New construction technologies for the installation of engineering systems, instead of conventional pipelines made of cast iron and steel pipes, offer much more profitable materials - polymer ones. For example, PVC pipes are increasingly used for sewer networks, polyethylene pipes for water supply, polypropylene pipes and fittings for heating systems. The main indicator is the internal diameter of polypropylene pipes; special attention should be paid to it.

Material properties

Polypropylene is a kind of thermoplastic polymer. It is made by combining (polymerizing) molecules of the derivative gas ethylene. International designation of polypropylene “PP”. Let's take a closer look at the properties and manufacturing technology of this new generation material.

Possessing unique resistance to alkaline solvents and aggressive substances, the material is widely used in the installation of any plumbing structures. Withstands low and high temperature conditions, they can vary from minus 10 to plus 100 C.

Types of polypropylene pipes and their purpose

Today we offer a huge range of these products. Before purchasing, you should pay special attention to the type of material. It could be as follows:

- reinforced;

- whole.

Based on the technical characteristics, we can safely say that they have a fairly wide range of applications. They are often used for:

- sewerage structures;

- transportation of toxic substances;

- water supply in the building;

- installation of the ventilation system.

Their service life is long, with proper operation it is 50 years. The age of the riser does not affect the functionality and technical characteristics; they are completely preserved.

For stove heating

If you have a stove, don't rush to get rid of it. It is unlikely, of course, that anyone has a large Russian stove with a stove bench in their home, but small stoves are still quite common. And it turns out that such a novelty as air heating is actually not a novelty at all. The principle of stove heating is that heated air passes through specially equipped channels in the walls. This is the same direct flow, only the heater is not a gas boiler, but a wood stove or fireplace.

In addition, you can improve your existing furnace and add a water heating circuit to it. To do this, a water collector is placed above the firebox, in which the coolant is heated. It is then carried through pipes to radiators. What pipes can be used for heating a furnace:

- metal-plastic;

- RR;

- PEX;

- PVC;

- steel;

- copper.

In other words, everything that is suitable is the same as for conventional water heating. The only difference is in the form of the heater. Let's not forget that many autonomous circuits operate on solid fuel and the operating principle of such systems is the same.

Marking of polypropylene pipes

The scope of application depends on the material used to make the product. The markings of the elements reflect their technical characteristics.

By pressure

Each material has its own characteristics; the main characteristic by which the area of application is determined is pressure. There are 3 main types - these are:

- for a warm floor system or conducting cold water into the house, part number N10 is used, you can also take a PN 10 pipe. Their pressure is not higher than 10 atmospheres, which allows substances to be carried out without problems;

- model PN25 has a structure that consists of several layers. It increases endurance. For this reason, this type is actively used for installing hot water supply systems in buildings of different heights. Withstands pressure up to 25 atmospheres.

- type PN20 or N20 has a pressure of 20 atmospheres and can withstand temperatures up to 85 - 90 degrees Celsius. Therefore, they are used for any plumbing work.

Pipes can be stored for quite a long time, but they should not be allowed to be near heating systems or devices with high temperatures. This may negatively affect the quality of the material.

Interesting! How to choose a water meter: its installation and saving options

Ground-based method of laying communications

If it is necessary to perform an open installation of a pipeline through which steam or hot liquid is to be moved, the provisions prescribed in SNiP must be observed. Ground-based arrangement, in contrast to the hidden option, allows for the joint laying of communications of different categories.

The open method is usually limited to the capital development plan of a settlement; it is used less frequently. Ground wiring can most often be found on the territory of industrial enterprises - it is usually used when a hidden option is not possible for a number of reasons.

Installation of an open pipeline is required if:

- high level of groundwater stagnation;

- seismic activity;

- permafrost territory.

An important point is the arrangement of communications laid above ground with high-quality thermal insulation. The insulation located on an open pipeline is not subject to pressure from the soil layer, it is not exposed to moisture and chemically active components, which affects the service life and operating conditions of the structure. One of the advantages of open installation is the cost of installation, which saves about 40%.

What determines the diameter of a polypropylene pipe?

The first question that arises before designing a polypropylene pipeline is the diameter. It should be selected in accordance with the results of hydrodynamic calculations. The point is to select the smallest allowable pipe size in a particular section. The calculation takes into account the operating pressure and circuit.

Diameter is a value indicating where certain tubes should be installed. If the internal diameter is large (40 - 200 mm), then such polypropylene pipes are used in the construction of structures intended for use by a large number of people (hospitals, saunas, hotels, large stores, entertainment centers).

Responsibilities of managers

At all sites where hot water or steam pipes are present, management must do everything to ensure an optimal level of safety. Among the main requirements imposed on the official heads of organizations are:

- Appointment of the main person responsible for the workflow of the pipeline system and its safe operation.

- Familiarization of employees with instructions and rules for maximum facility safety.

- Appointment of the required number of specialists, where everyone must have special access to the planned work and an official certificate.

- Drawing up and approving competent instructions intended for the service team.

- Establishing a consistent procedure for piping system maintenance. It must provide high quality control over the optimal operation of the facility.

It is equally important to periodically check employees for knowledge and skills that meet basic standards and high security requirements

Table of diameters of polypropylene pipes

The level of transported substances is one of the main parameters that are worth paying attention to. If the indicator is not high, then installations of the type with a small cross-section are made. The higher the level, the larger the diameter of the riser. For smaller buildings, types with a cross section of 1.6 - 11 cm are used. The main characteristic is the internal diameter of polypropylene pipes, it is described in detail in the table.

| External diameter/mm | PN 25 Inner Diameter/Wall Thickness cm | PN 20 Inner Diameter/Wall Thickness cm | PN 10 Inner Diameter/Wall Thickness cm |

| 16 | — | 1,06/0,27 | — |

| 20 | 1,32/0,34 | 1,32/0,34 | 1,62/0,19 |

| 25 | 1,66/0,42 | 1,66/0,42 | 2,04/0,23 |

| 32 | 2,12/0,3 | 2,12/0,54 | 2,6/0,3 |

| 40 | 2,66/0,37 | 2,66/0,67 | 3,26/0,37 |

| 50 | 3,32/0,46 | 3,32/0,84 | 4,08/0,46 |

| 63 | 4,2/0,58 | 4,2/1,05 | 5,14/0,58 |

| 75 | 5/0,69 | 5/1,25 | 6,12/0,69 |

| 90 | — | 6/1,5 | 7,36/0,82 |

| 110 | — | 7,32/1,84 | 9/1 |

If you are setting up a house or apartment

When creating a project for a standard private house or apartment, there is no need to carry out precise calculations. The number of plumbing fixtures will be minimal, and the difference in price for pipes of different diameters will differ minimally, which will have virtually no effect on the budget.

If you look at the faucet hose, you can see what a small diameter they have, that is, through what minimal holes water flows into the sink. Taking into account the fact that the cross-section of the polypropylene pipe will be much larger, it will always be sufficient, since the bottleneck in this case will be precisely this hose. That is, the patency of the entire system will rest on its narrowest point.

That is why the owners of private houses and apartments do not carry out complex calculations, but simply purchase a polypropylene pipe with a cross-section of 20 mm, saving their precious time. In the vast majority of cases, with a standard number of washbasins, sinks, bathtubs and other plumbing fixtures, such a pipe will be sufficient with a large margin.

conclusions

We hope everyone understands what diameter polypropylene pipes are measured by. Selecting them will not be difficult. As practice shows, you can often simply purchase the simplest and most inexpensive pipe - the result will be a high-quality and properly functioning water supply system.

Section of polypropylene fittings

Speaking about a polypropylene pipeline, one cannot fail to mention the fittings, which are responsible for connecting all its links and forming turns, bends and branches of the pipeline. These elements provide the most exact match, allowing you to implement any heating scheme in practice.

For polypropylene pipes, regular fittings or with a threaded brass insert are used. The first are connected to polypropylene plumbing by diffusion welding, the second are polypropylene, like metal pipes.

Today, the market offers fittings, the sizes of which vary over a fairly wide range, which makes it easy to select the appropriate sample. The choice of internal diameter of fittings for polypropylene pipes determines the operating conditions; it can be 20 or 50 mm.

There are two types of fittings - with and without threaded connections. Threaded fittings are removable and durable. Its type is selected depending on the operating conditions. For example, when connecting a storage tank, a removable threaded fastener is convenient, and when connecting a hose, it is a solid one.

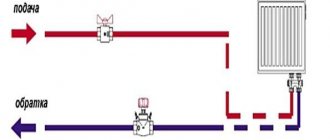

For heating and water supply

There are several ways to supply water to your home:

- on the ground;

- along the top.

Models that have an internal circumference from 16 to 75 mm are suitable for this work.

If installation work is carried out inside a building, then it is better to use a product with an internal diameter of 12 to 32 mm in cross section. Fittings for polypropylene pipes with a cut characteristic of 2 - 4 cm are used for cold water.

When planning the installation of a hot water supply system, you should pay attention to products with a size of 0.2 to 1 cm.

The correct size of the product directly affects the thermal conductivity throughout the building. It is also important to remember that the water heats up to a high temperature, on average it is 100 degrees, so it is better to purchase reinforced models.

For sewerage

In recent years, most builders, when laying sewer systems, use products made from polypropylene. This is due to the fact that they have a lot of advantages and high endurance.

For the design of private houses, types with an external parameter of 32 - 75 mm are selected, for internal work 100 - 110 mm. On an industrial scale, tubes larger than 1.10 cm are installed.

For ventilation

Previously, the ventilation system was created from metal structures; today polypropylene material is preferred. The circumference of their sections varies from 1 to 3 cm if mains are laid for ventilation of the building.

Installation Tips

The pipe material must be suitable for the purpose of installation. Be sure to pay attention to all the characteristics if you are assembling a heating system;

- Connect the elements correctly. You can use a tee; there is no metal in it, so salts will not be deposited;

- Carefully plan all connections and the entire system. Also cover traces of linear expansion;

- Calculate everything carefully, taking into account the development of different situations. It is better to leave space in reserve, especially where there is a wall;

- To do everything efficiently, pay attention to the conditions. Especially if the work takes place on the street. This way the soldering iron can cool down much faster;

- If you are fixing several elements together, do not rush. They must be firmly and firmly connected;

- The connection must be correct and tight;

- The plastic should not overheat during work. Otherwise, it may lose its shape, causing the hole to close;

Each connection has its own type of part. It is selected taking into account all characteristics and needs. Do not try to replace one with the other, this will reduce the quality of installation.

How to choose the right size of polypropylene fittings for your home line

Those who are faced with the purchase of risers for the first time do not know what internal diameter of a polypropylene pipe is required. Selecting all the design elements will not be any problem, since all products have special markings. All technical characteristics that are necessary for the work are indicated. The buyer only has to carefully select all the accessories according to the same parameters.

It is recommended to buy all elements from one manufacturer, then there will be no difficulties. If the manufacturer of pipes and fittings is different, then compatibility can be checked. You just need to try it on, insert the edge of one product into the other, if it fits tightly, then they fit perfectly.

Polypropylene is one of the best materials; it has many advantages. All designs have high strength and durability. They can be used for private cottages, as well as in apartment buildings.

Reinforcement with fiberglass

The PPR-FB-PPR marking indicates that such a pipe consists of two polypropylene layers separated by a fiberglass gasket. This type of pipe is also called fiberglass.

Fiberglass reinforcement has some advantages:

- There is no need for calibration or cleaning during installation.

- Soldering here is the same as when connecting solid plastic or any polymer-protected pipes. This helps to increase the speed of work and reduce its cost.

- Thanks to fiberglass, delamination of polypropylene pipes is not observed. This is due to the uniformity of its structure, because the central fiberglass layer is literally fused into the polypropylene structure.

- Due to fiberglass, products become more rigid.

The disadvantage of fiberglass-type pipes is that they have greater thermal elongation when compared with pipes with aluminum reinforcement.