Almost all modern household gas boilers are controlled electronically. The boiler control board is designed primarily to ensure its correct operation. If problems or malfunctions occur, the automation also informs the user of the cause of the failure in the form of an error on the screen. Error codes and probable causes of their occurrence are usually described in the gas boiler operating manual, and in this article we will look at the most common reasons for the appearance of error e01 on a baxi boiler

.

Attention! Before taking independent steps to troubleshoot your gas boiler, carefully study the operating instructions and manufacturer’s recommendations, or better yet, contact a specialist.

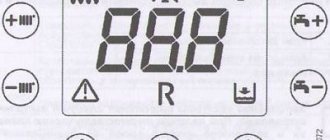

Error e01 is classified as critical, in which the boiler cannot continue to operate until the cause of the problem is eliminated, so it must be reset! Resetting the error in baxi boilers is done by pressing and holding the R button for 2-3 seconds. After resetting the error, the boiler should attempt to start in normal mode.

About Baxi gas boilers

Baxi gas boilers have been present on the heating equipment market for quite a long time, and have shown their best performance. These heating devices are quite reliable and easy to maintain, and are assembled from high-quality components. Baxi have an adjustable flame level, which allows you to more accurately maintain the set temperature. The adjustable flame allows you to operate the boiler in a gentle mode, since the number of turns on and off of the boiler is significantly reduced. This feature allows the burner nozzle to last much longer, and also increases the life of the heat exchanger. All this is because adjustable flames reduce the frequency of heating and cooling of the heat exchanger, which has a positive effect on its service life.

Also, heating devices of this brand are famous for their efficiency, and they save not only gas, but also electricity. Baxi boilers are equipped with several temperature sensors that are located inside the boiler. But it also provides for the installation of remote temperature sensors that can be installed from the street side. With this arrangement of sensors, the boiler itself will respond to changes in air temperature outside the window and select the most optimal operating mode.

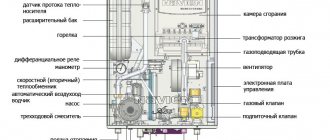

Despite the many innovative technologies used in heating devices of this brand, Baxi boilers are famous for their light weight and compactness. Even the floor-standing units from this manufacturer are quite light and small-sized. Baksi boilers are incredibly reliable, since all systems of this device are controlled by an electronic control unit. The electronics monitor all parameters of the boiler’s operation, and if the slightest malfunction occurs, the boiler’s operation stops and the error code is displayed on the liquid crystal display. Each code encrypts information about a particular malfunction, and decoding this code allows you to quickly identify the malfunction and eliminate it. Errors come in the following names.

Dimensions of components

When calculating the required amount of material, you should take into account not only the dimensions of the siding, but also the dimensions of its components. Basically they are the same as the panel, but the sizes of some elements may differ. For example, the length of the “G-trim” strip for most brands corresponds to the size of the siding. The finishing material “Doke” does not comply with accepted principles. In this case, the “J - trim” strip is only 3050 cm. Based on these individual features inherent in some elements, we can say that the characteristics below are considered common to all vinyl siding. It is recommended to check specific dimensions with the supplier or see the technical description of the official manufacturer.

- External corners – 3.05 m;

- Internal corners – 3.05 m;

- Starting bars – 3.66 m;

- Finishing bars – 3.66 m;

- Connecting strips – 3.05 m;

- G-trim planks - 3.66 m;

- Window trim strips – 3.66 m;

- Hanging strips – 3.66 m;

- Near-window strips (slopes) – 3.05 m;

- Soffits – 3.66 m.

As mentioned earlier, the general technical characteristics are average for all types and sizes of vinyl siding, therefore, in order to more accurately calculate the required number of components, it is recommended to check the dimensions of a specific manufacturer ahead of time. This is necessary in order not to make a mistake in the calculation, since when purchasing excess material there will be no one to blame. You can only hope that the seller will accept the excess back, but this is not practiced in all stores.

Advice from the “façade designer”

You should not purchase products from a little-known brand at an inexpensive price. This may be due to the low quality of the product. Often the thickness of cheap vinyl siding is so small that there are through holes in the panel, which renders it unusable.

Thanks to a wide selection of color shades and various sizes and textures, vinyl siding can satisfy almost any design solution for facade finishing.

Error e01

Malfunction e01 of Baksi boilers indicates a malfunction in the ignition system. This error is generated by the Baxi sensor, which monitors the flame. The error code can be reset manually, and to do this you need to hold down the “R” button. After 3-5 seconds have passed after pressing and holding this button, the boiler should start. If the flame does not appear and error E01 is displayed again on the screen, then only one thing will help in this situation - calling a boiler repairman. An error with this code can be caused by several reasons. This could be a failure of the ignition system, as well as incorrect operation of the electronic control unit. There have also been cases where this malfunction occurred due to an incorrectly adjusted gas valve. This error can also be caused by:

- weak draft in the chimney;

- low gas pressure.

Let's take a closer look at the reasons why error e01 occurs on Baxi boilers, and how to eliminate it. This error is sometimes very difficult to fix, since it can be caused by many factors. This malfunction is associated with difficulty igniting. On some models of boilers from this manufacturer, the electrode also contains a flame sensor, and this combination sometimes does not work correctly.

When the ionization current, which passes from the electrode through the burner to the ground loop without any obstacles, then the ignition works without any deviations. The control board records the parameters of the ionization current. If its strength is in the range from 5 to 15 microamps, then this can be considered the normal operating mode of the ignition system. When for some reason the ionization current strength deviates from the norm, the electronic control unit of the boiler records these deviations, and the Baxi gas boiler is blocked with error e01.

This error also appears if the contact of the electrode with the control board is broken. Also, if error e01 occurs, you should immediately check the gas pressure in the line. For natural gas, the pressure should not be lower than 2 mbar, and for liquefied gas - 5-6 mbar. The pressure can also be adjusted with a special nut located on the gas valve. It is also necessary to thoroughly check the operation of this valve - measure the resistance of the coils with a multimeter. The first coil should have a resistance of 1.3 kOhm, and the second - 2.85 kOhm.

The conductor that connects the gas valve to the electronic board may contain a diode bridge, which can also fail. This is a feature of some Baxi boiler models and the diode bridge should also be checked with a multimeter. You also need to check the resistance of the electrode itself. It should not exceed 1-2 Ohms. Also, the edge of the electrode must be at the required distance from the burner. This distance should be 3 mm.

Error e01 may also appear if ignition occurs, but the flame immediately goes out. This may be caused by reversed polarity on the 220 volt plug. By turning the fork 180 degrees, you can get rid of problems with ignition. These problems can also be caused by a ground fault. The voltage between phase and neutral phase and ground must be the same. The voltage between zero and ground should be no more than 0.1 Volt. If this parameter is violated, this may cause fault e01.

You also need to make sure that the gas line is isolated from the boiler. This line may carry a small electrical potential, which can cause a malfunction of the heating device. For insulation, a special dielectric spacer is used, which is placed between the gas pipe and the boiler.

A little more about electricity

In addition to the need for grounding, there are other nuances when connecting boilers:

Baxi luna 3 comfort 240 fi

- Gas boiler equipment ensures stable operation in the range of 170-250 V. When the voltage drops, the boiler turns off, and when the voltage rises, the varistor burns out.

- The sinusoid in the power supply must be free of interference. Such devices do not tolerate power surges well. Experts recommend connecting additional voltage stabilizers. You should not use UPS for installation of gas heating appliances.

- The connection must have a separate machine.

- For phase-dependent models, it is important to ensure that zero and phase match.

Error e02

Error code e02 indicates that for some reason the Baxi thermostat has tripped. If you hold down the “R” button, which is located on the boiler control panel, for 3-5 seconds, this error should go away. If after these manipulations this malfunction continues to appear on the display, then something serious has happened, and in this case you should also contact a service center. A malfunction with this code indicates that for some reason the Baxi gas boiler is overheating or the temperature sensors are not responding correctly to the temperature of the coolant. Incorrect temperature detection by the sensor can also be caused by weakened circulation of water or antifreeze in the heating circuit. There have been cases where foreign objects isolated the temperature sensor from the coolant, and therefore the sensor physically could not measure the temperature correctly, since it was isolated from water.

Automation

Automation for boiler equipment is very diverse. Some of it is preinstalled by the manufacturer. This category includes all sensors and electronic devices that ensure the safe operation of equipment.

The simplest example is a sensor that monitors the normal gas supply. When the gas is turned off, the sensor is triggered and the boiler automatically turns off. Restart will occur after the gas supply is restored.

Systems that ensure operational safety also include:

Boiler structure

- Frost protection (starts to work if the outside temperature is below 5 degrees).

- Protection against blocking of circulation pumping equipment.

- Protection against blocking of the three-way mixing valve in case of long-term equipment downtime.

- Protection against scale formation in the heat exchanger and boiler.

- Overheat protection.

- Voltage protection in the electrical network.

- Control of stray flames.

- Combustion and draft control.

- Coolant pressure control.

In addition to the pre-installed automatic systems, you can install additional electronics:

- Outdoor temperature sensor.

- Room temperature sensor.

- Thermostat.

- Electronic thermostat.

- Remote panels.

- Weather dependent sensors.

- Elements for remote control.

- Water quality sensors, etc.

Error e03

This error can occur in a situation where, for some reason, the pneumatic relay does not work correctly. Also, an error code e03 may appear if the traction sensor is faulty. Also, this malfunction can occur in a situation where, for some reason, there is difficulty in removing combustion products. This may be due to:

- improper installation of the chimney;

- chimney blockage;

- failure of the exhaust turbine;

- complete failure of the pneumatic relay.

The Venturi tube, which is used to measure the draft force in the smoke exhaust duct, may also be faulty. When the turbine starts, the pressure in the chimney changes, and this change is captured by the Venturi tube. The tube is connected to a pressure switch in which the membrane is located. The membrane reacts to pressure changes, and its movement closes or opens the contacts of the microswitch of the pressure sensor. Incorrect operation of these elements can cause error e03 to appear.

You also need to check the turbine itself. First of all, the presence of free rotation of the shaft is determined, and then the fan itself is checked. The presence of voltage at the terminals of the wire that comes from the electronic board is also checked. The windings of the turbine electric motor are also checked. Their resistance should be in the range from 38 to 48 ohms. If the resistance does not meet these parameters, the fan should be replaced.

Along with the turbine, you need to check the condition of the chimney and the correctness of its installation. The air relay must also be carefully checked for operation. You can use a pressure gauge to check.

Also, the cause of error E03 in Baksi gas boilers may be poor contact on the connectors that connect the electronic board to the turbine and relay. Poor contact can be caused by oxidation, which can occur when moisture gets into the connector.

Elimination

Let's look at possible problems and what needs to be done to fix them:

E 00

This error indicates a problem with the control board. The issue can only be resolved by the service center employees, since there can be many reasons and possible consequences of the intervention.

E 01

No ignition (no flame). The reason may be either a lack of gas in the line or a failure of the ignition system.

The solution to the problem is step-by-step - first checking the presence of gas, then examining the condition of the gas equipment, checking the ignition system, etc. This error occurs most often, since there can be quite a few reasons for its occurrence.

Solving the problem on your own is not recommended; it is better to invite a specialist.

E 03

The cause may equally be a clogged chimney and a lack of contact between the fan and the control board.

It is recommended to examine both positions and carry out work on both the chimney and the contact group of the fan (pressostat).

E 05 - 06

A failure in the operation of these sensors indicates a failure of either the elements themselves or a failure of contact with the control board.

First of all, you need to check the temperature of the extract air and hot water supply to determine whether the sensor readings are generally true.

Then contacts with the control board should be restored. If a positive result cannot be achieved, the sensors need to be replaced.

E 10

A drop in water pressure indicates leaks. It is necessary to inspect the heating circuit and check the boiler drain valve.

If no problems are found in them, you should check the sensor contacts. If necessary, it is changed.

E 25

A sharp increase in the temperature of the OM indicates a lack of circulation. The most likely reason for this is airing of the heating circuit elements. The solution to the problem will be to bleed air from the system. If this does not help, the sensor must be replaced.

E 35

The signal about the appearance of a parasitic flame indicates either a short circuit of the sensor contacts due to the appearance of drops of water (condensation) on the board, a breakdown through a layer of soot, or other similar situations.

The solution to the problem will be to clean the board, install high-quality grounding and additional insulation on the contact group of the sensor.

E 98 - 99

This error indicates a failure of the control board for unknown reasons. The solution to the problem must be entrusted to a specialist; correcting the situation on your own is unacceptable.

Error e10

Malfunction e010 occurs when the signal from the hydraulic pressure switch disappears. An error with this code may be caused by the operation of a sensor that monitors water pressure. There have been cases where an error with such a code occurred when the contact between the relay and the electronic control board was lost.

There are four main causes of error e10:

- Leaks in the heating system.

- Failure of the expansion tank, or lack of air in it.

- Failure of the water pressure sensor in the heating circuit.

- Clogged “oblique” filter on the return line.

Doesn't light up right away

The cause of delayed ignition may be incorrect information supplied by the extract air or DHW temperature sensor.

If it gives a signal about the high temperature of these liquids, the command to ignite the burner will not work.

You can check the correct operation of the sensor by disconnecting the contacts from the control board.

If after this ignition occurs as expected, then the reason is in the sensor. If the situation has not changed, the search for a solution should be carried out in the ignition equipment itself. Alternatively, condensation may accumulate in the air sensor tubes. They need to be blown out, after which the burner will start in normal mode.

Error e25

This error in Baksi boilers can also be caused by a large amount of air that has accumulated in the heating circuit. The airiness of the heating system contributes to the rapid heating of the coolant, and it is to this rapid heating that the electronics of the gas boiler reacts - it turns off the heating device, displaying error E25 on the screen. Also, the occurrence of this malfunction can be caused by a breakdown of the circulation pump, or failure of the temperature sensor. Most rarely, this error appears due to incorrect operation of the electronic control board, or lack of reliable contact between the circulation pump and the electronic control unit.

Why doesn't the device restart?

Failure to restart usually indicates the presence of air in the system or internal elements of the boiler.

The solution to the issue may be to bleed air from the circulation pump, which is done by loosening the central screw of the device . The air will hiss out, and when water comes out, you need to tighten the screw again until the coolant stops escaping. After this, restart the boiler.

Electronic board

External inspection, removal of dust, salt stains, condensation - these simple steps will remove the E99 error. At the same time, defective areas are identified: a damaged housing of a radio component as a result of thermal effects, burnt tracks, and the like. There's no point in digging deeper.

Baxi boiler control board

Error E99 is cumulative, as indicated by the manufacturer and the practice of repairing Baxi boilers. It is expressed in the fact that it is displayed periodically and disappears after the unit reboots itself.

Advice

It is impossible to unambiguously determine the cause of the ED malfunction. On the Internet there are recommendations for replacing relays and optocouplers, but each Baksi boiler has its own problem. It makes no sense to reject an electronic board only on the basis of suspicion, taking into account the price of the unit. If no visible defects are found, you need to contact a professional. When talking with a service employee, tell about the measures taken and ask the technician to take the EP, indicating its designation (alphanumerical) or the model of the Baksi boiler. Pros: the heating unit will not be idle for a long time, and professionals will diagnose the unit in the laboratory on a special stand. Restoring the functionality of the “native” electronic device will cost an order of magnitude cheaper than purchasing a new board.

Check what

Settings

If error E99 is displayed after replacing the boiler EP, the corresponding adjustments have not been made in the menu. The procedure for the Baxi model is described in the instructions.

Electrical network parameters

The manufacturer guarantees trouble-free operation of the Baxi boiler, provided that the requirements of the PUE are met and the voltage corresponds to the value specified in the unit passport (~230V). Error E99 is triggered by internal board failures in areas with intensive development, in houses whose power supply is supplied through an outdated substation that is not designed for the increased load. When connecting the Baxi boiler to an autonomous source, the network parameters must be monitored. If a diesel or gasoline installation produces voltage with U and f that do not correspond to standard values, incorrect operation of the board and errors E97–99 are inevitable.

Advice

Problems with incorrect functioning of the power supply in the city electrical network are eliminated by connecting the Baksi boiler through a UPS. The unit, in addition to voltage stability, guarantees reliable operation of Baxi in autonomous mode even in the event of a line failure. For owners of suburban properties - a rational solution.

Tips

The presence of potential where, by definition, it should not be, causes malfunctions in the electronic board, error e99. The reasons for the appearance on the metal parts of the boiler are different: a nearby power line or other source of EM radiation, wear of the insulation of the power cable. Testing the equipment is simple and is done using an indicator screwdriver. The LED indicates the presence of voltage at U = 55 (±5) V, causing an internal ED problem and error e99.

Interference also appears when the Baksi boiler is not properly grounded. It is organized according to the PUE, and there is a corresponding section in the instructions for the unit. Violation of the rules is the cause of electronic failures and error e99.

one dielectric coupling

Signal line

We are talking about the gas valve/electronic board circuit. Contact failure, breakage, melted insulation leading to a short circuit are the causes of error e99. A visual inspection of the insides of the Baxi boiler is not enough: the condition of the connector is assessed. Burnt contacts and oxides can be easily eliminated on your own. In practice, it is enough to undock and connect 3-4 times, and code 99 disappears.

Oxidation of contacts in a Baxi boiler

There is a spark, but no ignition

When this dilemma arises, the following factors appear:

- The valve responsible for the gas supply is closed. Measure - twist it all the way.

- Low water pressure. It may be not only in the main line, but also at the inlet section of the boiler, where the filter may become clogged.

- The water is slightly fixed annuity interest rate heated. Solution: cleaning the heat exchanger (HE). Fastenings on which plaque has accumulated can be cleaned using VD-40, and the radiator can be placed in a basin with a composition based on citric acid. Then heat on the stove for half an hour until the scale disappears completely.

- The burner is clogged. Sometimes a lot of soot and soot appear in the jets. You can get rid of it using a thin copper wire.

If the piezo did not work in the Electrolux geyser or other similar equipment, then you should periodically check it for gas leaks using a soap emulsion. If there are no bubbles, then everything is fine.

The advantage of domestic speakers

There are many types of faults, so it is easier to find domestically produced parts. Therefore, speakers made in Russia, such as Neva, are in great demand.

And the newer model “Neva 4511” consumes even less gas and is completely silent.

A gas water heater called “Oasis” is in demand, which can operate at low pressure and is protected from scale.

It is also equipped with a safety system that blocks operation if the column overheats.

Conclusions and useful video on the topic

The author of the video below examines another possible error that is not included in the list of the current publication. In particular, the video demonstrates a malfunction about:

The electronic system for detecting errors in the operation of the Baksi boiler with subsequent display of the corresponding code on the control screen is a very user-friendly service.

This is a significant help for mechanics when they have to deal with rather complex faults that require additional testing of equipment before and after repair.

If you have questions about the topic of the article or have valuable information that you can supplement our material with, please leave your comments in the block below.