A 5 kW gas boiler is not particularly powerful equipment. Such models are mainly suitable for heating a small area - a country house or a small apartment. The power is enough to heat 50 m², but possible heat losses are taken into account - up to 30%, depending on what materials the walls of the building are built from and the type of windows installed.

Description of gas boilers 5 kW

Basically, equipment of this power is a wall-mounted device. The unit is easy to install, economical and convenient to use. With an indicator of 5 kW and even with minimal heat loss, the device can only be installed in small buildings. But the device has an advantage - since it is a wall-mounted boiler, there is no separate room for the equipment - a boiler room, which is required for the floor-standing model.

The gas unit is supplied as single- or double-circuit. The first provides only heating of the house. It is equipped as standard with 1 heat exchanger, which in budget models is made of stainless steel, resistant to corrosion and temperatures. In more expensive equipment it is made of copper. This metal is corrosion resistant, strong and durable.

In addition, the heat exchanger is lightweight, which is important for compact wall-mounted units. In most units, the design allows the part to be removed from the device for cleaning and easily replaced. There are also models with aluminum heat exchangers. This alloy is also corrosion resistant and lightweight.

At the same time, a double-circuit boiler is equipped with 2 heat exchangers. The device provides heating and hot water supply. The latter is considered a priority, and when liquid is supplied, the coolant does not heat up.

Wall-mounted boilers have additional options. For example, electronic ignition, the presence of a remote control and a display showing performance indicators.

Low power boilers are not equipped with this. Only a standard set of functions is provided here, which provides control of the model. Mechanical control is implemented, there are no electronics, as well as the possibility of connecting an additional heating system or underfloor heating. The units do not have modern multi-stage safety systems.

Despite their characteristic reliability and efficiency, boilers with a power of 5 kW are considered not the most functional devices.

Features of installation and connection of the heating boiler

When installing KChM 5 yourself, a number of specific requirements must be met. If you follow all these rules, you will be able to significantly extend the life of the boiler, and will also make its use safe and convenient. Let's look at all the installation requirements in more detail :

- The boiler should be installed in such a way that the distance from the rear wall of the boiler to the wall of the boiler room is at least 0.25 meters. The distance between the side walls and the walls of the boiler must be at least 0.1 meter. In order to provide access to the rear, a passage should be made on one of the sides, and the minimum permissible width in this case is 0.4 meters. There should be at least 1 m2 of free space near the front of the unit to make stowing and cleaning convenient.

- Installation is carried out only on a floor made of non-combustible material or on a special plinth. Under no circumstances should there be flammable materials around at a distance of at least 0.4 meters. It is also prohibited to store fuel nearby; the minimum permissible distance is 0.4 meters from the boiler.

- Only clean water, free from various impurities, should be used in the heating system. When using a liquid with high hardness, scale will begin to form, and this will significantly reduce the service life of the heating boiler and the heating system itself.

According to reviews of the solid fuel boiler KChM 5, the installation procedure is as follows:

- First, you should install the boiler on a stand made of non-flammable material, possibly on a plinth.

- The device must be connected to the heating system and chimney.

- The system can be filled with water and then checked for leaks. Also, KChM 5 can be used for systems with forced and natural circulation.

By following the simple rules described below, you will be able to protect your loved ones and yourself, as well as make using the device convenient and enjoyable.

Technical features

Most models are equipped with a closed combustion chamber. This means that the devices are volatile. The air required for combustion is supplied and the resulting products are removed by force using a fan. And a coaxial output is provided for smoke removal. This design solution allows air to be supplied not only from the room, but also from the street. That is, the oxygen in the room is not burned out, as happens when installing models with an open firebox.

With a coaxial outlet, air is taken in through one pipe, and combustion products are discharged through another. An additional advantage of this technical solution is that a unit with a closed firebox is installed where it is not possible to install a stationary chimney. But the need for forced ventilation makes the device dependent on an uninterrupted power supply.

A coaxial pipe is supplied complete with such a gas-fired boiler. For installation, a hole is made in the wall. In order for the structure to function with maximum efficiency, it is located horizontally.

Although electronic ignition is not provided in such boilers, piezoelectric ignition is allowed. It also provides convenience and a high level of safety when operating the units.

The devices are also equipped with modern burners, including those with partial pre-mixing of gas and air. This also provides safety and reduces fuel consumption. In some models, you can change the speed of the fan in the forced circulation system by adjusting the operating parameters of the boiler.

Some devices have a post-circulation system. The latter ensures the movement of the coolant after the burner goes out. The water gradually cools, but the residual heat is transferred to heating devices.

When considering the technical features of 5 kW boilers, the installation conditions are taken into account. First, calculations are made. The unit does not always heat an area of 50 m². Heat loss reduces this indicator.

Their level depends on:

- the region where the house is located;

- properties of the material from which the walls are made;

- number of doors and windows.

There are programs that calculate the coefficient of thermal resistance and losses. Therefore, you can buy a boiler only after careful calculations.

Necessary conditions for installation of units:

- high-quality wall insulation;

- absence of gaps in doorways and other openings (and even better - installation of modern energy-saving windows);

- standard ceiling height is no more than 2.7 m;

- suitable climatic conditions – absence of long frosty winters.

In the conditions of central Russia, it is not always possible to use such boilers, not counting the northern regions. But for Crimea this is an acceptable option.

Station wagon 5M cast iron (200~530 kW)

The Universal 5M boiler with a manual combustion chamber for coal is designed for heat supply to residential, public and industrial buildings. Universal 5M boilers are produced in the form of spare parts.

The hot water boiler can operate with an absolute water pressure of up to 0.7 MPa (7 kgf/cm2) and a water heating temperature of up to 115 °C.

When the boiler is operating with a maximum water heating temperature of up to 115 °C, the absolute water pressure in the system must be no lower than 0.45 MPa (4.5 kgf/cm2).

To prevent scale formation in Universal 5M boilers, it is necessary to have a water treatment system in the boiler rooms. The water treatment scheme is carried out according to standard boiler house designs.

It is possible to supply burners and front plates to convert Universal boilers to gas or liquid fuel.

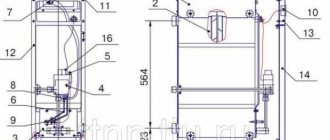

Construction of a water heating boiler Universal 5M (see photo above)

The hot water boiler is assembled from two types of sections: outer and middle. The sections are assembled into two packages using conical nipples and tie bolts passing through the holes of these nipples.

The packages are installed on the brick walls of the firebox and connected to each other using bends and tees. A front plate is attached to the boiler frame, which is equipped with a loading and ash door. The front plate has holes for attaching a blow outlet, which serves to supply air to the firebox.

The boiler firebox is equipped with grates, which are installed on the ledges of the brickwork of the side walls of the firebox.

On both sides of the boiler, along its axis, there are side gas ducts made of brick, in which dampers are installed (behind the boiler). Next, the side flues of the boiler are connected to the hog.

The outside side walls and top of the boiler are lined with brick, the front and rear walls are lined with heat-insulating mastic.

Operating principle of the water heating boiler Universal 5M

The boiler is fed with water through the lower tee, from where the water is directed to the sections of the right and left boiler packages, heats up and enters the heating system through the front tee.

The fuel is burned on a grate, and the resulting combustion products rise upward, washing the surfaces of the sections and, turning around the separating (joining) ribs of the sections of each boiler package, are lowered through the gas channels formed by the ribs of the sections, into the side flues of the boiler and then sent to the hog.

The boiler draft is controlled by dampers. The surfaces of the sections are cleaned from soot and entrainment through the upper openings formed by the boiler sections, which are covered with bricks.

Composition of sets of different power

At the customer's request, we can supply both a complete set of spare parts according to the list below, and individual spare parts for the repair of these boilers according to specified standard sizes.

| Name | Weight, kg/pcs. | Nominal heating output of the boiler, kW | ||||||

| 200 | 250 | 300 | 360 | 420 | 470 | 530 | ||

| Middle section | 71 | 10 | 14 | 18 | 22 | 26 | 30 | 34 |

| Outer section | 125 | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| Front plate | 73 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| Grate (890×250) | 26 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

| Top tee | 16 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| Bottom tee | 13 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| Gate assembly | 8,35 | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| Retraction | 11 | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| Front plate | 15,6 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| Nipple | 0,55 | 24 | 32 | 40 | 48 | 56 | 64 | 72 |

| Blind flange | 1,82 | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| Flange with hole | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| Link bracket | 0,52 | 8 | 8 | 8 | 8 | 8 | 8 | 8 |

| Stub | 0,2 | 8 | 8 | 8 | 8 | 8 | 8 | 8 |

| Characteristics of the assembled boiler | ||||||||

| Length, mm | — | 1125 | 1375 | 1625 | 1875 | 2125 | 2375 | 2625 |

| Width, mm | — | 2180 | 2180 | 2180 | 2180 | 2180 | 2180 | 2180 |

| Height, mm | — | 2570 | 2570 | 2570 | 2570 | 2570 | 2570 | 2570 |

| Weight of metal parts, kg | — | 1662 | 1974 | 2286 | 2598 | 2910 | 3222 | 3534 |

Advantages and disadvantages

Boilers with a power of 5 kW have pros and cons.

Advantages:

- compactness and light weight, which allows the units to be installed in any room, and a separate boiler room is not needed;

- affordable price;

- reliability and safety without electronic control systems;

- ease of installation and operation;

- no need to install a traditional chimney;

- relatively low gas consumption with high efficiency.

Such devices also have disadvantages, which include limited functionality, small selection and strict requirements for operating conditions.

Rating of the best models of low-power gas boilers

The ATEM ZHITOMIR AOGV 5 CH device is popular. This is a wall-mounted single-circuit parapet type model. Equipped with a heat exchanger made of durable and corrosion-resistant steel. The boiler has a high degree of safety. High-quality Italian components are responsible for this, including a gas valve and burner. The model is characterized by high efficiency of 90%, compactness, weight of 30 kg and low fuel consumption - 0.56 m³/h.

High-quality Ukrainian boiler – TERMOBAR KS-GS-5S. Unlike most low-power models, the device is a floor-standing type. The advantages include efficiency and almost silent operation. The unit is equipped with Italian components. Equipped with a safety system that blocks the fuel supply and operation of the device in the event of a gas leak.

The advantages of the model are a high-quality steel heat exchanger and a stacked sectional burner made of stainless steel. Characterized by convenient installation, included coaxial chimney, low fuel consumption, high efficiency. The warranty period for both described boilers is 12 months.