Home / Gas boilers

Back

Published: March 26, 2020

Reading time: 5 min

1

18438

Korean Navien gas boilers are characterized by the highest degree of reliability. They work for many years without bothering the owners with breakdowns.

This is confirmed by user reviews and conclusions by heat power specialists, which can be found on the Internet in the public domain. Malfunctions of Navien boilers are quite rare.

This modification of heating units has good software diagnostics, so it will not be difficult for the user to understand the causes of failures and understand what to do to eliminate them.

- 1 Causes of malfunctions of Navien boilers

- 2 Self-diagnosis of Navien boilers

- 3 Error codes and how to fix them 3.1 Error 03

- 3.2 Error 02

- 3.3 Error 10

Design Features

Boiler structure

To attract the attention of buyers, the Korean manufacturer developed a perfect design of the gas unit, minimized the number of breakdowns and released its product at a relatively low price. One of the advantages of a gas unit is the clear and detailed instructions, which greatly simplifies setting up the selected mode.

The company adheres to the same principles in installing an electronic control system and regulating other parameters.

The versatility of a gas boiler can be judged by its operating capabilities:

- The regulation circuit with a microprocessor chip allows you to both protect and smooth out voltage surges in the power supply network. In case of changes in the current parameters, the electronic system is able to maintain a mode for the full functioning of all components of the unit, which has a positive effect on the operational life of the device. The adjustment circuit also allows you to avoid possible malfunctions due to false activation of sensors. This feature of the electronic system is of particular importance for the operation of the equipment, given the instability of the voltage in the power network and its deviations over a wide range.

- The design of the gas boiler is designed taking into account a possible drop in water pressure to 0.1 bar. This allows blocking actions and device breakdowns to be reduced to a minimum, which is ideal for its installation on the upper floors of a building.

- The Navien boiler is capable of neutralizing possible malfunctions caused by a decrease in supply pressure to 4 mbar, which is critical for the normal functioning of many modern systems equipped with electronic control.

- Thanks to the design features of the Navien gas appliance , the heating system will not freeze even when the gas supply is cut off. To prevent the emergency mode from being activated when the coolant temperature drops below 5 degrees, as well as the inability to ignite the burner, a built-in pump was provided for forced and continuous circulation of water.

- There is a double heat exchanger for separate heating of hot water and coolant, which is very convenient (you can optionally adjust the preheating of water). Easy-to-use electronics allow you to precisely set the appropriate mode.

How to properly adjust and start

Procedure:

- The boiler startup procedure begins with filling with water. Gas dual-circuit units do not need to install additional devices, so you just need to open the make-up valve and increase the pressure to 1.5-2 At.

- After this, the valve is closed, air pockets are removed from the system and on the unit itself, for which Mayevsky valves on the radiators and an air valve in the boiler are used.

- Then you need to bleed the air from the circulation pump. The casing is removed and the water heating controls are turned on. Specific sounds appear, indicating the operation of the system. On the pump, gradually unscrew the screw in the middle until water appears. This procedure must be done 2-3 times, after which the air from the pump will be completely removed.

- As soon as the circulation pump is brought into operation, the burner will start electronically and the heating system will begin to function.

This completes the initial startup and adjustment procedure..

Operating principle of the Navien boiler

The operating principles of modern gas boilers are almost the same for all manufacturers, the only differences are in the configuration of the equipment and the internal arrangement of the actuators. The flow diagram of water in the boiler is shown in the figures. The Navien boiler works either to maintain the required temperature in the CO, when heated water from the first heat exchanger is pumped by a circulation pump in a large circle, or in the DHW preparation mode. The DHW mode is a priority, which means that if it is necessary to heat the water, a special three-way valve switches the circulation to the DHW plate heat exchanger, and the coolant flow through the heating circuit is blocked. The signal to switch the boiler to the DHW preparation mode comes from the flow sensor located on the hydraulic unit with the make-up tap.

Three way valve

Error 16 may occur if the three-way valve malfunctions. If there is a breakdown, then the boiler cannot switch between DHW and DHW modes. The price of a new crane is from 3 to 5 thousand rubles. But you can try to correct the situation yourself.

Reasons for failure:

- system contamination;

- microswitch is broken;

- the motor is broken (low resistance, open circuit, short circuit);

- destruction of gears of the gearbox.

Only if the system is dirty will it be enough to clean it for error 16 to disappear. In other cases, you need to buy new parts.

User manual

Navien gas boilers are operated automatically, with minimal human intervention.

The owner only needs to observe the readings on the display and respond in a timely manner to the appearance of an error code.

In addition, the user determines the operating mode - summer or winter:

- Summer mode is determined only by DHW heating.

- Winter mode starts the heating system simultaneously with the supply of hot water.

The display has a button with a corresponding icon (symbol of a snowflake or sun).

If it is necessary to adjust the extract air temperature or other parameters of the heating system, the winter operating mode must be turned on. Exhaust temperature is adjusted when the radiator icon is flashing.

If it lights up steadily, the display shows the current temperature . By pressing the “radiator” button so that the icon flashes, press the “+” or “-” buttons to change the set coolant temperature.

The icon stops flashing after a while (a few seconds), and the boiler will begin to heat or cool the coolant in accordance with the instructions received.

Doesn't start for a long time

The boiler is started when certain conditions are reached. If the temperature or pressure of water (OB, DHW) is within the specified range, heating will not start until it cools down .

A possible cause may also be partial clogging of the water filter, which slows down the flow and changes the circulation mode. It may be difficult for the circulation pump to operate if it is clogged with lime deposits or small debris.

Running self-test

The Navien boiler self-diagnosis system operates constantly and does not require a separate startup.

The probability of a failure of one or another node exists at any time, so the sensors send signals about the status of certain elements 24/7, never stopping.

If the sensor stops working for any reason, the corresponding error code immediately lights up on the display. This is an important function that helps maintain performance and timely troubleshooting .

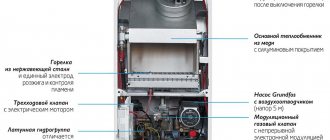

Navien Delux Coaxial device

The word Coaxial in the name of the boiler means the use of coaxial chimneys (pipe in pipe). This system is convenient in that only one pipe is used to supply air to the combustion chamber and remove exhaust gases, which can be led from the room to the street by the shortest route. In general, the boiler is not fundamentally different from products from other brands. You can note the convenient location of the expansion tank and the non-standard location of the fan - it is located below the burner.

It is noteworthy that Navien boilers do not have a built-in control panel. All adjustments are made using a separate control panel. The remote control is also equipped with a temperature sensor and displays various information about the operating status of the equipment and will report a malfunction with an error code. A special feature of Navien is also the presence of an air pressure sensor, which not only performs a draft check function, but also sends data to the control unit for portion control and determines the presence of reverse draft. If there is excess pressure in the chimney, for example due to wind blowing, the gas supply to the burner will be stopped and the boiler will stop.

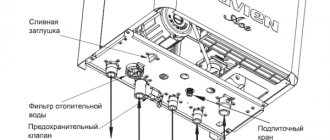

At the bottom of the boiler there are inlets and outlets of the heating and hot water circuits, a make-up tap, a drain plug, a cleaning filter and a safety valve for relieving excess pressure.

Causes of malfunctions and their elimination

To understand how to troubleshoot a particular problem in a gas unit, you need to know the causes of malfunctions:

- Code 01E indicates an increase in the temperature in the device. This is possible due to blockage in the ducts, which caused them to narrow, or there were problems with the circulation pump.

- Code 02E indicates the presence of air, insufficient water, damage to the impeller in the circulation pump, a closed distribution valve, or the flow sensor has become unusable.

- Code 03E is displayed as a result of problems with the ionization sensor, lack of gas supply, lack of ignition, when the tap is closed, or when the boiler is not properly grounded.

- Code 05E indicates poor contact between the temperature sensor and the controller, or a short circuit in the same area.

- Code 10E is displayed on the screen if the fan fails, as well as if the sensor tubes are incorrectly connected directly to the fan. In addition, a clogged chimney or a strong gust of wind can also cause the device to malfunction.

- Code 11E , as a rule, is displayed on European-made boilers (with appropriate sensors).

- Code 13E indicates a short circuit in the heating water flow meter.

- Noise and hum may occur if the coolant is poor.

- The reason for the lack of hot water is the valve , which has become unusable. The optimal valve service life is 4 years.

How to fix:

- Error 01E: carefully inspect the impeller in the circulation pump to detect various problems; check the resistance in the pump coil itself; examine the heating system for the presence of air (bleed off excess).

- Error 02E: deflate; check the pressure and resistance in the coil; whether a short circuit has occurred; open the valve (distribution); check the resistance in the flow meter; remove the sensor housing and clean the flag.

- Error 03E: clean the flame sensor from debris (you can use fine-grained sandpaper to get rid of gray deposits on the electrode).

- Error 05E: examine the circuit from the controller to the sensor. If there are problems, the sensor should be replaced with a new one. The meter and controller connectors must first be disconnected and then connected.

- Error 10E: repair the fan or replace it; check the connections on the tubes of the measuring device; Clean the chimney of all kinds of debris.

- Error 13E: replace the sensor.

You can get rid of noise and hum by disassembling the product and cleaning the heat exchanger. If the problem cannot be solved, the part must be replaced. Inspect the taps; they should be open as much as possible. Reduce water temperature.

Troubleshooting error 03

There were some obstacles in the way of the signal about the presence of flame entering the system. The cause of this malfunction of the Navien boiler may be a cessation of gas supply or a failure of the flame presence sensor in the burner. Often, problems of this type arise after repairs to a gas pipeline. Error 03 is also displayed when problems occur with ignition.

Elimination procedure:

- Checking the gas supply.

- Testing the serviceability of ignition.

- Cleaning the ionization sensor (it often gets dirty).

When using liquefied gas, you must ensure that the gearbox is in good working order. If the boiler is fully operational, the cause of error 03 may be improper grounding.

Recommendations for operation and repair

- To ensure that the equipment operates for a long time and productively, you can install a voltage stabilizer, filters (gas and water), a magnetic or polyphosphate water converter, etc.

- The gas boiler must be installed strictly in accordance with the requirements specified in the passport.

- To eliminate the causes of malfunctions, you must carefully study the instructions and act according to them.

Why does blood pressure drop?

The cause of a drop in water pressure in the system can only be a leak. At the same time, it can be both in the boiler itself and outside it - in pipelines, radiators, etc.

We recommend: Specific heat of combustion of kerosene: the physical meaning of the value, the meaning of the indicator and its comparison with oil

It is necessary to open the feed valve, start the boiler and carefully inspect the entire system, step by step. If no leaks are found, the boiler must be inspected. When looking for the cause, you should be guided by the rate of pressure drop.

Perhaps the water goes into the expansion tank, in which the membrane has ruptured. Another reason could be a worn safety valve. If it is connected to the sewer, the leakage will not be noticeable.

NOTE! In any case, the drop in pressure indicates that it is going somewhere. It is necessary to find the leak, otherwise it may get wet and destroy the structure of the house.

Errors 07 and 08

The purpose of double-circuit boilers is to provide homes with both heat and hot water. They consist of two circuits and a set of sensors. As a consequence, in this case there is not one temperature sensor, but two. One is designed to control the temperature of the heating circuit, and the second monitors the degree of heating of hot water. The appearance of codes 07 and 08 on the monitor indicates that the hot water in the Navien boiler does not turn on. Diagnosis and elimination occur in the same order as in the previous case.

Reasons for increased pressure

An increase in pressure in the boiler is primarily demonstrated by the safety valve, which begins to release excess pressure. This problem often confuses even experienced specialists.

The reason lies in the secondary heat exchanger. Hot water is heated from the already heated heating agent, receiving energy in a plate secondary heat exchanger. Both liquids exchange thermal energy without mixing with each other.

But, if a fistula occurs, allowing water from the hot water system to penetrate into the heating system, the pressure will increase and tend to balance with the higher pressure of domestic hot water.

If such a problem occurs, the secondary heat exchanger should be replaced, since repairing it is complicated and ineffective.

Navien boiler error 10

This error is related to the smoke removal system of the gas boiler. Combustion products must be removed; for this purpose, the boilers are equipped with a fan. To control the operation of the fan and determine the presence of permissible draft for boiler operation, a differential relay is used, which is connected to the turbine by two plastic tubes. When the fan is running, a vacuum is created, the relay closes, and the boiler functions normally.

Reasons for error 10

may be a clogged chimney, the presence of reverse draft, or incorrect connection of the air pressure control sensor to the fan. For the latter case, you need to check that the yellow tube is connected to the bottom of the fan, and the transparent one is connected to the top, and the tubes themselves are not damaged, deformed or condensation inside.

Increased resistance in the chimney can occur due to direct gusts of wind or blockage of the chimney (bird nest or cobwebs, freezing in winter). That's right, the location of the chimney should be taken into account the direction of the winds of a particular region at the design stage and the chimney should not be installed on the leeward side of the house.

We focused on the most common malfunctions of Navien boilers, but in fact there are significantly more error codes. Methods for checking and troubleshooting are the topic of a separate article. For convenience, here is a summary table of codes with a brief description:

| Fault number | Brief description of the problem |

| 02 | Low water pressure in the heating system or breakdown of the flow sensor |

| 03 | No signal from the ionization electrode |

| 04 | Incorrect signal from flame sensor or short circuit. Make sure there is no contact of the ionization electrode with the boiler or burner body, and diagnose the control board. |

| 05 | Damage to the heating temperature sensor. Measure the electrical resistance of the sensor and its compliance with the temperature table, and make sure that the connection between the sensor and the control board is secure. |

| 06 | Short circuit of the heating water temperature sensor circuit. Ring or replace the sensor. |

| 07 | Damage to the DHW temperature sensor. Check the dependence of the resistance on the temperature on the sensor, make sure that the connection of the sensor to the control unit is secure. |

| 08 | Short circuit of the DHW temperature sensor. Ring or replace the sensor. |

| 09 | Fan failure. Measure the resistance of the fan winding (test value is approximately 23 Ohms). Make sure that there is a voltage of 220 V at the fan terminals. There may be a problem with the control board circuit (diagnostics of the Navien board is required) |

| 10 | Malfunction of the combustion products removal system |

| 13 | Short circuit of the CO flow sensor. The sensor is stuck or the control unit is faulty. |

| 15 | Internal control board error (requires diagnosis and repair) |

| 16 | Boiler overheating. Signal from the emergency thermostat. The causes of overheating may be insufficient coolant circulation (see error 02), a clogged heat exchanger, or a malfunction of the thermostat itself. Operation occurs at 98 degrees, the alarm turns off when it cools down to 83 degrees. |

| 27 | Open or short circuit of the air pressure sensor circuit |

An autonomous water heating and heating system increases the comfort of life through personal control of parameters. Not to mention the cases when this is the only opportunity to get hot water or heating.

Power-on problems

There may be several reasons for such a malfunction.:

- There is no voltage in the network (or it has decreased too much, it has become less than 150 V).

- No gas.

- The boiler is blocked by a protection system that was activated due to a critical error (overheating above 98°).

Other reasons for failure may also occur . First of all, you should check the voltage in the network.

The boiler is capable of compensating for fluctuations of up to 30%, but with more significant changes, it simply will not start. You can solve the issue by using a separate outlet and installing a stabilizer.

If all possible causes have been checked and eliminated, but the boiler continues to be silent, you should invite a specialist . Perhaps the cause was a failure of the control unit, a breakdown, or another serious problem.

You should not attempt to resolve the issue yourself; this may cause the final destruction of the unit.

What to do if the aspirated air leaks?

For the Atmo model range with an open (atmospheric) burner, the primary heat exchanger is made of copper.

The appearance of a leak is almost always associated with its destruction. Purchasing a new heat exchanger is not an easy and expensive task, so most often the issue is solved by soldering the fistula .

To carry out repairs, you should contact a technician from the service center, since this requires a qualified specialist who can dismantle the unit, find the fistula that has arisen, solder it properly, simultaneously rinse the heat exchanger and install it in place without damage.

The work is complex and requires the participation of a trained person.

The control board is faulty

This error, which is difficult to accurately diagnose, is designated by code 15E. It is almost impossible to understand how the control board works without special education. The most correct algorithm of action in such a situation is to invite a specialist who can use testing to determine and eliminate the causes of the problem.

The place where the Navien gas boiler is repaired is chosen by the foreman: in particularly difficult cases it is necessary to transport the boiler to a service center. To avoid problems of this type, it is strongly recommended to equip the supply networks of the Navien boiler with a voltage stabilizer.

No need to heat

The first step is to clean the heat exchanger. At home, it is common to use citric acid, toilet bowl cleaners and special liquids (if available). Before cleaning the Navien gas boiler, you need to dismantle the heat exchanger and pour a suitable solution into it. After a short pause, it is washed out with high pressure of water.

A similar procedure should be carried out with the DHW circuit heat exchanger if problems are observed with heating hot water. In case of particularly contamination, it is easier to install a new exchanger. To prevent scale build-up, it is recommended to have a system for cleaning and softening your tap water.

Review of less common errors

We have listed the error codes that most often bother users. But there are other symbols that indicate irregularities in the operation of Navien gas boilers and potential repairs.

11 – failure in the operating parameters of water level or pressure. This error appears on the displays of boilers with automatic make-up. To fix it, you need to turn off the system, check the operation of the water filling valve, remove any remaining water in the pump drain, reconnect the pump and restart the system. If it doesn’t help, call technical service.

12 – absence of flame. There are many reasons, and we recommend acting as for errors 03-04. First, check if the gas taps are closed, if there is power supply and if everything is in order with the grounding.

15 – problems with the control board. If it does not respond to power supply, it requires repair or replacement.

We recommend: Choosing wall-mounted gas boilers

16 – overheating of the system, and any of the components can overheat: fan motor, heat exchanger, pump motor. What you can do yourself: clean the filters and heat exchanger, change the thermostat. After a half-hour “rest”, the unit can be restarted - most likely, it will work.

17 – errors related to the DIP switch. You need to correct the control board settings and restart the boiler.

27 – failure of the pressure sensor. If there is no blockage, you need to check the serviceability of the sensor and fan, and then replace the failed part.

30 – overheating of the smoke thermostat. It is necessary to turn off the boiler, allow it to cool for 30 minutes, then restart. If it doesn’t work, check the fan and air pressure sensor, clean the chimney.

93 – the “on/off” button is broken. You should replace it yourself or call a specialist.

Many problems can be solved independently, which is why the manufacturer provides brief instructions on how to resolve emergency situations.

But if it comes to complex repairs or replacements, it is better to have the unit repaired at a service center, with a subsequent guarantee for new spare parts

If an unknown error code appears on the display of a geyser or floor-standing Navien model, you also need to contact specialists.

What malfunctions occur

To repair the Navien heating boiler yourself, you need to read the special manual. It will help not only decipher the type of breakdown, but also eliminate it in the most effective way.

List of problem codes with the Navien boiler and their interpretation:

- 01E. The device overheated, and this was recorded by the temperature sensor.

- 02E. Indication of an open circuit in the flow sensor and a drop in the coolant level in the circuit.

- 03E. The signal confirming the presence of a flame has disappeared. In this case, the combustion can continue.

- 04E. This code has the complete opposite meaning of the previous designation: in this case, there is confirmation of the flame, although in fact it is absent. E

- 05E. Failure of the circuit responsible for controlling the degree of heating of the coolant in the heating system.

- 06E. This code also indicates a malfunction of the temperature sensor (the circuit is closed).

- 07E. Signal about failure of the temperature sensor in the DHW circuit.

- 08E. Malfunction of the Navien gas boiler in the same unit due to a short circuit.

- 09E. Alert about fan failure.

- 10E. The appearance of malfunctions in the smoke removal system.

- 12E. Flame extinguishment in the burner.

- 13E. The heating circuit flow sensor has shorted.

- 14E. Gas has stopped flowing from the main line, which is why the Navien boiler does not turn on.

- 15E. A general indication of errors in the operation of the control board, without specifying the problematic element.

- 16E. The equipment has overheated.

- 18E. Malfunctions in the operation of the smoke exhaust sensor.

- 27E. Air pressure sensor (APS) malfunctions.

The manufacturer itself does not provide any instructions for repairing the Navien gas boiler. The calculation is made that repair activities are the responsibility of service centers exclusively. In our country, people’s thinking is somewhat different, so many of them are accustomed to troubleshooting household appliances on their own.

Important nuances during repairs

When repairing a boiler, you need to know how to fill the coolant after draining. Before refilling, turn off the gas and turn off the power to the equipment. It is necessary to check the position of the distribution and shut-off valves and open them as much as possible.

The make-up tap, which is located at the bottom of the device, must be turned to the left. When the pressure gauge mark is 1.2-2 bar, close the tap. If the emergency indicator starts working, you should drain the water and repeat the procedure.

Another boiler malfunction, solution to the problem:

To ensure that the device works for a long time and properly , you can purchase a voltage stabilizer, a water and gas filter, as well as a polyphosphate or magnetic water converter.

We must not forget that installation of equipment must be carried out in accordance with the manufacturer’s requirements. Before fixing the problem, you need to familiarize yourself with the classification of problem codes and see what a specific error may mean. When making repairs, it is important to study the instructions and follow the information provided in it. Navien gas boilers are an excellent option for both a private home and a city apartment. In case of breakdowns, it is very important to diagnose and fix the problem in a timely manner. In case of serious malfunctions, it is best to entrust the work to a specialist.

Typical Navien Ice boiler breakdowns

Although the devices in this series are famous for their impeccable performance, they sometimes fail. When installing a Navien Ice boiler in your home, it is recommended to arm yourself with information about its most typical faults (there are not very many of them). For example, for the 24 K model, the most typical error is 10. The design of this double-circuit boiler uses a closed combustion chamber, which leads to periodic problems with smoke removal. Most often this happens due to fan breakdowns, which need to be replaced from time to time.

Typical malfunctions of the Navien gas boiler also include error 02: it indicates rapid heating and equally rapid cooling of the boiler. This usually occurs due to the appearance of air pockets in the circuit system or due to a breakdown of the flow sensor. All air must be bled from the heating circuit.

Rules of operation and timely maintenance

When purchasing a gas unit to heat your apartment or private home, you should remember that modern devices belong to the category of complex, high-tech, full of automation and protective systems. Therefore, in order to extend the life of the boiler and prevent its premature failure, it is necessary to follow certain operating rules.

- Firstly, this is installation in accordance with established requirements, according to the scheme recommended by the manufacturer, and not based on the advice of a familiar master.

- Secondly, these are high-quality materials and components: savings at this stage threaten to develop into financial costs for boiler repairs in the future.

- Thirdly, this is a thorough check of the condition of the sensors, chimney, water/gas supply before starting the boiler. Inspection and cleaning of main components should be done regularly, and not occasionally.

The automation will tell you the probable causes of problems by displaying coded messages on the display. Experience shows that following these recommendations will help avoid possible serious breakdowns and failures, which means that owners will not have to find out what typical malfunctions the Navienace boiler has and what will be required to eliminate them.

No hot water with normal heating

This situation occurs on double-circuit boilers due to the presence of air in the heating system, insufficient water, breakdown of the flow sensor, or due to the closure of the distribution valve.

To eliminate it you need to:

- Adjust the pressure in the system.

- Eliminate existing air from the water supply. It is this that leads to blocking the water supply from the heating circuit.

- Open the distribution valve.

Smoke exhaust problems

Occurs due to fan failure, chimney blockage or strong wind. When the causes are eliminated, the problem will disappear. As for the chimney blowing out, in order to avoid such phenomena, it should be closed from gusts of wind (at the same time, from precipitation).

Extraneous noise during boiler operation

Caused by clogging of the heat exchanger due to poor quality coolant. This can be solved by cleaning or replacing the heat exchanger. To eliminate the root of the problem, consider improving the quality of the coolant.

Serious problems

These include problems in the ignition system, in the electronic filling of equipment, or breakdown of sensors. If malfunctions of this kind occur, you should contact a professional, as self-diagnosis and repair can lead to even bigger problems.

Navien boilers are equipped with a self-diagnosis system, which displays information about problems on the display in the form of an error code. When you see this code, check the instructions. If it does not relate to the problems we have considered, then troubleshooting yourself is unlikely.

Gas boilers from the Korean company Navien are distinguished by a high level of reliability. They are able to work for years without bothering users with breakdowns. This is confirmed by numerous reviews from users and heating engineering specialists. But they are also prone to breakdowns, since nothing is ideal in nature. Let's see what error 03 is in Navien boilers, how to decipher other types of errors and which nodes to check when these errors occur.