Autonomous heating systems for private houses are gradually becoming no less common than centralized networks.

This is caused by the desire to save on paying for network resources, the unavailability of connecting to a central heating center in remote cottage villages, or other reasons.

There are a large number of samples of heating devices on the market, of which gas boilers are unanimously recognized as the most effective.

They are produced by all well-known companies in Europe and Southeast Asia.

Manufacturers from the countries of the former USSR are not lagging behind, their products are able to successfully compete with European models.

Danko gas boilers

The owner of the Danko brand is Agroresurs PJSC from Ukraine. The company simultaneously creates several types of heating equipment, the popularity and demand for which among users is steadily increasing.

The production facilities where Danko boilers are manufactured are located in the Ukrainian city of Rivne.

The company set as its goal to create a reliable, durable and durable gas boiler that has all the necessary functionality combined with a low price.

Ukrainian engineers were able to cope with this task, implementing a wide range of affordable and efficient gas units. It was possible to achieve high productivity, reliability, and eliminate unnecessary or unclaimed components and parts.

In parallel with high efficiency, the developers were able to reduce prices, which made Danko units available to a wide range of users.

Kinds

Danko gas boilers are produced in various structural types, which can be divided into groups according to general characteristics.

By installation type:

- Floor-standing. Installed on a special non-flammable stand or directly on the floor.

- Wall-mounted. Wall-mounted installation, on load-bearing walls or special metal support structures (Ramps).

- Parapet. These are non-volatile units with a hinged installation type. They differ from wall-mounted ones in some features of connection to the chimney and the need to ensure a slope of the heating system pipelines, ensuring natural circulation of the coolant.

By feature set:

- Single-circuit. Designed exclusively for heating the coolant and supplying it to the heating circuit.

- Dual-circuit. Capable of simultaneously heating the coolant and preparing hot water for domestic needs.

By type of combustion chamber:

- Open (atmospheric) . Air intake for normal combustion is carried out directly from the room in which the boiler is installed. Smoke is removed naturally using a stove-type draft.

- Closed (turbocharged) . Air intake and smoke removal are performed using a turbocharger fan.

IMPORTANT!

Turbocharged boilers are much more stable in operation and are not subject to frequent flame extinguishing due to drafts or gusts of wind.

In addition, there are models with a steel or cast iron heat exchanger.

Also, in some series of units, different types of automatic control of the operation of the gas unit can be used:

- Kare (Poland) . Manufactured specifically for installation in Danko boilers. The kit includes a reducer, valves, a thermostat and pressure, draft and boiling sensors.

- Honeywell (USA) . High-quality electromechanical gas supply control units, which are installed in the most advanced models of gas boilers.

- Sit (Italy) . Automatic control units for gas equipment, used in most European models of gas boilers.

The range of Danko boilers is wide; the user has the opportunity to choose the best option for any area and operating conditions.

How to choose?

Before you start choosing a model, you need to determine the functional purpose of the boiler and its power.

Double-circuit units should be selected if you plan to equip not only heating, but also hot water supply. Particular attention should be paid to the heat transfer coefficient of the device, which is especially important when calculating the power of the heating system in regions with cold climates. Convection models have the highest efficiency. This type of design is presented in many Danko floor-standing appliances and is recommended for use in northern regions

This type of design is presented in many Danko floor-standing appliances and is recommended for use in northern regions

This type of design is presented in many Danko floor-standing appliances and is recommended for use in northern regions

This type of design is presented in many Danko floor-standing appliances and is recommended for use in northern regions.

Judging by the reviews of the owners, it was convection boilers that showed their best performance when heating a private home in harsh conditions. In addition, floor-standing devices are non-volatile. In the event of a power outage, they will not leave the house without heat. The most popular model among floor-standing appliances is the Danko 18BC model. The boiler has dimensions of 41x85x49.7 cm, weighs 81 kg and is designed to heat a room up to 170 m².

For heating country houses or when installing a heating system in southern and temperate latitudes, wall-mounted and parapet units are quite suitable. These devices can effectively warm a medium-sized room and provide residents with uninterrupted hot water supply. The disadvantage of such devices is the presence of electronic ignition, which does not allow the boiler to light in the absence of electricity.

Many models are equipped with frost protection, which is important when operating the device in conditions of temperature changes in the absence of owners, when it is not possible to force the device to turn on or off

When choosing equipment, you should also pay attention to fuel consumption. Single-circuit appliances consume significantly less gas than dual-circuit models

For example, a floor-mounted single-circuit unit of the Danko 8 brand, having a heat transfer coefficient of 92% and capable of effectively heating a room of 70 square meters, consumes only 0.9 cubic meters of gas per hour, while some double-circuit boilers consume 2.5 and more than cubic meters of fuel

For example, a floor-mounted single-circuit unit of the Danko 8 brand, having a heat transfer coefficient of 92% and capable of effectively heating a room of 70 square meters, consumes only 0.9 cubic meters of gas per hour, while some double-circuit boilers consume 2.5 and more than cubic meters of fuel.

Series and models

Floor standing boilers are presented in the following series:

- CP or VSR - single- and double-circuit models with a power of 8, 10, 12, 15, 18, 20 and 24 kW. Equipped with a 3 mm thick steel heat exchanger.

- SN and VSN are floor-standing units with increased power from 30 to 48 kW. Steel heat exchanger.

- Rivnetherm. A series of floor-standing boilers with increased power for heating large areas. It is represented by single- and double-circuit models with a power from 30 to 96 kW, capable of serving premises up to 900 m2. Steel heat exchanger.

Series of wall-mounted boilers:

- US and UVS are single- and double-circuit boilers with a capacity of 7, 10, 12.5, 15.5, 18 kW. Equipped with a 3 mm steel heat exchanger.

In addition, there is a separate series of floor-standing boilers with a cast iron heat exchanger, the power of the models is 16-50 kW. They have an enlarged body due to larger parts.

Advantages

- The assembly is carried out in accordance with European technologies.

- Good technical characteristics - the manufacturer achieves a high level of efficiency and cost-effectiveness due to innovative technologies involved in production.

- Works stably and without noise.

- Can be used in a heating system without forced circulation - it operates energy-independently.

- Simple installation - you can handle it yourself, without the help of specialists.

- The kit includes instructions explaining how to light the device, how to connect it to the heating system, how to carry out repairs and maintenance, as well as other useful information.

- Equipped with reliable automation that ensures the safety of the equipment.

- The coil is made of copper. The water heats up quickly.

- The heat exchanger is made of steel. Characterized by high heat transfer.

- Three years warranty. Cast iron ones last an average of 25 years, steel ones – 15 years.

Specifications

Let's look at the characteristics of gas boilers:

| Parameter | Meaning |

| Boiler type | Gas heating |

| Fuel type | Natural gas with the possibility of conversion to liquefied gas |

| Feature Set | Heating and hot water supply |

| Combustion chamber type | Atmospheric or turbocharged |

| Average gas consumption | 1.9-2.7 m3/h |

| Efficiency | 92 % |

| Heating area | 70-900 m |

| Energy consumption | Non-volatile or single-phase 220 V 50 Hz |

Advantages and disadvantages

The advantages of Danko gas boilers include:

- The production process uses advanced technological methods and developments.

- High quality components and parts.

- Reliability, long service life of the boiler.

- Economical fuel consumption.

- Quiet operation.

- Relatively low price.

- Compact, attractive appearance.

The disadvantages of Danko boilers are:

- The need for periodic maintenance and chimney cleaning.

- In atmospheric models, cases of flame extinction due to external factors are noted.

- Wall-mounted models are limited in power, and floor-mounted ones have increased noise during operation.

The disadvantages of Danko boilers are completely surmountable and can be attributed to design features.

About company

is engaged in the production of heating equipment of various types - it produces gas, electric and solid fuel boilers, heaters and converters. The first products entered the market in 2002. The batch consisted of only 49 units of equipment. Today the company has about 850 thousand units of products sold. The production uses advanced equipment from foreign companies from Italy, Denmark, and Finland.

Device

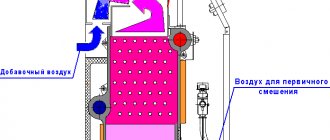

The Danko gas boiler is designed according to general methods adopted by all European companies . The main component of the boiler is a gas burner and a heat exchanger, combined into a single system .

Water enters the primary heat exchanger, heats up and passes into the secondary plate heat exchanger, which prepares hot water. After this, the coolant enters the three-way valve, where it finally receives the temperature set by the mode.

To do this, it is mixed with the colder return flow in the required proportion. Then the coolant is discharged into the heating circuit for the next round of circulation.

The operation of the system is monitored by a control board (in volatile boilers) or mechanical sensors and valves (in parapet non-volatile models).

Liquid circulation is ensured using a built-in or external circulation pump, or the natural upward movement of hot layers of liquid.

Air supply occurs under the influence of natural draft or using a turbofan.

Second group with a steel heat exchanger:

The Conord boiler with the design of a steel cylindrical heat exchanger made of cold-rolled metal is offered by the plant in single- and double-circuit versions. The service life is reduced compared to cast iron to 15 years. The designs use two automation options.

The first option: SIT automation from an Italian company known for its quality throughout the world. It is installed in the vast majority of all manufactured boilers in the European Union, such famous devices as: IMMERGAS, Fondital, Vaillant, Bosch and many others. The SIT valve allows you to guarantee a stable set temperature.

In addition, automation controls stable operation with a reduced gas pressure in the city pipeline. So the nominal value provides for operation with a pressure of 1.3 kPa, but a drop to 0.6 kPa is not a big problem and the Conord gas boiler continues to operate steadily, despite the fact that this is 46% less than required.

Single-circuit, with automatic SIT – heating only:

KSts-G-8S Heating capacity =8 kW KSts-G-10S Heating capacity =10 kW KSts-G-12S Heating capacity =12 kW KSts-G-16S Heating capacity =16 kW KSts-G-20S Heating capacity =20 kW KSts-G-25S Heating capacity =26 kW KSts-G-30S Heating capacity =30 kW KSts-G-40S Heating capacity =40 kW KSts-G-50S Heating capacity =50 kW

Single-circuit, with thermohydraulic automation

The second option is more budget-friendly, equipped with domestically developed AGU-T-M automatic equipment. AGU is an automatic gas burner device, consisting of nozzles and safety automation. The main manufacturers are Mimax and Tagonrog. ASU automation consists of:

- temperature sensor;

- igniter with thermo-bimetallic plate;

- adjusting screw with lever;

- gas valve;

- block crane;

- connecting parts.

Ignition order:

- We check the draft, move the damper, light the igniter.

- Press the gas valve and light the wick. We fix and do not release the button until the bimetallic plate heats up.

- While continuing to hold the button, follow the lever. It will creep onto the inscription “on the button”, we need to wait for the moment when it is fixed.

- Release the gas valve and set the required temperature using the control knob.

Domestic automation makes it possible to buy a Conord boiler a little cheaper. In contrast to European analogues, it has the simplest design. It is non-volatile - no power supply is required. The starting process is carried out manually by igniting with matches or a lighter. By the way, thermo-hydraulic automation type AGU-T-M is widely used in Russian gas boilers

According to customer reviews, such automation is completely unpretentious, and the Conord floor-standing boiler equipped with it is not “capricious.” In addition, it is not difficult to find spare parts on the market even far from city centers. The prices are also not satisfactory, for example, one of the frequently requested parts - a bimetallic plate - is found everywhere for no more than 100 rubles.

KSts-G-10N Heating capacity =10 kW KSts-G-12N Heating capacity =12 kW KSts-G-20N Heating capacity =20 kW KSts-G-25N Heating capacity =25 kW KSts-G-30N Heating capacity =30 kW

Double-circuit with DHW and SIT automatic control system

The Conord floor-standing gas boiler, when equipped with two circuits, copes with the task of heating buildings and at the same time is capable of preparing hot water used for household needs. The design uses the proven modulation function. Burner operation using modulation significantly increases the efficiency of hot water supply.

KSts-GV-8S Heating capacity =8 kW KSts-GV-10S Heating capacity =10 kW KSts-GV-12S Heating capacity =12 kW KSts-GV-16S Heating capacity =16 kW KSts-GV-20S Heating capacity =20 kW KSts-GV-25S Heating capacity =25 kW KSts-GV-30S Heating capacity =30 kW

Double-circuit with DHW, with thermo-hydraulic automation

KSts-GV-12N Heating capacity =12 kW KSts-GV-20N Heating capacity =20 kW KSts-GV-25N Heating capacity =25 kW KSts-GV-30N Heating capacity =30 kW

Boiler Conord decoding

- K – boiler

- C – steel material for the heat exchanger

- C – cast iron, heat exchanger material

- G – gas

- B – DHW circuit

- C – cylindrical.

Operation and setup

Operating requirements are detailed in the user manual, which must be carefully read before using the unit.

The key to successful operation is competent and high-quality installation. Floor-standing models are installed on a non-combustible substrate (a layer of asbestos, on top of which a metal sheet is laid), and wall-mounted boilers are hung on brackets secured with anchor bolts.

Only strong load-bearing walls are suitable for installation; temporary and plasterboard partitions for hanging are prohibited.

Boiler tuning consists of adjusting factory settings designed to increase efficiency and stability of operation.

The boiler must be adjusted by a specialist from the warranty workshop . Doing the work yourself can damage the unit.

In addition, unauthorized work with gas equipment is an offense and can be punished within the competence of the gas service.

Download instructions

Download instructions for the Danko gas boiler.

Installation

It is necessary to take into account the rules for installing gas equipment:

- The power is selected according to the heating.

- There must be at least 25 cm between the housing installed on a fire-resistant horizontal platform and a non-combustible wall.

- The device can be installed near fire-resistant walls if they are sheathed with steel sheets.

- The width of the passage in front of the facade is from 1 m.

- To improve water circulation, the installation should be lower than the level of heating devices.

- The expansion tank is located at the very top of the system.

- The minimum length of the chimney is 5 m.

- If the chimney is located outside, it must be insulated.

- The diameter of the smoke outlet must exceed the diameter of the smoke outlet pipe.

- At the junction of the boiler and the chimney, it is necessary to seal it with a solution of cement or clay.

Basic faults

The most common malfunctions of Danko gas boilers, experts and ordinary users include problems with the burner and gas consumption.

Cases of flame attenuation (failure), characteristic of boilers with an atmospheric burner, are often noted. In addition, the injectors often become clogged with soot, soot and other combustion products. Excessive gas consumption occurs due to the appearance of a layer of scale in the primary heat exchanger.

It acts as a thermal insulator, reducing the efficiency of heat transfer. The user notices that the coolant temperature has dropped and increases the flame burning mode.

This causes the heating of the outer surface of the heat exchanger to become stronger, which causes rapid failure of the unit.

The solution to the problem is the use of softening water filters (as a preventive measure) and periodic washing of the heat exchanger, for which you need to invite a technician from the service center.

IMPORTANT!

Attempts to independently solve any problems can cause boilers to fail. In addition, interference with the design of boilers becomes the reason for termination of the warranty agreement.

Recommendations

Despite the fact that Danko boilers have a long service life and reliability, some breakdowns still occur.

Therefore, all owners of gas equipment should know the main types of malfunctions and the causes of their occurrence.

- The formation of soot and soot on the internal surfaces of the boiler indicates problems with the chimney. In this case, you should clean the pipe from accumulated combustion products and wash the parts of the device from dirt.

- Unstable operation of the device and temperature fluctuations in the system indicate a malfunction of the fan or circulation pump. If you have the necessary spare parts, you can repair the device yourself.

- If the boiler's pilot light goes out or the wick does not light, the reason is most likely the absence of a special valve in the chimney system that prevents backdraft. The igniter going out may also be due to the thermostat tripping. In this case, adjustment of the device is necessary, which should be done by experienced specialists. Only single-circuit boilers are subject to attenuation. In dual-circuit devices, such problems are not observed.

- If the combustion sensor or pipe fails, the device is urgently disconnected from the gas supply and left to cool. Repairs can only be performed when the breakdown is not related to a fuel leak. For example, cleaning the pipe can be done independently, but more serious faults should only be trusted to a specialist.

- Increased fuel consumption and the presence of extraneous noise before attenuation are most likely caused by a failure of the controller. If you have the necessary spare parts, you can repair the part yourself.

In the next video you will find a review of the Danko 12.5 TN solid fuel boiler.

This is caused by the desire to save on paying for network resources, the unavailability of connecting to a central heating center in remote cottage villages, or other reasons.

There are a large number of samples of heating devices on the market, of which gas boilers are unanimously recognized as the most effective.

They are produced by all well-known companies in Europe and Southeast Asia.

Manufacturers from the countries of the former USSR are not lagging behind, their products are able to successfully compete with European models.

Why does it go out?

The first and most simple reason for attenuation is a stop in the gas supply. To resolve the issue, you need to close the gas tap and call the appropriate service for clarification . There are other possible reasons.

Self-extinguishing of the Danko boiler flame is often observed in models with an open combustion chamber. It is usually caused by a strong gust of wind or a draft that blows off the burner flame when doors or windows are suddenly opened.

To solve the problem, it is necessary to establish an air exchange mode that eliminates the possibility of reverse draft and drafts.

The chimney should be located on the leeward side of the roof so that strong gusts do not create the possibility of a flame breaking out.

Another possible reason is a breakdown of the regulator, gas valve or other parts of the gas equipment. In this case, you should turn off the boiler, turn off the gas supply and call a technician from the service center.

Additional systems

In the design of gas heaters, the manufacturer has additionally provided:

- water temperature sensors - triggered when boiling, turning off the system;

- a protective block that shuts off the gas supply when the wick goes out;

- a block that stops equipment operation in the absence of traction;

- draft control unit - to adjust the flame;

- multifaceted protection unit – turns off the device in case of any type of threat;

- intelligent block - for distributing liquid flows.

Price range

The cost of a Danko boiler, depending on the type of design and other functional features, ranges from 8 to 109 thousand rubles.

Please note that the delivery package does not include a chimney and other additional devices..

In addition, different models have their own equipment, so before purchasing you need to clarify its composition and purchase the necessary elements of the system.

Many buyers are trying to save money and do not sign a warranty service agreement. The benefits of such a solution are questionable, and the result may be increased costs for repairing the boiler if necessary.