*(tв-tп)

q is the heat loss per meter of pipe,

k is the linear heat transfer coefficient (for this pipe it is 0.272 W*m/s);

tw — water temperature in the pipe — 80°C;

tп — room air temperature — 22°С.

Substituting the values we get:

q = 0.272*3.15*(80-22)=49 W/s

It turns out that almost 50 W of heat is lost per meter. If the length is significant, this can become critical. It is clear that the larger the cross-section, the greater the losses will be. If you need to take these losses into account, then when calculating losses, add losses in the pipeline to reduce the thermal load on the radiator, and then, using the total value, find the required diameter.

Determining the diameter of heating system pipes is not an easy task

But for individual heating systems these values are usually not critical. Moreover, when calculating heat loss and equipment power, the calculated values are most often rounded upward. This gives a certain margin, which allows you not to make such complex calculations.

An important question: where to get tables? Almost all manufacturers' websites have such tables. You can read it directly from the site, or you can download it for yourself. But what to do if you still haven’t found the necessary tables for the calculation. You can use the diameter selection system described below, or you can do it differently.

Despite the fact that different values (internal or external) are indicated when marking different pipes, they can be equated with a certain error. Using the table below you can find the type and marking for a known internal diameter. You can immediately find a corresponding pipe size made of a different material. For example, you need to calculate the diameter of metal-plastic heating pipes. You did not find a table for MP. But there is one for polypropylene. Select sizes for PPR, and then use this table to find analogues in MP. Naturally, there will be an error, but for systems with forced circulation it is acceptable.

Correspondence table for different types of pipes (click to enlarge size)

Using this table, you can easily determine the internal diameters of the heating system pipes and their markings.

Penalty for excess return flow Blog of a heating engineer

Hello, dear readers of the blog teplosniks.ru! On my blog I previously wrote about overheating of the heating return. The most unpleasant thing in such a situation is when you are given a specific bill for overheating in the return pipeline. No one wants to part with money, especially when the volume of heat consumption is calculated in the form of penalties. You have to pay the meter and more. So, how exactly does the energy supply organization calculate the fine?

The first point determines the contractual flow of network water through the heating unit. It is determined by the formula:

where Qdog is the heat load for heating under the contract (this figure must be in the contract, look). Let's take a specific figure of 0.332 Gcal/hour.

C—heat capacity of water, kcal/kg °C

t1 — supply temperature according to schedule, °C

t2 — return temperature according to schedule, °C

We substitute specific numbers. Usually the temperature graph is 150/70 °C (but it can also be 130/70 °C and 105/70 °C, etc.). In our case t1 = 150°С; t2 = 70°C. The heat capacity of water can be taken to be unity, C = 1. In fact, the heat capacity will be slightly different from unity, but we don’t need such super-precision. So, we calculate the figure, the consumption of network water, which should be according to the contract.

Gdog = 0.332*1000 /(150-70)*1 = 4.15 t/hour.

We have the water consumption according to the contractual load that must pass through your heating unit. The actual consumption (according to the meter printout) should not exceed the contractual one. If it exceeds, it means you are overheating. In order to count further, you need a printout from the heat meter. The printout looks like this.

This is a printout from the KM-5 heat meter. I give it only as an example. Your metering device can be any other one, not necessarily KM-5. But the essence of the matter does not change, in any printout, from any heat meter, the main figures are heat consumption Q in Gcal and temperatures t1 and t2, in °C. Using this very printout, we need to calculate the actual water flow through the heating unit. It is calculated according to the same formula:

Gfact = Qfact*1000 ⁄(t1fact-t2fact)*C.

We look at your printout of the supply and return temperatures t1 and t2. Let t1 = 73.1 °C, t2 = 49.5 °C. We also look at the amount of heat Qfact from the printout, let this figure be 101.4 Gcal. We divide the number of Gcal per month by the number of hours in the month, 101.4 Gcal per 720 hours, we get 0.141 Gcal/hour. Let's count further:

Gfact = 0.141*1000 ⁄(73.1-49.5)*1 = 5.97 t/hour.

At t1 = 73.1 °C, return according to the schedule is 43.8 °C. In fact, here we have 49.5 °C. Overheating 49.5-43.8 = 5.7 °C. If expressed as a percentage, then it was overheated by 13.01%. Accordingly, such overheating gave us an excess of actual consumption over the calculated G exceeded. = 5.97-4.15 = 1.82 t/hour. Now you can calculate specifically how many Gcal penalties the heat supply organization will charge you.

It is calculated by the formula:

Qfine = Gexceed*С*(t2actual-t2 permissible excess according to schedule)*number of hours per month*0.001.

We calculate the permissible excess of t2 according to the 5% schedule as follows: take t2, which should be at t1 = 73.1 °C, according to the schedule - 43.8 °C and multiply by 1.05 we get 45.99 °C. Let's calculate how much we will be charged for overheating:

Selection of pipe diameter for heating

This method is not based on calculations, but on a pattern that can be traced when analyzing a fairly large number of heating systems. This rule was developed by installers and is used by them on small systems for private houses and apartments.

The diameter of the pipes can be simply selected following a certain rule (click to enlarge size)

Most heating boilers have two sizes of supply and return pipes: ¾ and ½ inches. It is with this pipe that the pipe is routed until the first branch, and then at each branch the size is reduced by one step. In this way you can determine the diameter of the heating pipes in the apartment. Systems are usually small - from three to eight radiators in the system, maximum - two or three branches with one or two radiators on each. For such a system, the proposed method is an excellent choice. The situation is practically the same for small private houses. But if there are already two floors and a more extensive system, then you have to count and work with tables.

Air locks in heating

If the radiators are not heated in any of the rooms, it means that the air accumulated in the system is preventing the free movement of the coolant. An air lock can form due to many reasons, including the following:

- air enters when water is drained from the system and then refilled;

- Oxygen is released from water when heated;

- a faulty expansion tank creates a local area of low pressure;

- air is sucked into the system through connections with broken seals;

- air diffusion occurs through the surfaces of plastic pipes.

Air bubbles can accumulate either at the highest point of the piping system, or only in one of the radiators. Then the bottom of the battery will be hot and the top will remain cold. The presence of air in the pipes also provokes the appearance of unpleasant gurgling sounds. Most often, heating devices on the top floor of a building stop heating.

Due to air bubbles, not only does the heat supply through the piping system stop, but also corrosion of metal elements begins. The smooth operation of the circulation pump is also disrupted.

The use of simple technical devices will help get rid of the problem of clogging the heating system with air locks.

The most effective way to remove air from a closed heating system is to use automatic air vents. If they are mounted in several problem areas at once, then the air from each group of system elements will be released as it accumulates.

In addition to automatic ones, there are also manual air vents (Maevsky valve). Such a device is installed at the end of the radiator, located on the topmost floor. You can learn how to use it from the video presented here.

How to bleed air through the Mayevsky tap

Depending on how the heating system is designed, it may sometimes be necessary to bleed air through an expansion tank in the attic. The circulation pump can also help expel air pockets from the system.