Gas instantaneous water heaters have long become an integral part of the comfort of many city apartments and private houses. This is the simplest and most reliable alternative to both centralized hot water supply and electric boilers. However, despite its simplicity and reliability, the gas water heater often takes a long time to ignite or refuses to work at all.

There are many reasons for breakdowns in this case. Therefore, correctly understanding and identifying the main reason why the geyser does not turn on when turned on is the most important task in solving this non-standard situation.

In the general list of situations why a gas water heater does not light up, three main points need to be highlighted:

- A situation where a gas water heater is working properly, but cannot work due to external factors - loss of draft, lack of water pressure or low gas pressure;

- A situation when a gas water heater does not ignite well under normal external factors, that is, problems arise directly with ignition;

- Cases when an automatic geyser does not heat water after normal switching on and the start of hot water supply.

All these cases, although generally similar to each other, indicate that there are completely different reasons why the geyser does not turn on when turned on. At the same time, the reason that the column has stopped igniting or is taking a long time to ignite are quite standard situations typical for most water heaters.

Traction disorder

One of the reasons why the Neva gas water heater does not light up is a violation of the draft in the air duct. Most often, a foreign object entering the air duct causes the automatic protection of dispensers with an open combustion chamber to trigger.

Under normal conditions, when natural air circulation is disrupted, the protective relay reacts to a sharp increase in temperature in the outlet channel and turns off the gas supply. In this case, the device starts to work normally, but does not work for a long time. Devices with a closed combustion chamber work similarly, for example, the vektor lux eco often does not ignite because even one of the channels is blocked - either the air supply to the combustion chamber or the removal of combustion residues.

Solving the problem of why the geyser does not work in this case is quite simple - clean the air duct and ensure normal air circulation in the room. By the way, one of the reasons for the disruption of natural air circulation in the house and draft in the ventilation duct can be metal-plastic windows and tightly closing entrance doors.

General information

A geyser is a reliable device that is unpretentious in operation. It is best to install it in rooms where the mandatory supply of hot water is much more important than its quantity. On average, the column can heat about 10 liters of water per minute. It is very important to carry out periodic maintenance and service control. Because its service life depends on the correct use of the equipment.

Is it possible to install a gas water heater in the bathroom? The answer is in this article

Of course, like any other water heater, the column can break. There are situations when all the elements are working properly, but the gas water heater stops igniting, or it first lights up and immediately goes out.

Also, very often when igniting, you can hear a click, the appearance of a spark, but the equipment does not ignite. All these shortcomings are contributed by a number of factors that we will deal with.

No pressure

If the gas water heater does not ignite automatically when you open the water tap, then a possible reason is the lack of pressure in the water supply. In order to make sure that this is the reason, you need to open the cold water tap.

The absence of normal pressure indicates that the water heating column is working properly, and the blocking is triggered because low pressure in the system will lead to overheating of the device and its breakdown. The situation can be corrected by cleaning the general filter for the apartment’s water supply system and the salt filter for water preparation. Usually, clogging of these filters occurs after repair of pipes on the main lines - internal deposits and simply dirt under the pressure of water enter the filter element and settle there.

It’s another matter if the gas water heater does not ignite when the hot water tap is open, while normal pressure comes from the cold water tap. Here you need to clean the mesh filter installed in front of the water block membrane. It turns out that with normal pressure in the system, the filter reduces the pressure in the device itself, preventing the gas valve from opening. The solution is simple - remove the nut and clean the brass mesh.

Recommendations for preventing breakdowns

To keep your equipment working as long as possible, follow these simple rules:

- Set the temperature correctly so that you do not have to mix cold and hot flow. The higher the set temperature, the faster the scale builds up.

- Install a purification filter that will soften the water and remove impurities from it.

- Clean the internal elements from soot and soot.

- Connect high-power devices to the network through a voltage stabilizer.

We have indicated the reasons for possible problems with the ignition system. Most of them can be eliminated with your own hands. This video will also help you:

Gas pressure

If the gas water heater does not light up when you turn on the water, the reason for this situation may be problems with gas pressure or a complete lack of gas in the system.

In this situation, usually the water pressure is normal, and the piezoelectric element gives a spark. The first thing you need to do is check the presence of gas in the gas pipeline; to do this, you need to try turning on the gas stove. If the stove does not turn on either manually or automatically, and the characteristic hiss of flowing gas is inaudible from the burner, then with a high probability it can be said that there is no gas in the gas pipeline.

The option when gas does not flow in the gas column while there is normal gas flow to other devices and when there is a spark on the piezoelectric element indicates a malfunction of the gas equipment or a clogged gas filter. When the gas water heater does not ignite when the water is turned on and the ignition system is activated, it is necessary to check the condition of the gas filter installed in front of the device.

The fact is that the composition of natural gas, the presence of impurities and gas condensate can clog the gas purification filter. Because of this, the gas pressure decreases, the pilot light does not light, or the gas safety valve turns off. One of the symptoms of filter contamination can be cases when the device does not light up immediately, or if it does turn on, it starts working intermittently at first, and then after a few minutes it reaches the desired mode.

What to do if the gas water heater does not light up due to low gas pressure or a clogged filter? First of all, you need to turn off the gas supply valve and open the vents for ventilation. Next, you need to inform the gas service about the problem and if this is not a centralized gas shutdown, then call a gas service technician.

The main thing in this case is not to try to do the repairs yourself and wait for the specialists to arrive.

Why does the speaker turn off during operation?

If the gas water heater lights up normally, but for some reason goes out during operation, this may indicate that the device’s security system is functioning properly.

The column design has a sensor that is triggered when the internal temperature rises. There are two plates inside the system that repel each other, stop the power supply, and turn off the column. This happens when your core temperature rises quickly and uncontrollably.

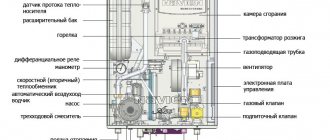

The gas water heater automation system includes three sensors: draft, flame, overheating. Plus two valves: gas and reset. They ensure safe operation of the device

You can check the sensors by resistance. A working part shows an infinity sign. When a different value is displayed, we call a technician.

If the device works for a long time and then turns off, check the settings. Sometimes users accidentally set it to turn off automatically after a certain time.

What else causes the shutdown:

- poor water or gas pressure;

- broken contact between the thermocouple and the solenoid valve (you need to clean the contacts and tighten the connections);

- oxidation of the power supply contacts, when the device clicks but does not light up.

It is also useful to check the batteries. Standard replacement of power supplies is carried out every six months. Batteries hold a charge longer.

Traction is poor or completely absent

The accumulation of combustion products is most often associated with clogging of the chimney with soot, soot, and debris. When there is no traction or it is insufficient, the work is not carried out.

To check the draft, you need to bring a burning match or lighter to the control window of the column. If the flame deviates to the side, there is draft. It remains to burn evenly - it’s gone

It is important to remember that the flame can go out due to external factors - gusts of wind, for example. The draft in the shaft increases or decreases under the influence of a draft

You can clean the chimney through the “pocket” located 25 cm below it. If such manipulations do not help, call the utility company.

Soot accumulation on the heat exchanger

During operation, the heat exchanger accumulates soot, soot, and scale. When it becomes clogged, the color of the flame changes from yellow to blue.

How to clean the heat exchanger:

- We remove the casing.

- Unscrew the screws holding the casing.

- We turn off the water supply.

- Open the faucet to drain hot water.

- Disconnect the heat exchanger thread and tap. You will need a stand as water may leak.

- Prepare a solution of hydrochloric acid (3-5%).

- Take a pipe with a diameter of 1/2” or use a hose.

- We connect one end to the input, the other to the output.

- Pour the solution into the funnel. If foam appears when washing, this is normal.

- As soon as a strong pressure appears at the outlet, we stop the procedure.

While working, be sure to wear gloves. After descaling, you need to thoroughly rinse the heat exchanger to remove acid residues.

If during the cleaning process defects were noticed on the tubes, then the heat exchanger will have to be repaired.

To clean the heat exchanger from scale, you can use citric acid (80 g of powder is needed for 700 ml of water). Boil the radiator in the solution for half an hour, leave until cool and rinse

It is recommended to carry out cleaning work once a year. Regular maintenance will help the device function properly.

Clogged shower head and hose

It happens that the gas water heater turns on and for some reason immediately goes out when switching to the shower. This may be due to clogged holes in the watering can.

You need to unscrew the watering can, clean and rinse the holes. Soaking metal elements in a solution of citric acid is also effective.

Scale on the watering can forms due to the increased hardness of tap water in some regions. To prevent this from happening, install filters or buy a faucet with a shower equipped with a built-in anti-scale system

The next part that can cause the wick to go out is the shower hose. If it gets tangled or clogged, the pressure power decreases and the column goes out.

The mixer can also break or become clogged. You need to disassemble it, check it, clean it if necessary.

At the entrance to the water supply unit there is a filter that retains small debris. It is also useful to clean it periodically. To do this, unscrew the screws, remove the element, rinse, and clean with a brush with citric acid.

Problems with ignition

One of the most common reasons why a gas water heater does not turn on is problems with ignition.

The most common types of non-standard situations encountered here are:

- For old-style models with an ignition wick, the gas water heater does not ignite when the water is turned on, while there is both draft and normal pressure of water and gas;

- For new models - the piezoelectric element in the gas water heater does not work;

- The spark ignition in the gas water heater occurs frequently, but the burner lights unevenly, and if it does turn on, it operates unstable.

Problems with ignition of the burner of older models arise mainly due to untimely maintenance of the burners. Over time, a layer of soot forms in the holes of the burner nozzles, they become smaller and, accordingly, allow less gas flow.

This affects not only the ignition process, but also the temperature of the heated water - it simply does not heat up normally. Therefore, many people set the regulator to maximum, which makes the coking process even more intense.

What to do if a gas water heater of this design does not light up? You just need to call a technician to service the burner; cleaning it from carbon deposits will ensure normal operation of the device. It is also recommended to install a gas filter; it will ensure gas purification from mechanical impurities and retain gas condensate.

One of the reasons why the Neva gas water heater does not ignite is the lack of a spark on the piezoelectric element. Unlike other models of water heaters, the Neva brand has an autonomous power supply for electronics - from lithium batteries.

During ignition, a weak battery does not provide the necessary charge to trigger the piezoelectric element. Despite the fact that the digital display continues to work and display information about the status of the device, the battery power is no longer sufficient to ignite the burner flame. It is a worn-out battery that is the reason why there is no spark at the Neva gas water heater.

Unstable ignition of the burner on water heaters with a piezo element may be due to incorrect configuration of the device and its connection to the autonomous water supply system of the house. Quite often, the vector geyser does not turn on due to voltage drops in the network and insufficient pressure in the water supply system.

This is due to the fact that when hot water is turned on, the pressure in the accumulator (especially if it is small) drops sharply. The electronics of the water heater diagnoses this moment as an accident due to which the gas supply is blocked. Subsequently, when the water pump is turned on, the pressure increases and when turned on again, the device begins to work safely.

Tip: If the water heater does not start working the first time at normal gas pressure and water pressure, you must turn off the device and set the temperature regulator to the minimum level.

Mixing cold water in the mixer

Many people, instead of adjusting the degree of heating on the gas water heater itself, mercilessly torment the mixer. If you open the cold water too much, the lit column will simply go out. If at that moment it was not burning, then it will certainly not catch fire. Make it a rule to turn on the hot water supply first, and only then the cold water supply. It’s best to adjust the degree of heating using the appropriate controls.

You also need to remember that intensive mixing of cold water is not welcomed by the developers of geysers - this can lead to their damage.

Blockages and their removal

If the gas water heater does not light up the first time or after starting, the water pressure is significantly less than usual, and besides, the water flows very hot, this indicates that maintenance is necessary. First of all, pay attention to the condition of the device filters - the gas filter and the mesh filter of the water equipment.

The gas filter is serviced by a gas equipment technician; it is installed in front of the device, so its disassembly and maintenance do not require opening the column. The water filter is a classic mesh sediment filter. To service it, simply remove the casing, unscrew the lid, and remove the mesh element.

If there is little debris and dirt, simply rinse the filter with a stream of water; if the debris cannot be removed, the mesh element simply needs to be replaced with a new one.

If, when you turn on the hot water, the column starts to work, and after a short time it goes out, the reason for this may be contamination of the heat exchanger. During long-term operation, especially from an individual water supply system without sufficient cleaning and preparation of water, scale begins to be deposited inside the heat exchanger.

Narrowing the diameter of the heat exchanger reduces the volume of water passed through, while its temperature increases sharply, which serves as a signal to the device’s safety system about the danger of overheating. Qualified cleaning can solve the problem of heat exchanger contamination. Previously, at home they used acid, pouring it into the heat exchanger tubes; to do this, they literally dismantled the entire device down to the screw. Today the procedure is much simpler - the heat exchanger is connected to the cleaning unit and in an hour or an hour and a half, under the pressure of the device’s pump, all the scale is removed.

Incorrect pipe connection

The defensive mechanism of the column itself blocks the gas if the pipes are connected incorrectly. As a result, the device quickly turns off, this is how its protection is triggered.

To eliminate this, pipes should be connected based on this diagram:

From the left side to the right side, pipes are connected to the device in the following order:

from gas - cold - hot water.

If there is no gas flow, the positions of the shut-off valves are checked. It can be mounted on a gas pipeline. And after that not a single valve with yellow handles was opened. And this must happen before turning on the equipment.

Gas block diaphragm

Another reason why the column does not turn on may be damage to the gas block diaphragm. The gas block diaphragm regulates the gas flow into the burner depending on the water pressure. Entering the housing, water presses on the elastic diaphragm - behind which there is a gas valve rod. The higher the pressure, the more the valve opens and the more gas enters the burner.

If the diaphragm has mechanical through damage and water enters the cavity of the rod, then the pressure on both sides is equalized, and the valve rod remains in place without movement. This is one of the reasons why the gas burner does not light up. You can solve the problem by removing the block and replacing the diaphragm with a new one.

Tip: When choosing a repair kit, it is recommended to pay attention to the silicone diaphragm. Unlike rubber, it is more elastic and has a longer life of “on-off” cycles than rubber.

After replacing the diaphragm, it is recommended to inspect the threaded connections of the column, replacing all gaskets and seals in the valve group.

Why does the column of the above models not light up, as well as for the Neva Transit?

You can find out complete information on the selection, operation and maintenance of gas water heaters (instantaneous water heaters) from all manufacturers if you go.

In addition to specific information on the site, you can also study specific problems from other people on this topic who have already purchased a gas water heater or instantaneous water heater and thus avoid them. You will find a regularly updated list of such problems and their solutions.

One of the most common reasons for a device malfunction is that it does not ignite. That is, the column does not start heating the water when you open the tap. Let's consider possible failure options:

The water pressure is less than the minimum permissible (for all Neva models).

This means that the device does not perceive the flow, since it is weak. From the technical side, it looks like the membrane changes shape due to the force of water pressure. Deflection may occur as a result of inappropriate assembly structure. Geysers make it possible to solve the problem with water pressure using a regulator located on the device.

Electronics failures

The presence in modern models of a large presence of electronic components, on the one hand, ensures high safety of the device and ease of use, on the other hand, it complicates troubleshooting and subsequent repairs.

The causes of electronic malfunctions are mainly related to the influence of external factors - voltage drops in the network, lightning discharges entering the main gas pipes and water entering the circuit boards from leaks inside the device. In addition, failure of individual electronic components due to failures in the electronics itself cannot be ruled out.

The reason that the vector geyser does not light up may be a malfunction of the electronics, and the following situations may arise:

- No spark when igniting;

- Extinguished digital display;

- The device does not start the first time;

- During operation, an alarm signal is constantly displayed;

- Protection systems are constantly triggered;

- The device turns on and then turns off again;

- Diagnosis of a breakdown usually begins with checking the batteries; old or dead batteries need to be replaced with new ones. If there are traces of electrolyte leaking onto the terminals, it must be cleaned.

If this operation does not resolve the device problems, you must call a technician to check the electronic unit. Most often, in such models, the electronics unit cannot be repaired; it is simply replaced with a new one. When replacing a unit, the technician must inspect all components of the device, and when connecting a new unit, in addition, test the system and configure its parameters. Particular attention is paid to the presence of leaks at the junction points and the integrity of the heat exchanger.

Malfunctions requiring mandatory contact with a specialist

There are two main reasons why a geyser goes out:

- one of three emergency sensors is triggered: traction, overheating or combustion;

- the column is clogged, which makes it completely impossible to ignite.

Initial actions in cases where the unit stops working:

- To exclude the first option, you need to make sure there is no smell of gas, and draft is carried out in the chimney. If this is detected, you need to call a professional to clean the smoke valve.

- The overheating sensor turns on if the heat exchanger is clogged or the control automation does not work. Its purpose is to protect the copper coil. In this situation, ventilate the room and wait until the unit cools down. Contacting a specialist is mandatory, since only a trained gas technician can properly regulate the column after descaling it.

- If the third sensor is triggered, the gas supply is automatically shut off. In fact, this sensor is a regular thermocouple. If there is a flame, a current is generated and gas is passed through the solenoid valve. When the fire goes out, the valve shuts off the fuel supply for 10 seconds. In this case, you can hear a characteristic sound reminiscent of snapping fingers.

Algorithm of actions when turning off the thermal mechanism:

- stand for 10-15 minutes (to cool the sensors);

- chimney draft is checked;

- the presence of gas is checked;

- the room is ventilated;

- an attempt is made to start the unit (put the power knob in the position required to turn it on, keep it on for 20 seconds, press the “piezo igniter” button);

- if the actions taken did not lead to the desired result, the functioning of the combustion sensor is checked;

- the non-working state of the combustion sensor can be caused by contamination of the pipe, which operates on the principle of a vacuum cleaner, so it should be thoroughly cleaned;

To clean the device that supplies combustion gas (pipe), the following actions are carried out:

- the handle that regulates the water temperature is removed;

- the required ignition position is set;

- the surface of the gas device is removed;

- use a screwdriver to lift up the pipe clamps located on top;

- These clamps are placed separately;

- by moving the lower clamp, the pipe is removed;

- the tube on which dust is collected is washed under running water and cleaned using cotton swabs and swabs;

- a prerequisite for normal pipe cleaning is the removal of all traces of detergent and water;

- the nozzle also undergoes thorough cleaning;

- the tube is installed back into the device, starting from the top mount, where the springy end is located;

- for the lower fastening, you will need to apply enough force to secure the pipe tightly;

- the clamps are put back in their original place;

- a second attempt is made to ignite the column by simultaneously turning on the piezo ignition and power regulator;

- handles and buttons are held in this position for at least 10 seconds;

- The temperature adjustment knob is inserted into its original place.

In addition, the most common reason for the damping of a geyser is described in this video: