In pursuit of comfort, most owners of private houses or apartments install heated floors.

However, it is worth noting that if there is air in the structure (if it is not vented), the quality of operation of the entire system is significantly reduced. In addition, this leads to equipment failure, the cost of which is quite high.

To avoid these problems and additional financial expenses, you should know how to bleed air from heated floors.

How problems appear

In parts of the system that are connected to radiators, problems can be detected quickly. They are located indoors, so noise is heard when air passes through. By touch, the low temperature of individual sections of the batteries where gas “plugs” have formed is determined.

But the pipeline, hidden deep in the concrete screed, is well insulated. If the cabinet with a collector comb and pump is installed away from living rooms, extraneous sounds will not be heard. Malfunctions are detected by significant differences in heating in different circuits.

The following list shows the reasons that contribute to the penetration of air into the coolant:

- Replacement of taps and other system elements;

- Faulty condition of automatic devices that are designed to remove air from the system;

- Laying a pipeline route with large differences in height;

- Significant change in pressure level during operation. With low pressure, voids may form at the top points;

- Excessive heating of the coolant, accompanied by the release of gases. Some types of chemical compounds can cause similar negative processes;

- The process of filling the system after the summer period was carried out too quickly, so not all the air was removed;

- During installation of the system or later, the tightness of the connections was broken. In the worst case scenario, leaks have formed inside the concrete screed. For this reason, after installing heated floors, a thorough check is carried out using high pressure.

Causes of air

The main reason why water circuits become airy is violations during the preparation of the project; during installation work; due to the use of the floor.

The accumulation of air masses in the coil is caused by:

- Inaccurate calculation of thermal load;

- Errors made when calculating the size and number of loops, as well as the diameter of the pipes;

- Incorrect selection of pump, safety and control components;

- Laying a highway with a large number of differences in height;

- Not high quality material;

- Poor installation - lack of tightness of joints and threaded connections;

- Violations of the rules when the floor is first launched;

- Failure to comply with the temperature level during operation;

- Depressurization of the pipeline due to a breakdown or defect;

- Impaired fluid circulation in the circuit, which is caused by a decrease in pressure due to a pump malfunction;

- Breakdown of the automatic air vent, as well as the safety and shut-off valve;

- The release of gases when heating the coolant contained in it.

Important! Before starting the device for the first time, you should remove air from the heated floor circuits.

What are the dangers of air jams?

If there are voids in the pipes, heating the floor will be less effective. If you do not pump the pipeline, the voids will increase and lead to a decrease in pressure.

Depending on the design features of the device, airiness can lead to:

- to freezing of pipes in corner rooms - when installing floors from central heating;

- to a complete or partial cessation of heating - in the presence of heating hydrofloors and radiator heating operating from the central heating of the entire house located in the basement;

- to partial or complete cessation of heating, the occurrence of emergency shutdowns of the boiler and freezing of CO - with floors operating from an autonomous heating system;

- to a complete or partial stop of heating, as well as to frequent interruptions in the operation of the boiler - if the house has heated floors and radiator appliances that operate from an individual heating source.

For your information! Taking into account all the design features: the number of loops in the room, the presence of separate wiring for each room, we can say with confidence that a complete cessation of circulation in the pipeline cannot occur.

Only if all loops of the circuit are clogged with plugs at the same time will the water stop moving along the main line through all rooms and floors of the house, as a result of which all heating will stop functioning.

Why do you need to remove air?

The formation of voids reduces the efficiency of the heating system. Pumping equipment, like other components, operates less efficiently. To ensure comfortable indoor temperature conditions for users, more resources have to be spent.

As such voids increase, the pressure gradually decreases. After reaching the maximum minimum level, the corresponding signal is sent to the boiler control unit. In addition to electronic devices, mechanical means for similar purposes are used. This is an emergency situation, so the automation turns off the supply of gas or other fuel.

To turn it on again, you have to manually increase the pressure. But there are a lot of gaseous inclusions in fresh water, so negative processes are accelerated. The equipment will turn off more often.

It is dangerous to leave it in this condition without constant supervision. If the air is not removed while simultaneously eliminating the underlying causes, the equipment will completely lose functionality.

It should be remembered that oxidation, which destroys metals, occurs in the presence of water and oxygen. Adding a new coolant activates the corresponding negative processes. In this operating mode, the durability of heating equipment is reduced.

It is necessary to exclude the appearance of air “plugs” in the heat exchange units of boilers. These parts are exposed to very high temperatures.

If heating is not uniform enough, the heat exchanger will be damaged beyond repair.

The reasons listed above are enough to understand the need for preventive measures. Carrying them out will prevent complex breakdowns and costs associated with restoration work.

Procedure for draining water from the system

Warm floors are a closed system, so it is necessary to take care of the drain taps at the installation stage. The number of valves must correspond to the number of water circuits.

A heated floor is actually a long hose laid into the floor. Installation method - the configuration of the circuits may be different, but the principle of operation of the water circuit is the same - the coolant transfers heat to the surrounding space by heating the floor surface.

Image of the outline of a copper pipe underfloor heating system laid on reinforcing mesh in front of the screed device

Before starting the operation to drain the coolant, the heating system is turned off, after which the time necessary for all its elements to cool completely is waited.

Considering the fact that the water circuit is connected to the main pipeline, and the connection point is located above the floor level, the water is drained forcibly using an air compressor.

Note: the power of a household vacuum cleaner is not enough to empty a heated floor system.

Important! To purge the water circuit, a compressor with an operating pressure of up to 5 bar is used - using a more powerful unit risks destroying the heat pipes.

The pressure gauge needle is at 6 bar - the maximum permissible blowing pressure of the underfloor heating system has been exceeded! The drainage is carried out through a return line equipped with a drain valve, and the compressor is connected to the manifold on the inlet pipe, so the check valve may create some interference when purging the pipe. After connecting to the manifold, the compressor is turned on to displace the coolant from the circuit, and the air supply pressure is gradually increased - to a value after which liquid begins to flow out at the outlet. It should be remembered that the volume of water in each of the heated floor circuits is insignificant, so an ordinary bucket with a volume of 8-10 liters is sufficient to receive it.

The compressor should operate until air begins to flow continuously from the pipe following the water.

Note: if you do not have a compressor at hand, there is another way to empty the system of water and avoid defrosting the heating system. A hose of suitable diameter 1 m long with a funnel at the end is tightly placed at the inlet of the heat pipe. The end with the funnel is raised higher and liquid for washing car windows is gradually poured into it - “anti-freeze” (it is better to use a brightly colored one). As it is displaced, water will flow out of the return pipe, and then technical fluid - a lengthy but effective process.

Technical subtleties and nuances

In preparation for draining, it is necessary to study the structure of the collector in order to find and mark on the supply and return the location of the valves, marked as follows:

- servers are red;

- reverse flow - blue.

Connection diagram for a compressor for emptying the circuits of a heated floor system.

If you confuse the supply with the return, the drain system will not work - the check valve will block the pipeline.

How to prevent air from getting into your flooring system

Despite following all the recommendations regarding proper installation and laying of the heated floor pipe, there is a possibility of further airing of the system during operation. How to prevent the formation of air locks?

- The circulation pump is installed exclusively to supply coolant. The solution eliminates the entry of air masses due to the fault of circulation equipment.

The main disadvantage of water heated floors remains their sensitivity to the appearance of traffic jams. In all other respects, the heating design of this type is distinguished by: ease of operation, good technical characteristics at low costs for heating the coolant.

The accumulation of air in the heating system prevents it from functioning properly. If you do not remove it in time, performance will deteriorate. Under such conditions, the likelihood of breakdowns of expensive equipment increases. To eliminate unnecessary risks and extra costs, you need to know how to pump a heated floor yourself. The technique is quite simple, so in most cases, contacting specialized specialists is not required.

Inspection and troubleshooting should be carried out before the start of the regular heating season.

Coolant circulation in a combined (branched) heating system

Let's start analyzing the coolant circulation with a complex system - then you will understand simple circuits without problems.

Here is a diagram of such a heating system:

It has three circuits:

1) boiler - radiators - boiler;

2) boiler - collector - water heated floor - boiler;

3) boiler - indirect heating boiler - boiler.

Firstly, it is necessary to have circulation pumps (H) for each circuit. But this is not enough.

For the system to work as we want: the boiler is separate, the radiators are separate, we need check valves (K):

Without check valves, let’s say we turned on the boiler, but the radiators “out of the blue” began to heat up (and it’s summer, we just needed hot water in the water supply). Cause? The coolant went not only to the boiler circuit, which we now need, but also to the radiator circuits. And all because we saved on check valves, which would not allow coolant to pass where it was not needed, but would allow each circuit to operate independently of the others.

Even if we have a system without boilers and not a combined one (radiators + water heated floor), but “only” branched with several pumps, then we install check valves on each branch, the price of which is definitely less than reworking the system.

Air removal algorithm

As the coolant moves through the system, gas accumulates at the highest points. For a heated floor system, this is a manifold distributor (comb). Mayevsky taps or automatic air exhaust devices are screwed into them during installation.

Below is the standard sequence of correct actions:

- Many modern pumps of this type are equipped with a step speed controller. It is set to position “1”, which corresponds to minimum performance. It will take more time, but the removal of gases will be accurate.

- Overlap all contours except one. Further, similar operations are performed sequentially in other areas.

- The screw of the Mayevsky primary circuit valve is turned with a slotted screwdriver in a counterclockwise direction. Before this, the polymer insert is turned with the hole down, and a suitable container is placed to collect the liquid.

- After the air has escaped, the screw is turned in the opposite direction until the tap is completely closed.

- Despite the fact that the minimum engine speed is set, the circuit will have to be pumped repeatedly. After the first release of gases, the pump is turned off. Wait for air to accumulate in the tap, open the tap. Next, power is supplied to the electric drive again, and the coolant is circulated at low speed for several minutes.

- This procedure is repeated 3-4 times. Afterwards, turn off this circuit with a tap and move on to the next one.

Typical pump with red shaft speed control knob

If the pump is installed above the comb, or only a standard unit (heating boiler) is used, air can also be released from it. To do this, slightly loosen the screw located in the center of the cover. In the picture above it is marked with an arrow.

After completing the entire set of work actions, the pressure will need to be raised to the nominal level. It should be understood that during this procedure air will again enter the system. Therefore, it is possible that we will have to release it again.

Formation of air masses in a heated floor system

A pump is needed to bleed the system.

How to bleed air accumulated in the system will depend on the incident that led to such a result.

Some circumstances require immediate intervention, while others are not capable of causing significant damage to the system.

If the heated floor was installed with noticeable differences, it is worth acquiring an additional pump for pumping the coolant.

It is recommended to install several automatic air vents that will help bleed air masses from the system. One is installed on the return lines, while the second should be on the supply.

Running the circulation pump will also help expel excess air. The more air that has accumulated, the louder the circulation pump will operate. It is worth paying attention that the system must be pumped at maximum speeds. This will significantly save time and allow you to completely remove air from the system. If it was recently pumped, but the air has already collected again, the problem may be in the pump itself.

Air vent

With the comb installed, each circuit is closed in turn, and the air vent must be open on each of them. It is necessary to bleed air gradually, so after cleaning the first circuit, the next one opens. The descent is carried out in stages and at the moment of bleeding only one circuit should be open.

If this procedure does not give the expected result, the next air release should be carried out no earlier than in a few days.

To properly clean the system, a person must understand the structure of the comb and understand the principle of its operation. If you do not have the necessary knowledge, you should seek help from specialists. For more information on releasing air, watch this video:

Recently, separators have become increasingly popular, whose function is to automatically remove air bubbles from the system, which significantly simplifies the further operation of the entire system.

Traditional method

If you follow the traditional method, you will need to expel the water from the heated towel rail. Since it is connected to the water supply system, you just need to drain the water through the riser. The situation becomes more complicated if there are many residential floors above you, since the descent is carried out on the top one.

If this does not help, slowly begin to unscrew the nut that secures the dryer to the pipe. Let us repeat that you need to unscrew it very slowly and as soon as you hear air escaping, you should not unscrew it further. It would be a good idea to place an empty container under the mounting location to prevent water from dripping from the pipe.

How to remove air from a warm water floor yourself

Use the given algorithm, and you will not have a question about how to pump a warm water floor.

- We transfer the pump to the minimum performance state.

- All contours overlap, one remains open.

- When using a Mayevsky tap to bleed air, it must be turned counterclockwise with a screwdriver or a special wrench. Air masses will come out with a characteristic sound. Wait for the process to complete and turn the tap back. Do the procedure with each circuit.

- When starting the system at high speeds, there will be a lot of bubbles inside. How to bleed air from a heated floor in this case? You need to turn off the pump completely. The coolant will stop moving, the bubbles will rise up to the collector. After a few minutes, open the Mayevsky tap and release the air. After this, we turn on the pump at low speeds, run the system, turn off the pump, wait and open the tap again. This must be repeated several times with each circuit until the plugs are completely cleared.

What are the dangers of airing a heated floor?

The traditional heating system in the house continues to work even in cases where the circulation of the coolant is difficult due to the appearance of air masses in the radiators, the coolant passes through the jumper. When air layers occur, the floors completely stop working and heat the room. Stopping heating is associated with the design and small thickness of the pipes used to heat the room. Although it is possible to bleed the air after the start of operation, it is easiest to perform this operation before the start of the heating season. Afterwards it will be necessary to ensure that traffic jams do not appear again.

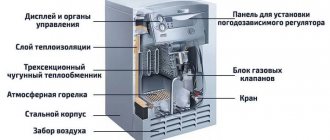

Components of equipment

It is worth taking a closer look at the parts of the system that were mentioned above.

Disassembled crane

The operating principle is described in the air release instructions. The design of the Mayevsky crane is easier to study using this drawing. Such a miniature product is installed instead of a plug in the upper part of the collector comb. There is a carving in the central part. A screw is screwed in there, pressing the plastic seal.

To ensure the tightness of the connection, a rubber ring is used. All listed parts are included as standard with the product. No additional consumables are required for installation and operation.

The use of automated devices greatly simplifies the task. Without careful user control and additional settings, they are able to perform their functions over a long service life.

Automatic gas vent

Here is a schematic diagram of one of the devices in this category:

- The node (1) creates a rigid fastening of the rod (2) to the inside of the body with the desired angle. They regulate the opening level of the exhaust valve.

- During operation, air accumulates in the upper part. The float goes down. In a certain position, it will open the shut-off device, which will release the gas out.

- Next, the float rises to its original position, and the cycle repeats again.

- A soft seal (4) is installed in the lower part, ensuring the tightness of the connection.

Separator The following device performs similar functions more effectively:

- Here is an example of a flow separator. It is installed at the top point in the pipeline section using threaded connections (4, 5).

- A mesh (3) is fixed in the central part. When a stream of water passes through such a structure, air bubbles are released from it (2).

- They rush upward. The same unit is installed in this part as in the automatic gas vent. When the float drops below a certain level, the draft will open the valve (1) to release air to the outside.

- The cell sizes and other mesh parameters are selected so as not to create unnecessary obstacles to the movement of the coolant. However, this design traps rust particles (6). They accumulate at the bottom (7). There is a screw-on cap that can be opened to remove contaminants when performing routine maintenance.

Removing mechanical impurities reduces the load on different parts of the heating system. If you install a simple filter on the main water supply line, clogging of radiator ducts and boiler heat exchangers will be prevented. This will also extend the life of the valve jets of automatic air vents.

Pumping station piping options

The piping of a pumping station usually means connecting pumping equipment to the pipeline system and other elements.

Connecting the station to the well

To install a pumping station in a caisson or in a house, the same scheme is used. The beginning of the scheme is the supply pipeline, which is laid underground, at a depth below the freezing level of the soil. A coarse filter consisting of a fine mesh is installed at the end of the pipeline. A check valve is installed after the filter to prevent reverse flow of water when the pump is turned off. Below is a technological diagram (drawing) of the pumping station.

Important! This pumping station connection diagram implies the location of the supply pipe inside the foundation of the house. It should be well insulated in this place.

Next, the supply pipe is connected to the pump using a coupling. The following figure shows a simple wiring diagram for a pumping station.

The above assembly diagram can be improved (see figure below) if you need to connect several water intake points to the unit.

Well connection

To connect a station with a surface pump to a well in which the dynamic water level is below 8 meters, you will need to install it in a caisson about 2 m deep. If a submersible pump is used, you can also place a hydraulic accumulator and various electrical equipment in the caisson, for example, a voltage stabilizer, a system automation, etc.

Automation of the process of collecting water into the pressure tank is implemented using a pressure switch, which turns the pump on and off at certain pressure levels in the system. You can also make a control unit yourself to automate the operation of the pump. Below is a schematic electrical diagram of such a block.

The control unit works according to the following principle:

This circuit uses a low-power transformer from a conventional broadcast receiver. The voltage supplied to the capacitor must be at least 24 V. Any diodes can be used, with a reverse voltage greater than 100 V and a current of 1 A.

The assembly of a station with a submersible well pump is carried out according to the diagram given below.

Connecting the station to the water supply system

Sometimes it becomes necessary to use a pumping station, even when a centralized water supply is connected to the house. A station with a storage tank is usually installed if there is low pressure in the water supply system. Also, this equipment will be indispensable if water is supplied through the main line at certain hours.

The pumping station is connected to the centralized water supply as follows:

- connect a pipe from the centralized main to the storage tank;

- connect the pump intake pipe to the tank;

- the outlet pipe from the pump should be connected to the water supply system of the house;

- lay and connect electrical wiring to the unit;

- perform a test run of the device, and then configure the equipment to the desired performance.

The main reasons for the accumulation of air masses

Air often gets into the pipes when the system is depressurized.

The problem of the formation of air masses in modern heating systems is very pressing. All owners of private and country houses, without exception, face it.

One of the main reasons is depressurization of the system itself, problems in the risers and untimely replacement of individual devices. Often, air pockets form during the process of flushing and connecting individual elements to the heating radiator.

The formation of similar problems can also occur when work aimed at installing or installing a heating system is carried out incorrectly. In any case, this problem requires an urgent solution.

A scheduled release of air will be required before first use. The air must leave the underfloor heating pipe system before it is heated.

Most heating systems are able to function even after air bubbles enter the system.

In this case, circulation will be difficult due to the appearance of bubbles in the radiator, but the warm floor will stop heating if air gets into its system.

The small thickness of the pipes, combined with the peculiarity of the system, will not allow it to heat up, and the floors will be cold.

You can get rid of air during the operation of the system, but it is much easier to do this before the first cold weather sets in when the mechanism is not running. After some time, bubbles may appear again, so the system must be monitored and checked carefully, periodically bleeding the air.

Vent the air in the summer, before starting the heating system.

Methods for deferrizing water

Rough cleaning, reagent disinfection and deferrization of all water, elimination of excess chlorine and sorption additional purification of water, water softening for heating and hot water systems.

The maximum permissible iron content in water for technical needs, in particular for the heating system, should not exceed 1 mg/l. The ideal value is 0.3 mg/l. An excess of iron leads to silting of the internal surfaces of pipes and the proliferation of bacteria in the ferrous sediment, which occurs especially actively already at 30-40 degrees Celsius. This leads to rapid wear and tear of the hot water supply and heating system.

The easiest way to deferrize is settling. Under the influence of oxygen, the iron contained in the water oxidizes on its own, forming a rusty sediment. To carry out iron removal yourself, you will need a large tank with a capacity of 200-300 liters and a device for pumping oxygen: a spray unit or a compressor (for small tanks a regular compressor for aquariums is suitable).

To deferrize water, the same method is quite applicable as to soften it - using the reverse osmosis method. Filters with ion exchange resins are also used. To prevent the proliferation of iron bacteria, chlorination (50 mg/l) is used, but first you should find out how resistant the installed water supply facilities are to chlorine.

If the iron content in water is over 5 mg/l (which is not uncommon for water from wells), then filters with glauconite sand enriched with manganese oxide are used for purification. After passing through a filter medium that serves as an oxidation catalyst, the water gets rid of iron, manganese and hydrogen sulfide, which precipitate. When such a filter becomes clogged, it must be washed with solutions that restore its oxidizing capacity (potassium permanganate solution). It should be remembered that with this cleaning method, harmful chemicals are discharged into the sewer system, so it can only be used if there is a centralized sewer system on the site. Removal of mechanical impurities, manganese, microorganisms, oxygen

Rough water purification, removal of dissolved gases, deferrization, sorption purification, water softening and disinfection.

To remove foreign impurities (sand, peat fibers, phyto- and zooplankton, fine clay, dirt, organic substances, etc.), various mechanical filters equipped with washable or removable cartridges are used. For very heavy contamination, pressure filters with granular loading are used (quartz sand, expanded clay, activated carbon, anthracite).

The most obvious sign of the presence of manganese in water is a black precipitate. Its concentration rarely exceeds 2 mg/l, but already at a concentration of 0.05 mg/l, manganese can deposit on the walls of pipes, gradually clogging them. Typically, manganese is dissolved in water along with iron, so that with the de-ironization of water, demanganation also occurs simultaneously. To remove manganese, filters with ion exchange resins are used.

Related article: Sealing a bathtub with a wall

To disinfect water, that is, remove viruses, bacteria, protozoan microorganisms, ozonation, chlorination, and irradiation with ultraviolet rays with a wavelength of 200-300 nm are used.

Rough cleaning, reagent disinfection and iron removal, water softening, elimination of excess chlorine and sorption purification of water, final fine cleaning.

The ultraviolet irradiation method is the safest method of water disinfection among the above, since it does not affect its chemical composition, affecting only harmful microorganisms. Water disinfection using UV units occurs in a few seconds.

The corrosive activity of water strongly depends on the presence of oxygen dissolved in it. The dissolved oxygen rate for closed and open heating systems is the same and is no more than 0.05 mg/cub.m. To reduce the oxygen content in water, deaeration units and columns are used.

To prevent oxygen from entering heating systems in other ways (with air), you need to monitor the overall integrity and tightness of the system and not fill it with water too quickly, as this contributes to the formation of air locks. If pipes made of gas-permeable materials, such as polyethylene or polypropylene, are used, they must be protected with an anti-diffusion layer of aluminum.

Additional recommendations

As complexity increases, the cost increases, but the overall reliability of the equipment decreases. As an example, control valves on a manifold comb can be used. Designs with mechanical drives cost little.

Their characteristics have been developed over many years of practice, so breakdowns rarely occur. Servo drives are more expensive. The corresponding systems contain electronic units, miniature electric motors, wire connections, and sensors. There are more components that can fail.

The components for removing air from the system should be selected taking into account the design features. Simple Mayevsky cranes are capable of performing their functions flawlessly for a long time. They do not need to be adjusted during operation. Automatic devices are more complex and more expensive. They can be damaged by dirt, so they need protection from mechanical impurities.

Sometimes intensive formation of air pockets indicates violations of the integrity of connections or other damage. Automatic diverters are so effective that it will not be possible to notice the appearance of problems in the early stages.

Video

In any case, the heating system should be inspected regularly. To remove air, you must follow the instructions exactly. If an engineering structure is highly complex, and independent actions cause difficulties, you need to seek help from specialized specialists. In addition to removing air, they can be entrusted with adjusting the manifold comb.

He has built thousands of multi-storey buildings and knows almost everything about thermal insulation and sound insulation. I am always happy to answer your questions on these topics.

Source

Tips on how to expel air from a water heated floor

Comfort and coziness in the house is ensured by optimal air temperature. Today, water-based heated floors are especially popular, which, unlike other heating systems, have a number of advantages.

It is worth noting that if there is air in the system, the heating efficiency is significantly reduced, so you should know how to properly remove air from the system. Air in the fuel system can also lead to failure, so if a problem is discovered, it must be addressed as quickly as possible.

There is a certain method for removing air, which is so simple that it does not require the involvement of specialists.

How problems appear

If there are batteries or radiators installed in the apartment, then you can hear about a problem, as noise appears. The heating temperature decreases in those places where air has collected. Pipes in water-heated floors are located under the screed and it will be difficult to sense the problem, especially if the distribution cabinet is not located near the room itself. The problem can also be determined by the difference in contours, which will be quite noticeable.

Air in the heating system can occur in the following cases:

· Pipeline elements were replaced;

· Devices for removing air from the system do not work;

· Large differences in height near the installed heating main;

· The tightness of the system under the concrete screed is broken.

All these reasons can provoke the formation of air in the system and the only thing left is to remove it for proper operation.

Why do you need to remove air?

When a gas or air chamber forms in the heating system, heating efficiency decreases. The pump and other components of the system are not working correctly and are ineffective. In order to heat a room, you have to spend more energy and resources, therefore, in order to save and optimize the operation of the equipment, it is necessary to promptly determine the cause and eliminate it.

Design features

Equipment should be selected individually for each room. It is worth considering that for large areas the built-in pump will not be able to provide circulation in the heating system, so you will need to install an additional pump unit.

If radiator heating is used, a special heating main is created with minimal bends and slopes. When the height changes, the water has a gravity force due to which it circulates. To increase circulation efficiency, it is necessary to install an additional pump. It is quite difficult to remove air from such a system and you have to call in specialists to modernize the system.

Air removal algorithm

As you know from physics lessons, as a result of the movement of liquid in heated floors, air can accumulate at the highest points. Considering that the highest point is the manifold distributor directly at the inlet, taps or valves must be installed to release the gas. Sequence of actions when removing air from the fuel system:

1. New pumping units have different speed modes, so the minimum value should be selected. Despite the fact that this procedure will take a long time, it will help to completely clean the system.

2. The next step is to cover all the contours except one. The procedure is carried out with all contours in turn.

3. Unscrew the screw on the tap while turning the polymer insert towards the bottom with the hole for liquid to drain. You need to place a container so that water does not get on the floor.

4. When the air comes out completely, the screw must be tightened completely.

5. At low pump speeds, the circuit must be pumped several times to achieve maximum effect. When you are finished with one circuit, you can move on to the next.

When all the air has been removed from the system, the pressure will have to be increased again when starting it up. If you can’t do the work yourself, then it’s better to trust the professionals.

Additional recommendations

The more complex the equipment, the higher its cost, while the reliability of the equipment decreases. In order for the underfloor heating system to work properly, it is necessary to initially take care of installing high-quality and reliable equipment. Today, manufacturers offer a huge selection of pumps and components for underfloor heating systems. When choosing equipment, it is necessary to take into account the characteristics and features of the heating system.

The appearance of air in the system may indicate problems with tightness; if you install automatic devices for removing air, you may not notice the main problem, so in this case it is better to use mechanical devices.

Design features

It is necessary to take into account in advance the details that distinguish certain equipment. So, in some situations, a built-in boiler pump is used to circulate coolant throughout all circuits. For a large facility, its performance may not be enough, so you will need to install a separate power unit.

When using radiator heating, routes are created with a minimum number of turns, without sharp corners. By adding tilts towards the boiler, natural circulation can be ensured under the influence of gravity.

In heated floors, long pipelines with a large number of bends are installed

It is more difficult to pump water through such a system. Only coercive methods are used here. If there are errors in the calculations, the power of a separate pump will not be enough for distant circuits. In this case, their poor heating cannot be eliminated by removing air plugs. The system will need to be modernized.

The comb regulators must first be correctly adjusted. In addition to mechanical flow meters, valves with electric drives are installed. Such devices change the coolant supply rate taking into account the readings of temperature sensors.

Automated adjustment system

Types of air vents

To bleed air from a heated floor, vents are often used, which can be manual or automatic.

Manual devices are mainly installed on heat exchangers, and automatic devices are installed on the upper section of the collector or pipeline.

Automatic models

These devices are produced by both domestic and foreign manufacturers, and each type has its own design features - it depends on the brand. Devices are:

- With a reflective plate inside the housing - it is installed at the entrance to the working chamber, and is designed to protect internal parts from water hammer.

- With a spring shut-off valve, which is equipped with an air vent, air can be released through it.

- With side threaded connections.

- Microbubble separators - installed in the pipeline on two inlet pipes. The liquid, passing through a tube with a copper mesh, forms a water vortex, it slows down the air and directs it upward. After which, air bubbles are released through an automatic valve.

- With a rocker mechanism - their chamber contains a plastic float connected to a shut-off drain needle. When it descends into the airy environment, with the help of a needle, the release hole is opened to allow the air flow to escape.